Specially doped perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of poor stability of perovskite solar cells, low photoelectric conversion efficiency, poor ability to block water and oxygen, etc., to reduce excitation Sub-recombination probability, improved photoelectric conversion efficiency, and good water and oxygen barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

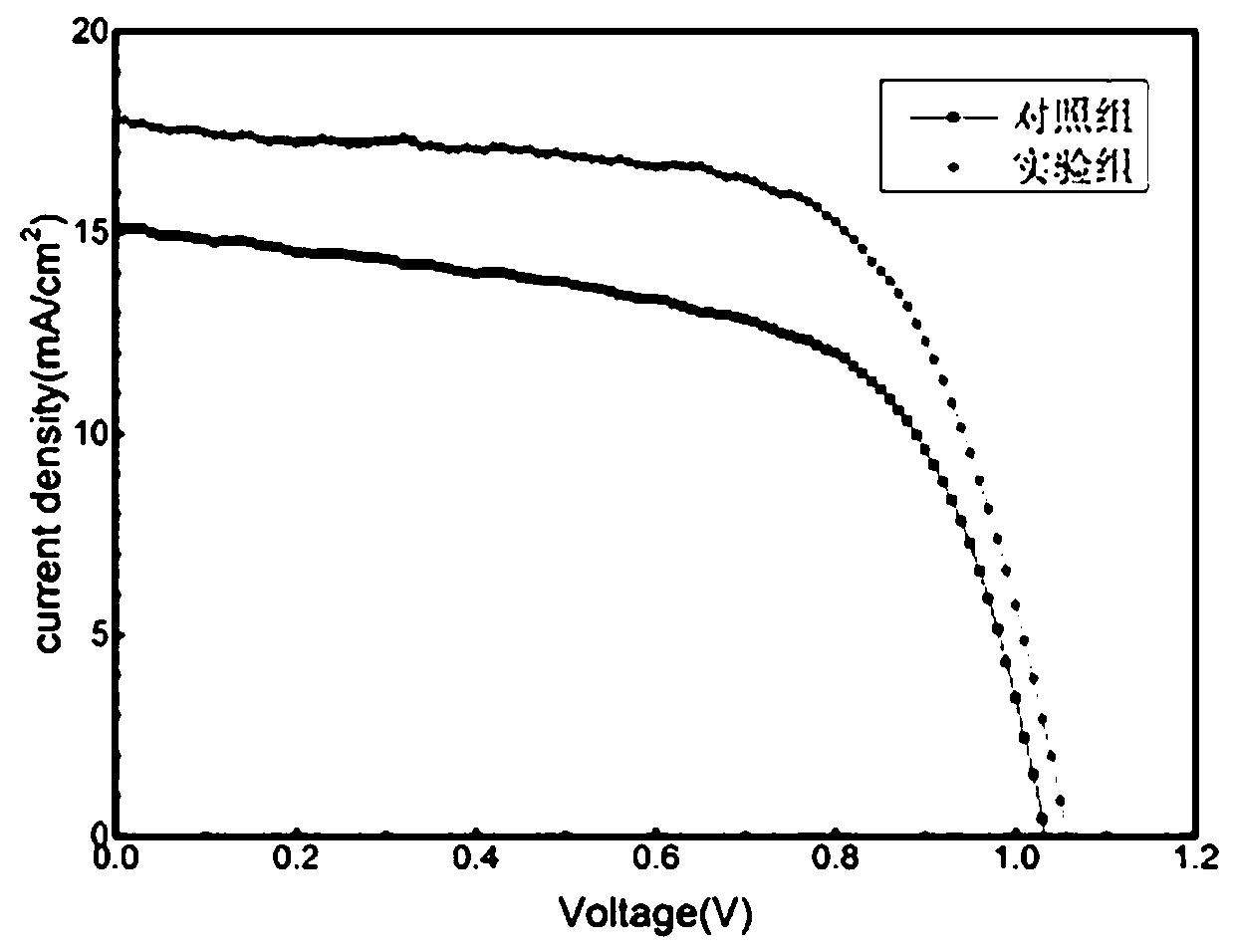

[0037] control group

[0038]The surface of transparent conductive anode ITO is spin-coated with TAPC (spin-coating speed of 3000rpm, spin-coating time of 40s, thickness of 15nm) to prepare a hole transport layer, and the formed film is thermally annealed (annealing temperature 120°C, annealing time 15min); Spin coating of MAPbI on the hole transport layer 3 Precursor solution (mixed with DMF as solvent to form a mixed solution with a solute concentration of 500mg / mL, spin-coating speed is 4000rpm, spin-coating time is 25s, thickness is 500nm) to prepare the perovskite layer, first let the chip rotate at a speed of 4000rpm , then drop the perovskite precursor solution, and then quickly drop the chlorobenzene solution to the perovskite activated carbon layer to inhibit the disordered crystallization of perovskite, and then anneal at 120°C for 20min; The surface is spin-coated with PCBM solution (mixed with chlorobenzene as a solvent to form a mixed solution with a solute conce...

