Patents

Literature

31results about How to "Improved thermo-oxidative aging performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

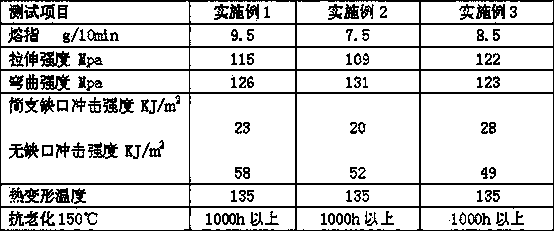

Anti-impacting anti-ageing modified polypropylene material and preparation method thereof

InactiveCN102766299AImprove impact resistanceImprove mechanical propertiesPolymer scienceUv absorber

The invention relates to an anti-impacting anti-ageing modified polypropylene material and a preparation method thereof and aims at providing the anti-impacting anti-ageing modified polypropylene material which has basic physical characteristics of polypropylene and simultaneously has improved anti-impacting performance and good anti-ageing performance. The material comprises, by weight, 65-85% of polypropylene, 5-25% of inorganic fillers, 0.3-1.5% of antioxidant, 0.2-1.0% of light stabilizer, 0.2-1.0% of ultraviolet absorber, 5-15% of flexibilizer, 5-15% of compatilizer and 0.2-1.0% of coupling agent. Experiment results show that the material can achieve the purposes, and products can be widely applied to the fields such as electronics and electrics, automobile and household appliances, communication devices and building materials.

Owner:长沙达联塑料有限公司

Long-term heat and oxidation aging resistant polypropylene compound and preparation method thereof

ActiveCN102827422AImproved thermo-oxidative aging performanceImprove interface compatibilityPolymer scienceLaboratory oven

The invention discloses a long-term heat and oxidation aging resistant polypropylene compound prepared in percentage by weight: 52%-89% of polypropylene resin, 10%-40% of inorganic filler, 0.1%-1% of beta nucleating agent, 0.5%-5% of stem grafting assistant, 0.2%-1% of antioxygen and 0.2%-1% of processing agent. A preparation method comprises the following steps of: evenly mixing each component, putting in a twin screw extruder for extrusion, enabling a temperature of the extruder to be 190-210 DEG C, enabling a rotating speed to be 50-400 circle / minute, cooling extrusion objects by using water, conducting sized dicing and obtaining the compound. The compound prepared by the preparation method has an excellent comprehensive mechanical property, has long-term heat and oxidation aging resistant characteristics, cannot pulverize after baking for 3000 hours in a 150-DEG C forced convection oven, and is widely applied to heat and oxidation aging resistant components of household appliances.

