Modified polypropylene insulation material and manufacturing method thereof

A polypropylene and insulating material technology, applied in the field of polypropylene insulating materials, can solve the problems of poor high and low temperature performance, poor thermal aging performance, etc., and achieve the effects of improving processing performance, improving thermal oxidative aging performance, and preventing catalytic aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

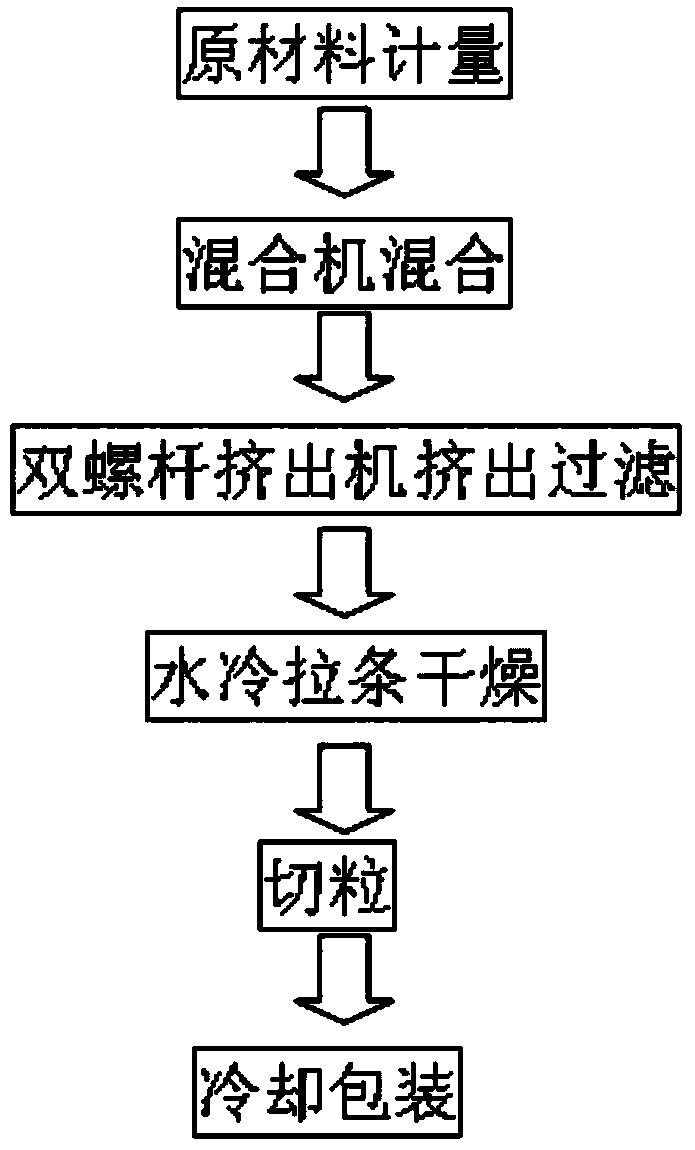

[0014] The preparation method of the modified polypropylene insulating material of the present invention is characterized in that the raw materials are prepared and measured according to their respective parts by weight, put into a mixer and mixed uniformly, and then blended, filtered, extruded in a twin-screw extruder, The strips are then cooled in a water tank, dried by a blower, and then cut into granules by a granulator, and finally packaged to obtain the finished product.

[0015] The preparation method of the modified polypropylene insulating material of the present invention, wherein, the mixing time of the mixer is 5 to 10 minutes; the extruder is a twin-screw extruder with a diameter of 50 mm, and its extrusion temperature is 170 to 100 minutes. 210°C, the extrusion speed is 200 to 300 rpm; the temperature of the package after cooling is below 50°C.