Embodiment 1

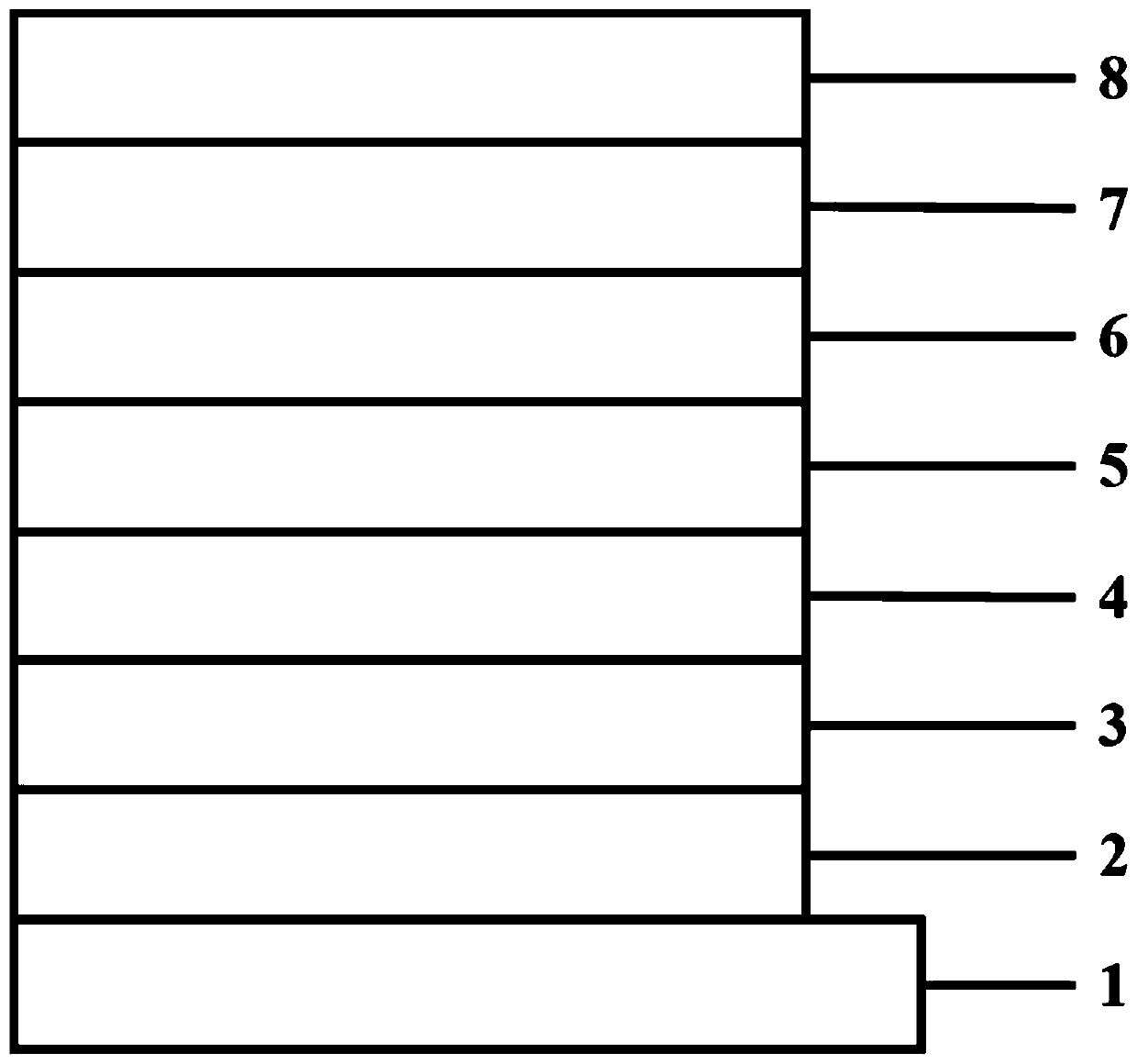

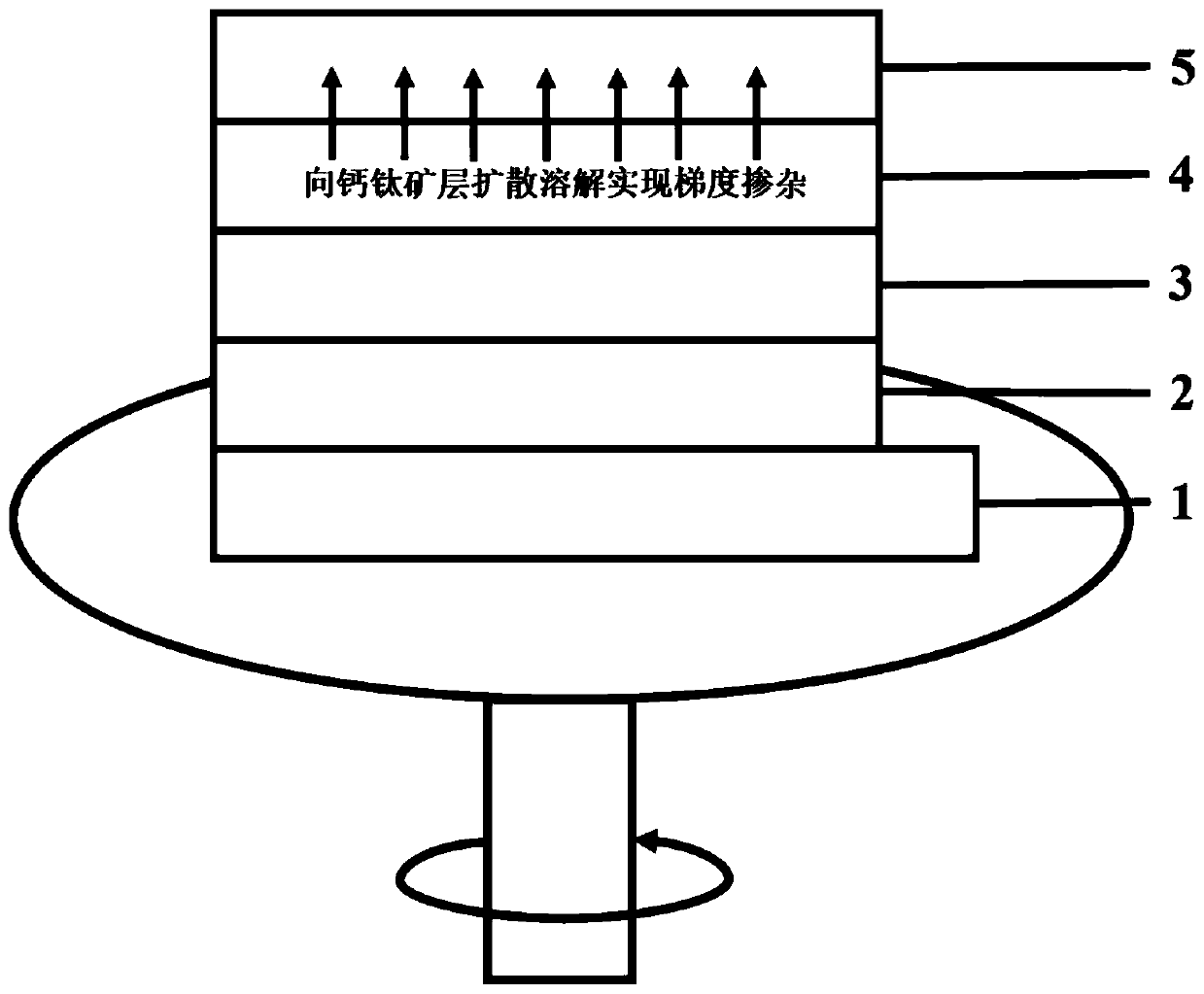

[0041] The substrate composed of the substrate and the transparent conductive anode 2ITO was cleaned, and then dried with nitrogen gas; the surface of the transparent conductive anode 2ITO was spin-coated with TAPC (the spin-coating speed was 3000rpm, the spin-coating time was 40s, and the thickness was 15nm). Hole transport layer 3, and the formed film is subjected to thermal annealing (annealing temperature 120 ℃, annealing time 15min); On the hole transport layer 3, spin-coat passivation doped layer 4 material PEABr, (its solution concentration is 3mg / ml, spin-coating speed is 5000rpm, spin-coating time 30s) passivation doping layer 4, need not annealing; Spin-coat MAPbI on hole transport layer 3 3 Precursor solution (mixed with DMF as solvent to form a mixed solution with a solute concentration of 500mg / mL, spin-coating speed is 4000rpm, spin-coating time is 25s, thickness is 500nm) to prepare the perovskite layer, first let the chip rotate at a speed of 4000rpm , then dr...

Embodiment 2

[0043] The substrate composed of the substrate and the transparent conductive anode 2ITO was cleaned, and then dried with nitrogen gas; the surface of the transparent conductive anode 2ITO was spin-coated with TAPC (the spin-coating speed was 3000rpm, the spin-coating time was 40s, and the thickness was 15nm). Hole transport layer 3, and the formed film is subjected to thermal annealing (annealing temperature 120 ℃, annealing time 15min); On hole transport layer 3, spin-coat passivation doped layer 4 material PEABr, (its solution concentration is 5mg / ml, spin-coating speed is 5000rpm, spin-coating time 30s) passivation doping layer 4, need not annealing; Spin-coat MAPbI on hole transport layer 3 3 Precursor solution (mixed with DMF as solvent to form a mixed solution with a solute concentration of 500mg / mL, spin-coating speed is 4000rpm, spin-coating time is 25s, thickness is 500nm) to prepare the perovskite layer, first let the chip rotate at a speed of 4000rpm , then drop t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com