Owner:KINGFA SCI & TECH CO LTD +2

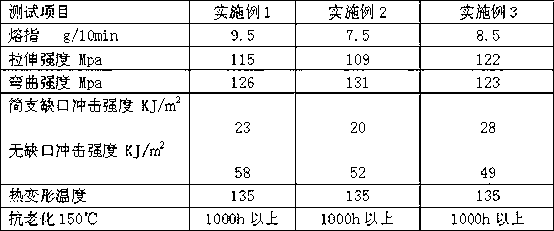

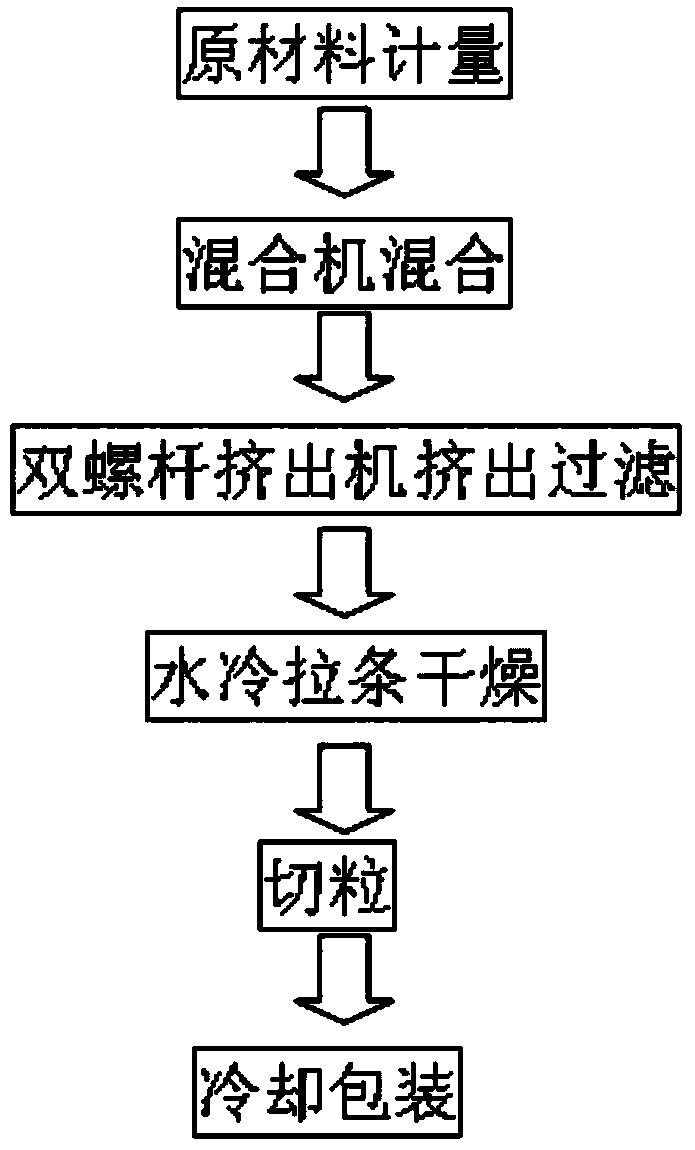

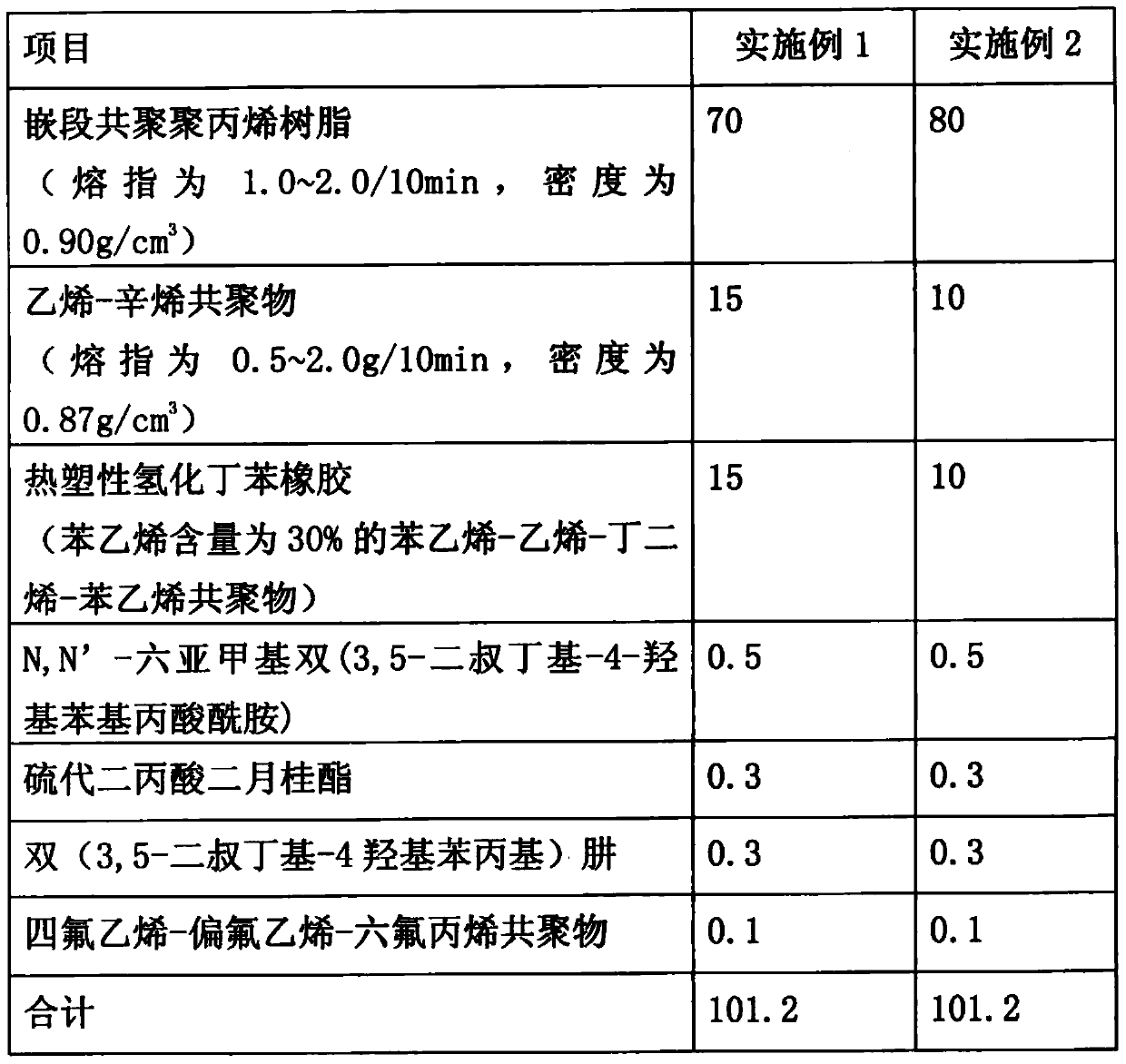

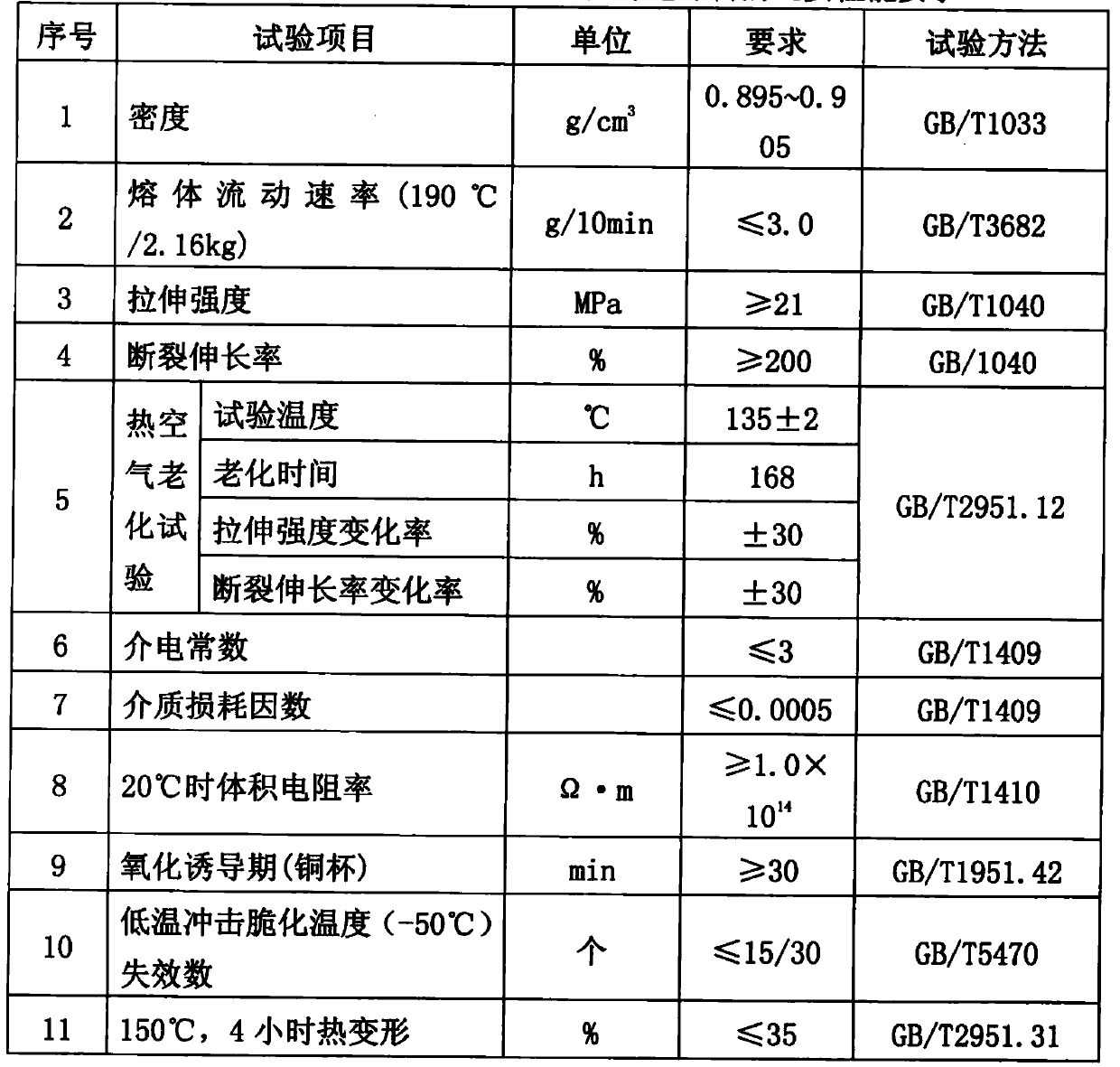

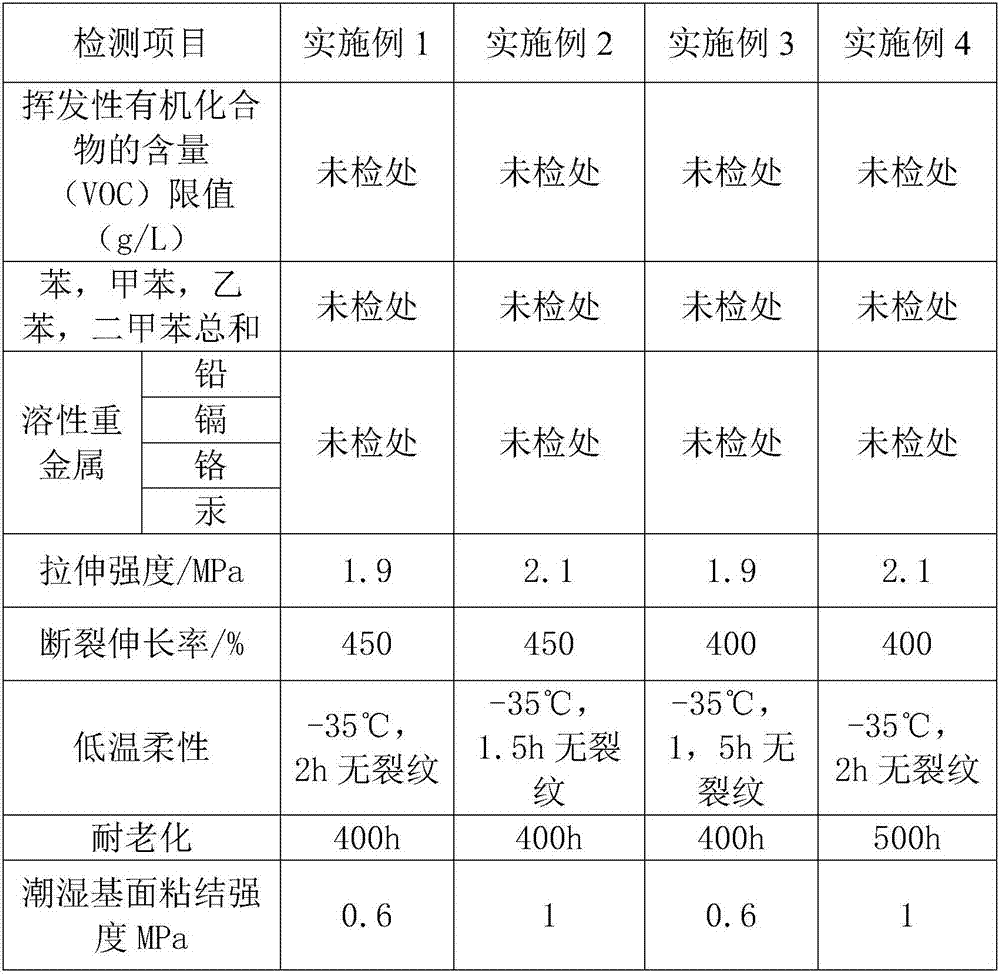

Modified polypropylene insulation material and manufacturing method thereof

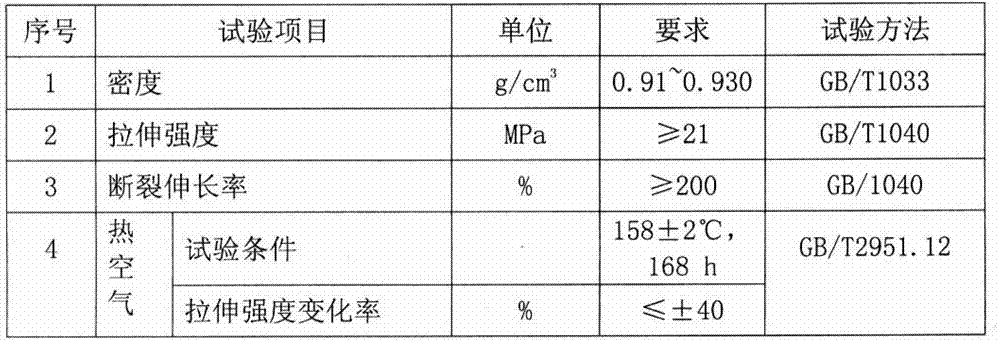

The invention relates to a modified polypropylene insulation material and a manufacturing method thereof, and the modified polypropylene insulation material includes the following components by weight part: 70-80 parts of polypropylene resin, 10-15 parts of polyolefin elastomer resin, 10-15 parts of thermoplastic hydrogenation butadiene styrene rubber, 0.5 parts of anti-oxidant A, 0.3 parts of anti-oxidant B, 0.3 parts of an anticopper agent and 0.1 parts of a rheological agent. The manufacturing method includes the following steps: metering the raw materials according to weight parts and putting in a mixer for uniformly mixing, then sending to a double screw extruder for blending and extruding, filtering and drawing into strips, and then cooling through a water tank and drying, putting in a pelleter for cutting into particles, and then packaging to obtain the finished product. The insulation material has the advantages of good performance, good high-and-low temperature performance, high strength and low cost, and is capable of being used in insulation of telecommunication cable, detection cable and oil pump cable; the manufacturing method has the advantages of reasonable design and convenient operation.

Owner:天津市普立泰高分子科技有限公司

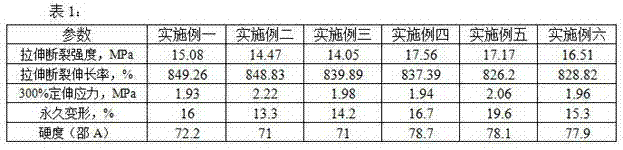

High-strength and high-temperature-resistant silicon rubber composite

The invention discloses a high-strength and high-temperature-resistant silicon rubber composite comprising the raw materials in parts by weight: 100 parts of silicon rubber, 8-21 parts of ethylene-propylene-diene rubber, 4-13 parts of polyurethane, 10-28 parts of fumed silica, 5-11 parts of carbon nanometer tubes, 1-8 parts of graphite, 4-13 parts of nanometer calcium carbonate, 3-15 parts of micairon oxide, 6-11 parts of montmorillonite, 2-9 parts of coal ash, 3-10 parts of calcium sulfate whiskers, 0.5-2.8 parts of zirconium fluoride, 0.9-2 parts of vulcanizing agent, 0.5-2 parts of methylsilicone oil, 1-2.5 parts of hexamethylcyclotrisilazane, 0.5-3.8 parts of vinyl tris(2-methoxyethoxy) silane and 1-2.5 parts of tetraethyl orthosilicate. The high-strength and high-temperature-resistant silicon rubber composite provided by the invention is good in high temperature resistance and strength and excellent in toughness and ageing resistance.

Owner:天长市荣盛有机硅科技有限公司

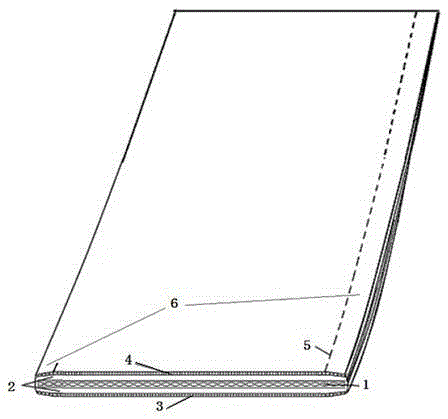

Application of lignin in preparation of radial tires

ActiveCN111748133AImproved thermo-oxidative aging performanceLow rate of aging changeSpecial tyresMaterials scienceResorcinol

The invention belongs to the field of rubber tire processing, and particularly discloses an application of lignin in preparation of radial tires. The lignin can completely or partially replace resorcinol, and meanwhile, the lignin can completely or partially replace an anti-aging agent. Compared with the prior art, resorcinol is replaced or partially replaced by biomass-derived lignin or modifiedlignin, so that the requirements of cost reduction, environmental protection and no toxicity are met. Especially, the demethylated modified lignin can effectively enhance various properties of the rubber. In addition, lignin is used as a thermo-oxidative aging agent to improve the thermo-oxidative aging performance of rubber products, and the aging change rate is obviously lower than that of radial tires without lignin.

Owner:NANJING TECH UNIV

High-strength and anti-impacting natural rubber cable sheathing material

ActiveCN106117644AHigh strengthGood compatibilityInsulated cablesInsulated conductorsLow-density polyethylenePolymer science

The invention discloses a high-strength and anti-impacting natural rubber cable sheathing material. The high-strength and anti-impacting natural rubber cable sheathing material is prepared from the following raw materials: natural rubber, polyvinyl chloride, low-density polyethylene, an ethylene-vinyl acetate copolymer, zinc oxide, stearic acid, sulfur, high-abrasion-resisting furnace black, carbon nanotubes, nano calcium carbonate, montmorillonoid, zirconium diboride, calcium sulfate whiskers, lignocellulose short fibers, cotton short fibers, an accelerant M, an accelerant BZ, a poly-3-hydroxybutyrate-4-hydroxybutyrate, epoxy soybean oil, an anti-aging agent RD, an anti-aging agent MB, p-aminodiphenyl amine, gamma-epoxypropoxy propyltrimethoxysilicane and vinyltriethoxysilane. The high-strength and anti-impacting natural rubber cable sheathing material disclosed by the invention is high in strength, good in anti-impacting performance, excellent in anti-aging performance and long in service life.

Owner:ANHUI ELECTRIC GRP SHARES

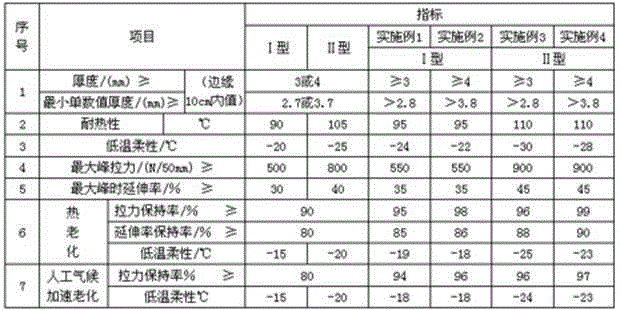

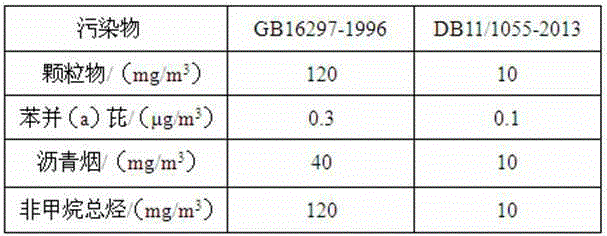

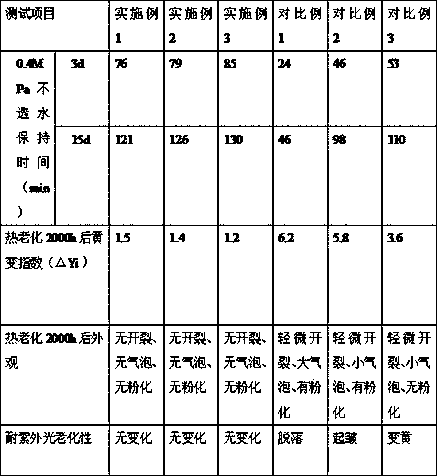

Environment-friendly type elastomer modified asphalt waterproof roll

InactiveCN105386525AReduce generationEmission reductionRoof covering using flexible materialsBuilding insulationsFiberPolyester

The invention relates to an environment-friendly type elastomer modified asphalt waterproof roll which is a multi-layer composite structure. A long fiber polyester base material reinforcing layer is arranged in the middle of an environment-friendly type elastomer modified asphalt layer; and the environment-friendly type elastomer modified asphalt layer consists of the following components in parts by mass: 45-55 parts of low-smoke asphalt, 4-12 parts of SBS (styrene butadiene styrene) thermoplastic rubber, 1-4 parts of powdered butadiene styrene rubber, 5-10 parts of natural asphalt master patch, 0-3 parts of polybutylene elastomer, 5-10 parts of rubber processing oil, 0-2 parts of polyolefin auxiliaries, 0-2 parts of amide wax, and 20-30 parts of 180-mesh talcum powder. The environment-friendly type elastomer modified asphalt waterproof roll has the beneficial effects that: by optimizing and applying environment-friendly raw materials such as the low-smoke asphalt and the like, a low-temperature production process of the modified asphalt is realized, so that generation and discharge of atmospheric contaminant such as non-methane hydrocarbon, particulate matters and the like in a production process of the elastomer modified asphalt waterproof roll are effectively reduced, and therefore, the pollution problem in the production process of the elastomer modified asphalt waterproof roll is completely solved.