Embodiment 1

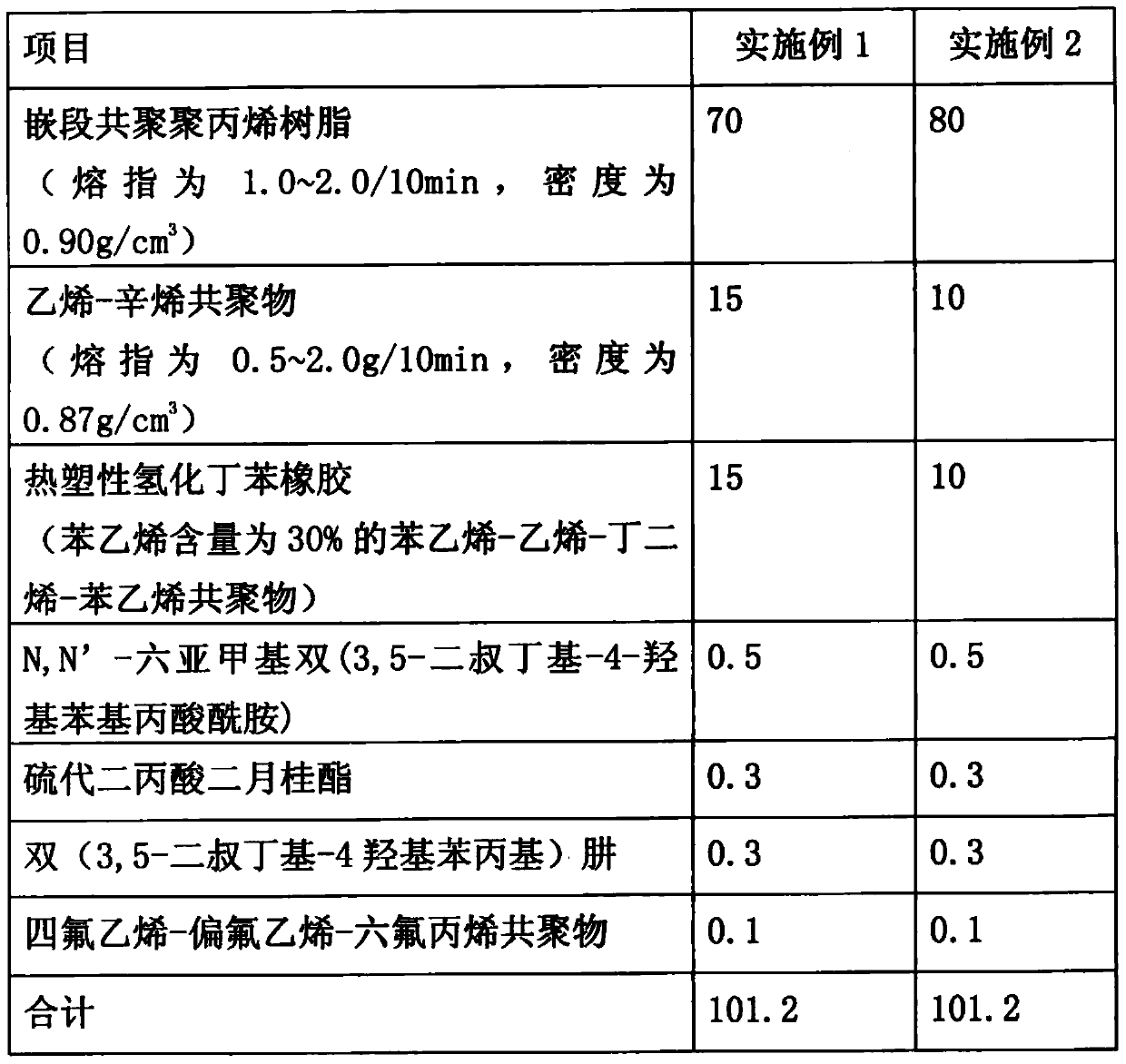

[0017] Embodiment 1 and embodiment 2 are prepared according to the parts by weight of each component shown in table 1:

[0018] Table 1 is the parts by weight table of each component of the embodiment of the present invention

[0019]

[0020] The preparation of embodiment 1:

[0021] The raw materials described in Table 1 are prepared according to their respective parts by weight, and then put into a mixer and mixed evenly. The mixing time is 5 to 10 minutes, and then sent into a twin-screw extruder with a diameter of 50mm for blending, filtering, extrusion and pulling. Strips, the extrusion temperature is 170°C to 220°C, the extrusion speed is 200 rpm, then cooled in a cooling water tank, dried by a blower, and then entered into a pelletizer to cut into granules, and finally cooled to below 50°C for packaging , to get the finished product, such as figure 1 shown.

Embodiment 2

[0022] The preparation of embodiment 2:

[0023] The raw materials described in Table 1 are prepared according to their respective parts by weight, and then put into a mixer and mixed evenly. The mixing time is 5 to 10 minutes, and then sent into a twin-screw extruder with a diameter of 50mm for blending, filtering, extrusion and pulling. Strips, the extrusion temperature is 170°C to 210°C, the extrusion speed is 300 rpm, then cooled in a cooling water tank, dried by a blower, and then entered into a pelletizer to cut into granules, and finally cooled to below 50°C for packaging , to get the finished product.

