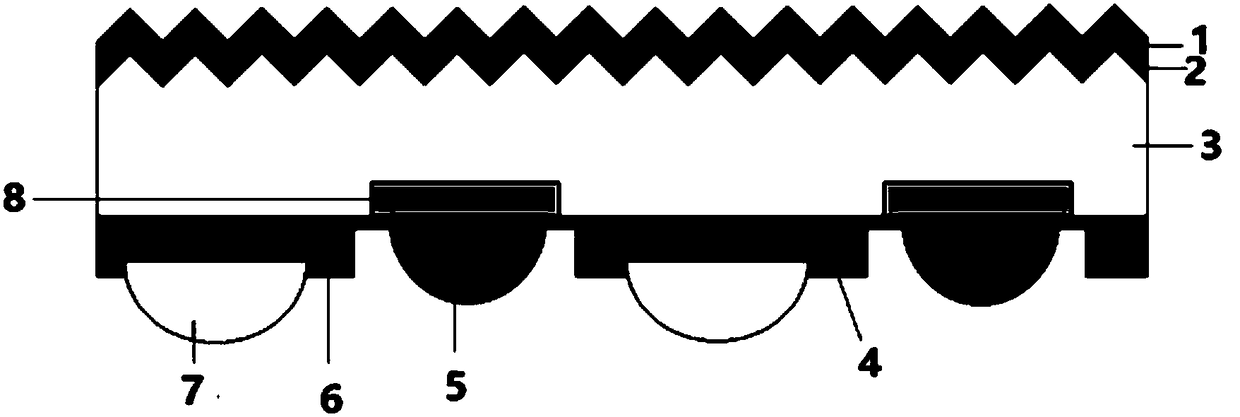

N type IBC battery and preparation method therefor

An N-type, battery technology, applied in the field of solar cells, can solve the problems of many production equipment, high production cost, complex structure, etc., and achieve the effects of low cost, stable electrical performance, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