Owner:胜利油田大明新型建筑防水材料有限责任公司

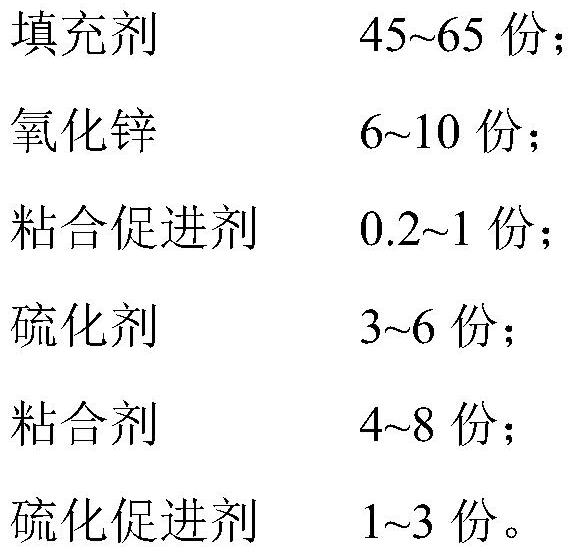

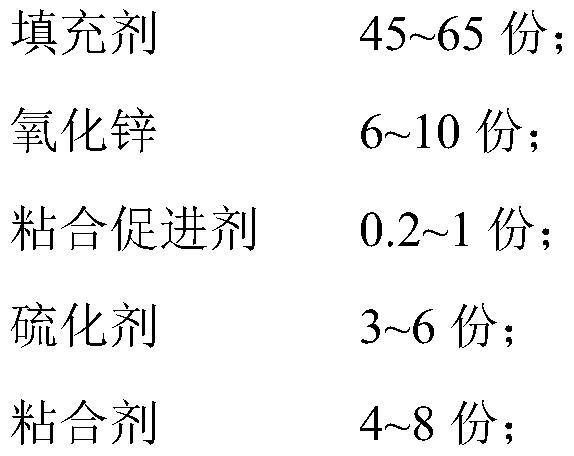

Outer rubber material for steel wire-woven hydraulic rubber pipe and preparation method of outer rubber material

InactiveCN105778311AImprove plasticityImproved thermo-oxidative aging performanceRubber materialBreaking strength

The invention discloses an outer rubber material for a steel wire-woven hydraulic rubber pipe and a preparation method of the outer rubber material, relating to the field of rubber materials. The outer rubber material is prepared from the following raw materials in parts by weight: 100 parts of rubber, 9 parts of an activating agent, 3 parts of an anti-aging agent, 20-25 parts of a plasticizer, 77 parts of a reinforcing filler, 5 parts of an adhesive and 3.3-3.75 parts of a vulcanizing agent. The outer rubber material has the beneficial effects that by utilizing the outer rubber material, the elongation of the rubber pipe is more than or equal to 600%, the rubber pipe cracks only after 72 hours when the ozone concentration reaches 50mg / L or the temperature reaches 120 DEG C, and the ozone aging resistance, the thermo-oxidative aging resistance, the wear resistance and the plasticity of the rubber pipe are improved, furthermore, the breaking strength of the rubber pipe is more than or equal to 12MPa, the hardness of the rubber pipe is more than or equal to 73 DEG C, the service life of the rubber pipe is prolonged, and the production cost of a user is lowered.

Owner:HENGSHUI JIDIER SPECIAL RUBBER HOSE CO LTD

Green environmental protective flame-proof ABS alloy

The invention discloses a composite material of green environment protective flameproof ABS alloy and making method, which is composed of ABS and PVC, wherein fitful quantity of heat stabilizer and lubricant are added into co-blending system, which improves flameproof property with fire retardant within Sb2O3 and halogen fire retardant; the composite material reinforces extending property, bending property and hinging property, which improves mechanic strength and electric property obviously.

Owner:哈尔滨鑫达高分子材料股份有限公司

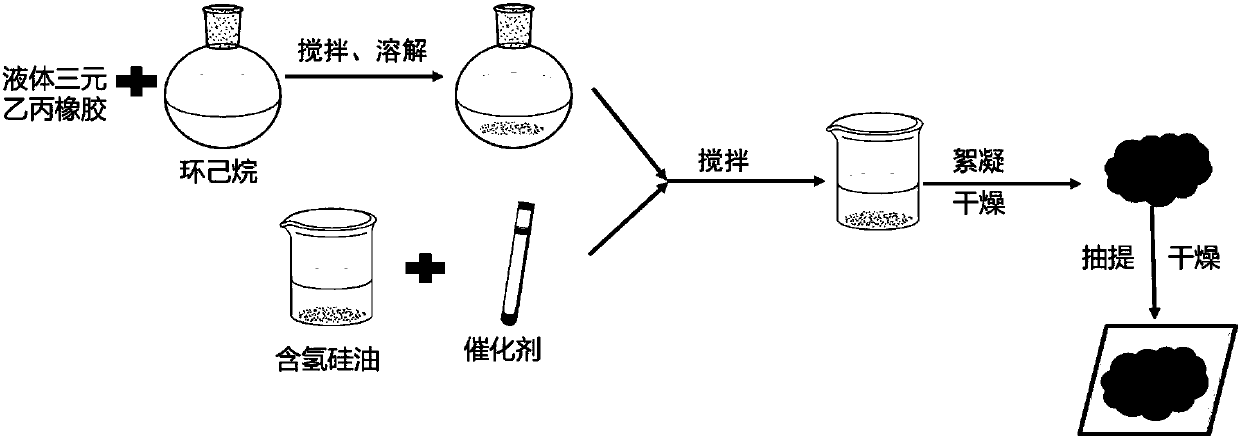

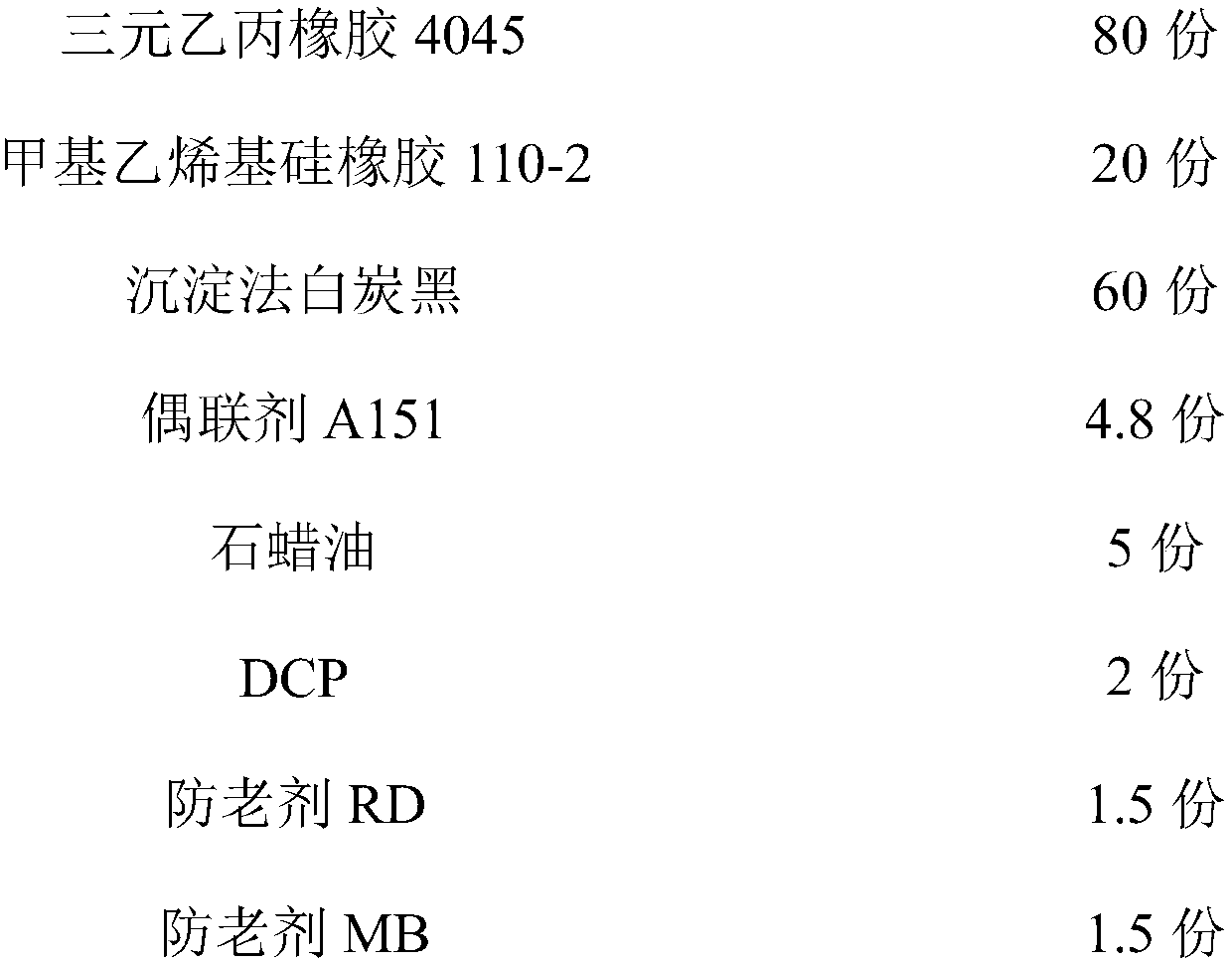

Compatilizer for improving blending compatibility of ethylene propylene diene monomer with silicone rubber and preparation method of compatilizer

InactiveCN109867789AImprove blend compatibilityImproved thermo-oxidative aging performanceChemical effectsHydrosilylation

The invention relates to a compatilizer for improving blending compatibility of ethylene propylene diene monomer with silicone rubber. The compatilizer comprises 100 parts of liquid ethylene propylenediene monomer, 30-50 parts of hydrogen-containing silicone oil and 0.5-1 part of a catalyst. The preparation method comprises the following steps: firstly, dissolving the liquid ethylene propylene diene monomer, then adding the hydrogen-containing silicone oil and the catalyst, and carrying out a hydrosilylation reaction to graft the hydrogen-containing silicone oil onto the liquid ethylene propylene diene monomer to prepare the compatilizer. The novel compatilizer can be enriched at the interface of two phases in a blending process of ethylene propylene diene monomer with methyl vinyl silicone rubber, and surface tension of the two phases is reduced through physical or chemical effects generated by the compatilizer with a two-phase polymer component, so that an effect of improving compatibility of the two components is achieved, and performance of blended rubber is improved.

Owner:BEIJING UNIV OF CHEM TECH +1

Fused method silica modified silicone rubber composite material

InactiveCN108456427AEasy to processImprove high temperature resistancePolymer scienceCarbon nanotube

The invention discloses a fused method silica modified silicone rubber composite material. The fused method silica modified silicone rubber composite material is prepared from the following raw materials in parts by weight: 80 to 90 parts of methyl vinyl silicone rubber, 10 to 20 parts of methyl phenyl silicone rubber, 10 to 26 parts of fluorine rubber, 15 to 32 parts of fumed silica, 2 to 10 parts of carbon nanotube, 2 to 9 parts of graphite, 2 to 9 parts of nano-alumina, 5 to 12 parts of boron nitride, 6 to 11 parts of montmorillonite, 0.8 to 1.8 parts of vulcanizing agent, 0.2 to 1.3 partsof methyl silicone oil, 1 to 3.5 parts of methyltriacetoxysilane and 1 to 2.5 parts of tetraethyl orthosilicate. The fused method silica modified silicone rubber composite material provided by the invention has high strength, excellent high-temperature resistance and excellent aging resistance.

Owner:天长市荣盛有机硅科技有限公司

Thermal-oxidizing-aging resisting polypropylene composite

ActiveCN102604209BImprove interface bonding performancePrevent free diffusionLattice defectsAntioxidant

The invention discloses a thermal-oxidizing-aging resisting polypropylene composite. The thermal-oxidizing-aging resisting polypropylene composite comprises the following components in percentage by weight: 30%-85% of polypropylene, 0-10% of flexibilizer, 2%-10% of compatilizer, 10%-40% of filling agent, 0.1%-0.5% of nucleating agent, 1%-10% of load type functional agent and 0.2%-1.0% of processing agent. Due to the nucleating agent, the polypropylene spherocrystal is refined, the crystallization is uniform and regular and the degree of crystallinity is increased, so that the lattice defect of a substrate is avoided effectively, and the oxygen is prevented from dispersing to the inner part from the surface of the composite freely; due to the compatilizer, the interface bonding force of the polypropylene and the filling agent is improved, so that two phase interfaces are combined tightly, the and the oxygen is prevented from dispersing to the inner part from the surface of the composite freely, and the thermal-oxidizing-aging resistance is improved; and the load type functional agent solves the problem of dispersibility and solvent resistance of an antioxidant and a light stabilizer. The thermal-oxidizing-aging resisting polypropylene composite has a simple preparation method, is high in thermal-oxidizing-aging resisting efficiency and is widely applied to the field of household appliances such as electric cookers, microwave ovens, washing machines, dish-washing machines and the like.