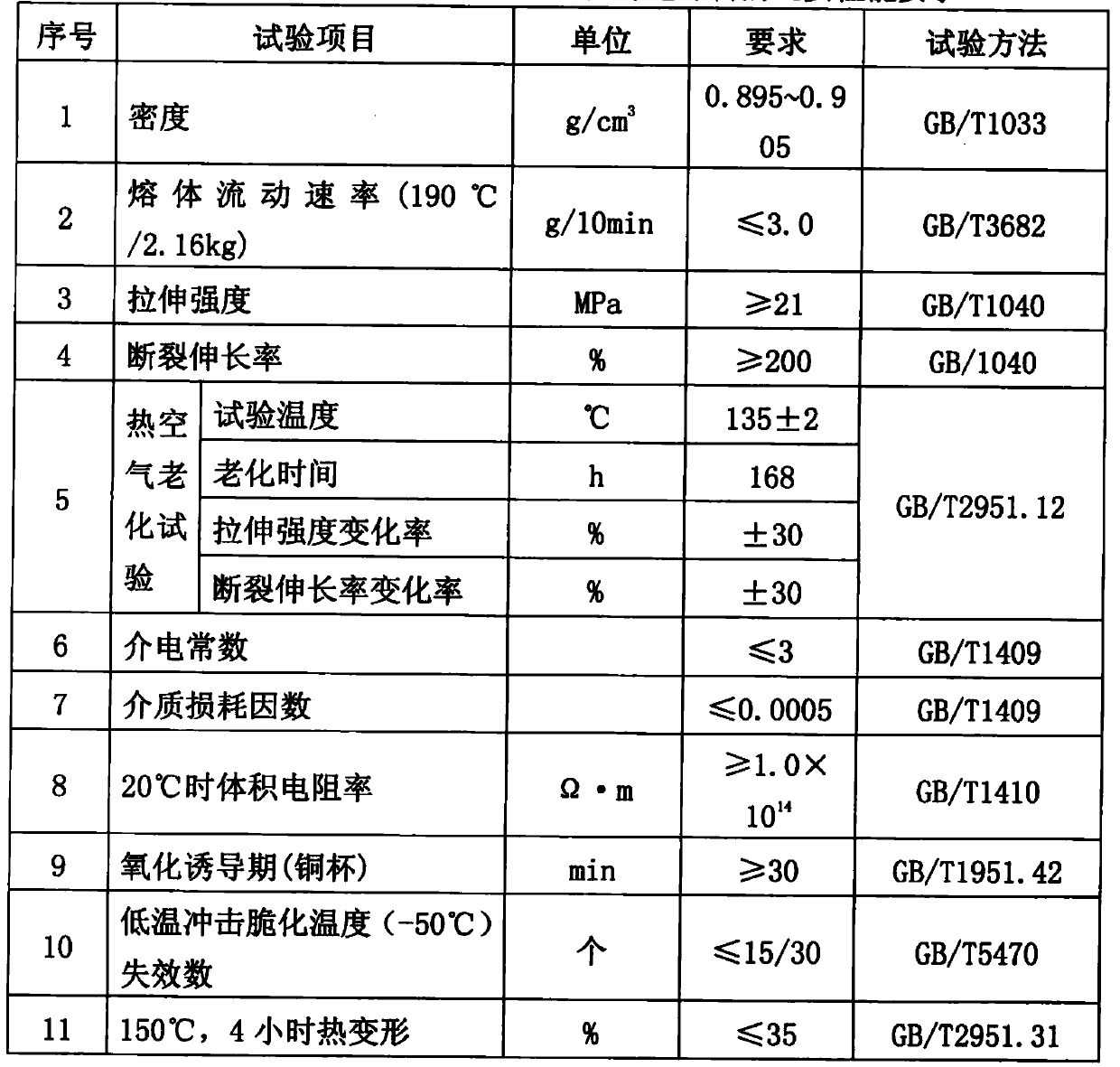

[0024] Examples of the present invention are prepared as shown in Table 2 below:

[0025] Table 2 is the main performance requirements of the modified polypropylene insulating material prepared by the embodiment of the invention

[0026]

[0027] The modified polypropylene insulating material obtained in the embodiment of the present invention is pressed at a tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com