High-efficiency planar perovskite solar cell and fabrication method thereof

A solar cell and perovskite technology, applied in the field of solar cells, achieves the effects of easy realization, promotion of conduction and collection, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

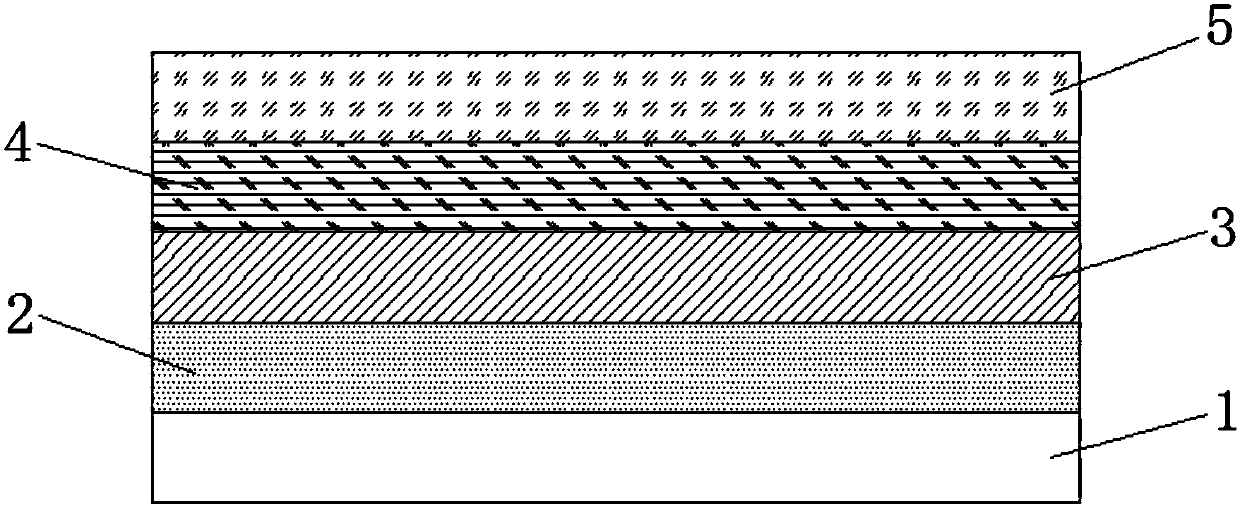

[0027] The method for preparing a high-efficiency planar perovskite solar cell provided by the present invention includes the following steps:

[0028] (1) Preparation of the electron conductive layer: first add gallium nitrate to the ice-water mixture, and then add the titanium tetrachloride aqueous solution to prepare the gallium-doped titanium dioxide colloidal solution. Then take the clean transparent conductive substrate and soak it in a gallium-doped titanium dioxide colloidal solution at 60~80℃ for 40~60 minutes, take it out and rinse with deionized water and ethanol in turn, and then heat it at 180~220℃ for 30~60 In minutes, a dense layer of gallium-doped titanium dioxide prepared on a transparent conductive substrate as an electron conductive layer is obtained.

[0029] (2) Preparation of the perovskite layer: the molar ratio of CH 3 NH 3 I and PbCl 2 Dissolve in dimethylformamide to obtain a perovskite precursor solution. The gallium-doped titanium dioxide dense layer obt...

Embodiment 1

[0033] The preparation of the high-efficiency planar perovskite solar cell in this embodiment is specifically carried out as follows:

[0034] (1) Preparation of the dense layer of gallium-doped titanium dioxide: first add gallium nitrate to the ice-water mixture, and then add a titanium tetrachloride aqueous solution with a volume ratio of titanium tetrachloride to water of 1.5 to 4:100, and configure gallium doped Mixed titanium dioxide colloidal solution. Then take the clean fluorine-doped tin dioxide conductive glass and irradiate it with an ultraviolet lamp for 10-20 minutes, then soak it in a gallium-doped titanium dioxide colloidal solution at 70°C for 50 minutes, take it out, and rinse with deionized water and ethanol. Then heat treatment is performed at 200°C for 30-60 minutes to obtain a gallium-doped titanium dioxide dense layer prepared on fluorine-doped tin dioxide conductive glass. The molar ratio of gallium atoms to titanium atoms in the gallium-doped titanium diox...

Embodiment 2

[0039] The steps for preparing a high-efficiency planar perovskite solar cell in this embodiment are basically the same as those in embodiment 1, except that: in step (1), the moles of gallium atoms and titanium atoms in the gallium-doped titanium dioxide dense layer prepared The ratio is 7:100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com