Owner:KINGFA SCI & TECH CO LTD +2

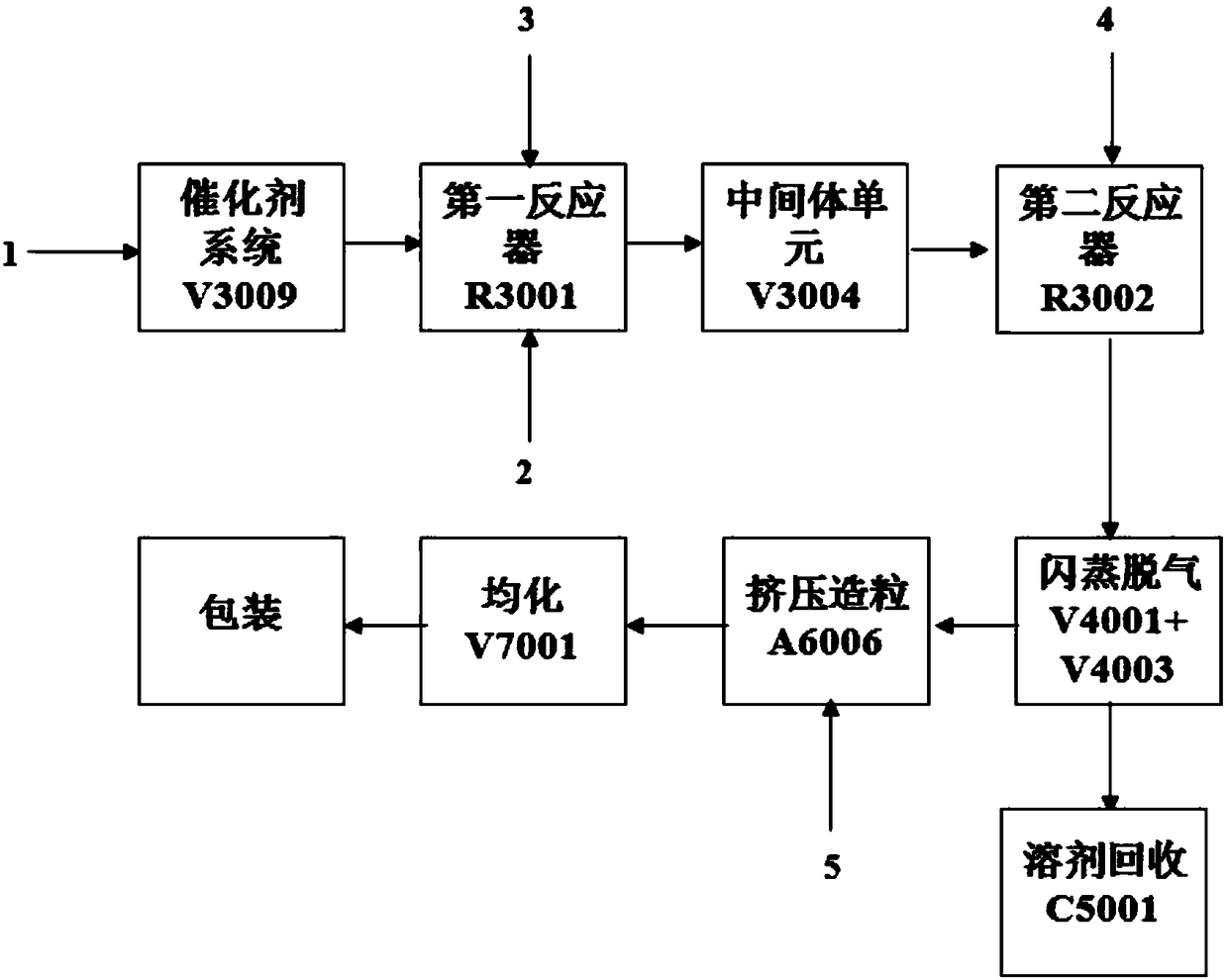

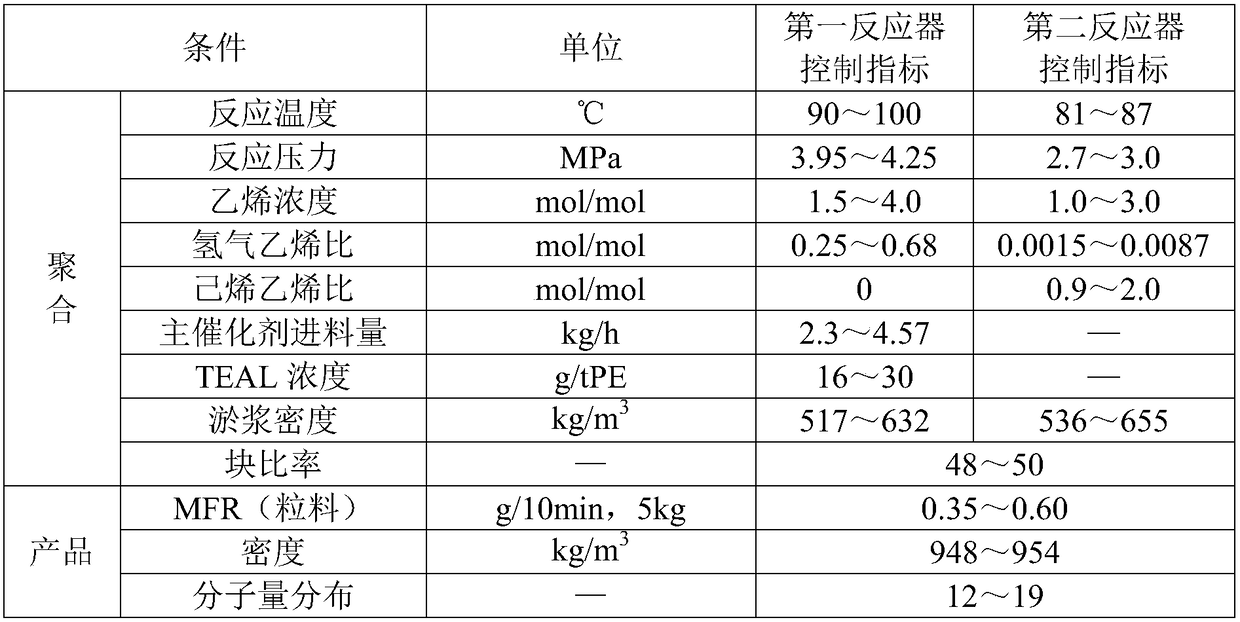

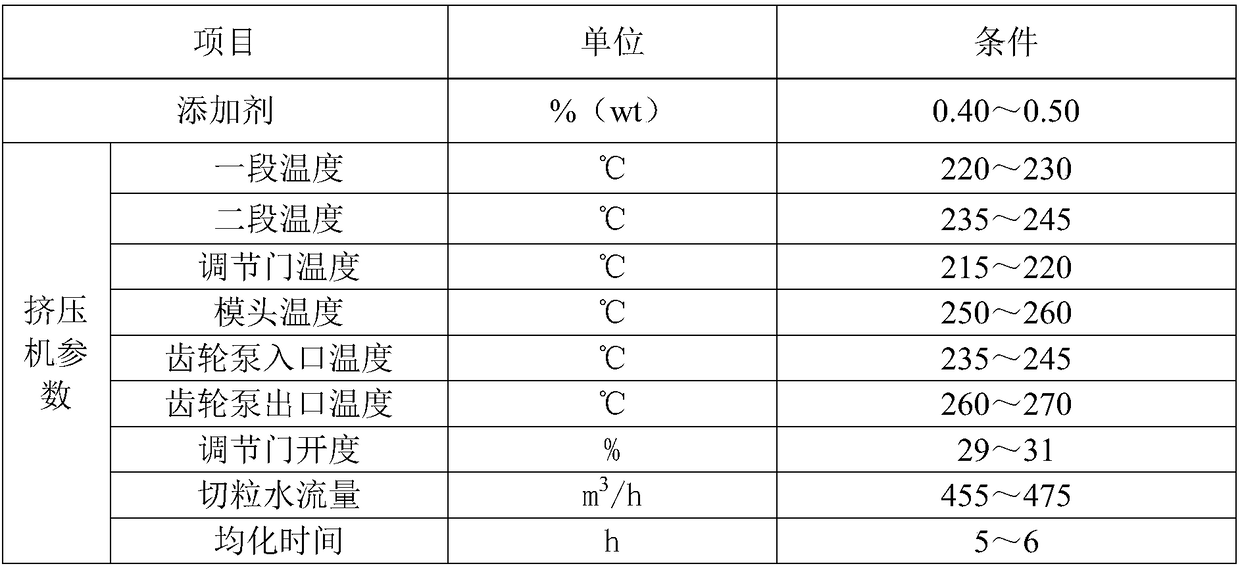

Method for synthesizing special resin for PE100 pipe fitting

ActiveCN108148251AMeet high liquidity requirementsIncrease mutual restraint abilityHydrogenPipe fitting

The invention discloses a method for synthesizing special resin for a PE100 pipe fitting. The method comprises the following steps: (1) diluting a main catalyst, adding the diluted main catalyst intoa first reactor, adding a co-catalyst, adding hydrogen and ethylene to the first reactor, controlling the reaction temperature, pressure and slurry density, and carrying out a reaction; (2) after theproduct of step (1) is treated by an intermediate to remove hydrogen, adding the treated product into a second reactor, adding hexane, ethylene and hydrogen into the second reactor, wherein the molarratio of the hexane to the ethylene is (0.9-2.0):1, and the molar ratio of the hydrogen to the ethylene is (0.0015-0.0087):1, controlling the reaction temperature, pressure and slurry density, controlling the polymerization reaction block ratio to be 48-50, and continuing the reaction; (3) carrying out extruding granulation on the reaction product in the step (2); and (4) cooling the material strip by cooling water, then cutting the cooled material strip into cake-shaped uniform particles, and carrying out homogenized packaging on the particles to obtain the special resin for the PE100 pipe fitting. The special material meets the standard requirements of PE100.

Owner:PETROCHINA CO LTD

Preparation method of composite polyurethane waterproof coating

InactiveCN110437728AImprove waterproof performanceImprove UV aging resistancePolyurea/polyurethane coatingsUltravioletOxygen

The invention belongs to the technical field of building materials, and particularly relates to a preparation method of a composite polyurethane waterproof coating. The method comprises the followingsteps: firstly, preparing organic silicon microcapsules by taking polyvinyl alcohol and maltodextrin as wall materials and organosilane as a core material; then mixing tetraethoxysilane and calcium nitrate to perform a reaction, and preparing tricalcium silicate self-made filler by a sol-gel method; then mixing zinc nitrate, ferric nitrate and tetrabutyl titanate and carrying out a reaction to generate nano metal oxide filter residues in the presence of ammonia water; and finally, preparing the waterborne polyurethane emulsion. The polyurethane waterproof paint has the advantages of great mechanical ultraviolet aging resistance, thermo-oxidative aging resistance and waterproofness, durable waterproofness and wide application prospects.

Owner:慈溪市果雨电子商务有限公司

Styrenic thermoplastic elastomer and preparation method thereof

The invention discloses a styrenic thermoplastic elastomer, which is mainly prepared by using a styrenic thermoplastic elastomerglue solution, extending oil and antioxygen as raw materials and by mixing and refining. The elastomer consists of 2,000 to 3,000 weight parts of styrenic thermoplastic elastomerglue solution, 150 to 250 weight parts of extending oil and 1,000 to 5,000ppm of antioxygen. The antioxygen at least comprises compound hindered phenol antioxygen. The invention also discloses the preparation method of the styrenic thermoplastic elastomer, which is very antioxidant and environment-friendly.

