Patents

Literature

97results about How to "Play a passivation role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

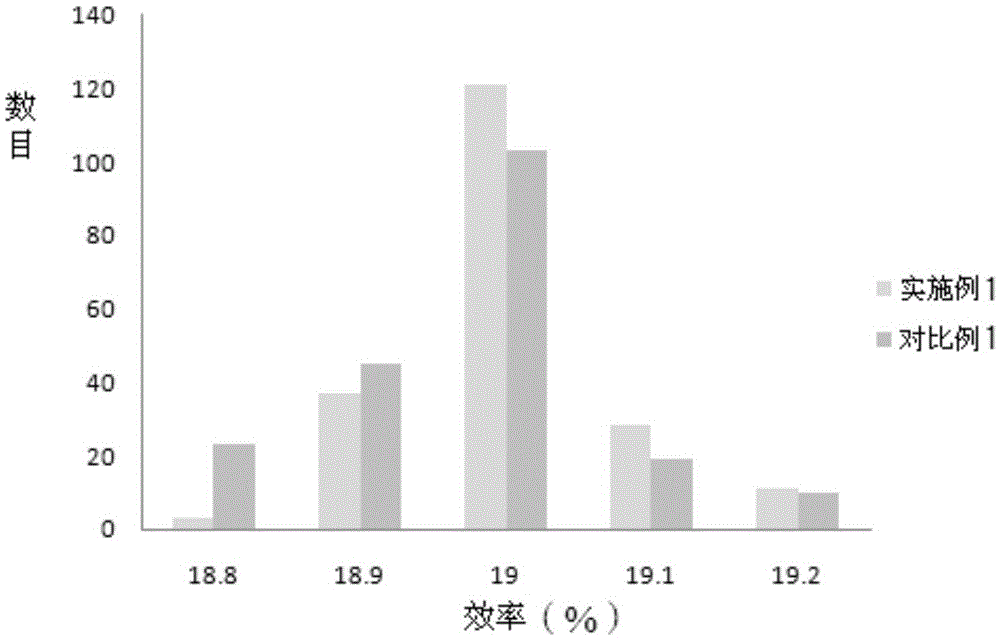

N-type double-sided battery and manufacturing method thereof

InactiveCN104538501AImprove efficiencyIncrease production capacityFinal product manufactureSemiconductor/solid-state device manufacturingScreen printingOptoelectronics

The invention discloses an N-type double-sided battery and a manufacturing method thereof. The manufacturing method comprises the following steps that S1, texturing treatment is performed; S2, a boron source is evenly coated on the upper surface of an N-type silicon wafer in a spin coating or silk-screen printing mode, and boron diffusion is conducted in a furnace tube; S3, a mask is manufactured; S4, phosphorus diffusion is conducted on the lower surface of the N-type silicon wafer, and a high-low-junction structure is formed on the lower surface; S5, phosphorosilicate glass and the mask manufactured in the step S3 are removed; S6, a passivation anti-reflection film made from aluminum oxide and silicon nitride is manufactured on the surface of the diffused boron, and a silicon nitride passivation anti-reflection film is manufactured on the surface of the diffused phosphorus; S7, electrodes are manufactured. The manufacturing method of the N-type double-sided battery is simple in process, and the efficiency of the battery is effectively improved. In addition, a passivation layer manufacturing method of the N-type double-sided battery is a low-temperature process, and a PN junction is not damaged.

Owner:SUZHOU TALESUN SOLAR TECH CO LTD

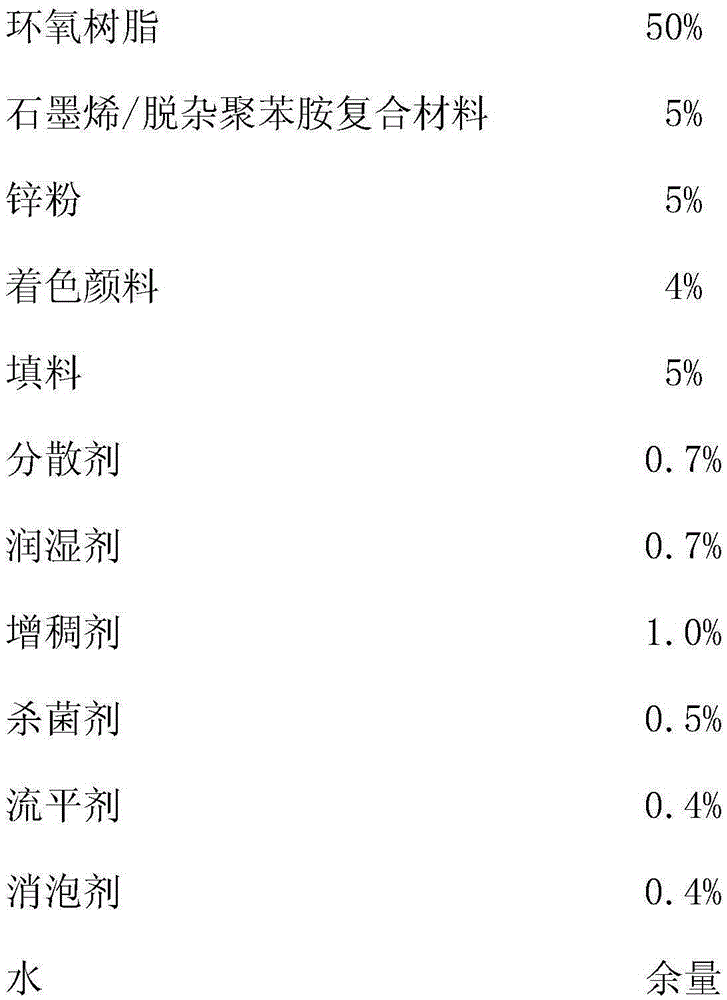

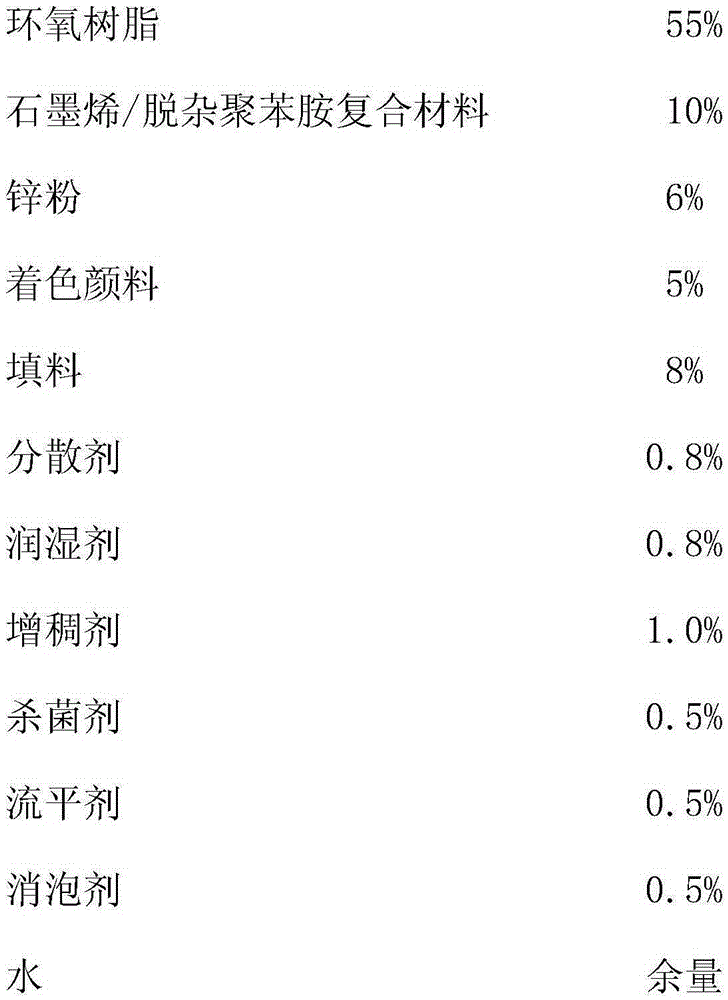

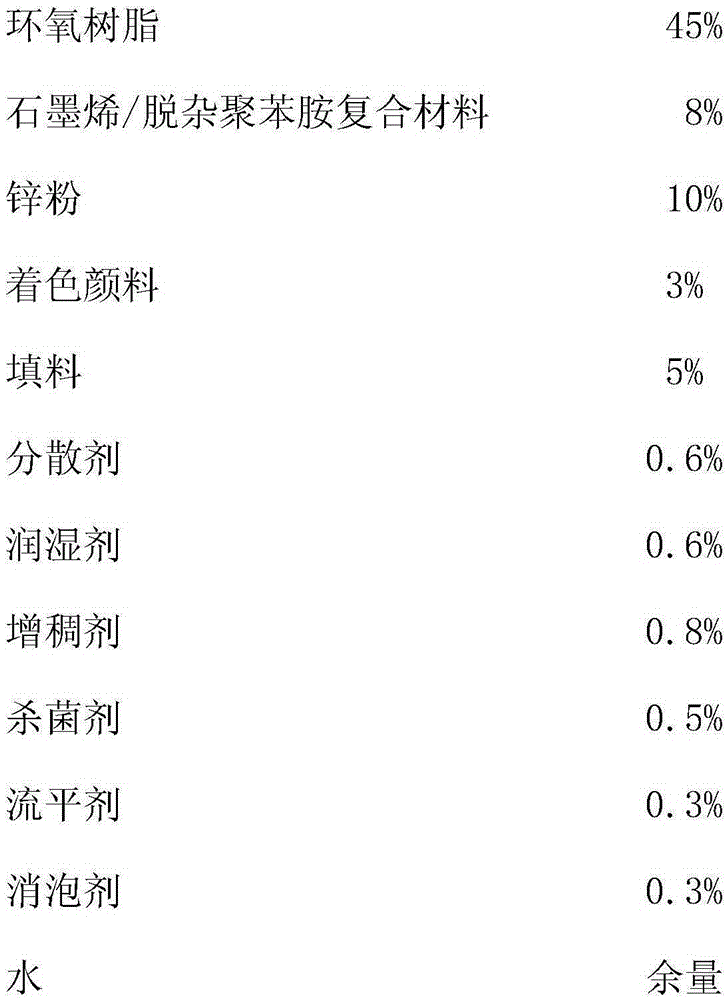

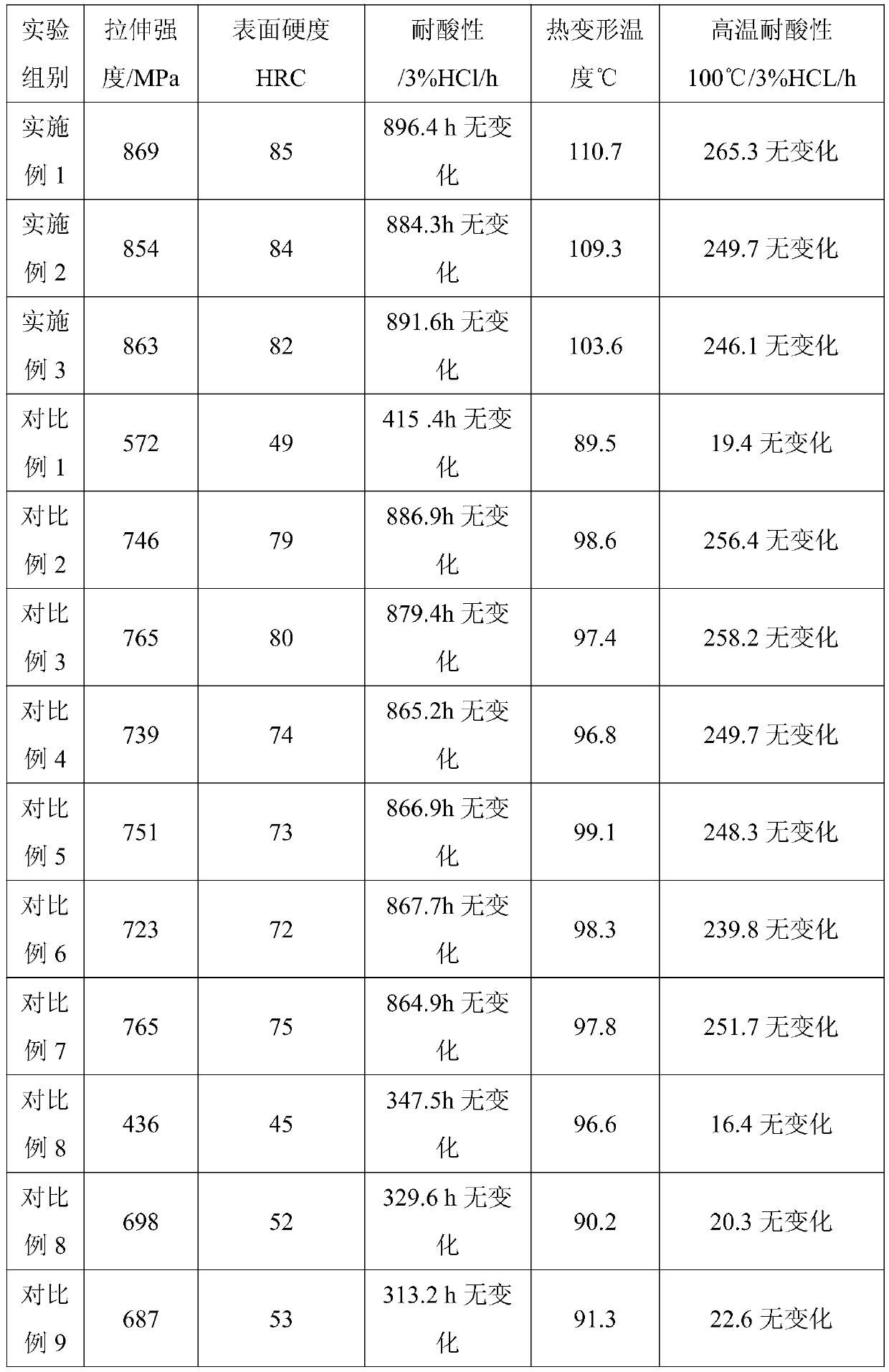

Graphene/deimpurity polyaniline-containing anticorrosive coating and preparation method thereof

ActiveCN105400373AEfficient electron transfer capabilityExcellent electron transfer abilityAnti-corrosive paintsEpoxy resin coatingsEpoxyIn situ polymerization

The invention belongs to the field of anticorrosive coating, and in particular, relates to a graphene / deimpurity polyaniline-containing anticorrosive coating. The anticorrosive coating is composed of the following raw materials in parts by weight: 20-80% of epoxy resin, 5-15% of a graphene / deimpurity polyanilin composite material, 5-10% of a zinc powder, 5-10% of a filler, 1-10% of a coloring pigment, 0.1-3% of a dispersion agent, 0.1-3% of a wetting agent, 0.1-3% of a thickening agent, 0.1-1% of a levelling agent, 0.1-1% of a defoaming agent, 0.1-1% of a bactericide, and 1-35% of water. In the preparation process of the anticorrosive coating, polyaniline is loaded on graphene by an in-situ polymerization method, so that the dispersion of polyaniline is improved, polyaniline agglomeration is avoided, and the graphene / deimpurity polyaniline-containing anticorrosive coating is prepared.

