Method for preparing gallium-doped nano silicon particles by utilizing silicon waste

A technology of silicon waste and nano-silicon, which is applied in the field of semiconductor nano-material preparation, can solve problems such as light attenuation, and achieve the effects of simple preparation method, reduced environmental pollution, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

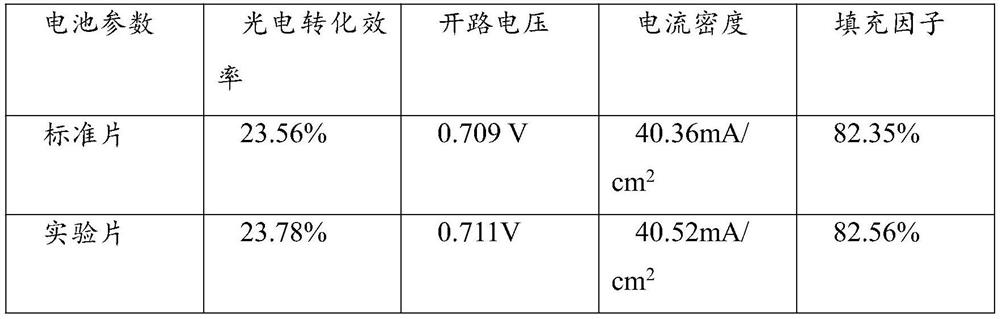

Embodiment 1

[0028] This embodiment provides a method for preparing gallium-doped nano-silicon particles by using silicon waste materials. Silicon waste materials obtained by cutting gallium-doped silicon ingots with diamond wires are used as raw materials to prepare gallium-doped nano-silicon particles. Specific steps are as follows:

[0029] Step 1: Select silicon waste obtained by diamond wire cutting gallium-doped silicon ingots with a resistivity of 0.5-1Ω·cm as the raw material, and purify it to obtain silicon purity ≥ 95%, and the size range of silicon micropowder is 5-10 μm Silicon micropowder; in addition to using silicon waste as raw material, using pure silicon powder obtained by metallurgy and primary ball milling method as raw material will not affect the result of the final gallium-doped nano-silicon particles, but considering the economy, diamond is preferred Silicon waste after wire cutting silicon ingots is used as raw material;

[0030] The second step: preparing gallium...

Embodiment 2

[0045] This embodiment provides a method for preparing gallium-doped nano-silicon particles by using silicon waste materials. Silicon waste materials obtained by cutting gallium-doped silicon ingots with diamond wires are used as raw materials to prepare gallium-doped nano-silicon particles. Specific steps are as follows:

[0046] Step 1: Select silicon waste obtained by diamond wire cutting gallium-doped silicon ingots with a resistivity of 0.5-1Ω·cm as the raw material, and purify it to obtain silicon purity ≥ 95%, and the size range of silicon micropowder is 0.5-3 μm Silicon micropowder; in addition to using silicon waste as raw material, using pure silicon powder obtained by metallurgy and primary ball milling method as raw material will not affect the result of the final gallium-doped nano-silicon particles, but considering the economy, diamond is preferred Silicon waste after wire cutting silicon ingots is used as raw material;

[0047] The second step: prepare gallium ...

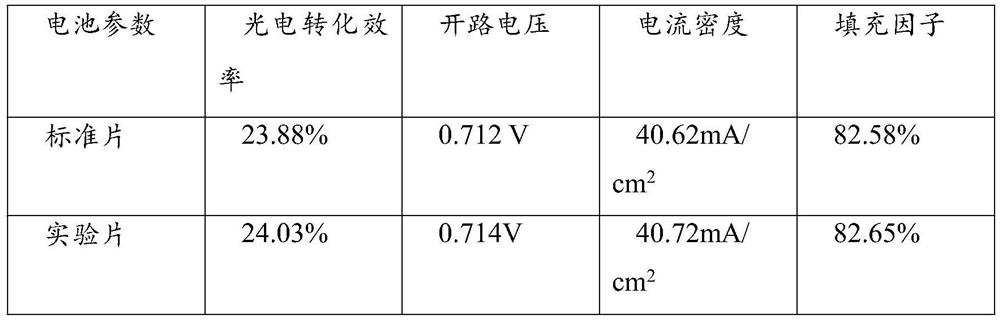

Embodiment 3

[0062] This embodiment provides a method for preparing gallium-doped nano-silicon particles by using silicon waste materials. Silicon waste materials obtained by cutting gallium-doped silicon ingots with diamond wires are used as raw materials to prepare gallium-doped nano-silicon particles. Specific steps are as follows:

[0063] The first step: choose the silicon waste obtained after diamond wire cutting gallium-doped silicon ingots with a resistivity of 0.5-1Ω·cm as the raw material, purify it to obtain silicon purity ≥ 95%, and the size range of silicon micropowder is 1-5 μm Silicon micropowder; in addition to using silicon waste as raw material, using pure silicon powder obtained by metallurgy and primary ball milling method as raw material will not affect the result of the final gallium-doped nano-silicon particles, but considering the economy, diamond is preferred Silicon waste after wire cutting silicon ingots is used as raw material;

[0064] The second step: prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com