Owner:CHINA PETROLEUM & CHEM CORP

Environment-friendly polyurethane waterproof coating and preparation method thereof

InactiveCN107446482ACuring speed effectReflexivePolyurea/polyurethane coatingsTriolMechanical property

The invention relates to the technical field of coatings and in particular relates to an environment-friendly polyurethane waterproof coating and a preparation method thereof. The environment-friendly polyurethane waterproof coating comprises components A and B. The component A comprises the following substances in parts by weight: 20-30 parts of polyether glycol, 30-50 parts of polyether triol, 3-6 parts of montmorillonite, 3-6 parts of nano silicon dioxide and 4-7 parts of methylbenzene-2,4-diisocyanate; the component B comprises the following substances in parts by weight: 6-8 parts of water, 0.5-1 part of a dispersant, 8-12 parts of petroleum fraction oil, 3-6 parts of calcium hydroxide, 3-6 parts of talc powder, 3-6 parts of light calcium carbonate and 0.3-0.6 part of a plasticizer. By taking water or other diamines and polyhydric alcohol as a curing agent, the coating does not contain volatile organic compounds, so that the coating is harmless to the environment and has excellent mechanical properties and anti-ageing property.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

150 DEG C thermoplastic halogen-free flame-retardant polyolefin thin-wall insulation material and preparation method thereof

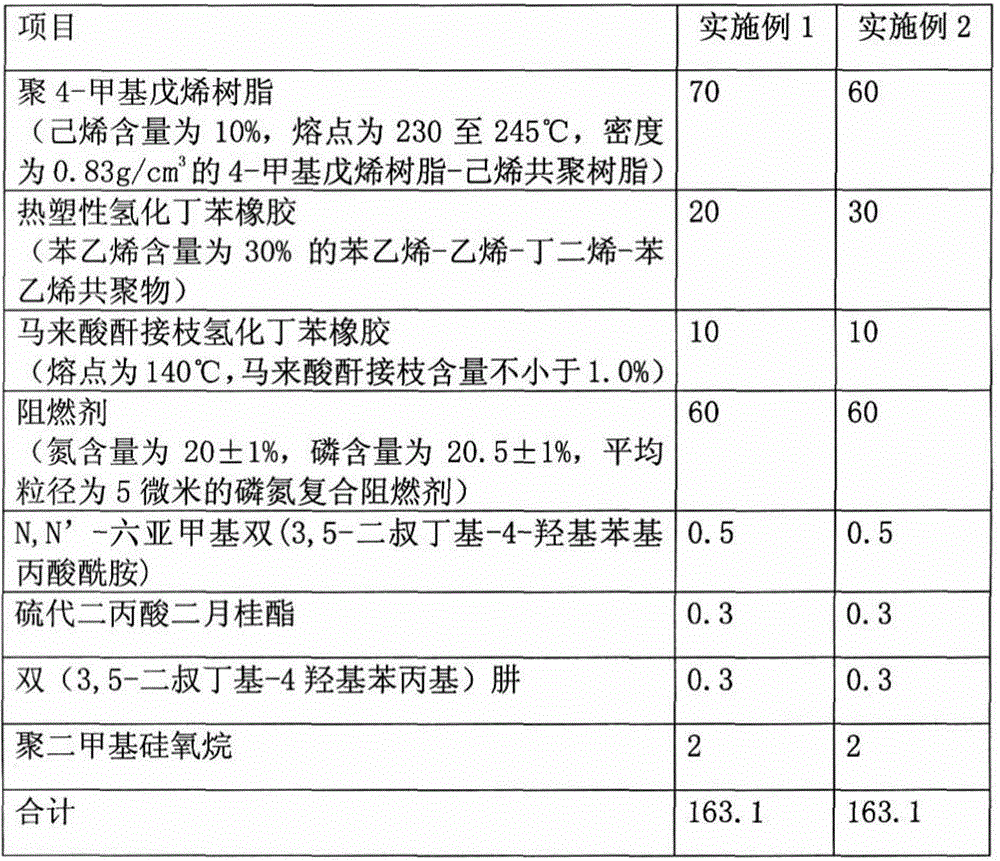

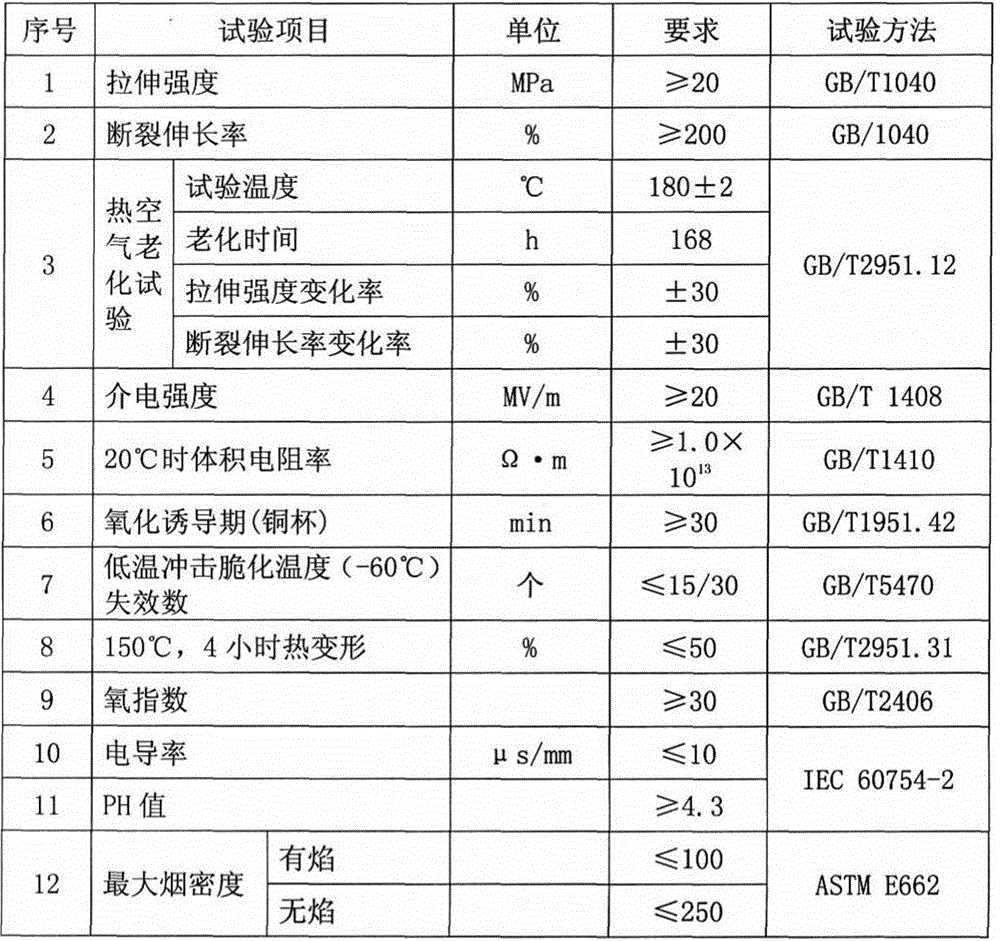

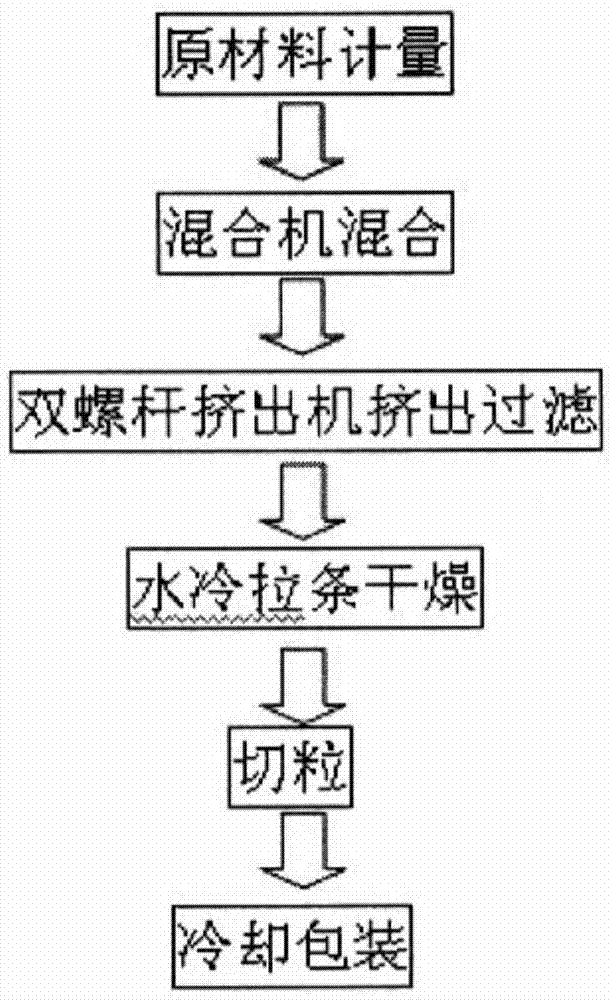

Provided are a 150 DEG C thermoplastic halogen-free flame-retardant polyolefin thin-wall insulation material and a preparation method thereof. The insulation material comprises the main components in parts by weight: 60 to 70 parts of poly(4-methyl-pentene) resin, 10 to 20 parts of thermoplastic hydrogenated styrene butadiene rubber, 10 to 20 parts of a compatilizer, 50 to 60 parts of a flame retardant, 0.5 part of an antioxidant A, 0.3 part of an antioxidant B, 0.3 part of an anti-copper agent, and 2 parts of a lubricant. The preparation method comprises the steps: after preparing the amounts of the raw materials according to the weight parts, putting into a mixer for mixing evenly, then sending into a twin-screw extruder for co-mixing, filtering, extruding and dragging strips, next cooling with a water tank, drying, allowing to go into a dicing cutter for cutting into particles, and then packaging to obtain the finished product. The insulation material has the advantages of good insulating performance, excellent flame retardance, high temperature resistance, easy processing and low cost, and can be widely used in thin-wall insulation of communication cables, locomotive vehicle wire cables and automobile wires; and the preparation method is reasonable in design and simple in operation.

Owner:天津市普立泰高分子科技有限公司

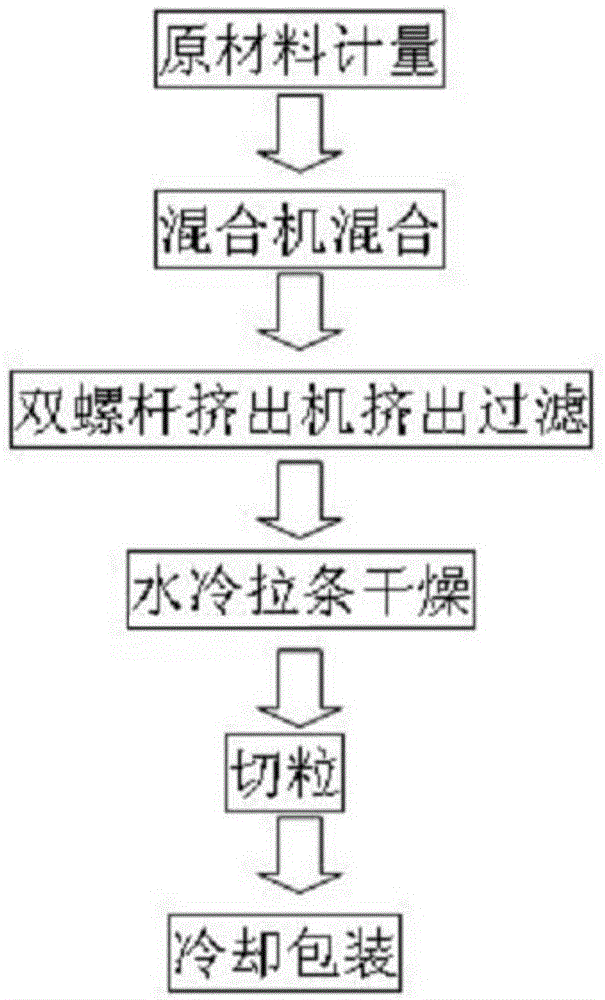

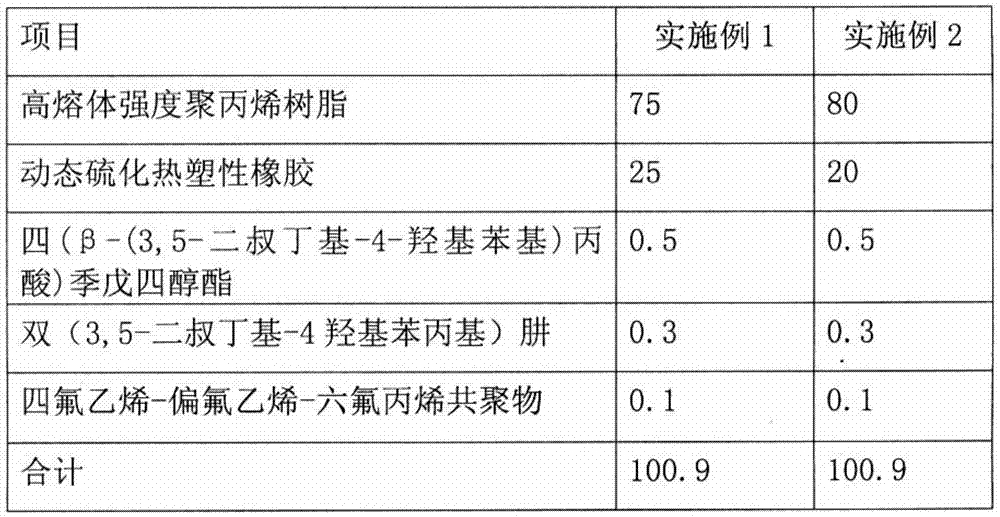

Thermoplastic oil-resistant polyolefin elastomer sheath material and preparation method thereof

InactiveCN106928538APrevents catalytic agingGood oil resistancePlastic/resin/waxes insulatorsElastomerPolyolefin

The invention provides a thermoplastic oil-resistant polyolefin elastomer sheath material and a preparation method thereof. The material is mainly prepared from, by weight, 70-80 parts of polypropylene resin, 20-30 parts of dynamic vulcanized thermoplastic rubber, 0.5 part of antioxidant, 0.3 part of anti-copper agent and 0.1 part of rheological agent. The preparation method includes the steps that the raw materials are metered by weight and put into a mixer to be evenly mixed, then the mixture is conveyed into a dual-screw extruder for blending extrusion, filtering and drawing, the mixture is cooled through a water tank and dried and then enters a granulator to be cut into particles, the particles are packaged, and finished products are obtained. The sheath material is low in density, good in heat resistance and oil resistance, and capable of serving as a hydraulic packaged cable sheath material for well logging; the preparation method is reasonable in deign and easy to operate.