Owner:常州纳欧新材料科技有限公司

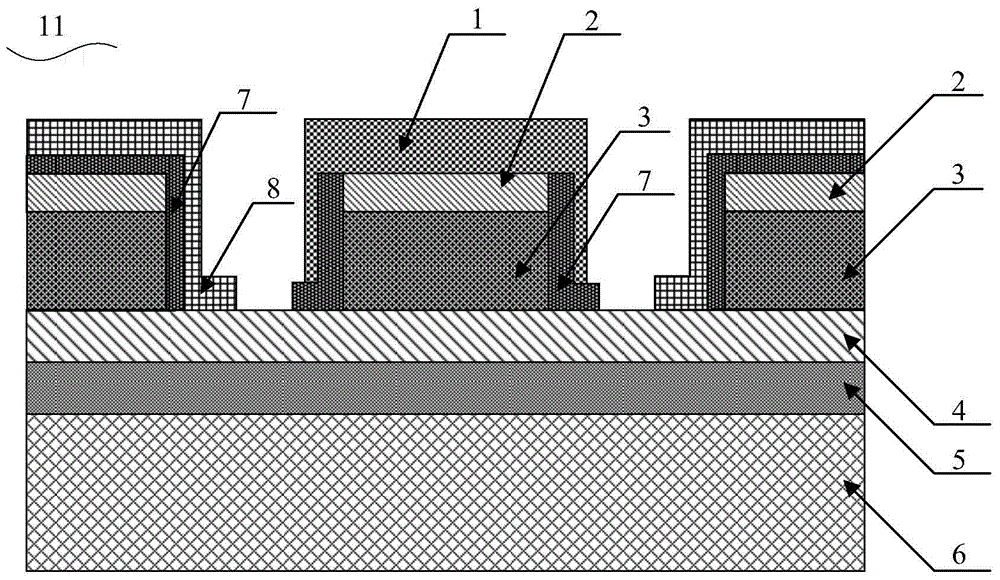

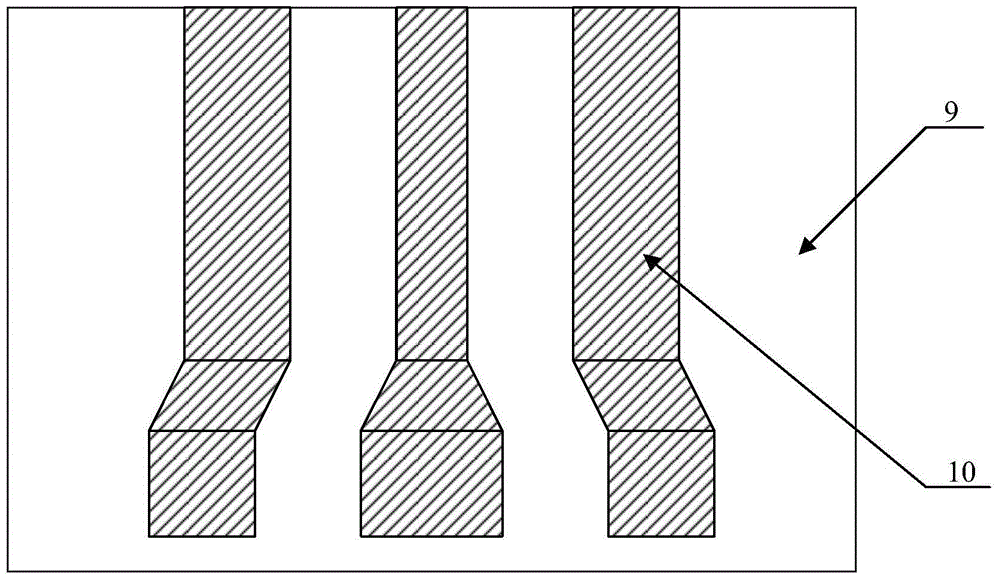

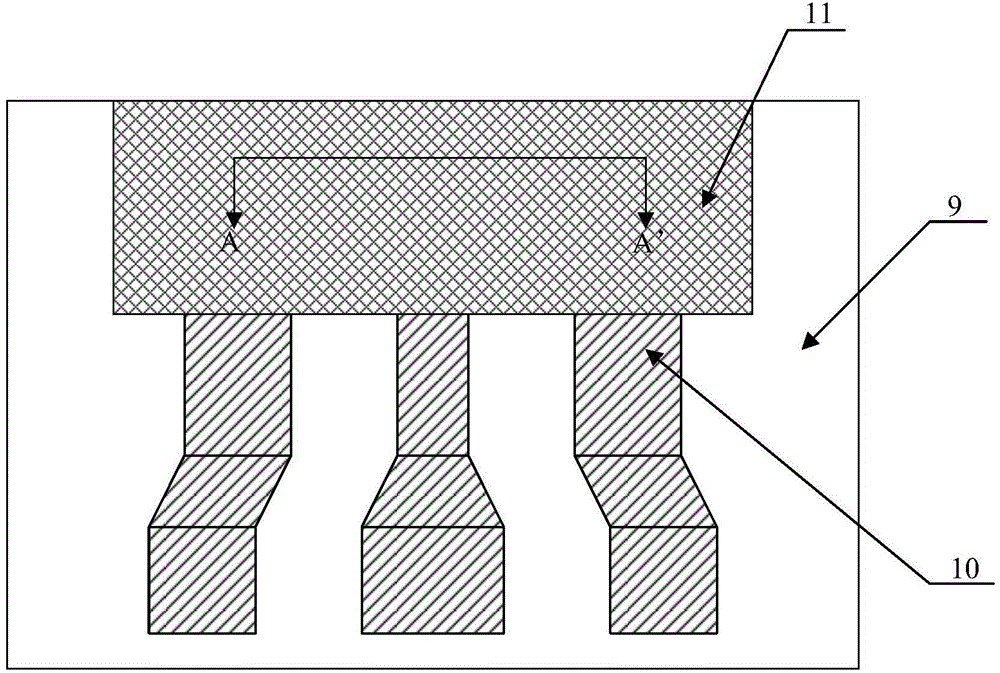

Terahertz quantum cascade laser device structure and production method thereof

ActiveCN104538844AStrong cooling capacityImprove heat dissipationLaser detailsSemiconductor lasersThermal conductivitySemi insulating

The invention provides a terahertz quantum cascade laser device structure and a production method thereof. The terahertz quantum cascade laser device structure at least comprises a ridge waveguide structure, wherein the ridge waveguide structure comprises a semi-insulating GaAs substrate, a GaAs buffer layer, a lower contact layer, an active region, an upper contact layer, a heat-conducting insulating layer, an upper metal layer and a lower metal layer. By depositing the heat-conducting insulating layer and covering metal on the side surface of the device, a transverse heat dissipation channel is provided for a device, so that the device has stronger heat dissipation capability compared with THz QCL uncovered by metal on the sidewall. A flip chip packaging method is adopted, and a supporting substrate adopts a high heat-conductivity material such as silicon, so that the heat dissipation capability of the supporting substrate is improved compared with the normal semi-insulating GaAs substrate for packaging the device, and the supporting substrate has a relatively large electrode area and also is favorable for the heat dissipation of the device. The novel structure is used for improving the temperature characteristics and the energy efficiency of THz QCL, thus being favorable for working in a continuous or high-duty-cycle pulse state; the device can be produced by a standard semiconductor process, and the production method of the device is suitable for industrial mass production.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Fabrication method for crystalline silicon solar cell

InactiveCN102332495ASimple processReduce manufacturing costFinal product manufactureSemiconductor devicesEtchingBoron nitride

The invention discloses a fabrication method for a crystalline silicon solar cell. A phosphorous silicon nitride film is deposited on one surface of a P-type crystalline silicon wafer or an N-type crystalline silicon wafer after cleaning and etching, a boron nitride film or a boracic silicon nitride film is deposited on the other surface, the crystalline silicon wafer with deposited films is then annealed under high temperature, so that the elements of phosphorus and boron in the films can be diffused into the crystalline silicon wafer, consequently, the P-type crystalline silicon wafer is formed into a N plus PP plus structure, the N-type crystalline silicon wafer is formed into a P plus NN plus structure, afterwards, metal electrodes are fabricated, and the fabrication of the cell is fulfilled. Compared with the conventional fabrication method, the fabrication method integrates the high-temperature diffusion doping process for forming the PN junction and the preparation process of an antireflection film together, avoids the edge junction etching process, and reduces the usage of phosphorus source and boron source, thus greatly simplifying the process flow and reducing the fabrication cost, and the fabrication method has a broad application prospect in the technical field of solar cell fabrication.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Modified polypropylene insulation material and manufacturing method thereof

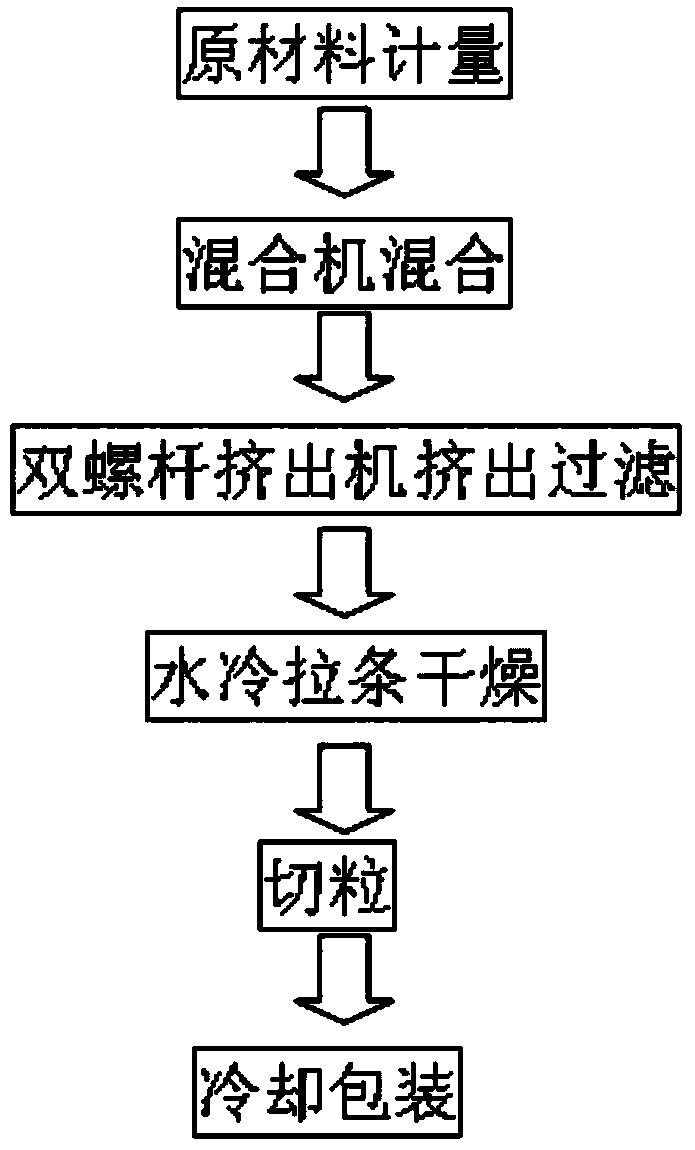

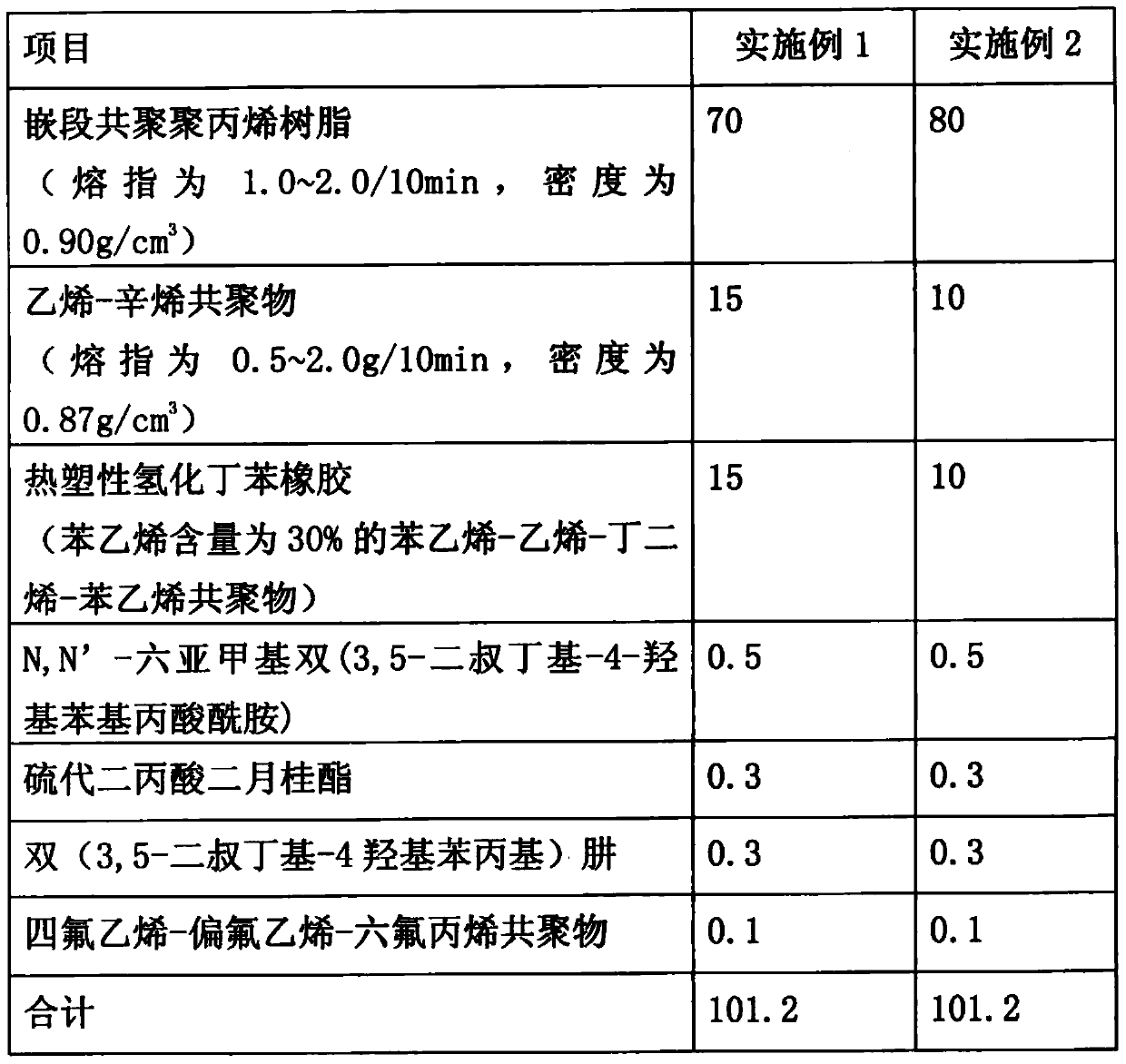

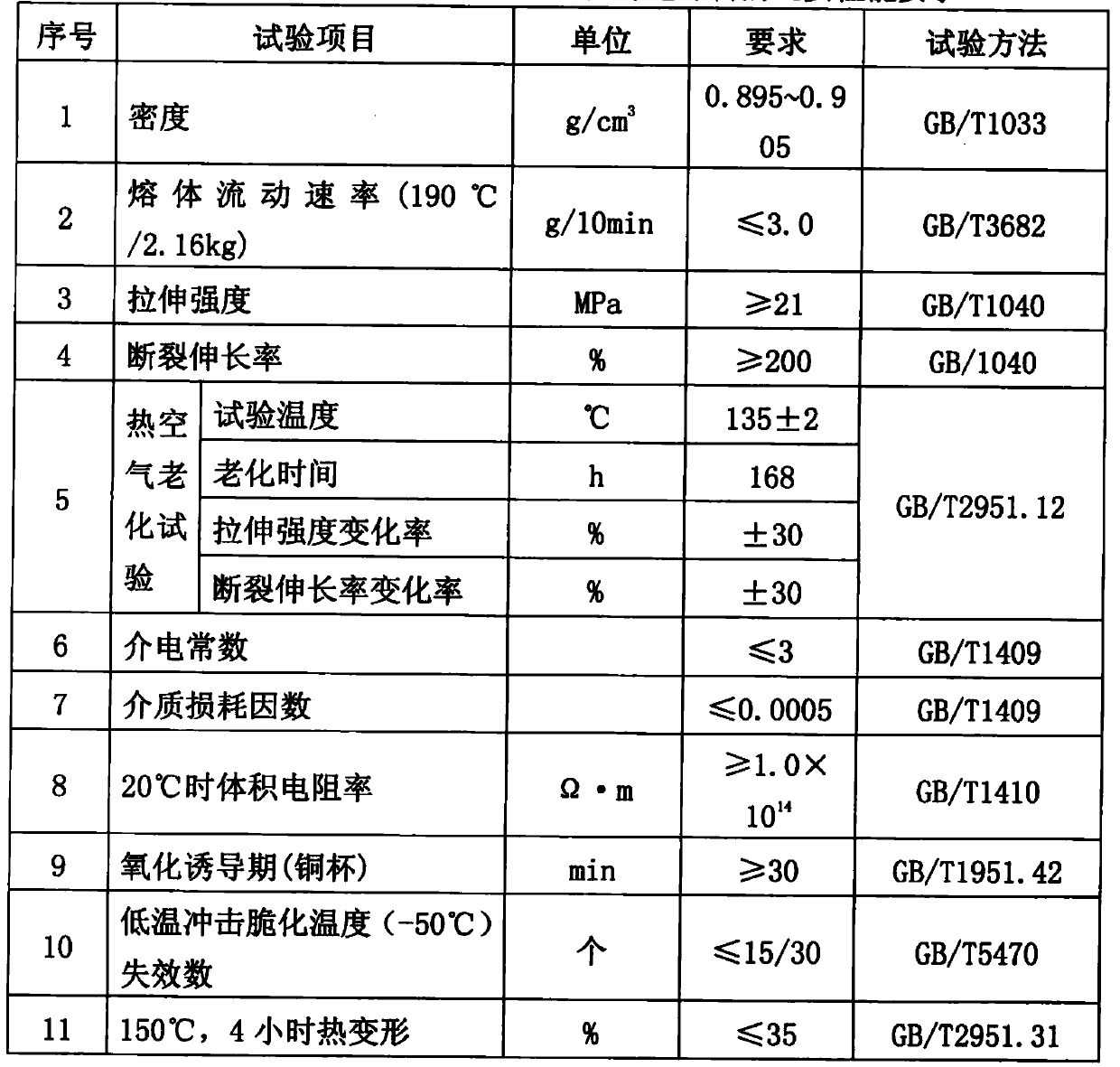

The invention relates to a modified polypropylene insulation material and a manufacturing method thereof, and the modified polypropylene insulation material includes the following components by weight part: 70-80 parts of polypropylene resin, 10-15 parts of polyolefin elastomer resin, 10-15 parts of thermoplastic hydrogenation butadiene styrene rubber, 0.5 parts of anti-oxidant A, 0.3 parts of anti-oxidant B, 0.3 parts of an anticopper agent and 0.1 parts of a rheological agent. The manufacturing method includes the following steps: metering the raw materials according to weight parts and putting in a mixer for uniformly mixing, then sending to a double screw extruder for blending and extruding, filtering and drawing into strips, and then cooling through a water tank and drying, putting in a pelleter for cutting into particles, and then packaging to obtain the finished product. The insulation material has the advantages of good performance, good high-and-low temperature performance, high strength and low cost, and is capable of being used in insulation of telecommunication cable, detection cable and oil pump cable; the manufacturing method has the advantages of reasonable design and convenient operation.