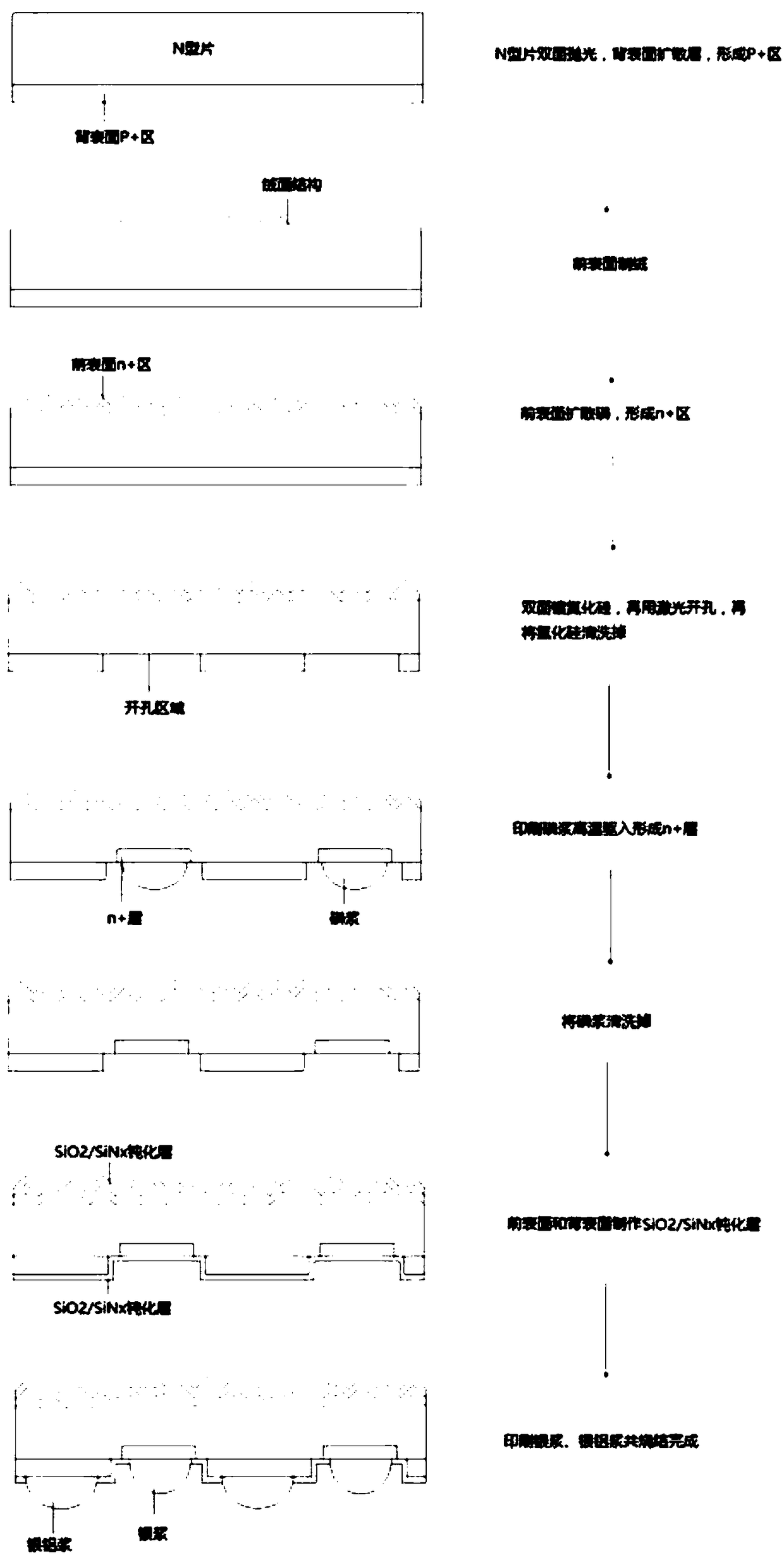

[0038] This embodiment discloses a method for preparing an N-type IBC battery, such as figure 2 The following steps are shown:

[0039] Step 1, the N-type silicon wafer is double-sidedly polished on the surface of the silicon wafer with hot alkali;

[0040] Step 2. Carry out single-sided boron diffusion on the polished surface of the silicon wafer to form a p+ region, the average junction depth is 0.7-0.9 microns, and its square resistance is 65-80Ω / □, and then remove the borosilicate glass with HF acid;

[0041] Step 3, making cashmere on the front surface;

[0042] Step 4. Use a high-temperature diffusion furnace to perform single-sided phosphorus diffusion on the front surface of the silicon wafer;

[0043] Step 5, using PECVD equipment to coat silicon nitride films on both sides of the silicon wafer;

[0044] Step 6, using a laser to open holes on the silicon nitride layer on the back surface of the silicon wafer;

[0045] Step 7, corroding the opening area on the bac...

Embodiment 2

[0051] This embodiment discloses a method for preparing an N-type IBC battery, comprising the following steps:

[0052] Step 1. Select an N-type silicon substrate with a resistivity of 1-8Ω·cm, remove the damaged layers on both sides of the silicon wafer by chemical etching, and polish both sides of the silicon wafer with an alkaline solution.

[0053]Step 2. Use the BBr3 source to diffuse the surface of the silicon wafer, insert the wafer back to back, and generate p on the surface of the silicon wafer + Area

[0054] Step 3. PECVD is used to deposit silicon nitride film on the boron-expanded surface of the silicon wafer, and a tank type alkali is used for texturing, and then the silicon nitride is cleaned with hydrofluoric acid.

[0055] Step 4. Use a high-temperature diffusion furnace to perform single-sided phosphorus diffusion on the front surface of the silicon wafer, and generate an n+ region on the front surface of the silicon wafer. The insertion method is back-to-ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com