Owner:天津市普立泰高分子科技有限公司

Muffler

ActiveCN105348737AImproved thermo-oxidative aging performanceExtended service lifePositive displacement pump componentsPositive-displacement liquid enginesGlass fiberEpoxy

The present invention relates to a muffler, the muffler includes a hollow cylindrical muffler net and a casing wrapping the muffler net, muffler cotton is arranged between the casing and the muffler net, the casing, the muffler cotton and the muffler net are arranged in parallel, the muffler further comprises a mounting member arranged on two ends of the muffler net, a mounting through hole is arranged in the middle part of the mounting member, the upper end face of the mounting member is provided with a cutting face, muffler net holes are arranged on the middle part of the lower end face of the mounting member, the muffler net holes and the mounting through hole can be coaxially arranged, the muffler net can be clamped and embedded by the muffler net holes, a casing groove capable of clamping and embedding the casing is dug on the outer side face of the mounting member, and the casing is made of a composite material which comprises, 40-50wt% of epoxy; 5-20wt% of alkali-free glass fiber; 15-30wt% of mineral fiber; 0.5-5wt% of a flow modifier; 1-3wt% of a heat modifier; 3-5wt% of a compatibilizer; 0.3-0.5wt% of a primary antioxidant; 0.3-0.5wt% of a secondary antioxidant and 1-3wt% of a processing aid. The muffler is simple in structure, the casing is made of the composite material, the mounting member is made of a reasonable compatibility material, and the use efficiency and the service life of the entire blast blower can be further improved.

Owner:NINGBO SHENGHONG MACHINERY EQUIP

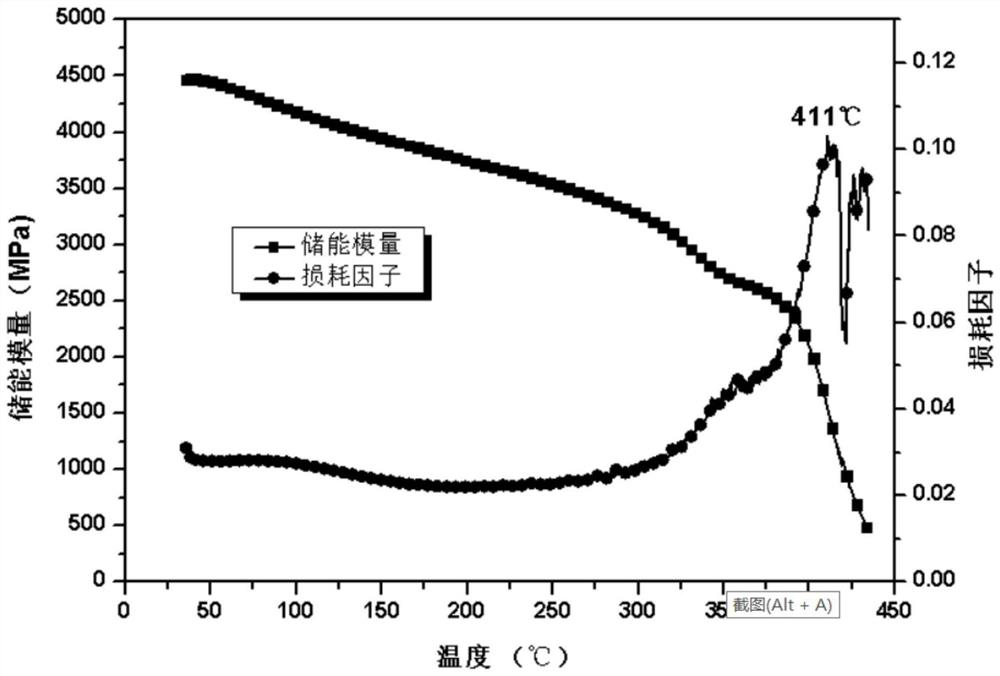

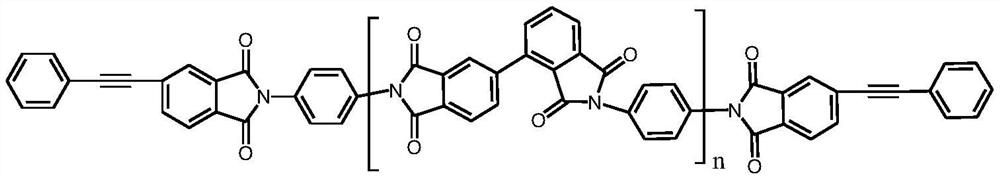

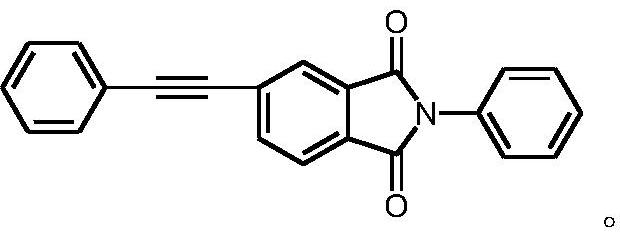

Ultrahigh-temperature polyimide heat-conducting insulating material and preparation method thereof

PendingCN113930073AExcellent high temperature thermal oxygen/thermal stabilityGood mechanical propertiesThermal dilatationPolymer science

The invention discloses an ultrahigh-temperature polyimide heat-conducting insulating material and a preparation method thereof, and belongs to the field of high polymer materials. The ultrahigh-temperature polyimide heat-conducting insulating material comprises the following raw materials in parts by mass: 100 parts of reactive polyimide resin, 5-20 parts of a heat-conducting filler, 3-5 parts of a repairing agent, 0.5-3 parts of an anti-aging agent, and 1-10 parts of a reactive diluent. According to the preparation method of the ultrahigh-temperature polyimide heat-conducting insulating material, reactive polyimide resin is taken as a base material, the heat-conducting filler, the repairing agent, the anti-aging agent and the reactive diluent are added, a modified resin system is prepared by adopting a melt blending process, an insulating material system with the glass transition temperature being greater than 350 DEG C, the initial thermal decomposition temperature being greater than 500 DEG C, the heat conductivity coefficient being greater than 0.3 W / m.K, the electric breakdown strength being greater than 80kV / mm and the thermal expansion coefficient being less than 40PPM / DEG C is obtained by means of program temperature controlled curing, the excellent performance of the insulating material system meets the use requirements of sealing and insulation of special motor stator electromagnetic wire windings, and the material has a wide application prospect in the technical field of heavy oil thermal recovery.

Owner:辽宁鲸苇科技有限公司

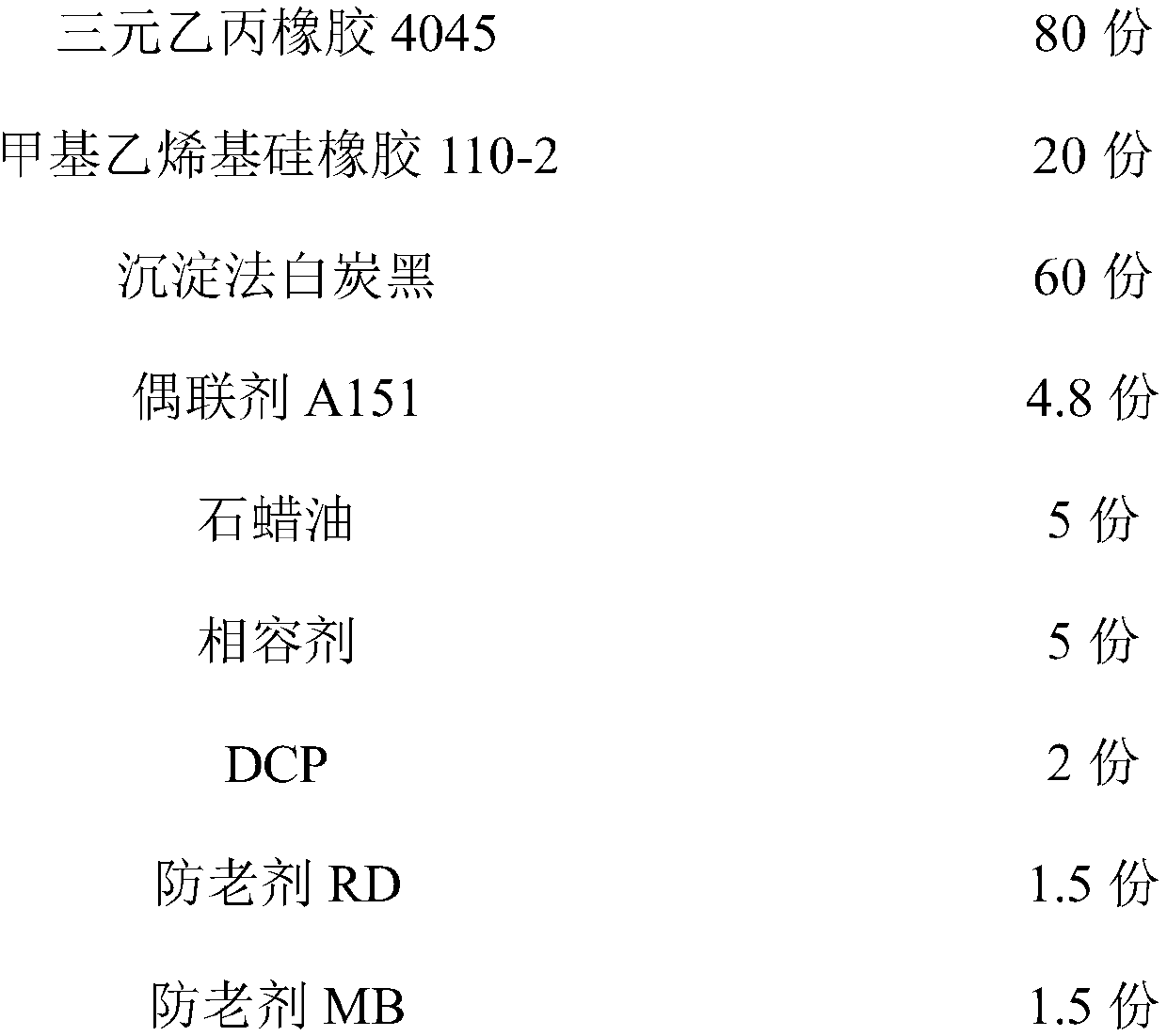

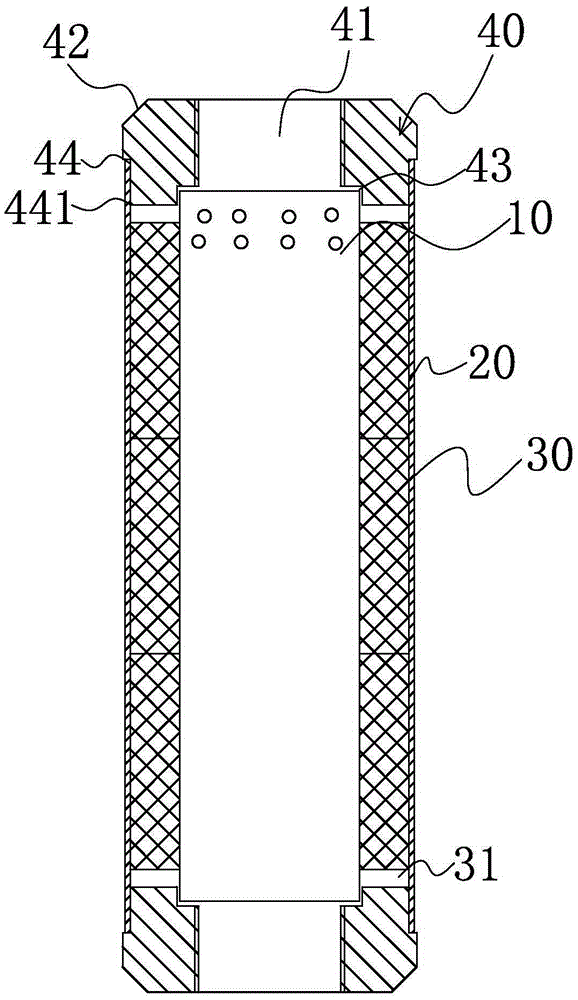

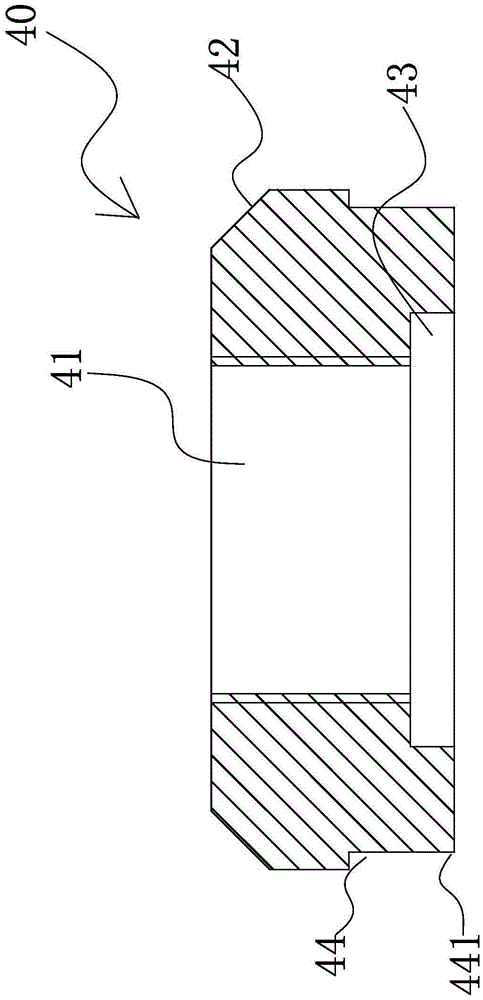

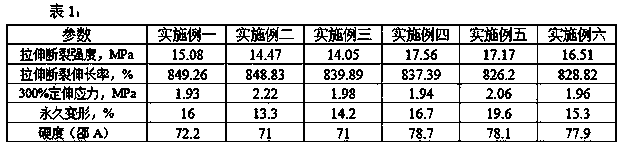

Encapsulation sleeve prepared by compounding butyl rubber and ethylene-propylene-diene monomer, and preparation method thereof