Owner:天津市普立泰高分子科技有限公司

Perovskite photoelectric detector based on composite electron transport layer and preparation method of perovskite photoelectric detector

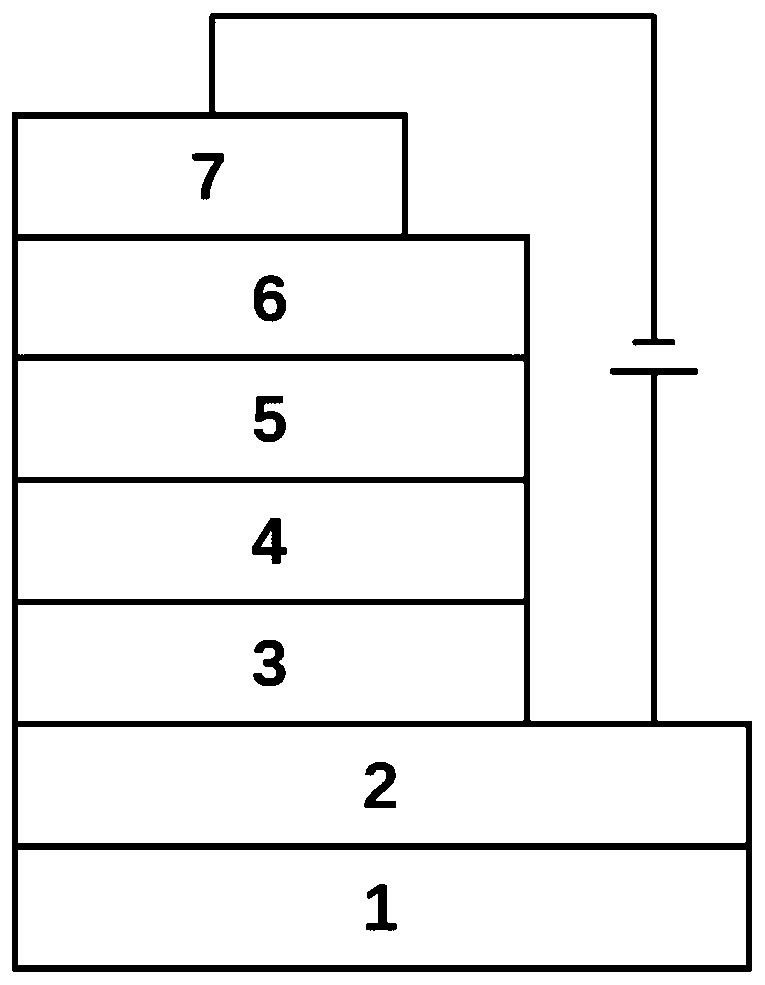

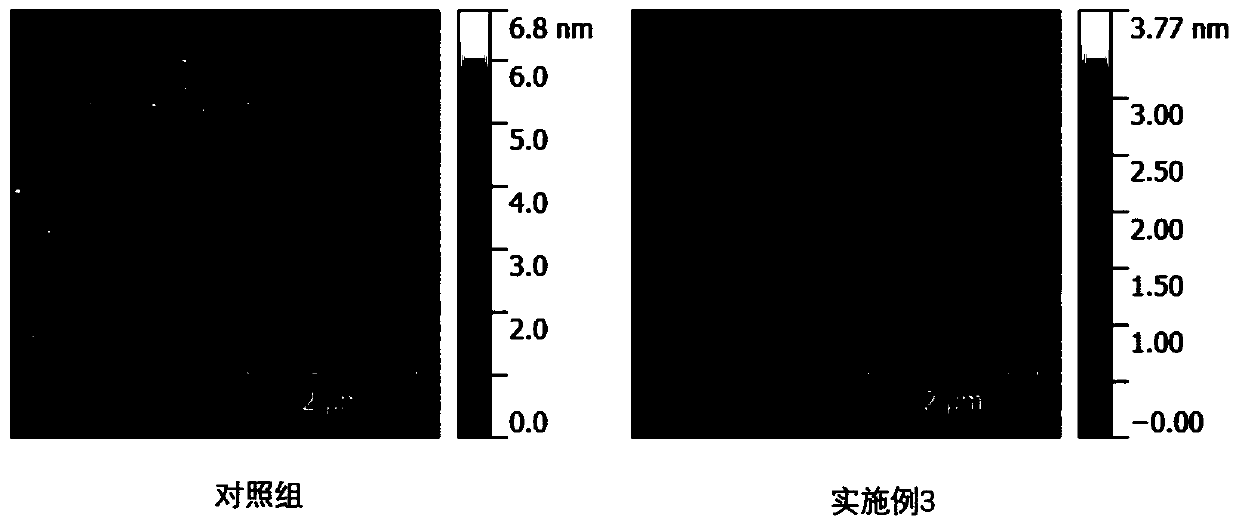

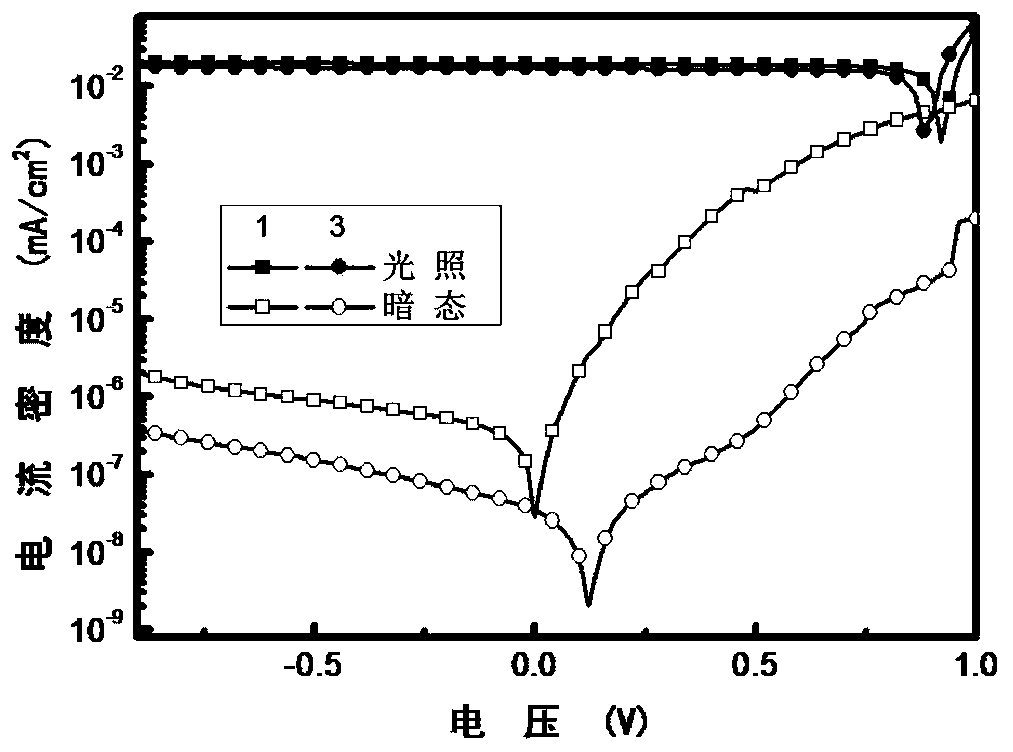

ActiveCN109920918AHigh dielectric constantIncrease contentSolid-state devicesSemiconductor/solid-state device manufacturingUltravioletHole transport layer

The invention relates to a perovskite photoelectric detector based on a composite electron transport layer. The perovskite photoelectric detector structurally comprises a substrate, a conductive anode, a hole transport layer, a perovskite photoactive layer, a composite electron transport layer, a hole barrier layer and a metal cathode from bottom to top sequentially, wherein the composite electrontransport layer is formed by a mixture of PCBM and gelatin; and the composite electron transport layer comprises 0.1%-6% by mass of gelatin and the balance PCBM. With the adoption of the composite electron transport layer doped with a bioactive material, namely, gelatin, the surface topography of an original PCBM electron transport layer is improved, so that an original mesoporous interface becomes uniform and compact, the device has better water oxygen resistance and anti-ultraviolet capability, the stability of the perovskite photoelectric detector is improved, and the working life is prolonged; besides, the carrier transport capability of the electron transport layer is improved, leakage current in work of devices is reduced, dark current is substantially reduced, and finally, the detection performance of the perovskite photoelectric detector is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

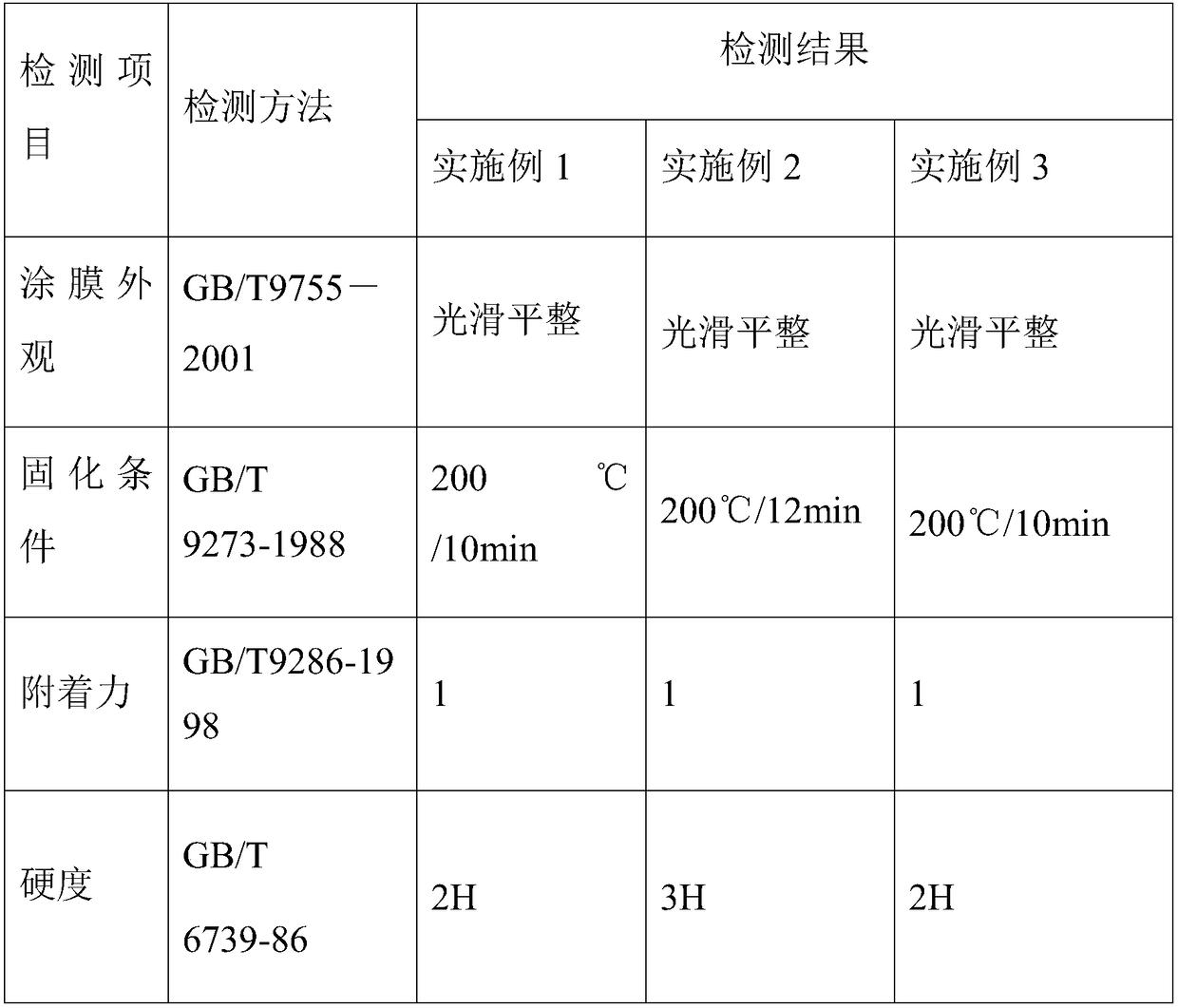

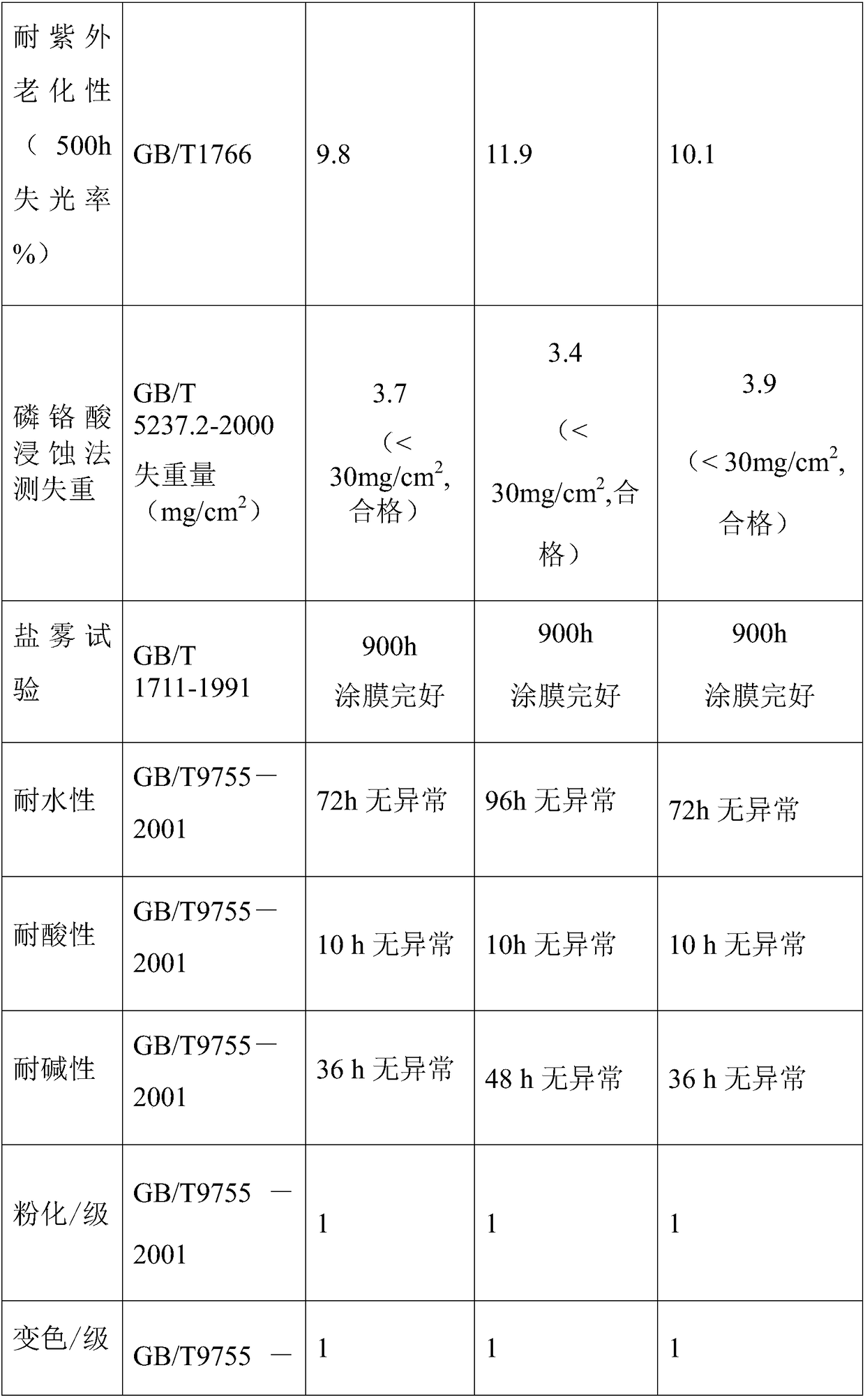

Fluoro-carbon preservative weather-resistant coating and preparation method thereof

InactiveCN108610782AGood compatibilityImprove cracking defectsAnti-corrosive paintsPolyester coatingsCarbon coatingEmulsion

The invention provides a fluoro-carbon preservative weather-resistant coating and a preparation method thereof. By means of researching of modification to a fluoro-carbon coating with a graphene oxidedispersant, penetration of water and gas atoms, such as oxygen and the like, is effectively inhibited, so that contact between the coating and corrosive or oxidizing mediums is prevented, thereby achieving excellent protective effect to the substrate material. In addition, the graphene also can passivate a coating metal in order to enhance anti-corrosion performance of the coating. The graphene can improve antifriction and wearing-resistance of the coating layer. Hydroxyl groups in polyhydroxystyrene emulsion and alkyd resin emulsion can be subjected to esterification and amination reactionswith residual carboxyl groups and amino groups remaining on surface of the graphene oxide, thus forming stable covalent bonds, increasing compatibility of the resin substrate and graphene oxide, and fully achieving the excellent anti-corrosion performance of the graphene. The coating has excellent anti-corrosion performance, good weather resistance, outstanding comprehensive performance and greatconstructability, and has excellent economic and social significances.

