Anti-impacting anti-ageing modified polypropylene material and preparation method thereof

A polypropylene material and anti-aging technology, which is applied in the field of preparation of new impact-resistant and anti-aging polypropylene materials, can solve the problems of reduced mechanical properties such as tensile strength, loss of gloss, poor low-temperature impact performance, etc., and achieve physical and mechanical properties and Improved thermo-oxidative aging resistance, simple process, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

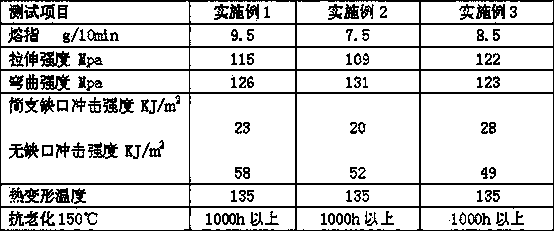

[0028] In order to better understand the present invention, examples are given in detail.

[0029] As shown in Table 1, the polypropylene resin used in this example is Daqing Petrochemical T30S Jun polypropylene with a melt index of 3, and the talc powder is commercially available 1600 mesh talc powder, which is dried at 100°C-110°C for 2 hours It is obtained by adding the coupling agent KH792 according to the specified ratio. The antioxidant is lrganox1010, the light stabilizer is Tinuvin 770, the ultraviolet absorber is UV-531, the toughening agent is American Dow POE8150, and the compatibilizer is commercially available maleic acid rod grafted PP.

[0030] Dry the polypropylene resin at 75°C-85°C for 4-6 hours, then add talc powder, antioxidant 1010, Tinuvin 770, UV-531, POE Dow 8150, maleic anhydride grafted PP according to the ratio specified in Table 1 The raw materials are mixed in a high-speed mixer for 10 minutes, put into a twin-screw extruder, extruded, drawn, air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com