InactiveCN111117083AImproved thermo-oxidative aging performanceIncrease elasticitySilane couplingCarbon black

The invention relates to an encapsulation sleeve prepared by compounding butyl rubber and ethylene-propylene-diene monomer, and a preparation method thereof, and belongs to the technical field of encapsulation sleeves. The encapsulation sleeve is prepared from 50-100 parts of IIR 268, 5-50 parts of EPDM J2070, 10-50 parts of carbon black, 10-50 parts of white carbon black, 5-30 parts of paraffin oil, 0.2-3 parts of a silane coupling agent, 1-10 parts of zinc oxide, 0.5-2 parts of stearic acid, 2-6 parts of an anti-aging agent, 3-10 parts of a homogenizing agent, 2-6 parts of a processing aid,1-3 parts of sulfur, 0.1-1.5 parts of an accelerant TMTD, 1-3 parts of an accelerant MBT, 1-3 parts of an accelerant ZDBC and 0-2 parts of an accelerant DTDM. The encapsulation sleeve has excellent thermo-oxidative aging resistance, excellent mechanical properties and longer service life. The invention also provides a simple preparation method.

Owner:山东海益橡胶科技有限公司

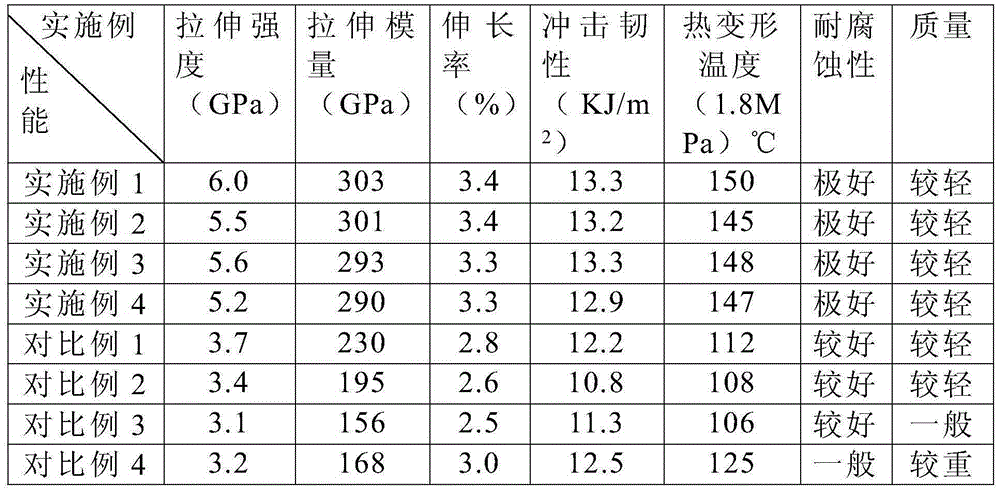

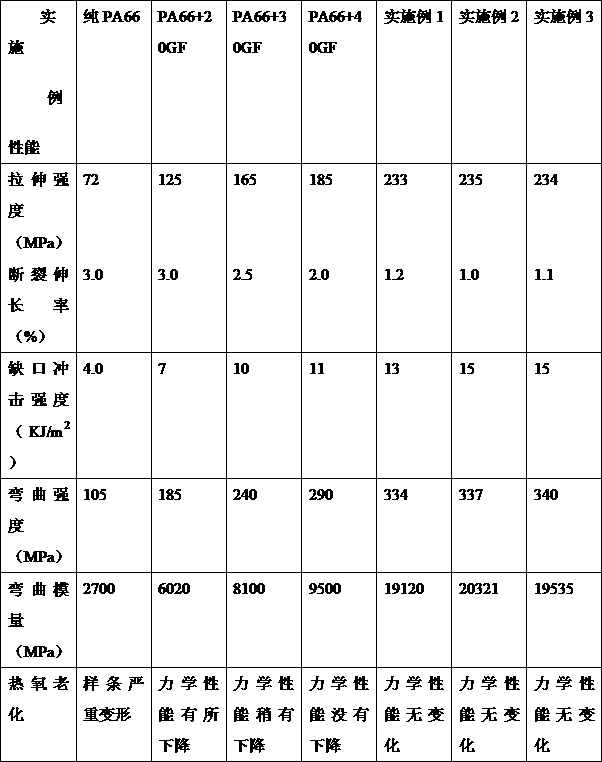

High-content glass fibre-enhanced nylon 66 composite material and preparation method thereof

InactiveCN108219451AFast crystallizationImprove interfacial adhesionAntioxidantSilicon carbide nanotubes

The invention relates to a high-content glass fibre-enhanced nylon 66 composite material and a preparation method thereof, and belongs to the field of high polymer materials. The composite material isprepared from the following components in percentage by mass: 31.9 to 38 percent of nylon 66, 58 to 62 percent of alkaline-free glass fibres, 2 to 5 percent of a compatilizer, 0.3 to 0.5 percent of amain antioxidant, 0.3 to 0.5 percent of an auxiliary antioxidant and 0.5 to 1.0 percent of a lubricating agent, wherein the surfaces of the alkaline-free glass fibres are coated with an enhancement layer; the enhancement layer is made of carbon nano-tubes or silicon carbide nano-tubes which are extruded and granulated by using a twin-screw extruder. The composite material provided by the invention is high in glass fibre content; the mechanical properties and the physical properties of the composite material are improved; moreover, the surfaces of the alkaline-free glass fibres are coated withthe nano-tubes; the compatibility of the alkaline-free glass fibres and the nylon 66 is increased by selecting suitable lengths and diameters of the glass fibres and the molecular weight of the nylon66; the defect that the appearance of the material becomes poor along with the increment of the content of the glass fibres filled in the nylon in the past is overcome.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

Long-term heat and oxidation aging resistant polypropylene compound and preparation method thereof

ActiveCN102827422BImproved thermo-oxidative aging performanceImprove interface compatibilityPolymer scienceLaboratory oven

The invention discloses a long-term heat and oxidation aging resistant polypropylene compound prepared in percentage by weight: 52%-89% of polypropylene resin, 10%-40% of inorganic filler, 0.1%-1% of beta nucleating agent, 0.5%-5% of stem grafting assistant, 0.2%-1% of antioxygen and 0.2%-1% of processing agent. A preparation method comprises the following steps of: evenly mixing each component, putting in a twin screw extruder for extrusion, enabling a temperature of the extruder to be 190-210 DEG C, enabling a rotating speed to be 50-400 circle / minute, cooling extrusion objects by using water, conducting sized dicing and obtaining the compound. The compound prepared by the preparation method has an excellent comprehensive mechanical property, has long-term heat and oxidation aging resistant characteristics, cannot pulverize after baking for 3000 hours in a 150-DEG C forced convection oven, and is widely applied to heat and oxidation aging resistant components of household appliances.

Owner:KINGFA SCI & TECH CO LTD +2

Anti-impacting anti-ageing modified polypropylene material and preparation method thereof

InactiveCN102766299BImprove impact resistanceImprove mechanical propertiesPolymer scienceUv absorber

The invention relates to an anti-impacting anti-ageing modified polypropylene material and a preparation method thereof and aims at providing the anti-impacting anti-ageing modified polypropylene material which has basic physical characteristics of polypropylene and simultaneously has improved anti-impacting performance and good anti-ageing performance. The material comprises, by weight, 65-85% of polypropylene, 5-25% of inorganic fillers, 0.3-1.5% of antioxidant, 0.2-1.0% of light stabilizer, 0.2-1.0% of ultraviolet absorber, 5-15% of flexibilizer, 5-15% of compatilizer and 0.2-1.0% of coupling agent. Experiment results show that the material can achieve the purposes, and products can be widely applied to the fields such as electronics and electrics, automobile and household appliances, communication devices and building materials.

Owner:长沙达联塑料有限公司

High-performance vulcanized rubber sleeve for transmission belt

The invention provides a vulcanized rubber jacket for transmission belts. The vulcanized rubber jacket comprises, by weight, 95 parts of brominated butyl rubber, 5 parts of chloroprene rubber, 30-60 parts of reinforcing agents, 1-5 parts of homogenizing agents, 5-10 parts of tackifying resin, 5-10 parts of vulcanizing phenolic resin, 1-3 parts of microcrystalline wax, 1-3 parts of surface lubricants, 1-3 parts of anti-aging agents, 1-3 parts of accelerators, 0.2-1 part of stearic acid, 0.5-2 parts of magnesium oxide and 5 parts of zinc oxide. The vulcanized rubber jacket has the advantages of excellent air tightness, anti-aging property, permanent deformation resistance and thermal-oxidative aging resistance, long service life and low service cost of products.

Owner:QINGDAO UNIV OF SCI & TECH +1

Modified boehmite butadiene styrene rubber

InactiveCN104311930AGood dispersionImprove impact resistance2-mercaptobenzimidazoleMelamine phosphate

The invention discloses modified boehmite butadiene styrene rubber. The modified boehmite butadiene styrene rubber is prepared from the following raw materials in parts by weight: 65-68 parts of butadiene styrene rubber, 30-33 parts of silicon nitride rubber, 6-9 parts of a styrene-butadiene-styrene segmented copolymer (SBS), 1.5-1.8 parts of an aluminum-zirconium coupling agent TL-5, 2-5 parts of 2,5-dimethyl-2,5-bis(tert-butylperoxyl)hexane, 4.3-4.7 parts of sulfur, 1-2 parts of divinyl benzene, 33-36 parts of modified boehmite, 8-11 parts of zeolite powder, 18-21 parts of precipitation barite, 3-4 parts of trioctyl trimellitate, 5-8 parts of epoxidized soybean oil, 17-20 parts of magnesium hydroxide, 2.5-3 parts of melamine phosphate, 1-1.5 parts of an environment-friendly flame retardant FR-T801, 1.3-1.6 parts of an antioxidant MBZ (2-Mercaptobenzimidazole Zinc), and 1.8-2.1 parts of an antioxidant BLE (high temperature condensation compound of diphenylamine and acetone).

Owner:TIANCHANG HIGH TECH ENTREPRENEURSHIP SERVICE CENT

A high-strength impact-resistant natural rubber cable sheath material

ActiveCN106117644BHigh strengthGood compatibilityInsulated cablesInsulated conductorsLow-density polyethylenePolymer science

The invention discloses a high-strength and anti-impacting natural rubber cable sheathing material. The high-strength and anti-impacting natural rubber cable sheathing material is prepared from the following raw materials: natural rubber, polyvinyl chloride, low-density polyethylene, an ethylene-vinyl acetate copolymer, zinc oxide, stearic acid, sulfur, high-abrasion-resisting furnace black, carbon nanotubes, nano calcium carbonate, montmorillonoid, zirconium diboride, calcium sulfate whiskers, lignocellulose short fibers, cotton short fibers, an accelerant M, an accelerant BZ, a poly-3-hydroxybutyrate-4-hydroxybutyrate, epoxy soybean oil, an anti-aging agent RD, an anti-aging agent MB, p-aminodiphenyl amine, gamma-epoxypropoxy propyltrimethoxysilicane and vinyltriethoxysilane. The high-strength and anti-impacting natural rubber cable sheathing material disclosed by the invention is high in strength, good in anti-impacting performance, excellent in anti-aging performance and long in service life.

