Compatilizer for improving blending compatibility of ethylene propylene diene monomer with silicone rubber and preparation method of compatilizer

A technology of EPDM rubber and compatibilizer, which is applied in the field of polymer material processing, can solve the problems of poor mechanical properties, poor compatibility, and failure to meet general use requirements of silicone rubber, and achieve thermal oxygen aging performance improvement and improvement The effect of blend compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Prepare compatibilizer according to following basic composition and mass parts:

[0032] Liquid EPDM T67 100 parts

[0033] (the third monomer is norbornadiene, with a mass content of 9.5%)

[0034] Hydrogen-containing silicone oil (Si-H mass content 0.4%) 30 parts

[0035] Catalyst H 2 PtCl 6 ·6H 2 O(50ppm) 0.5 parts

[0036] making process:

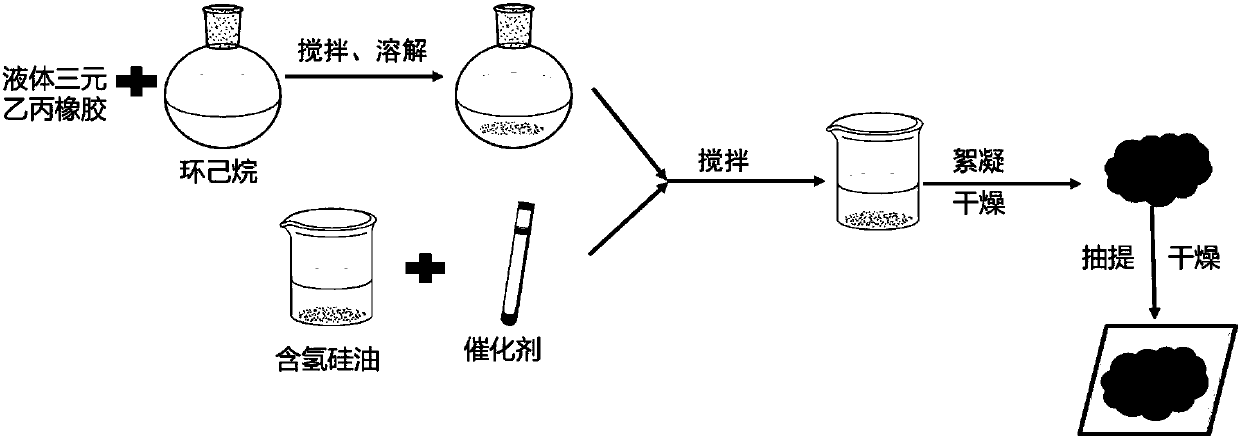

[0037] 1) Dissolution of EPDM rubber: first weigh 100 g of liquid EPDM rubber, then add 1000 ml of cyclohexane, stir and dissolve at room temperature;

[0038] 2) Hydrosilylation reaction: Add 30g of hydrogen-containing silicone oil to the EPDM solution, then add 0.5g of catalyst, and stir the reaction at a temperature of 60°C;

[0039] 3) Flocculation: Pour the reaction liquid product into boiling water and keep boiling for 30 minutes, evaporate the solvent, extract the product by Soxhlet extraction for 12 hours, and dry the extracted product in a vacuum oven at 60°C to obtain the obtained the above-mentioned compatibili...

Embodiment 2

[0041] Prepare compatibilizer according to following basic composition and mass parts:

[0042] Liquid EPDM T67 100 parts

[0043] (the third monomer is norbornadiene, with a mass content of 9.5%)

[0044] Hydrogen-containing silicone oil (Si-H mass content 0.4%) 40 parts

[0045] Catalyst H 2 PtCl 6 ·6H 2 O(50ppm) 0.8 parts

[0046] making process:

[0047] 1) Dissolution of EPDM rubber: first weigh 100 g of liquid EPDM rubber, then add 1000 ml of cyclohexane, stir and dissolve at room temperature;

[0048] 2) Hydrosilylation reaction: Add 40g of hydrogen-containing silicone oil to the EPDM rubber solution, then add 0.8g of catalyst, and stir and react at a temperature of 60°C;

[0049] 3) Flocculation: Pour the reaction liquid product into boiling water and keep boiling for 30 minutes, evaporate the solvent, extract the product by Soxhlet extraction for 12 hours, and dry the extracted product in a vacuum oven at 60°C to obtain the obtained the above-mentioned compati...

Embodiment 3

[0051] Prepare compatibilizer according to following basic composition and mass parts:

[0052] Liquid EPDM T67 100 parts

[0053] (the third monomer is norbornadiene, with a mass content of 9.5%)

[0054] Hydrogen-containing silicone oil (Si-H mass content 0.4%) 50 parts

[0055] Catalyst H 2 PtCl 6 ·6H 2 O(50ppm) 1 part

[0056] making process:

[0057] 1) Dissolution of EPDM rubber: first weigh 100 g of liquid EPDM rubber, then add 1000 ml of cyclohexane, stir and dissolve at room temperature;

[0058]2) Hydrosilylation reaction: Add 50g of hydrogen-containing silicone oil to the EPDM solution, then add 1g of catalyst, and stir the reaction at a temperature of 60°C;

[0059] 3) Flocculation: Pour the reaction liquid product into boiling water and keep boiling for 30 minutes, evaporate the solvent, extract the product by Soxhlet extraction for 12 hours, and dry the extracted product in a vacuum oven at 60°C to obtain the obtained the above-mentioned compatibilizer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com