Owner:FOSHAN UNIVERSITY

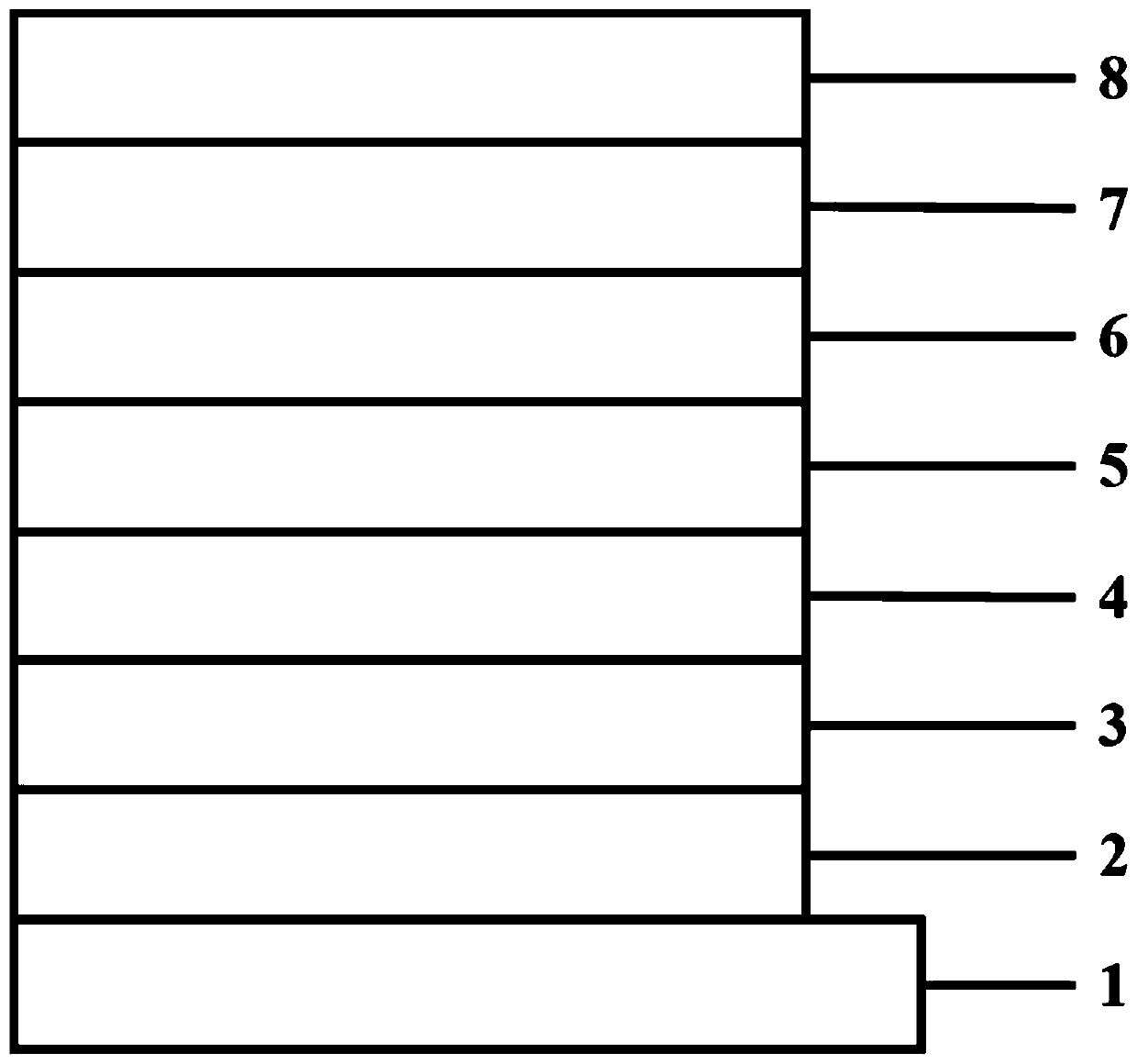

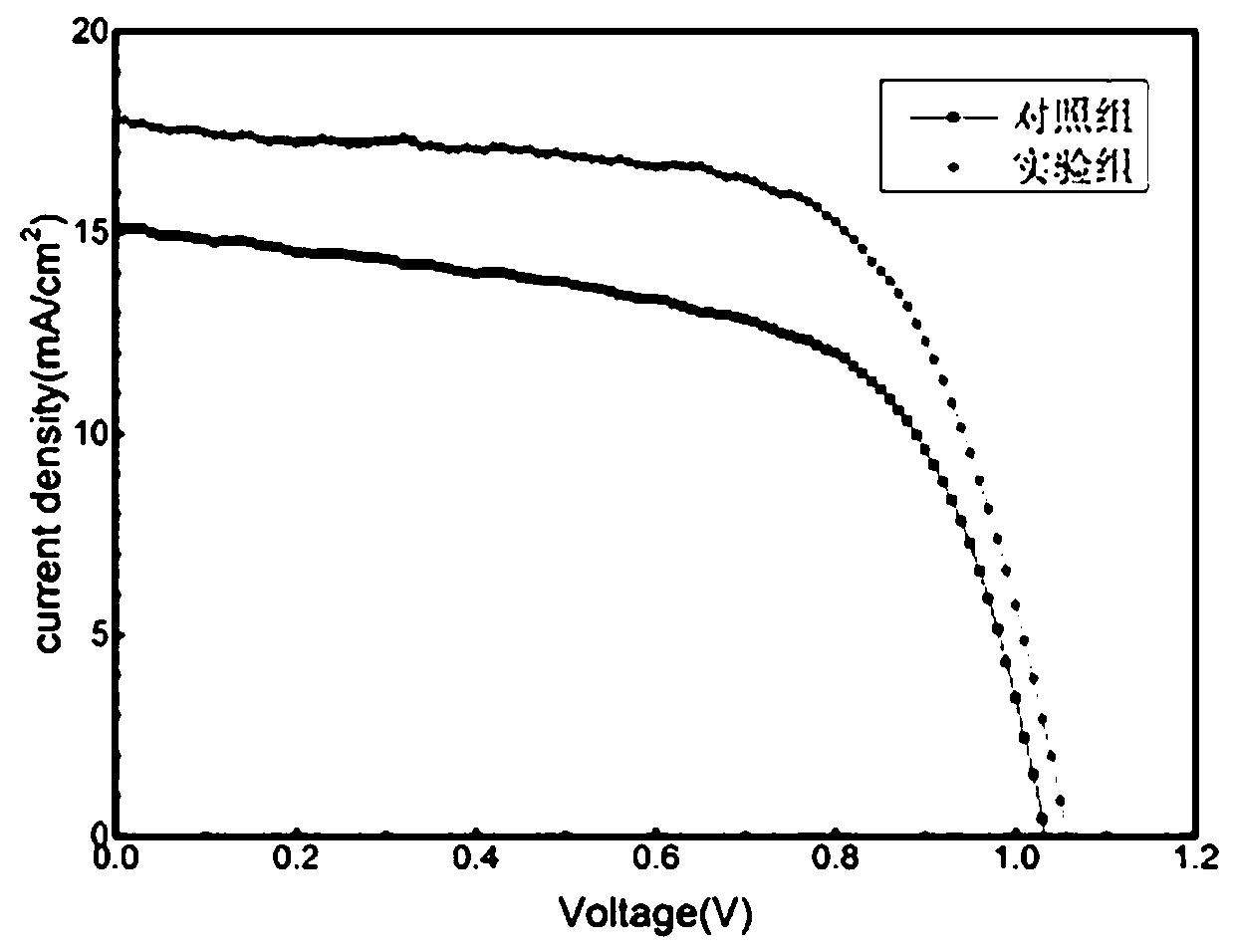

Specially doped perovskite solar cell and preparation method thereof

ActiveCN111180587AFill the crystal gapFill the holeSolid-state devicesSemiconductor/solid-state device manufacturingHole transport layerBlocking layer

The invention relates to a specially doped perovskite solar cell and a preparation method thereof. The perovskite solar cell is sequentially provided with a transparent substrate, a conductive anode,a hole transport layer, a passivation doping layer, a perovskite active layer, an electron transport layer, a hole blocking layer and a metal cathode from bottom to top, the passivation doping layer is made of a two-dimensional perovskite precursor material or organic ammonium salt, and the thickness of the passivation doping layer is 0.1-10 nm. Compared with a traditional perovskite solar cell, the photoelectric conversion efficiency is higher, the water and oxygen blocking capacity is better, and the stability of the perovskite solar cell is better.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

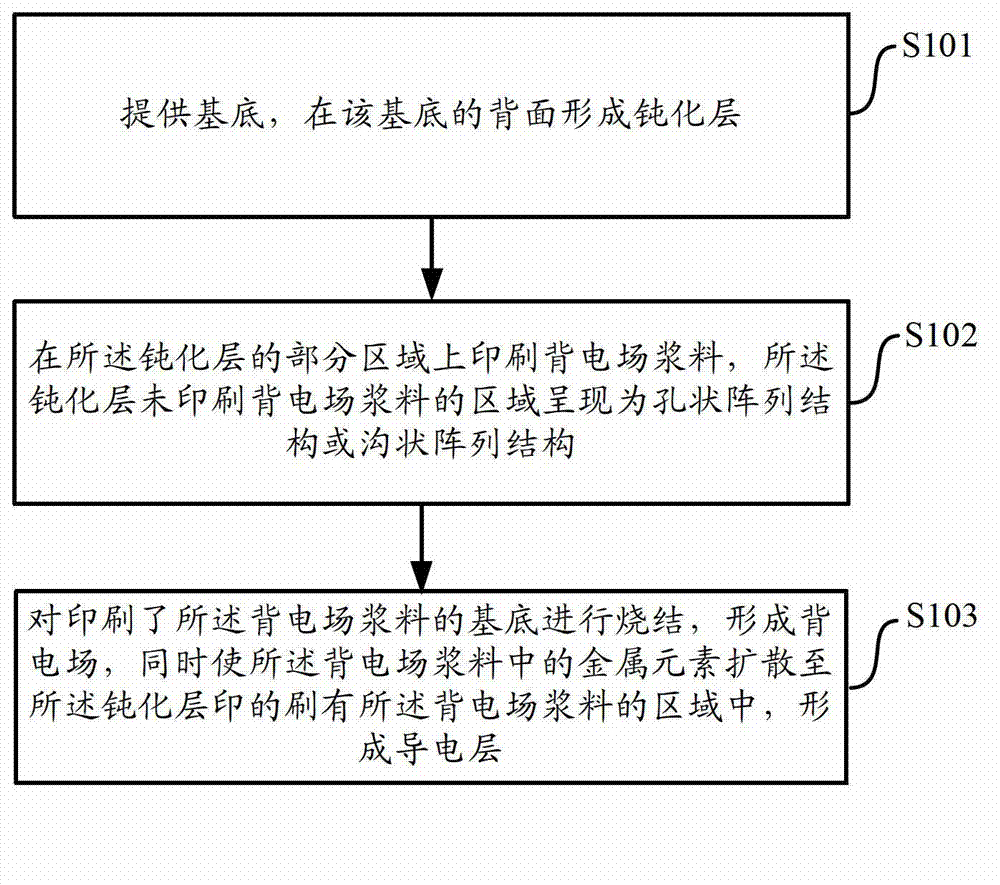

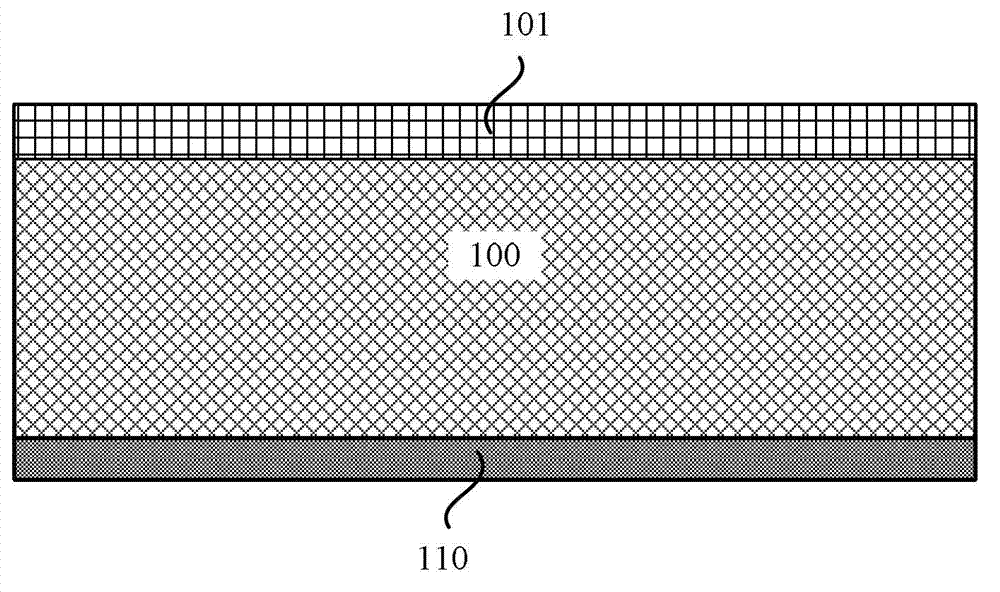

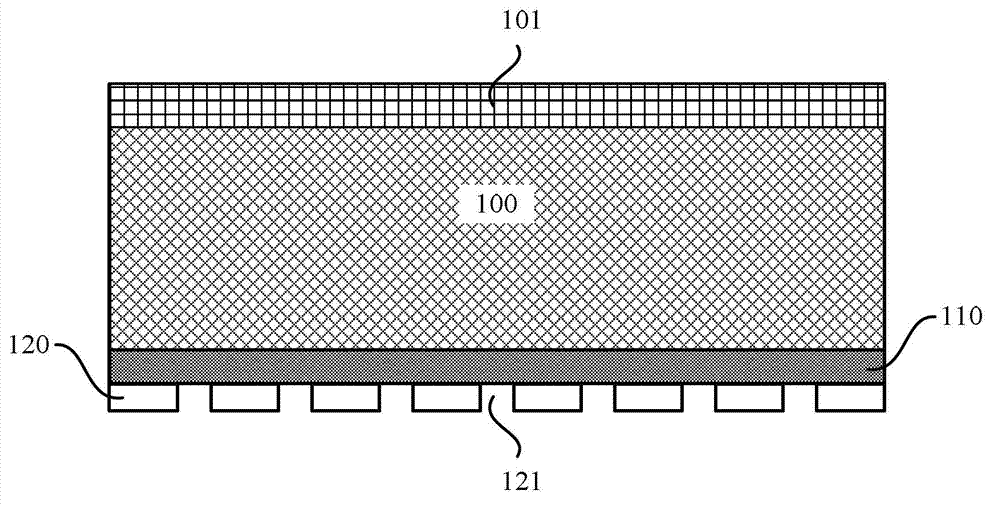

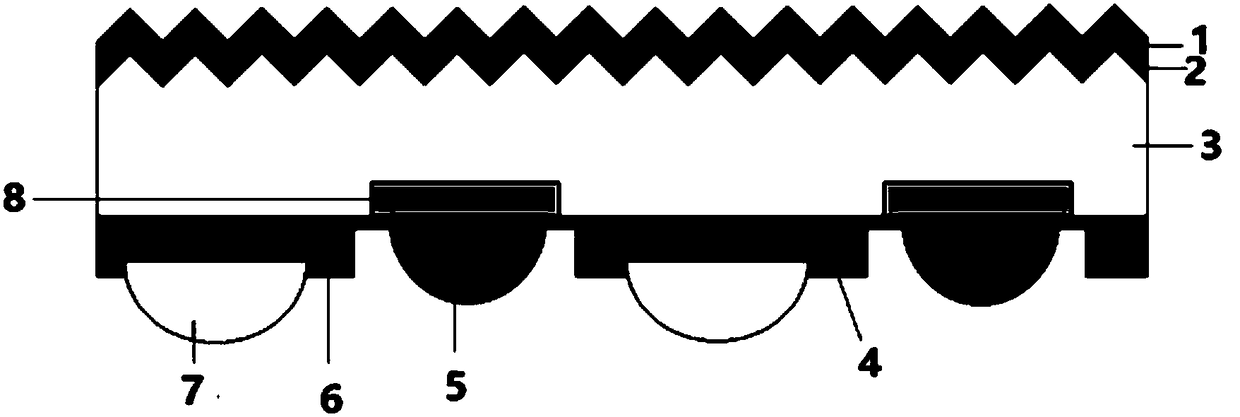

Preparation method of back surface field of back-passivated solar cell and back-passivated solar cell provided with back surface field

ActiveCN103094414AImproved bow limb effectImprove toughnessFinal product manufactureSemiconductor devicesElectrical batteryBack surface field

The invention discloses a preparation method of a back surface field of a back-passivated solar cell. The preparation method comprises the following steps. A base is provided, and a passivating layer is formed at the back of the base. Back surface field size is printed on part of the passivating layer, and an area, not being printed with the back electric size, of the passivating layer is of a hole-shaped array structure or a ditch-shaped array structure. Sintering of the base printed with the back surface field size is performed so as to form the back surface field, and meanwhile metal elements in the back surface field size are spread to the area printed with the back surface field size of the passivating layer so as to form a conductive layer. Accordingly, the invention also provides the passivating solar cell provided with the back surface field. The preparation method of the back surface field of the back-passivated solar cell and the back-passivated solar cell provided with the back surface field is capable of effectively simplifying preparation technology of the passivated solar cell, increasing toughness of the solar cell and reducing production cost of the solar cell.

Owner:CHINT NEW ENERGY TECH (HAINING) CO LTD

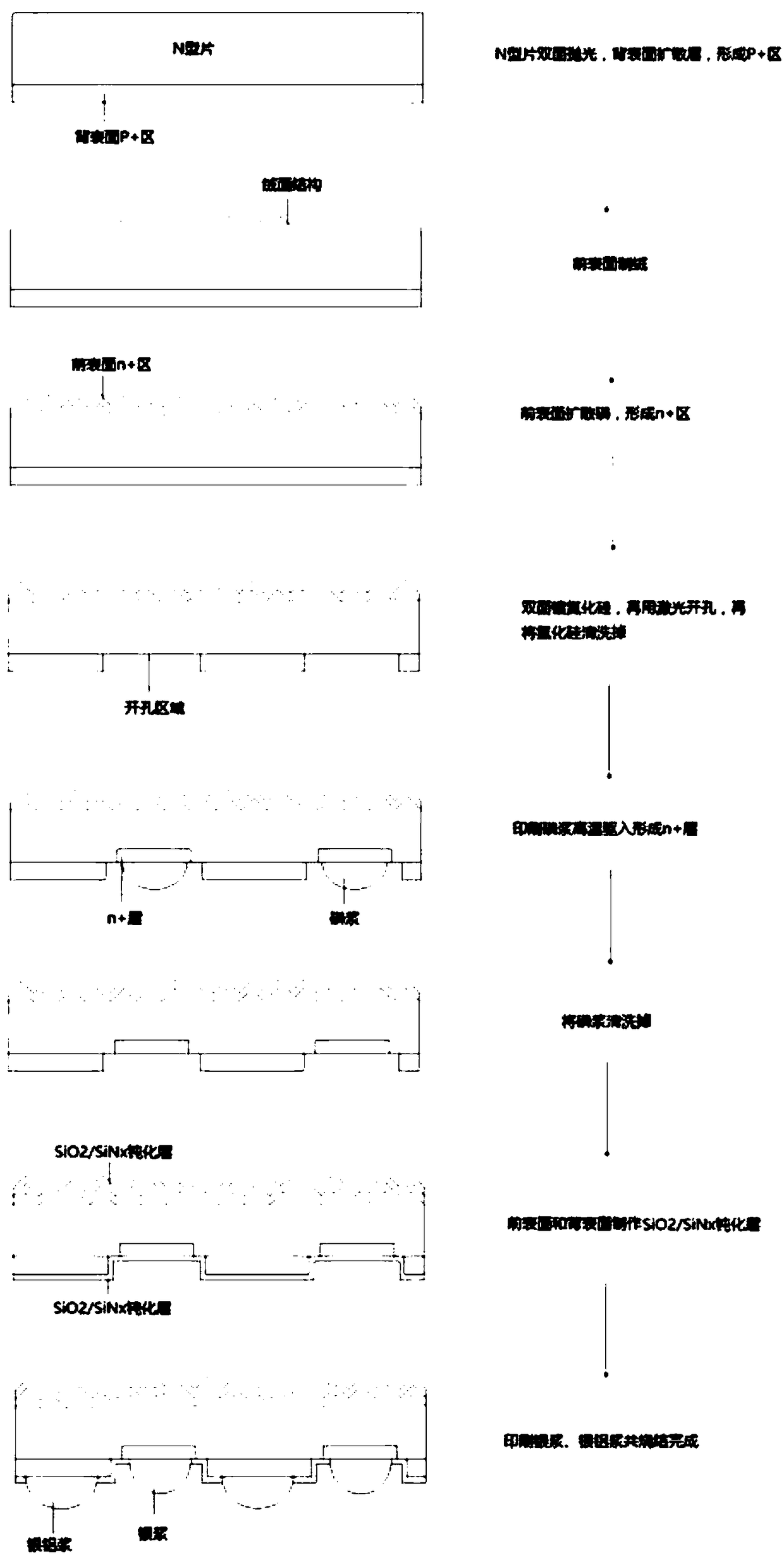

N type IBC battery and preparation method therefor

ActiveCN108538958AImprove life expectancyLight attenuation is smallFinal product manufactureSemiconductor devicesSlurrySilicon dioxide

The invention provides an N type IBC battery and a preparation method therefor. The preparation method for the N type IBC battery comprises the following steps: double faces of a silicon chip are polished, polished faces of the silicon chip are subjected to single face boron diffusion operation, HF acid is used for removing borosilicate glass, a front surface is flocked, a front surface of the silicon chip is subjected to phosphorus diffusion via use of a diffusion furnace, a PECVD device is used for plating silicon nitride on two faces of the silicon ship, a back surface of the silicon chip is perforated via laser, a perforated area of the back surface is corroded via alkali liquid, the silicon nitride is washed away via hydrofluoric acid, a phosphoric paste is printed on the back surface, cleaning operation is performed after the phosphoric slurry is driven in at a high temperature, silica and silicon nitride are grown on the front surface and the back surface of the silicon chip soas to perform passivation operation, a silver electrode and a silver-aluminium paste are printed on the back surface of the silicon chip, and one-time sintering operation is performed. According to the battery and the preparation method disclosed in the invention, an IBC battery structure can be prepared via simple equipment and technology, laser equipment and screen printing are used for preparing a main structure of the IBC battery; the battery and the method are simple in processing steps and low in cost and is suitable for large scale industrial production.

