Preparation method for iron/aluminum intermetallic compound and ZrO2 multiphase material cell phone ceramic back board

A technology of intermetallic compounds and ceramic backplanes, applied in the structure of telephones, etc., can solve the problems of high cost of low-speed machining, low yield of high-speed machining, and difficulty in large-scale application, so as to optimize mechanical properties and reduce residual stress The effect of releasing cracking and improving the toughening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

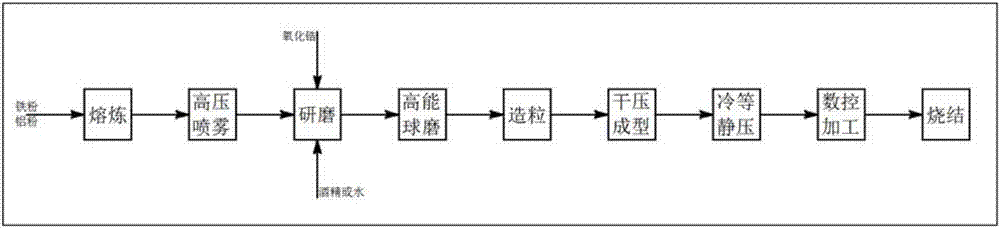

[0024] The present invention is described in further detail below: a kind of iron-aluminum intermetallic compound and ZrO 2 A method for preparing a mobile phone ceramic backplane made of a composite phase material, comprising the following steps:

[0025] a) Mole percentage Fe: Al=(71-77): (23-29) Weigh iron powder and aluminum powder to smelt the alloy, and spray under high pressure in an inert atmosphere to prepare iron-aluminum intermetallic compound powder;

[0026] b) weighing the yttrium-stabilized zirconia powder and the iron-aluminum intermetallic compound powder obtained in step a) into a grinding jar according to the weight ratio (60-90): (10-40), using alcohol or water as the grinding medium, Grinding for 18-24 hours to obtain mixed grinding powder;

[0027] c) high-energy ball milling the mixed grinding powder obtained in step b) for 3h to 5h;

[0028] d) granulating the mixed grinding powder treated in step c) to obtain granulated powder;

[0029] e) subjectin...

Embodiment 1

[0043] Calculated on the basis of 10kg of alloy ingredients, weigh iron powder and aluminum powder according to the molar percentage Fe:Al=71:29 and add them to the vacuum melting furnace, heat up to 1300°C for 2 hours to obtain iron-aluminum metal liquid, and drain it to an air pressure of 0.3MPa Ar gas atmosphere spraying prilling tower cooling powder to obtain iron-aluminum intermetallic compound powder.

[0044]Calculated on the basis of 3kg of alloy ingredients, weigh yttria-stabilized zirconia powder and iron-aluminum intermetallic compound powder into the grinding tank at a weight ratio of 60:40, use alcohol as the grinding medium, and grind for 24 hours to obtain a mixed grinding powder. The mixed and ground powder was high-energy ball milled again for 3 hours, then dried and ground by manual addition of paraffin wax binder, and closed spray granulation with nitrogen protection to obtain granulated powder. Put the granulation powder into the mold and dry press it to de...

Embodiment 2

[0048] Calculated on the basis of 15kg of alloy ingredients, weigh iron powder and aluminum powder according to the molar percentage Fe:Al=77:23 and add them to the vacuum melting furnace, heat up to 1350°C for 1.5 hours to obtain iron-aluminum metal liquid, and drain it to a pressure of 0.5 The Ar gas atmosphere of MPa is sprayed in a prilling tower to cool and make powder to obtain iron-aluminum intermetallic compound powder.

[0049] Calculated on the basis of a 30kg alloy batching, the magnesia-stabilized zirconia powder and the iron-aluminum intermetallic compound powder are weighed into the grinding tank at a weight ratio of 90:10, and water is used as the grinding medium to grind for 18 hours to obtain a mixed grinding powder. The mixed milled powder was high-energy ball milled again for 5 hours, and then a polyvinyl alcohol binder was added to spray and granulate to obtain granulated powder. Put the granulation powder into the mold and then dry press it to demould, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com