Owner:ANHUI ELECTRIC GRP SHARES

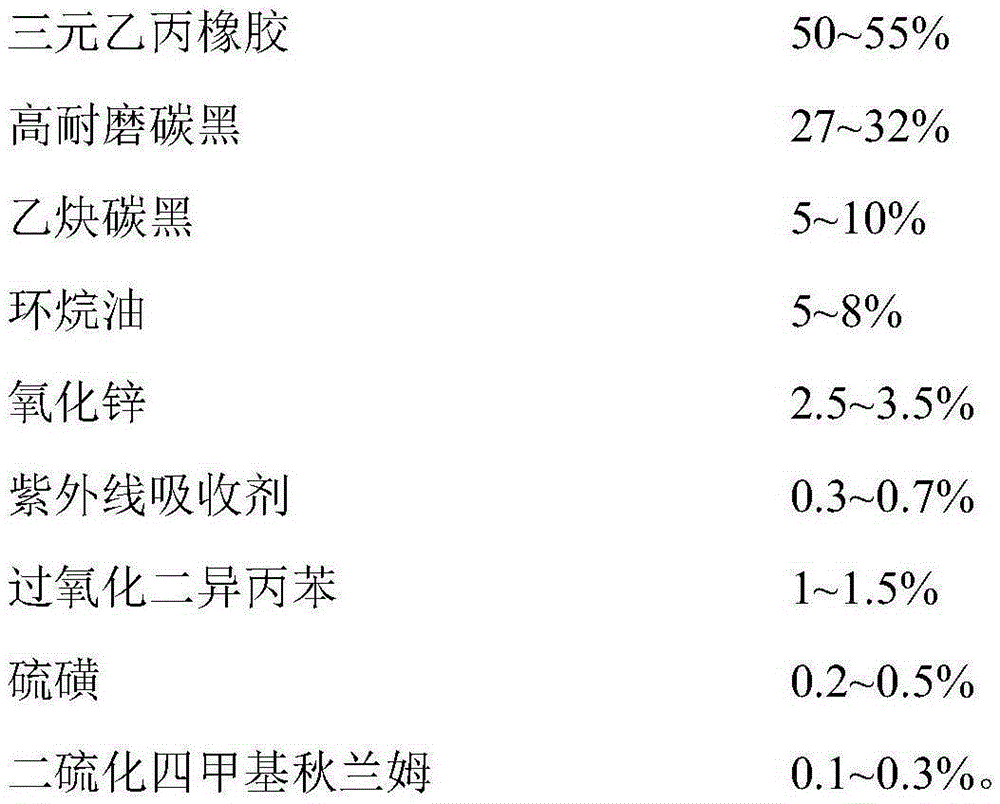

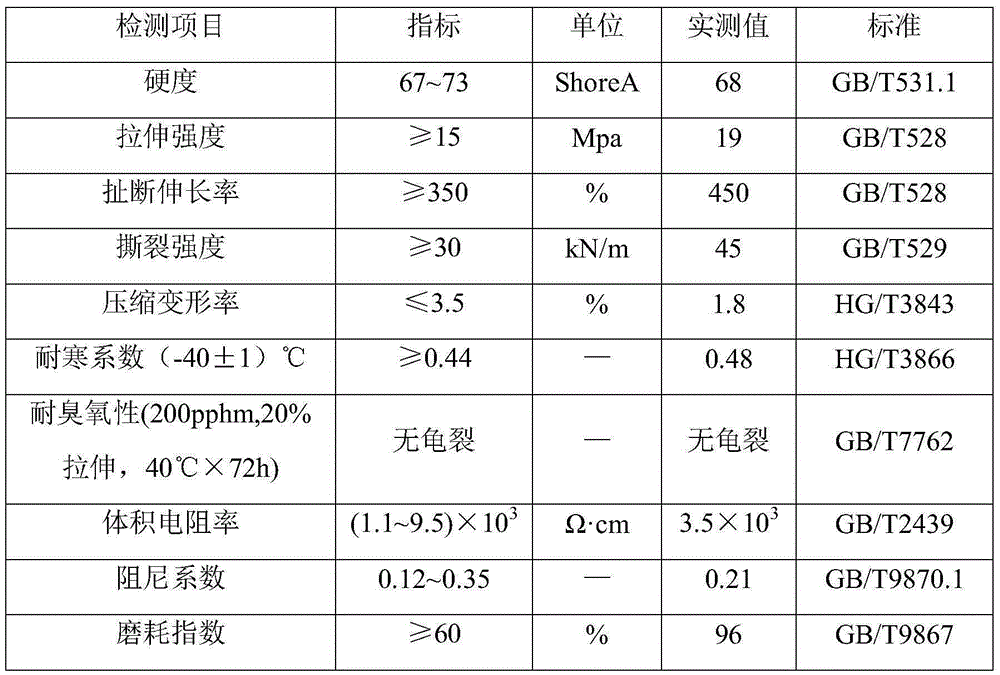

Material and preparation method of damping spacer rubber parts for UHV transmission lines

The invention discloses a material of a rubber part of a damping spacer for an ultra-high voltage transmission line and a preparation method thereof, and belongs to the fields of rubber materials and the preparation method thereof. The material comprises the following components in percentages by weight: 50-55% of ethylene propylene diene rubber, 27-32% of high abrasion-resistant carbon black, 5-10% of acetylene carbon black, 5-8% of naphthenic oil, 2.5-3.5% of zinc oxide, 0.3-0.7% of ultraviolet light absorber, 1-1.5% of dicumyl peroxide, 0.2-0.5% of sulfur and 0.1-0.3% of tetramethylthiuram disulfide. The preparation method comprises the following preparation steps of mixing a master batch, sulphureting the master batch, forming and vulcanizing. The prepared rubber part of the damping spacer for the ultra-high voltage transmission line has the advantages of excellent physical and mechanical properties, excellent weather resistance, ozone resistance and ultraviolet radiation aging resistance performance, higher electrical conductivity, moderate damping property, high elasticity and low compression permanent deformation performance. The service life of a product can reach 25-30 years.

Owner:南京金三力橡塑有限公司

Styrenic thermoplastic elastomer and preparation method thereof

The invention discloses a styrenic thermoplastic elastomer, which is mainly prepared by using a styrenic thermoplastic elastomerglue solution, extending oil and antioxygen as raw materials and by mixing and refining. The elastomer consists of 2,000 to 3,000 weight parts of styrenic thermoplastic elastomerglue solution, 150 to 250 weight parts of extending oil and 1,000 to 5,000ppm of antioxygen. The antioxygen at least comprises compound hindered phenol antioxygen. The invention also discloses the preparation method of the styrenic thermoplastic elastomer, which is very antioxidant and environment-friendly.

Owner:CHINA PETROLEUM & CHEM CORP

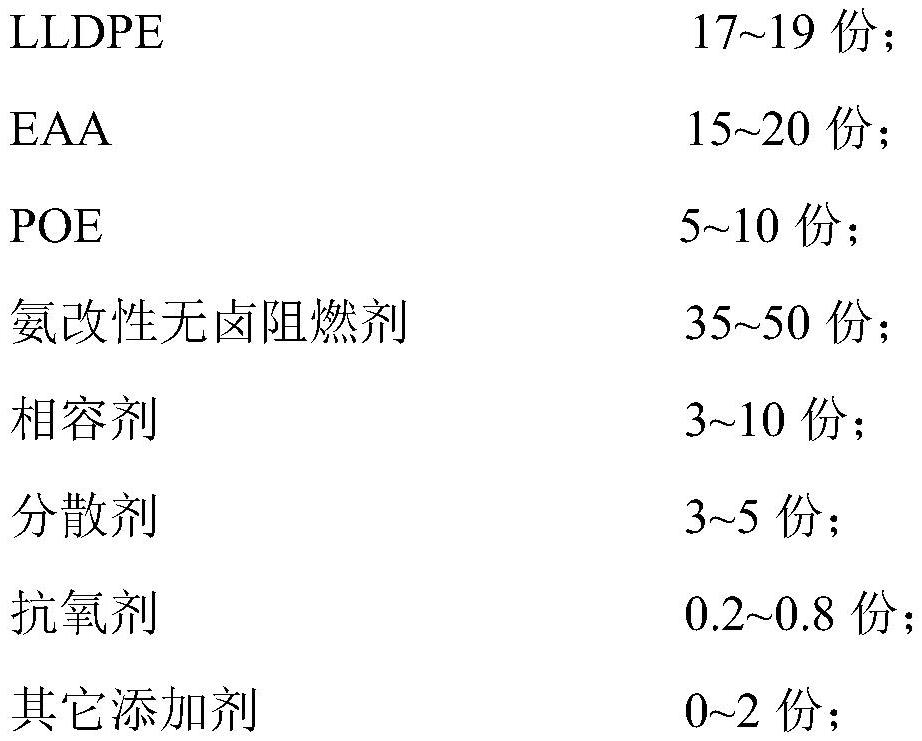

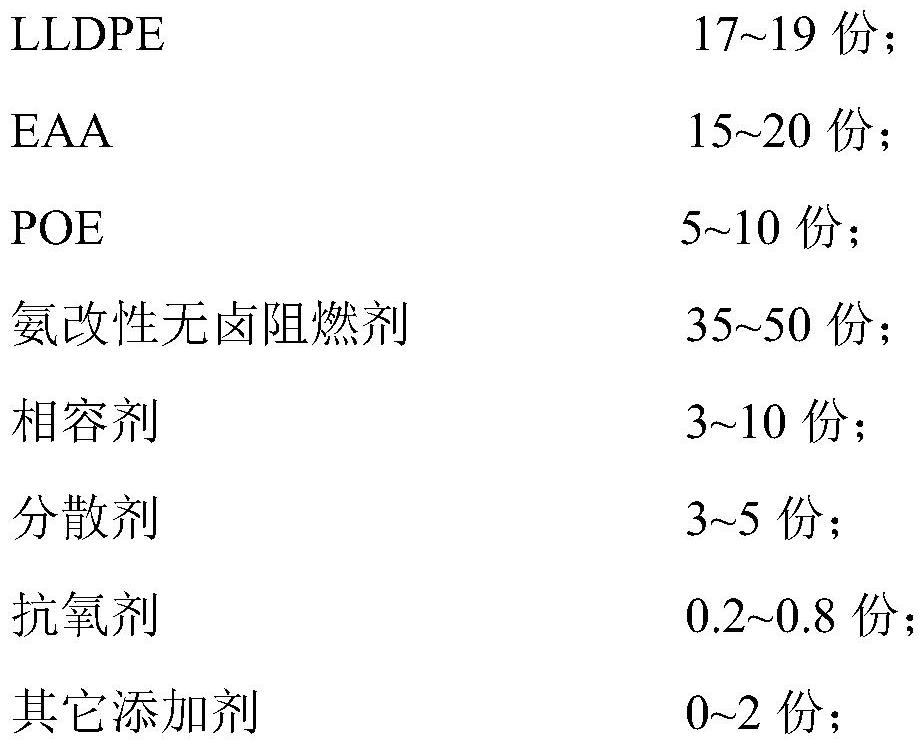

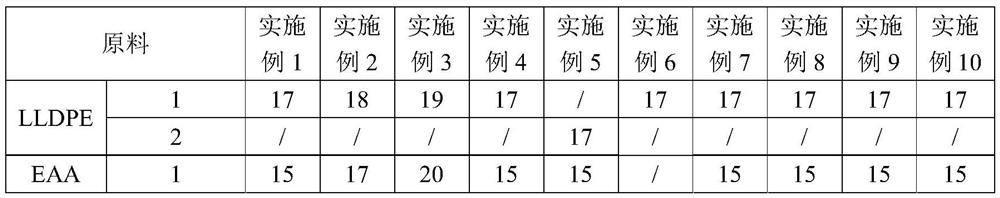

Polyolefin material with high thermal shrinkage resistance, high toughness and thermo-oxidative aging resistance as well as preparation method and application thereof

InactiveCN114736450AExcellent heat shrinkage resistanceImprove toughnessClimate change adaptationLinear low-density polyethyleneElastomer

The invention provides a polyolefin material with high thermal shrinkage resistance, high toughness and thermo-oxidative aging resistance as well as a preparation method and application thereof. The polyolefin material comprises the following components in parts by weight: 17-19 parts of LLDPE (Linear Low Density Polyethylene), 15-20 parts of EAA (Ethylene Acrylic Acid), 5-10 parts of POE (Polyolefin Elastomer), 35-50 parts of an ammonia modified halogen-free flame retardant, 3-10 parts of a compatilizer, 3-5 parts of a dispersing agent, 0.2-0.8 part of an antioxidant and 0-2 parts of other additives, and in the ammonia modified halogen-free flame retardant, the halogen-free flame retardant is one or a combination of two of magnesium hydroxide or aluminum hydroxide. Under the interaction of the ammonia-modified aluminum hydroxide or magnesium hydroxide halogen-free flame retardant and EAA and POE in a resin matrix, the heat shrinkage resistance, toughness and thermo-oxidative aging resistance of the polyolefin material can be improved at the same time, and the polyolefin material can be used for a long time in a higher temperature environment as a cable protection material.

Owner:KINGFA SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com