Owner:锦州阳光能源有限公司 +1

Mfg. method of metal ripple tubes

A technology for making metallic bellows includes providing annealed cold-rolling bright stainless steel band, rolling to become pipe shape, welding, cutting, shaping, cutting edge, surface treating in a treating liquid prepared from nitric acid and water, flushing with water and dewatering with alcohol. Its advantages are high productivity and quality.

Owner:锦州经济技术开发区天华波纹管有限公司

Chemical machine polishing liquor for KTP crystal

The invention discloses a chemical mechanic buffing liquid of titanium potassium oxide phosphate, which comprises the following parts: 10-90 percent nanometer SiO2 sol, 0.5-10 percent inorganic alkaline and organic alkaline, 0.5-10 percent non-ionic surfactant, 0.5-10 percent chelant and deionized water. The invention can prevent surface fish tail effectively, which improves the surface flatness.

Owner:HEBEI UNIV OF TECH

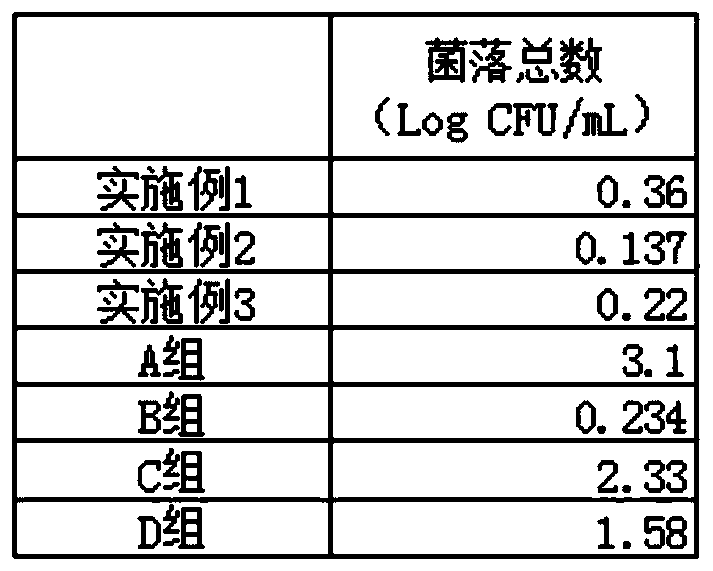

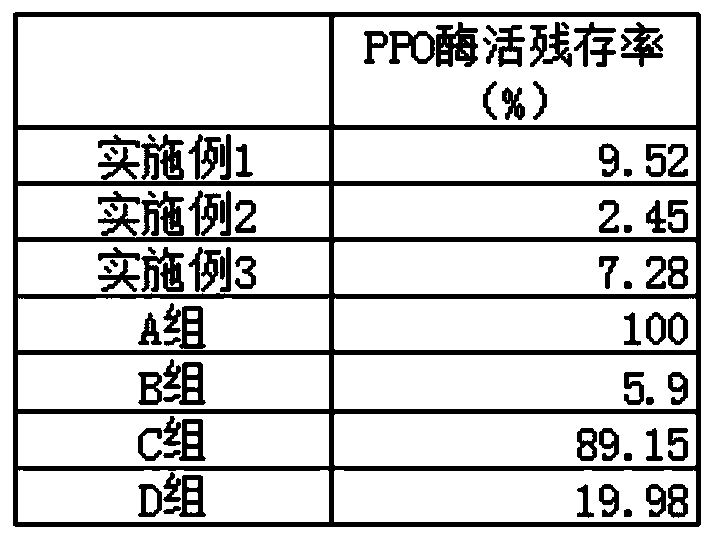

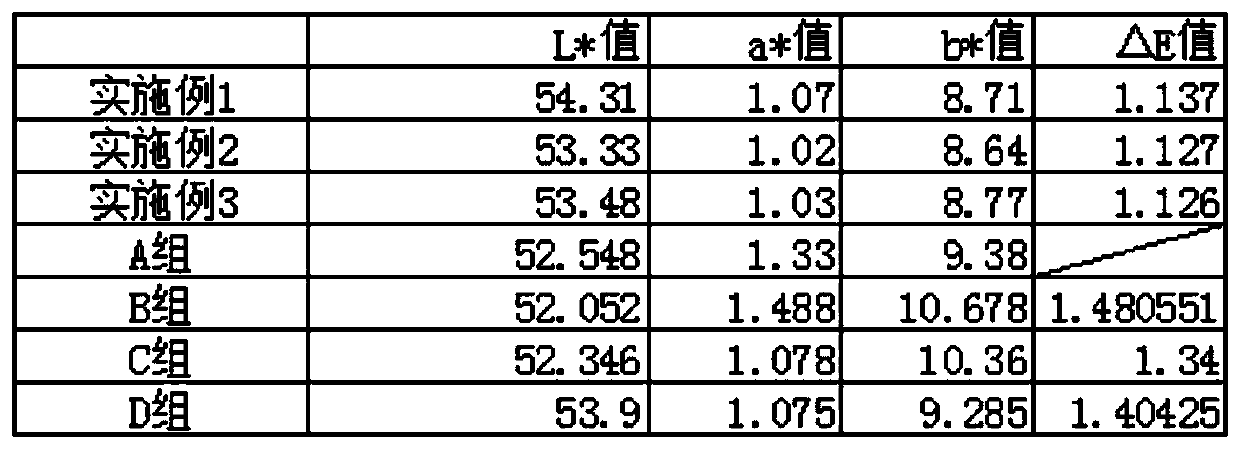

Fruit juice processing method capable of sterilizing and maintaining color

InactiveCN111000110AImprove the bactericidal effectPrevent browningFood scienceBiotechnologyBrowning

The invention discloses a fruit juice processing method capable of sterilizing and maintaining the color. The method comprises the following steps: S1, selecting fruits which are close in maturity, intact in appearance and free from plant diseases and insect pests; S2, cleaning, peeling, denucleating and dicing the fruits, then juicing the fruits, filtering the obtained juice, and filling the juice into a container; S3, transferring the juice and the container to a high light treatment chamber, and carrying out intensive pulse light flash treatment; S4, carrying out heat treatment on the fruitjuice subjected to the pulsed flash treatment; and S5, cooling the fruit juice subjected to heat treatment, and putting the cooled fruit juice into a sterile bottle. The intensive pulse light treatment sterilizes the fruit juice and passivates polyphenol oxidase in the fruit juice; the treatment of pulsed highlight treatment makes enzymes or bacteria more sensitive to heat, so good sterilizationand enzyme inactivation effects on the juice can be achieved without a very high temperature in following-up heat treatment, so browning of the juice is effectively inhibited, and the original color and flavor of the juice can be reserved as much as possible.

Owner:ZHEJIANG WANLI UNIV

PERC solar cell and preparation method thereof

ActiveCN105489709AImprove yieldFacilitate subsequent texturingFinal product manufacturePhotovoltaic energy generationEtchingSlurry

The invention relates to a PERC solar cell and a preparation method thereof. The preparation method of the PERC solar cell comprises the following steps that double-sided polishing, texturing, diffusion, etching, impurity glass removing and permanganate oxidation are performed on a silicon chip in turn; a passivation layer and a protective layer are deposited on the back surface; an antireflection layer is deposited on the front surface; and the local parts of the back surface are provided with openings, printing of front and back surface metal slurry is performing and sintering is performed so that the PERC solar cell is obtained. Compared with the conventional preparation method of the PERC solar cell, double-sided polishing is performed before texturing of the silicon chip so that subsequent texturing is facilitated by the preparation method of the PERC solar cell; meanwhile, the silicon chip of which impurity glass is removed is oxidized before the passivation layer and the protective layer are deposited on the back surface so that the passivation effect can be realized. Junction area recombination can be reduced, open-circuit voltage can be enhanced and product yield rate can be enhanced. Meanwhile, the preparation method of the PERC solar cell is high in the product yield rate based on the conventional process. Besides, the PERC solar cell is prepared according to the preparation method of the PERC solar cell.

