Solar cell and preparation method of gallium and hydrogen doped monocrystalline silicon

A solar cell, hydrogen doping technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve problems such as midpoint defects, metal defects, dislocation defects, etc., to improve conversion efficiency and increase minority carrier The effect of lifespan and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

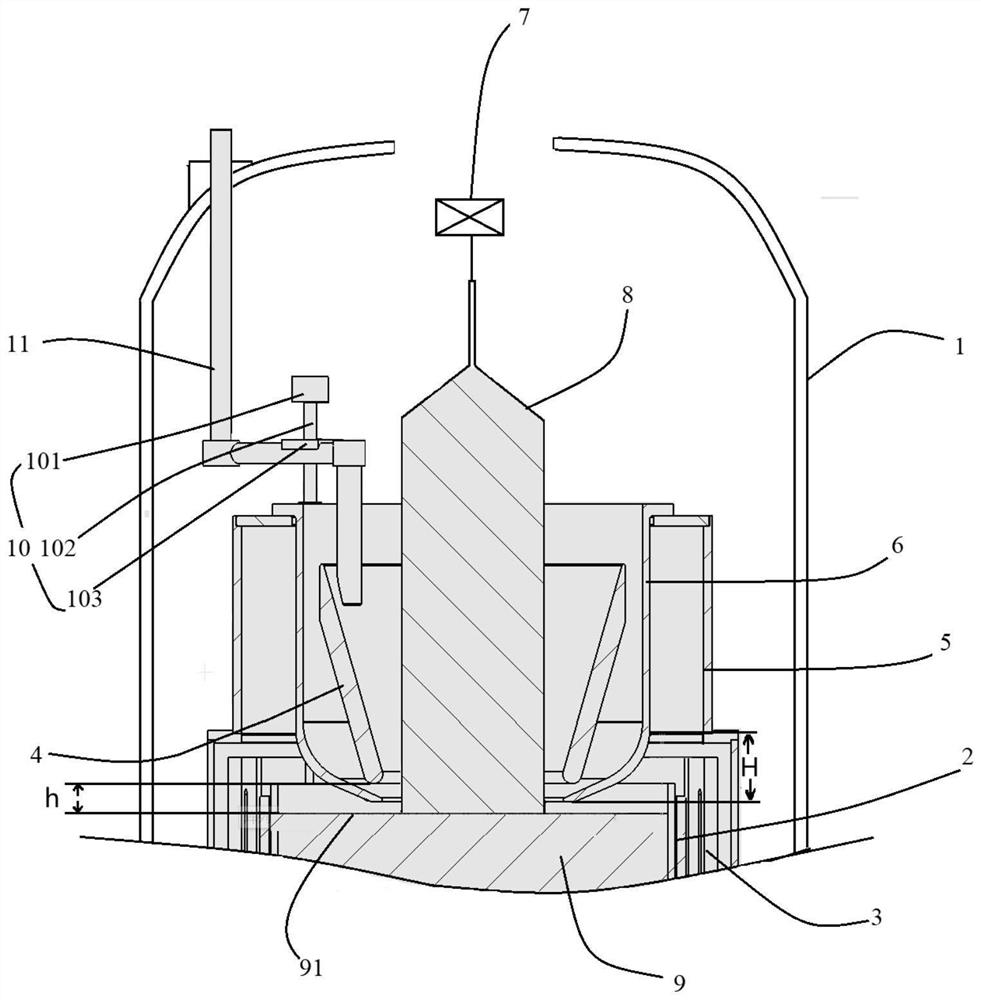

[0061]image 3 The flow chart of a method for preparing gallium and hydrogen doped monocrystalline silicon is provided in an embodiment of this application, such asimage 3 As shown, the preparation method includes the following steps:

[0062]Put the polysilicon raw material and the gallium dopant into the quartz crucible;

[0063]Put the quartz crucible in a single crystal furnace to vacuum, and melt the polysilicon raw material under the protection of inert gas to obtain a silicon melt;

[0064]When the temperature of the silicon melt is stable, add a hydrogen source to the single crystal furnace, and immerse the seed crystals in the silicon melt to start seeding;

[0065]After seeding is finished, start to shoulder, so that the diameter of the crystal is gradually increased to the preset width, and then the equal diameter growth is carried out;

[0066]After the isodiametric growth is completed, it enters the finishing stage, so that the diameter of the crystal is gradually reduced until it sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com