Method for studying optimum sintering process of gallium-doped zinc oxide ceramic by spark plasma sintering

A technology of discharge plasma and zinc oxide, applied in the field of preparation of GaxZn1-xO conductive ceramics, can solve the problems of high energy consumption, high sintering temperature, long preparation cycle, etc., achieve low energy consumption, improve preparation efficiency, and shorten preparation cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] (1) High-purity ZnO (99.99%) and Ga 2 o 3 (99.99%) powder according to Ga 0.00075 Zn 0.99925 After the O ratio is weighed, place the ZrO 2 In the nylon tank of the grinding medium, use absolute ethanol as the dispersant for ball milling for 24 hours, dry and sieve to obtain uniformly mixed ZnO, Ga 2 o 3 Powder;

[0022] (2) powder is packed in graphite grinding tool, compaction, graphite grinding tool is placed in the furnace chamber of discharge plasma sintering furnace, vacuumize, pre-pressure is 15MPa;

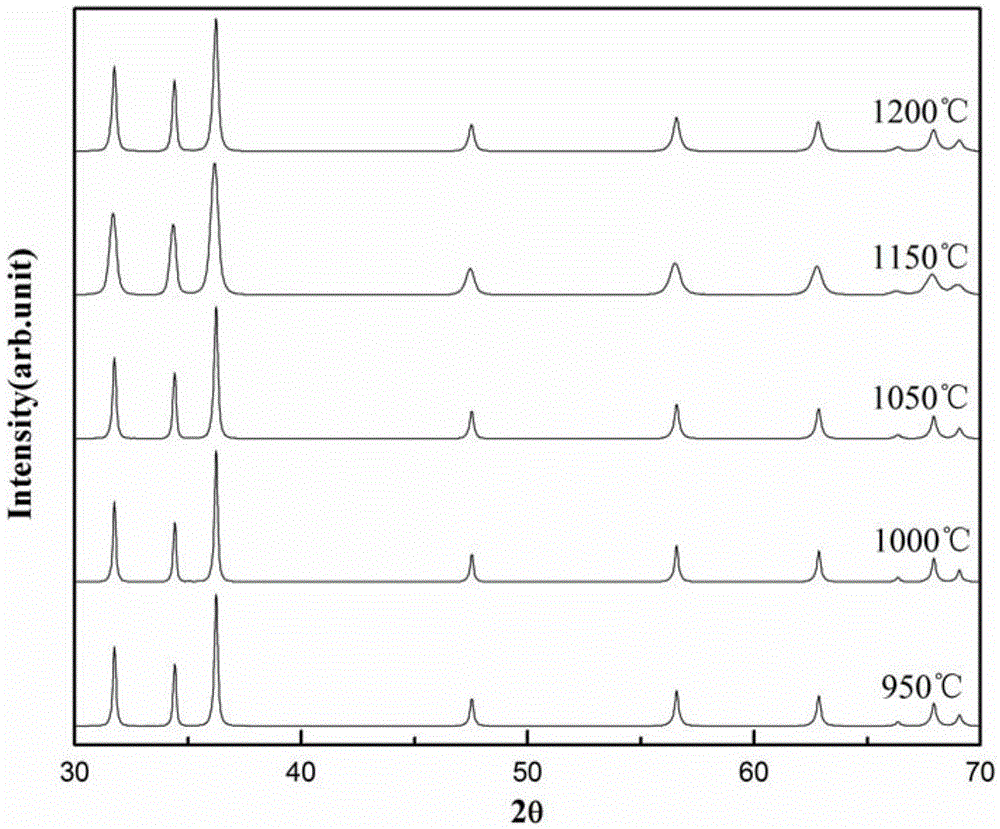

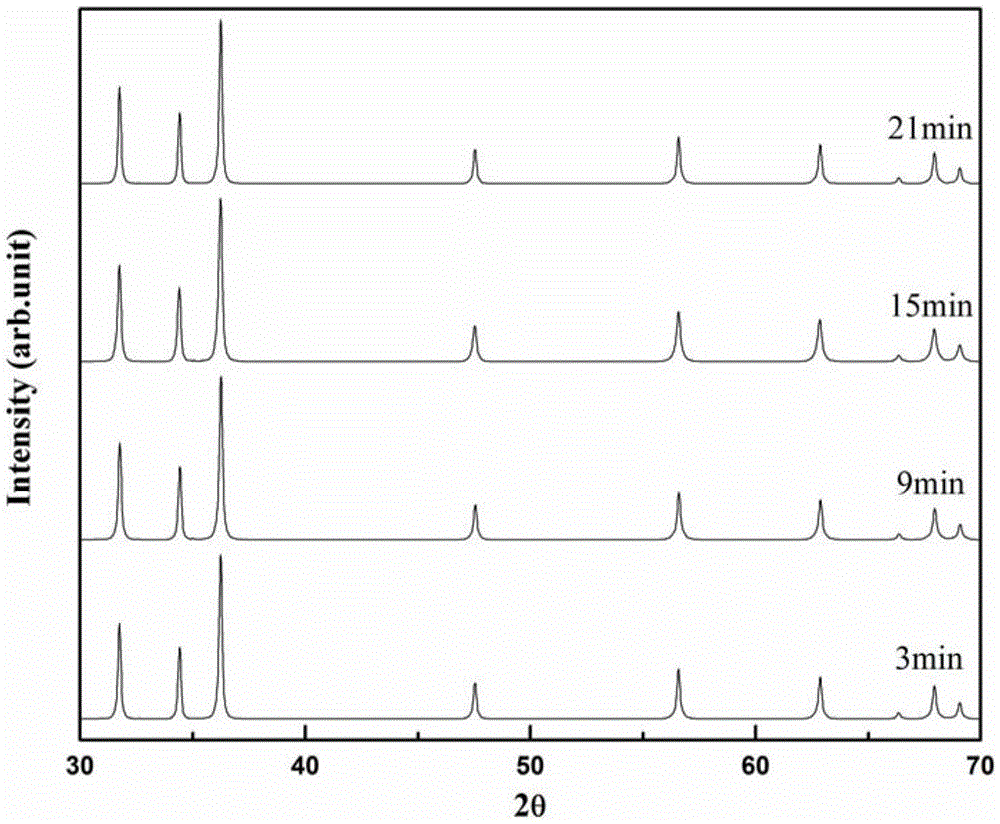

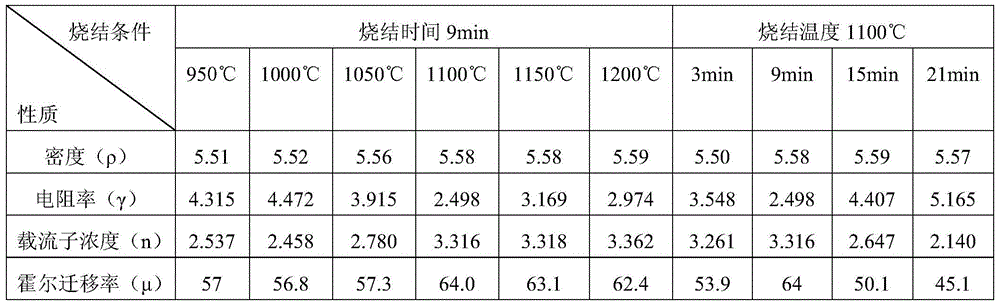

[0023] (3) Increase from room temperature to 600°C within 4 minutes, and then increase the temperature at a rate of 10°C / min. When the displacement curve in the computer screen of the SPS sintering furnace has the largest peak value (the shrinkage rate of the sample is the largest at this time) ( 720°C or so) to raise the pressure to 60MPa, and then increase the temperature to (950°C, 1000°C, 1050°C, 1100°C, 1150°C, 1200°C) at the same heating rate, keep the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com