Owner:HANS LASER TECH IND GRP CO LTD +1

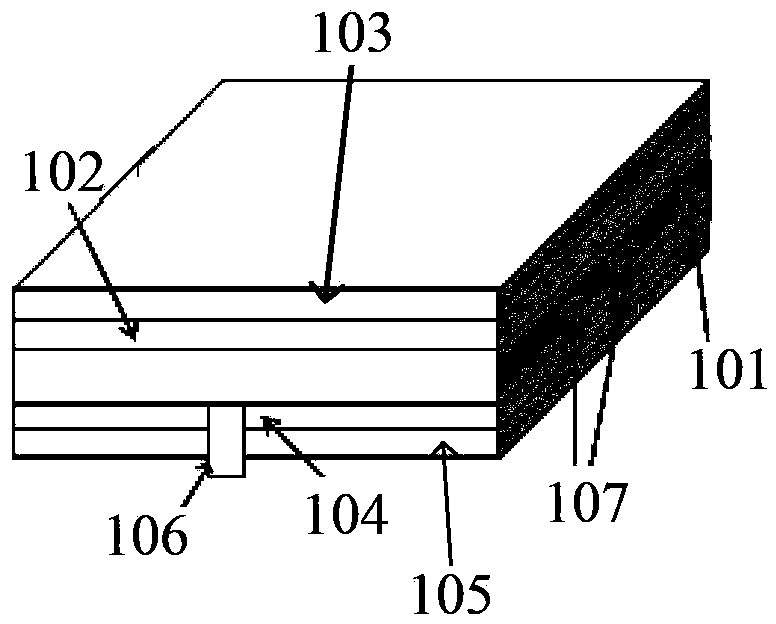

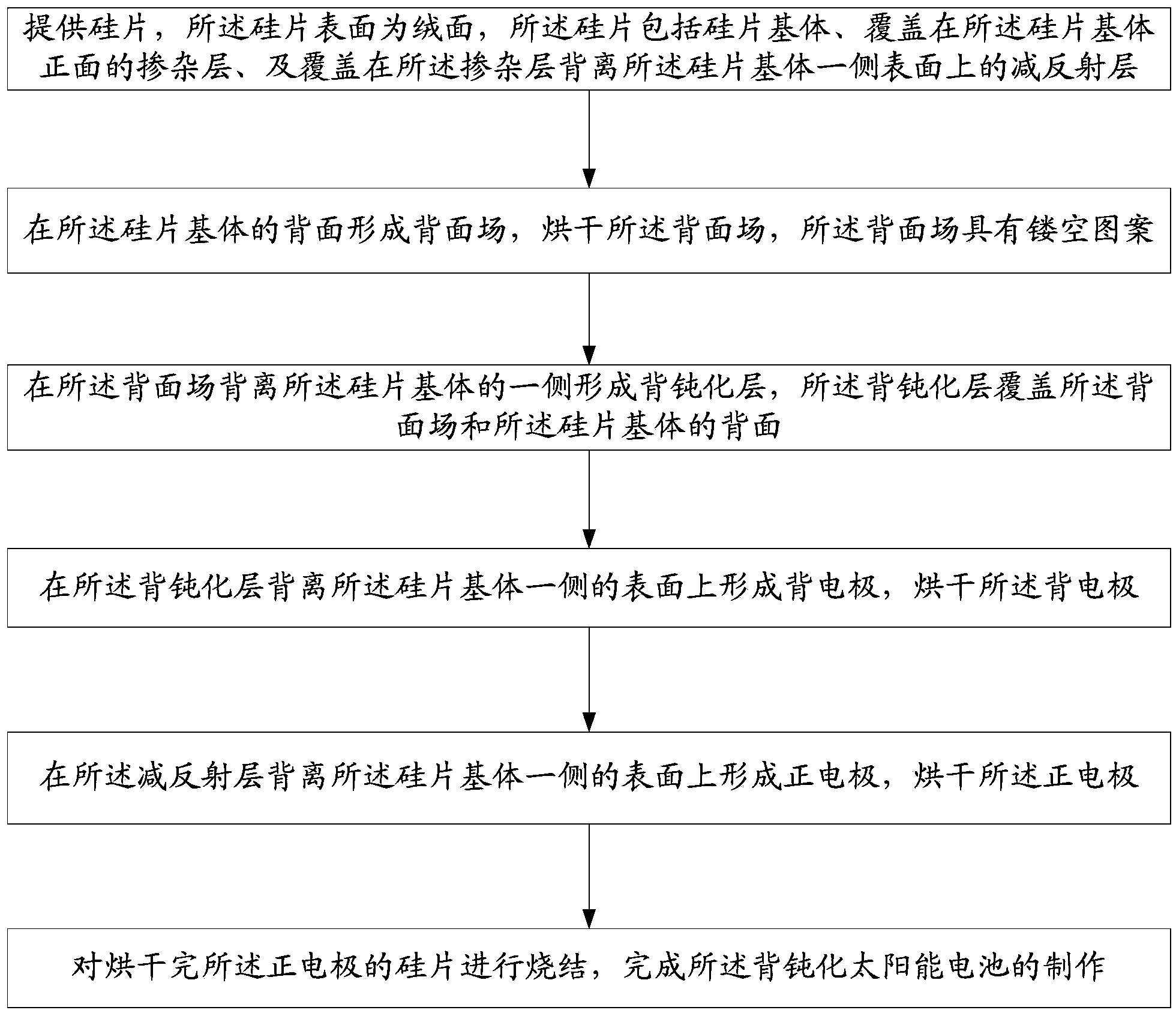

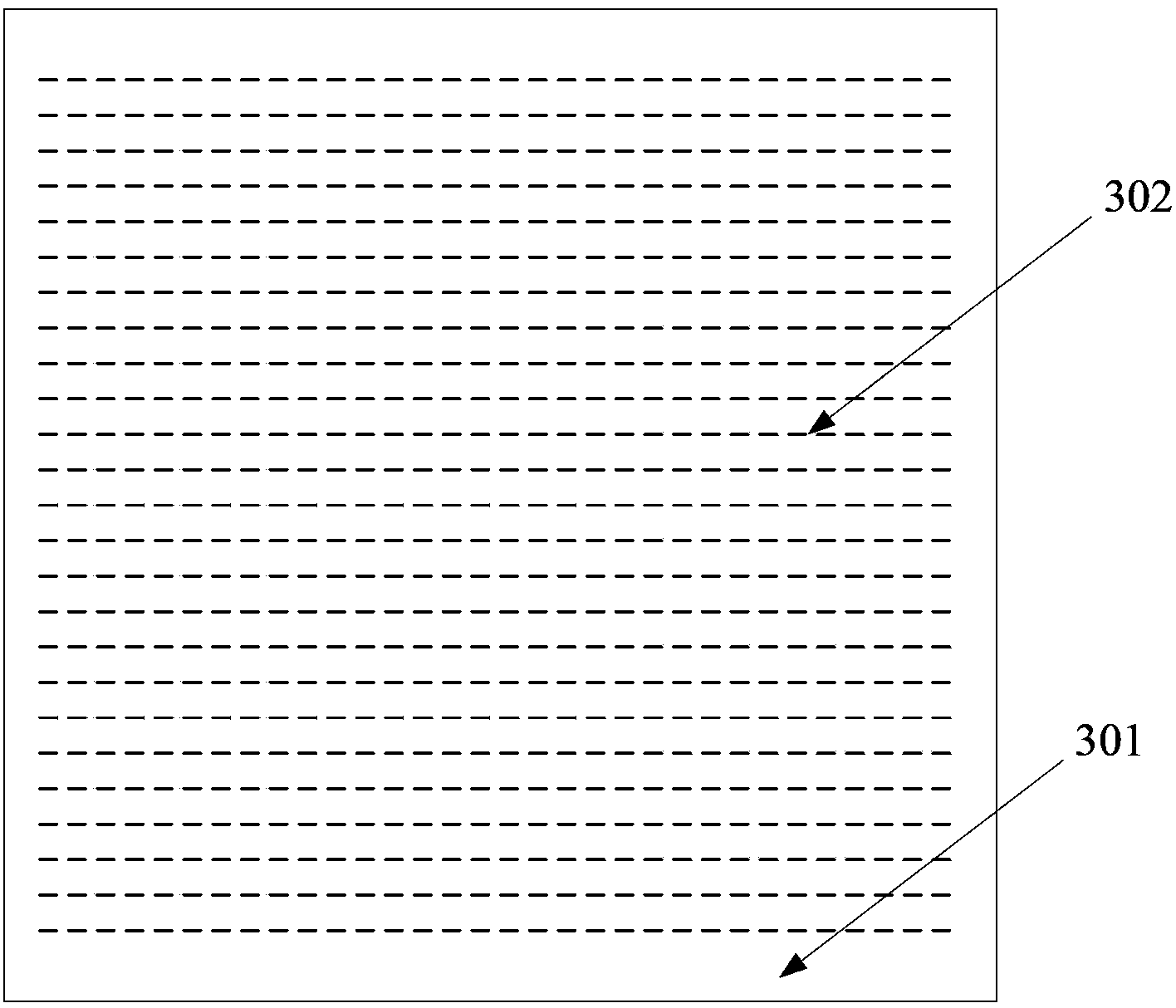

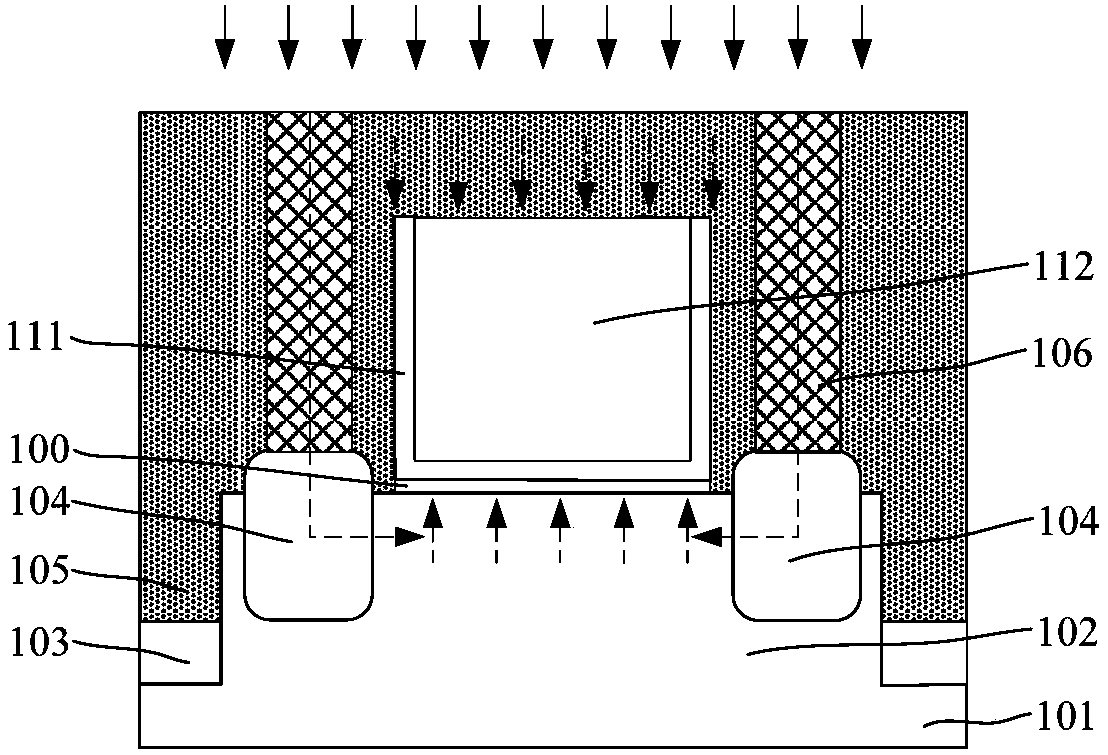

Back passivation solar cell and manufacturing method thereof

InactiveCN103367540AImprove conversion efficiencyImprove performanceFinal product manufacturePhotovoltaic energy generationBack surface fieldAluminum can

The invention provides a manufacturing method of a back passivation solar cell. After an antireflection film is prepared on a silicon wafer, a back surface field with hollowed-out patterns is firstly formed, then a back passivation layer is formed, and afterwards, a positive electrode is formed. Through forming the back surface field before the back passivation layer, the step of laser grooving is saved, so that damage to the silicon wafer caused by laser grooving is avoided; and since the back surface field is in a hollowed-out structure, the contact area of the back surface field with the back passivation layer is reduced, so that the erosion degree of the back surface field over the back passivation layer is lightened, the back passivation layer can well play a passivation effect, recombination of current carriers on the back surface of the cell is reduced, and finally, the conversion efficiency of the back passivation solar cell can be improved. Since the step of laser grooving is not needed, the production process is simplified; since the back surface field is in the hollowed-out structure, the use amount of materials needed for manufacturing the back surface field is reduced, so that the production cost is lowered; and by using the back surface field in the hollowed-out structure, stress bending caused by differences of expansion coefficients of silicon and aluminum can be reduced, so that cell breakage caused by cell bending is reduced.

Owner:YINGLI GRP +2

Zinc coating passivation solution, preparation method and coating method thereof

ActiveCN101654781AImprove densification performanceAccelerated corrosionMetallic material coating processesThio-Zinc

The invention discloses a zinc coating passivation solution, a preparation method and a coating method thereof. The zinc coating passivation solution comprises the components by weight percent: 0.001-0.05% of metal ion, 0.01-0.4% of oxidant, 0.01-1% of corrosion inhibitor, 0-0.2% of thio-carbonyl compound and the rest of deionized water. After being prepared, the zinc coating passivation solutioncan be placed for 24h at the room temperature, and the properties of the solution can be maintained; compared with the prior art, the stability is greatly enhanced, and the zinc coating passivation solution has better corrosion resistance and abrasion resistance.

Owner:TIANJIN XZB SHERARDIZING METAL PROD CO LTD

Non-chrome hot galvanizing passivation solution and preparing method thereof

The invention relates to a non-chrome hot galvanizing passivation solution and a preparing method thereof. The solution comprises 6% to 10% of titanate, 6% to 9% of molybdate, 5% to 8% of tungstate, 10% to 16% of water-based acrylate, 5% to 12% of phytic acid, 2% to 5% of sodium citrate, 4% to 8% of mineral acid, 4% to 10% of phosphoric acid and 35% to 45% of water. Compared with the prior art, the solution has the beneficial effects that the solution does not contain chrome, the salt spray test can reach 72 hours, and the passivation effect is good.

Owner:淄博传能新材料科技有限公司 +1

Chromium-free steel surface treating liquid

InactiveCN104372322AReduce pollutionLow costMetallic material coating processesChromium freeImpurity

The invention discloses a chromium-free steel surface treating liquid. The chromium-free steel surface treating liquid comprises the following components in mass concentration: 0.1%-1.5% of titanium salt, 2%-15% of a vanadium compound, 5%-20% of fluoride, 1%-2% of water soluble resin, an acid, 0.5%-1.5% of molybdate, 2%-8% of sodium polyphosphate and the balance of water and other unavoidable impurities, wherein the acid is used for regulating the pH value of a passivation solution to be 3-4. A surface treating process of the chromium-free steel surface treating liquid is simple, easy to implement and low in cost; the chromium-free surface treatment can be completely carried out on steel plates on a traditional chromium treatment production line only by adding few auxiliary instruments or equipment, so that the wastewater treatment is simplified, the cost is lowered, and the economic benefit is remarkable.

Owner:WUXI EPIC TECH

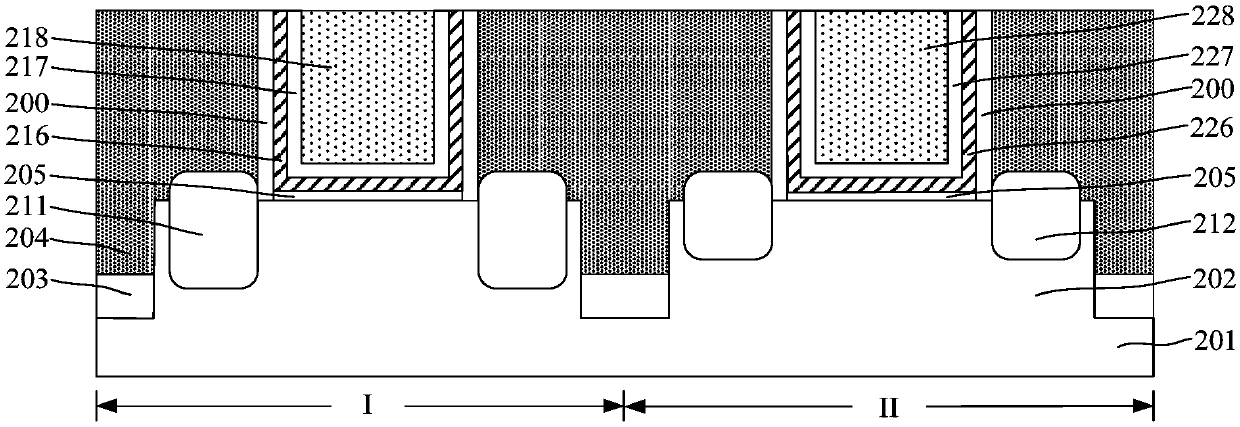

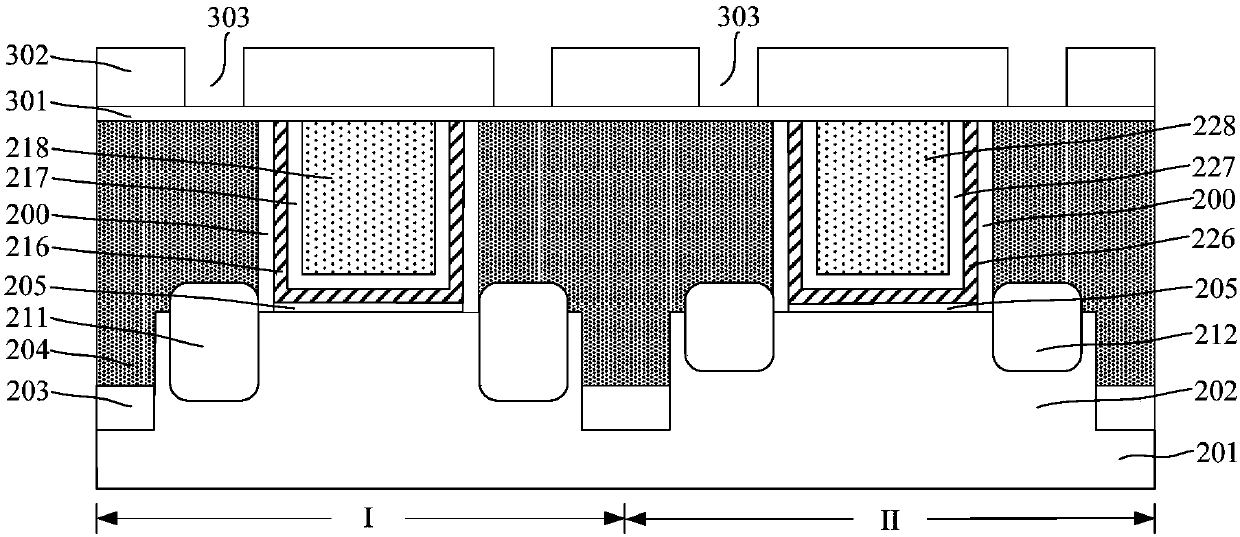

Semiconductor device and forming method thereof

ActiveCN107591370AGood electrical propertiesImprove conductivityTransistorSemiconductor/solid-state device manufacturingGate dielectricEngineering

The invention discloses a semiconductor device and a forming method thereof. The forming method comprises steps: a first conductive plug is formed inside an interlayer dielectric layer, wherein the first conductive plug is electrically connected with a source and drain doping area; before or after the first conductive plug is formed, a gate electrode layer with a first thickness is etched and removed, and a blocking layer is formed at the top part of the gate electrode layer after etching; an upper dielectric layer is formed on the interlayer dielectric layer and the blocking layer; a second conductive plug passing through the upper dielectric layer is formed in the upper dielectric layer; and annealing treatment is carried out, the annealing treatment is carried out in an atmosphere containing passivated ions, the passivated ions are diffused to the base below the gate structure through the second conductive plug and the first conductive plug, and the passivated ions located in the base are diffused to a gate dielectric layer. While the interface performance between the gate structure and the base is improved, the passivated ions can be prevented from being diffused inside the gate electrode layer, and the electrical performance of the formed semiconductor device is thus improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Perovskite quantum dots based on castor oil as green solvent and preparation method of perovskite quantum dots

ActiveCN111349437APlay a passivation roleImprove stabilityLuminescent compositionsPhotovoltaic energy generationAlcoholPhysical chemistry

The invention relates to perovskite quantum dots based on castor oil as a green solvent and a preparation method of the perovskite quantum dots, wherein the pollution of an organic solvent to the environment can be reduced and the preparation method is greener and more environment-friendly; the passivation effect on the surface defects of the perovskite quantum dots can be achieved, so that the perovskite quantum dots are more stable. According to the technical scheme adopted by the invention, the method comprises the steps: taking 0.430-0.438 part by dry mass of cesium bromide and 0.608-0.616part by dry mass of bismuth bromide, putting the cesium bromide and the bismuth bromide into a 20 mL three-neck bottle, then adding 0.259-0.271 part by dry mass of octylamine and 58.239-58.639 partsby dry mass of castor oil, and stirring at normal temperature for 6 h to form a precursor solution; taking out 5 mL of the precursor solution, slowly dropwise adding the precursor solution into 40.15-40.35 part of absolute ethyl alcohol, violently stirring at the temperature of 80 DEG C, carrying out a reaction for 10 min, and naturally cooling to room temperature; and centrifuging at 8000 r / min,and removing a precipitate to obtain a Cs3Bi2Br9 quantum dot solution.

Owner:SHAANXI UNIV OF SCI & TECH

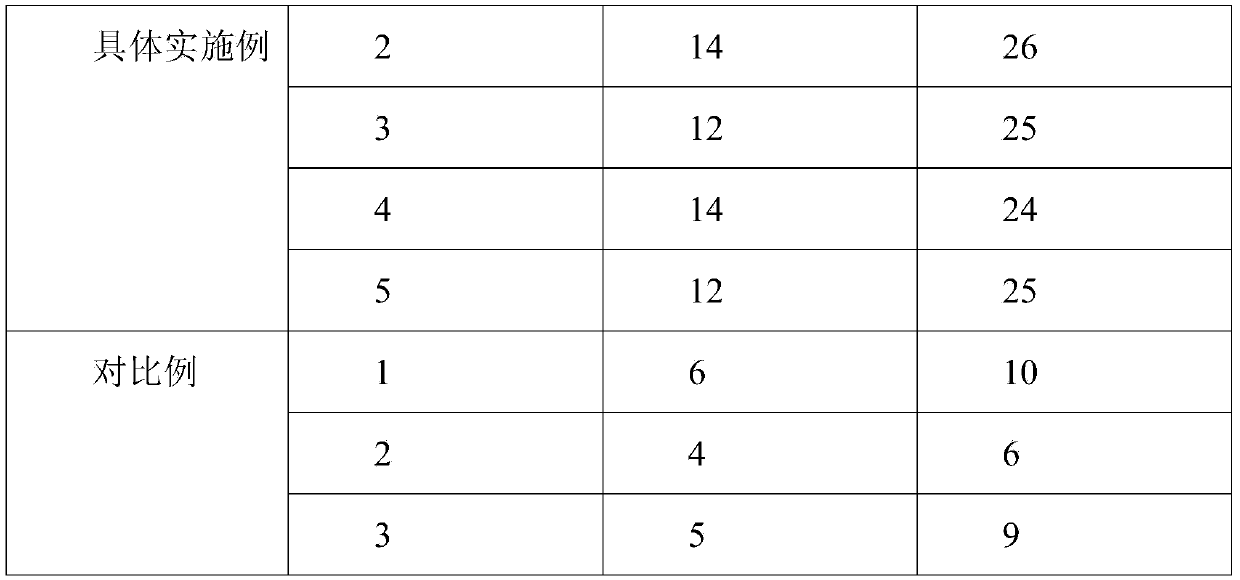

Controllable degrading magnesium-based metal material

InactiveCN105363068AHigh pyrolysisImprove thermal stressSurgeryLiquid/solution decomposition chemical coatingBioactive glassMetallic materials

The invention provides a controllable degrading magnesium-based metal material. The surface of the controllable degrading magnesium-based metal material is coated with biological active glass components modified by tannic acid, wherein the biological active glass components modified by tannic acid is formed by grafting nano biological active glass particles with tannic acid. By controlling the use amount of tannic acid grafted in the modified biological active glass components, adding amino structure compounds and controlling the coating thickness of biological active glass modified by tannic acid, the degrading time of the magnesium-based metal material can be effectively controlled.

