Manufacturing process of solar P-type polycrystalline silicon wafer

A polycrystalline silicon wafer and manufacturing process technology, applied in the direction of manufacturing tools, polycrystalline material growth, fine working devices, etc., can solve problems such as light-induced attenuation, achieve fast heating speed, increase temperature, and save production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Preparation of P-type silicon ingot: In an argon atmosphere, the silicon material was sintered to 1550 °C in a microwave sintering furnace, and the microwave frequency was 2.45 GHz ± 25 MHz. The heating rate was 26 ℃ / min, and the heat preservation was 120 min. The whole process of temperature rise and fall was protected and cooled by argon gas, and the purity of argon gas was 4 N (99.99%). The role of argon is to prevent the silicon material from being oxidized during the heating process. The temperature of the microwave sintering furnace is controlled by an intelligent control system, and the temperature is measured by infrared rays. The microwave generated by the microwave sintering furnace is diffracted (diffraction) inside the silicon material, and the silicon material is heated at the same time, with a fast heating rate and less heat loss. Compared with a resistance furnace, the same temperature increase can save energy by more than 40%. At the same time, the sil...

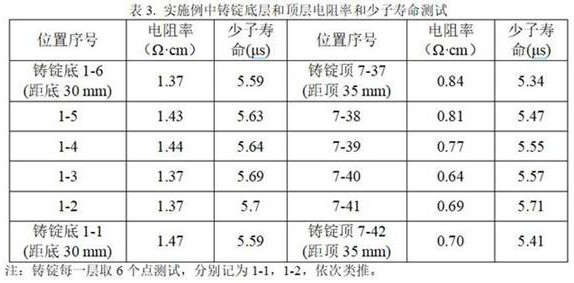

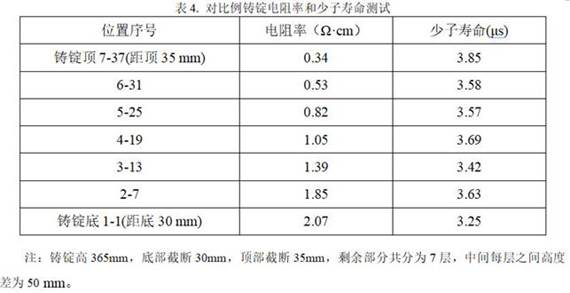

Embodiment

[0040] Step 1: Prepare P-type recycled silicon material. The recycled silicon material contains metal impurities such as hair, staples, and diamond wires, and organic impurities such as sticky glue, sticky board glue, and resin board. After magnetic separation, hot water degumming, carbonization and other stages, and then after 20% HF corrosion, 25% HCl and 30% H 2 o 2 Mixed liquid pickling, water isolation, 12% NaOH alkali washing and other stages, followed by appropriate concentration of HCl to neutralize the residual liquid on the surface of the fragments, deionized water ultrasonic rinsing and other procedures, the final rinse water conductivity 936 μS / cm, Rinse water pH = 7.01. After drying in a microwave oven at 105 ℃, manual sorting and other procedures, the broken silicon wafers without impurities are packaged and put into storage. Manual sorting mainly screens non-silicon impurities such as stones that cannot be treated by pickling, alkali washing and other procedu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com