Owner:WUXI QINGYANG MACHINERY MFG

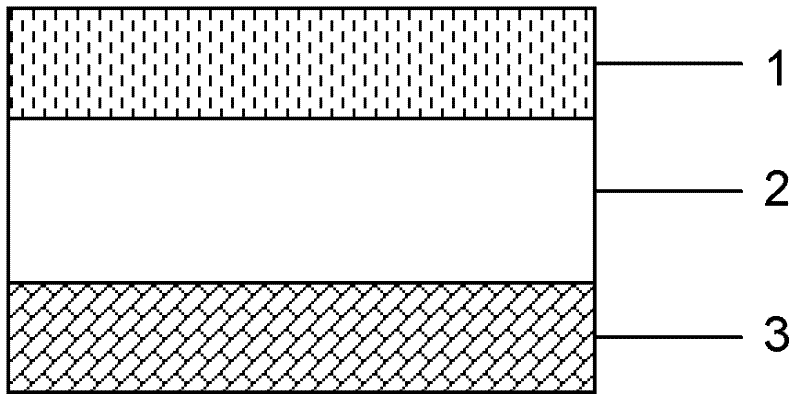

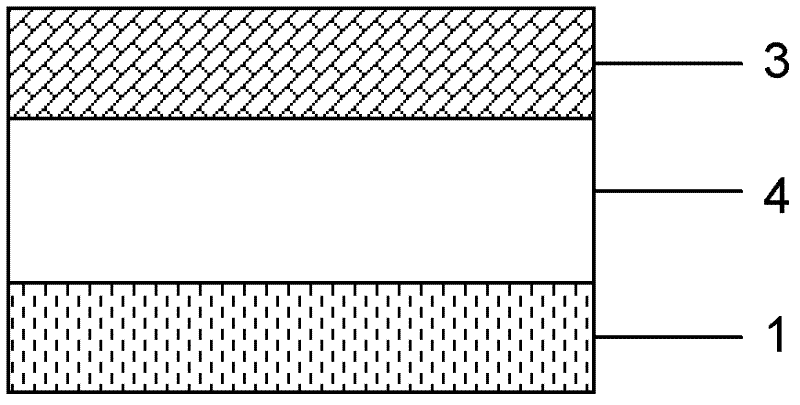

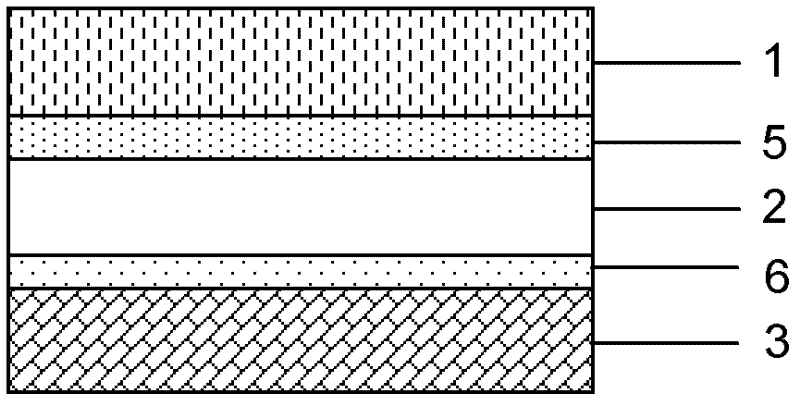

Method for manufacturing T-shaped grid of GaN microwave device

ActiveCN102064104AObvious control advantageImprove featuresSemiconductor/solid-state device manufacturingSemiconductor devicesMicrowaveSchottky barrier

The invention discloses a method for manufacturing a T-shaped grid of a GaN microwave device. The method comprises the following steps: (1) growing a high temperature dielectric layer on a GaN substrate, wherein the ingredient of the high temperature dielectric layer is Si3N4; (2) growing a low temperature dielectric layer on the upper surface of the high temperature dielectric layer, wherein the ingredient of the low temperature dielectric layer is SiOxNy; (3) photoetching a grid groove photoetched pattern in a required size on the low temperature dielectric layer, etching a grid groove on the low temperature dielectric layer and the high temperature dielectric layer through dry etching and removing the residual photoresist; (4) photoetching a grid cover photoetched pattern aligned with the grid groove on the low temperature dielectric layer; and (5) manufacturing a Schottky electrode on the GaN substrate in the grid cover pattern. By adopting the method, the grid length is easier to control and the reliability of the GaN microwave device is improved.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

Stamping die surface phosphating processing method

InactiveCN110042376AExcellent high temperature corrosion resistanceGood adhesionMetallic material coating processesHigh-temperature corrosionHot Temperature

The invention discloses a stamping die surface phosphating processing method, and relates to the technical field of mold processing. The stamping die surface phosphating processing method includes thefollowing steps of polishing, heating, phosphating, twice soaking and twice drying processing and pressurizing processing. By means of the stamping die surface phosphating processing method, a uniform and compact phosphating film can be formed on the surface of a stamping die, the surface of the stamping die can be better protected, and the processed stamping die has excellent high-temperature corrosion-resistant performance.

Owner:长沙而道新能源科技有限公司

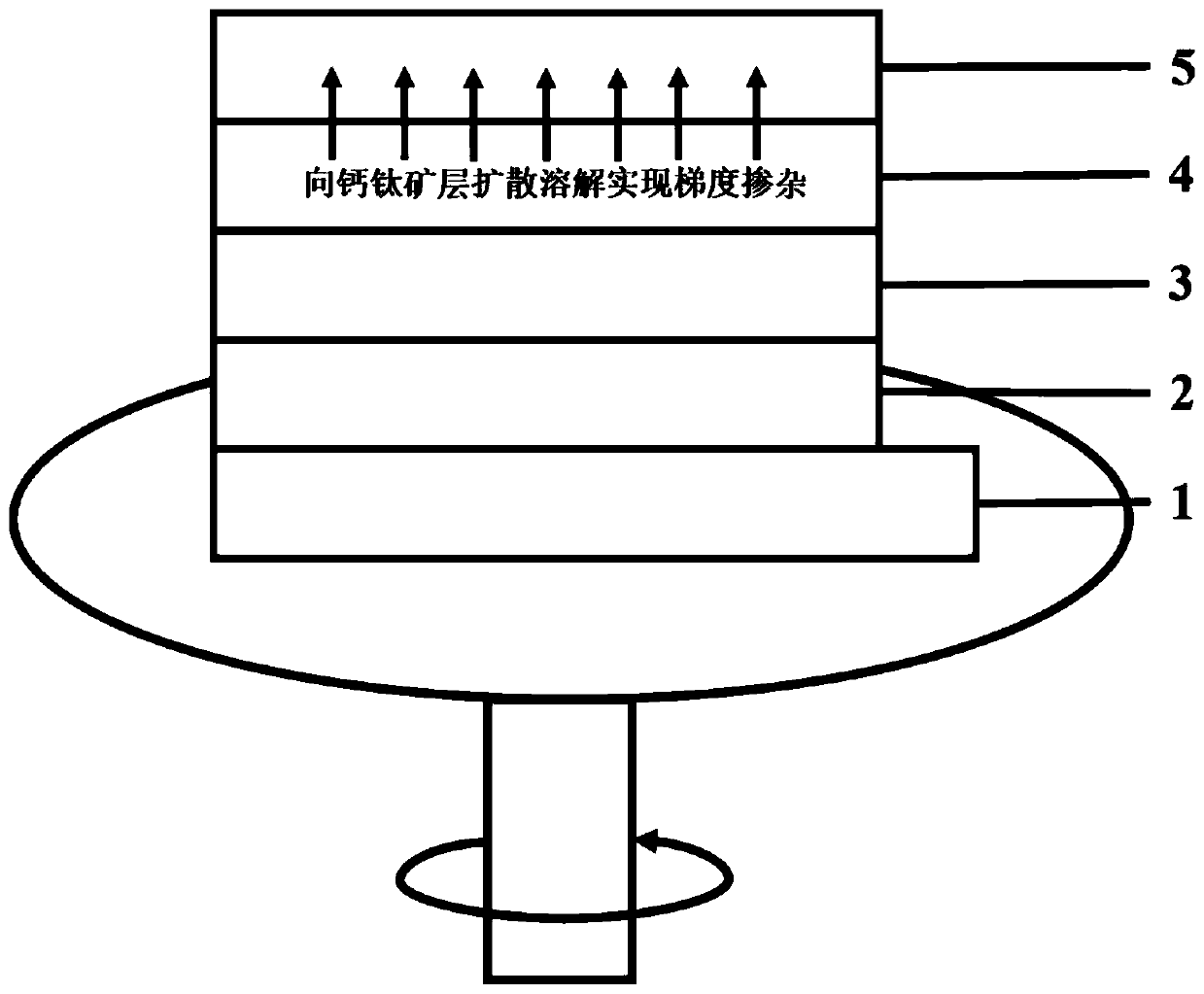

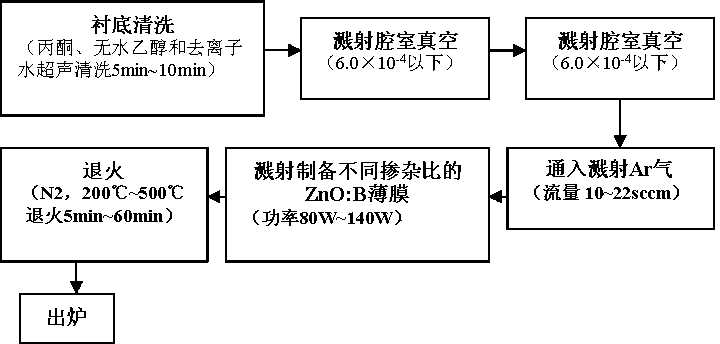

Preparation method of surface coating for colored thin film solar cell

InactiveCN103966565AAchieve the desired effectImprove thermal stabilityFinal product manufactureVacuum evaporation coatingNano structuringCoating system

The invention relates to a preparation method of a surface coating for a colored thin film solar cell, and belongs to the field of thin film solar cells. The preparation method of the surface coating mainly comprises steps as follows: ZnO:B ceramic targets with different doping concentrations are taken as raw materials, a ZnO:B thin film is sputtered and prepared on plate glass with a magnetron sputtering coating system, and ZnO:B thin films with different thicknesses can be obtained by controlling the sputtering condition; rapid annealing treatment is performed in N2 atmosphere, and micro-nano structure ZnO:B thin films with different grain sizes, crystallization ratios and the like can be obtained by controlling the annealing condition; and optical parameters of the refractive index, the reflectivity and the like of the ZnO:B thin films with different doping concentrations, thicknesses, grain sizes, crystallization ratios change, and the ZnO:B thin films can be used as transparent conductive oxidation films of the thin film solar cell and can show different colors on the surface of the cell, so that the colored thin film solar cell is prepared. The preparation method has the advantages as follows: the surface of the thin film cell can be endowed with different colors, and the effect of colored thin film solar cell is realized; and the surface inactivation can be realized, the life of a device is prolonged, a reflection layer can be formed, and absorption of the thin film cell absorption layer to sunlight is increased.

Owner:YUNNAN NORMAL UNIV

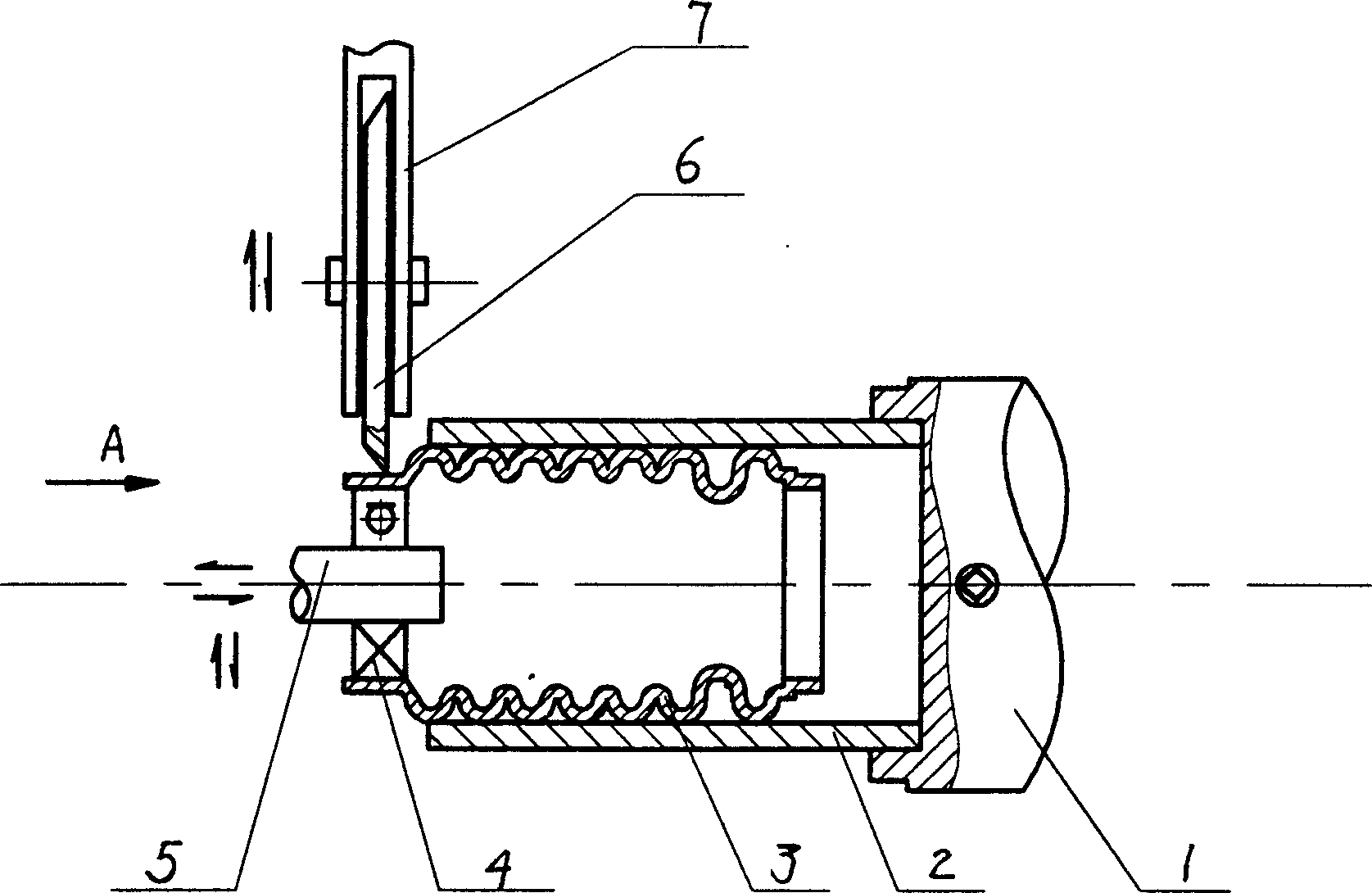

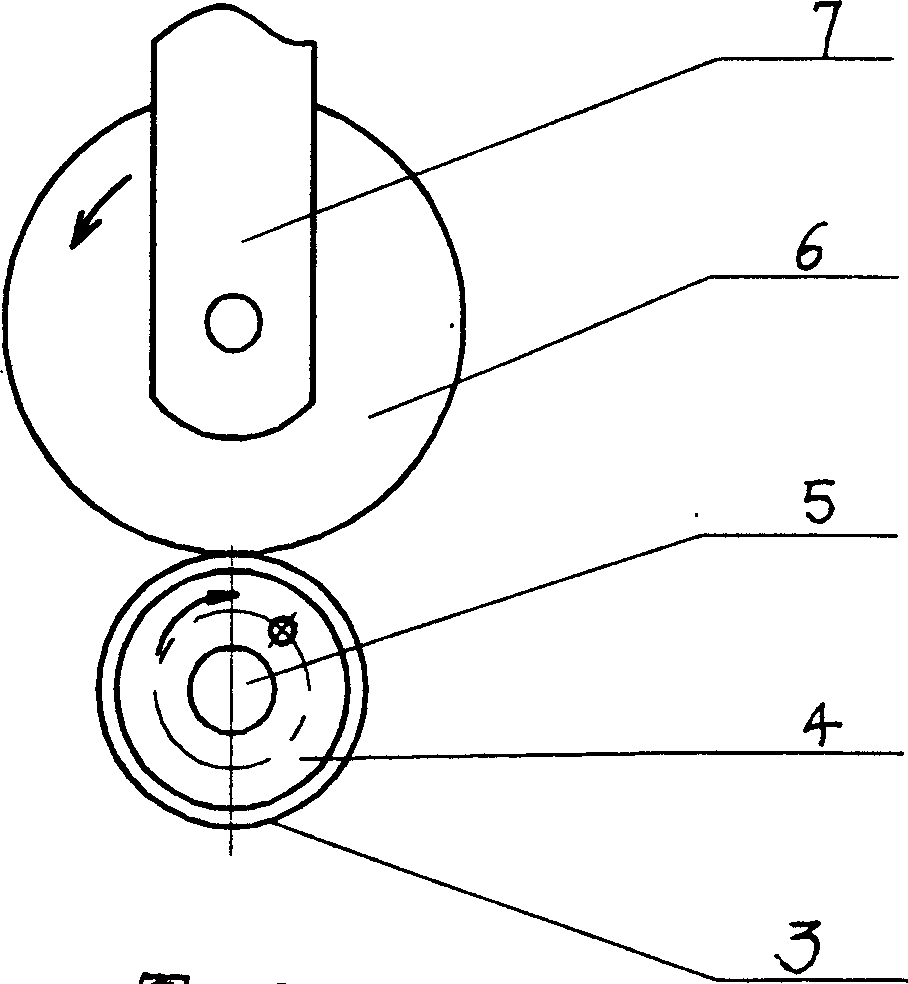

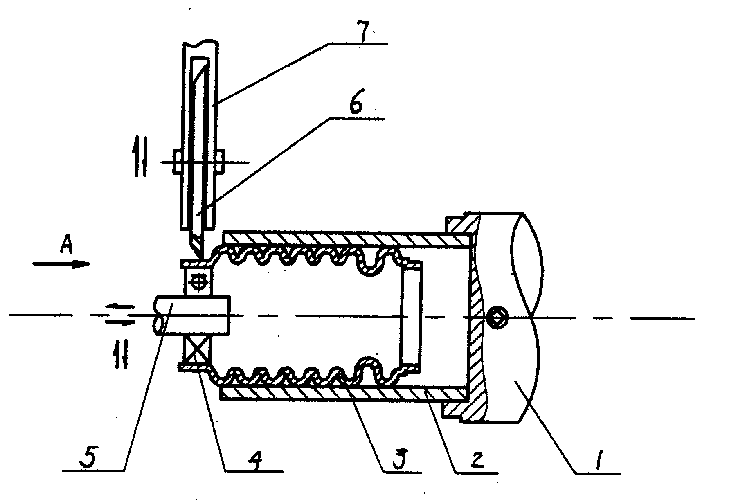

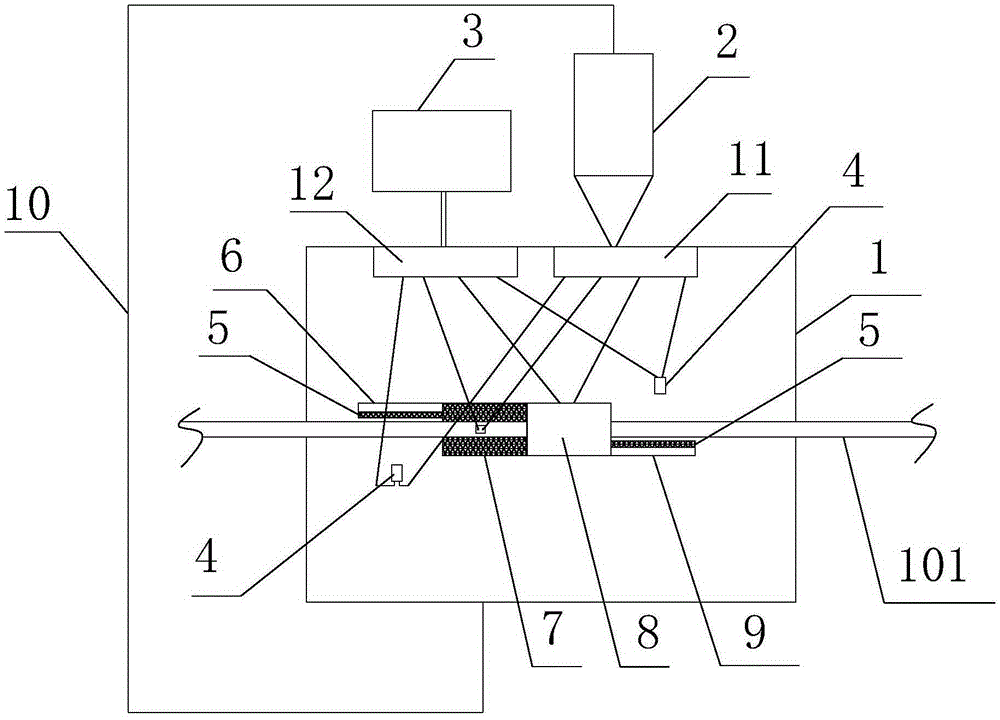

Machining device for matt cable

ActiveCN105382705AEffect of mechanical strengthAffect conductivityAbrasive machine appurtenancesAbrasive blasting machinesSand blastingEngineering

The invention discloses a machining device for a matt cable. The machining device comprises a sand blasting box, a centrifugal chamber and a high-pressure gas source. A sand guide pipe and a high-pressure gas pipe are arranged in the sand blasting box. The centrifugal chamber is arranged above the sand blasting box and communicated with the sand guide pipe. The high-pressure gas source is communicated with the high-pressure gas pipe. A cable inlet and a cable outlet are formed in the two sides of the sand blasting box respectively. Multiple baffles are arranged at the portion, between the cable inlet and the cable outlet, in the sand blasting box and distributed criss-cross in the cable conveying direction. One side of each baffle is provided with at least one spray gun, spray openings of the spray guns face the baffle faces, close to the conveyed cable, of the baffles, gaps allowing the cable to pass are reserved between the spray guns and the baffle faces of the baffles, each spray gun is provided with two inlets, one inlet of each spray gun is connected with the sand guide pipe, and the other inlet of each spray gun is connected with the high-pressure gas pipe. By the adoption of the machining device, the baffles are arranged criss-cross in the cable conveying direction, so that the situation that the cable swings and shakes due to blasting force in the sand blasting process, the sand blasting face is uneven, and conveyance is unstable is avoided.

Owner:蚌埠格识知识产权运营有限公司

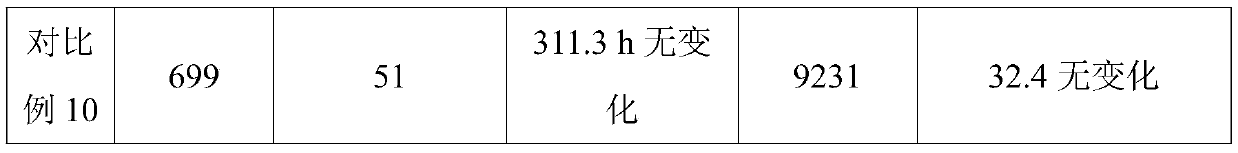

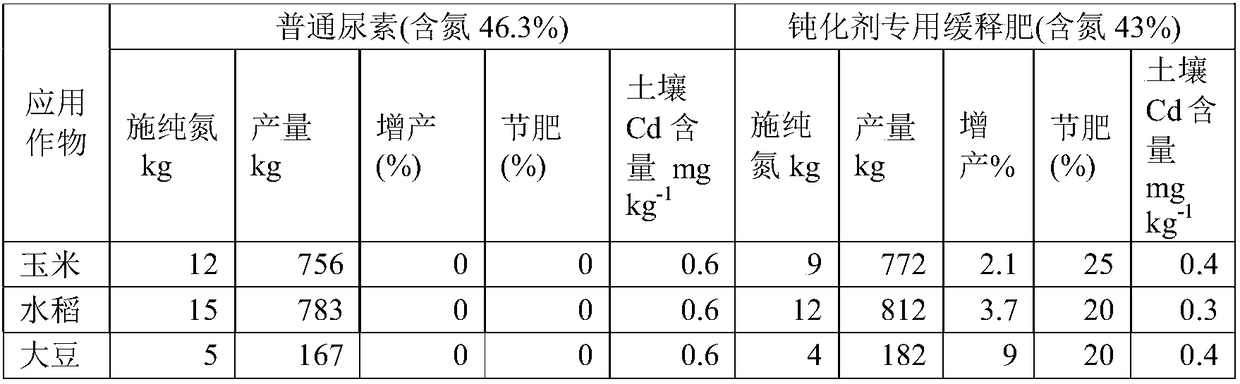

Heavy metal cadmium passivation repair slow-release urea fertilizer and preparation method thereof

PendingCN108264393AReduce nitrogen lossPrevents increased cadmium levelsCalcareous fertilisersClimate change adaptationFertilizerUrea

The invention belongs to the field of soil and environment, and mainly relates to slow-release urea fertilizer comprising a heavy metal cadmium passivation agent and a preparation method. The fertilizer comprises urea, a biochemical inhibitor and a soil heavy metal cadmium passivation material according to a weight proportion of 1:0.001-0.1:0.05-0.5. The heavy metal cadmium passivation material comprises one or multiple of charcoal modified by hydrochloric acid, powdered rock phosphate modified by hydrochloric acid, sepiolite modified by hydrochloric acid and lime. Cadmium in medium-mild cadmium contaminated soil can be controlled within a reasonable range by applying the fertilizer for several times, so that cadmium absorbed by crops can be reduced, accumulative-state cadmium of the cropscan be reduced, and intake of cadmium content by people can be reduced; crop yield can be increased, and economic benefit can be increased.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

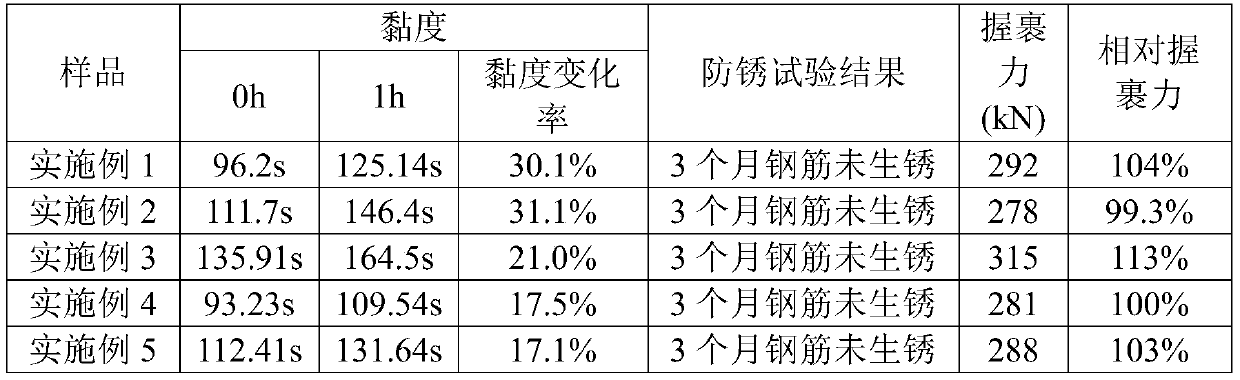

Polyaniline-modified cement-based antirust paint and preparation method and application thereof

InactiveCN105504907AImprove rust resistanceIncreased electrochemical corrosion potentialAnti-corrosive paintsCement coatingsSteel barPolyaniline

The invention discloses polyaniline-modified cement-based antirust paint for concrete steel bars and a preparation method and application of the antirust paint. The antirust paint is prepared from 100 wt% of cement, 0.5-3 wt% of polyaniline, 1-3 wt% of a rust inhibitor, 0-15 wt% of an ethylene-vinyl acetate copolymer, 0.5-1 wt% of a water reducing agent, 0-0.22 wt% of retarder and 35-55 wt% of water by taking the cement mass as a criterion. The properties of the cement-based antirust paint are improved by improving the characteristics such as the positive potential of the steel bar surface through the polyaniline. A steel bar coated with the antirust paint is not rusted after being soaked in a 3.5 wt% NaCl solution for 3 months, the bond stress is larger than the bond stress between concrete and a bare steel bar, and the longest working time reaches up to 2 hours.

Owner:YANCHENG INST OF TECH

Preparation method of crystalline silicon solar cell passive film

InactiveCN103633185APlay a passivation roleFully passivatedFinal product manufacturePhotovoltaic energy generationCrystalline siliconSilicon chip

The invention provides a preparation method of a crystalline silicon solar cell passive film. The preparation method comprises that: a silicon chip is preprocessed, an a-Si:H thin film is formed on the surface of the silicon chip, a SiNx:H thin film is formed on the surface of the a-Si:H thin film, and sintering is performed. That is to say, firstly, a film layer is formed on the surface of the silicon chip with H as the primary part so that certain passivation effect on the surface of the silicon chip is realized, then the SiNx:H thin film is formed. Besides, H in the SiNx:H thin film has an effect of secondary passivation on the surface of the silicon chip so that passivation on the surface of the silicon chip is fully realized, and defects of impurities, dislocation and crystal boundaries on the surface of the silicon chip are reduced as much as possible. Compared with existing antireflection films, the defects of impurities, dislocation and crystal boundaries existing on the surface of the silicon chip can be effectively reduced by the method provided by the application so that output power of crystalline silicon solar cells is enhanced.

Owner:RENESOLA JIANGSU LTD

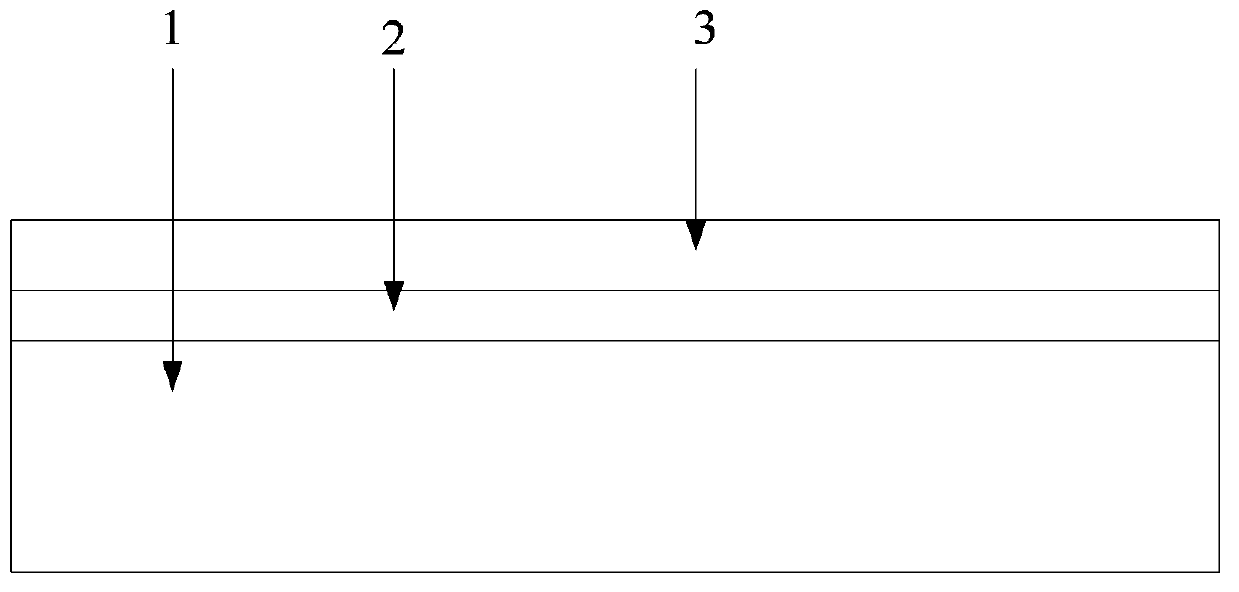

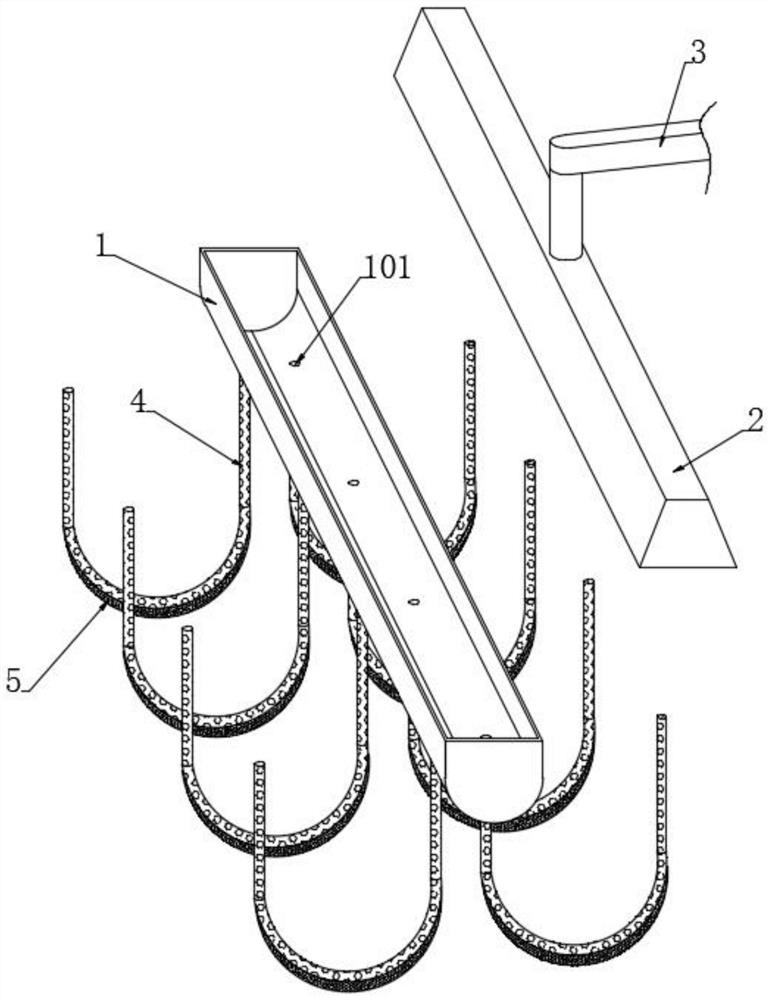

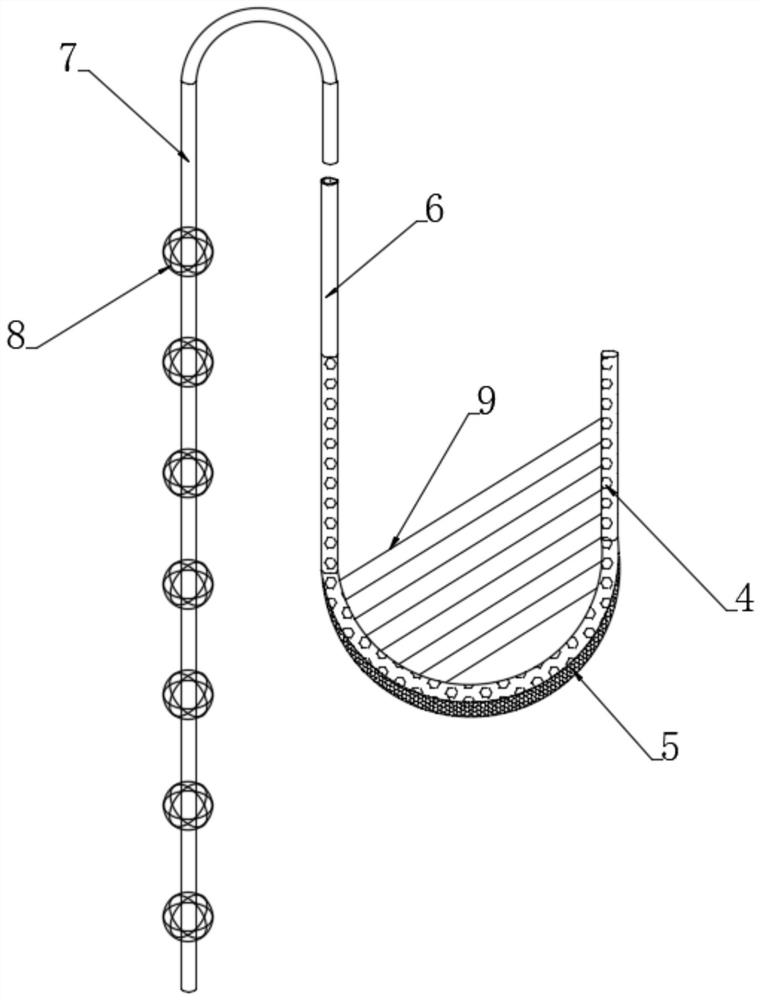

Embedded dual restorer for heavy metal soil improvement

The invention discloses an embedded dual restorer for heavy metal soil improvement, and belongs to the technical field of soil restoration, a microbial soil restoration agent can be periodically injected into an improver embedding box through cooperation of the improver embedding box and a plurality of U-shaped seepage rods, and the microbial soil restoration agent is guided into soil from a plurality of filter holes in the U-shaped seepage rods, so the diffusion balance degree of the microbial soil adsorbent is effectively improved; the microbial soil remediation agent has the effects of directly or indirectly improving soil, restoring soil fertility, preventing soil-borne diseases, maintaining rhizosphere microflora balance, degrading toxic and harmful substances and the like, and is matched with the attapulgite buried rod arranged on the outer side of the U-shaped material seeping rod; the attapulgite buried rod is matched with a plurality of heavy metal adsorption balls arranged outside the attapulgite buried rod in a sleeving mode, so the effects of gathering, adsorbing and passivating heavy metal in soil are achieved; the operation is easy, convenient and feasible, the improvement and adsorption are combined, and the remediation effect on the heavy metal soil is effectively improved to a certain degree.

Owner:王清水

Aluminium wiring polishing fluid for super large scale integrated circuit

InactiveCN1861726AAct as a bufferPlay a role in complexationSemiconductor/solid-state device manufacturingPolishing compositionsVery large scale integrated circuitsChemical reaction

The invention discloses aluminium wiring polishing fluid of the grand scale integration which is composed of the pH modifier 1-10%, the silica sol 10-90%, the surface active agent 0.5-5%, the oxidant 0.5-5% and the de-ionized water. The invention is in the condition of the alkali to use the strong complexation and chemical action, so the chemical reaction and the grinding speed are uniform. The grinding material is the SiO2 sol to solve the problem of the big hardness of the Al2O3 grinding material. The ether alcohol active agent can accelerate the mass transmission of the reactant and the resultant.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com