Dust-resistant weather-proof additive for processing rubber sealing strips of aluminum alloy doors and windows

A technology of rubber sealing strips and aluminum alloy doors and windows, which is applied in the field of aluminum alloy doors and windows, can solve problems such as easy dust absorption, physical and mechanical performance degradation, and cracks on the surface of sealing strips, so as to prolong the service life, improve dust resistance and weather resistance , Guarantee the effect of using quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Warm up 0.5g of glass fiber powder to 115-120°C and keep grinding for 5 minutes, then add 0.05g of N-isopropylacrylamide and 0.01g of ferrocene, and continue to keep grinding at 115-120°C for 30 minutes to obtain Modified glass fiber powder;

[0018] (2) Add 0.5g of polyether modified silicone oil and 0.05g of vulcanized lard to 5g of chlorinated polyvinyl chloride, raise the temperature to 120-125°C for heat preservation and grinding for 30min, and transfer to 0-5°C to seal and stand for 2h. Then it is made into fine powder by ultrafine pulverizer to obtain modified chlorinated polyvinyl chloride;

[0019] (3) Add 2g of hydrogenated rosin pentaerythritol ester and 0.2g of polyaluminum chloride to the modified chlorinated polyvinyl chloride, heat up to a molten state and mix for 5 minutes, then add 1g of molecular sieve powder and modified glass fiber powder, fully mix to Cool down at a cooling rate of 5°C / min. After the temperature drops to 75-80°C, add 1g of poly...

Embodiment 2

[0022] (1) Warm up 1g of glass fiber powder to 115-120°C for 5 minutes, then add 0.1g of N-isopropylacrylamide and 0.01g of ferrocene, and continue to heat and grind for 30 minutes at 115-120°C. Sexual glass fiber powder;

[0023] (2) Add 1g of polyether modified silicone oil and 0.1g of vulcanized lard to 10g of chlorinated polyvinyl chloride, raise the temperature to 120-125°C for heat preservation and grinding for 1h, and transfer to 0-5°C environment to seal and stand for 2h, then It is made into fine powder by ultrafine pulverizer to obtain modified chlorinated polyvinyl chloride;

[0024] (3) Add 2g of hydrogenated rosin pentaerythritol ester and 0.3g of polyaluminum chloride to the modified chlorinated polyvinyl chloride, heat up to a molten state and mix for 10 minutes, then add 2g of molecular sieve powder and modified glass fiber powder, and fully mix to Cool down at a cooling rate of 5°C / min. After the temperature drops to 75-80°C, add 3g of polyglutamic acid and m...

Embodiment 3

[0039] The additives prepared in Example 1, Example 2, Comparative Example 1, Comparative Example 2, and Comparative Example 3 are prepared according to the ratio of raw materials described in Table 1, and rubber sealing strips of the same specifications are made through the same processing technology. The comparative example 4 of the dust-proof and weather-resistant additive measures the dust-proof and weather-resistant performance of the rubber sealing strip, and the results are shown in Table 2.

[0040] Table 1 Raw material ratio for rubber sealing strip preparation

[0041]

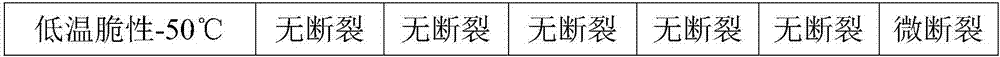

[0042] Table 2 Dustproof and weather resistance performance of rubber sealing strip

[0043]

[0044]

[0045] Ozone resistance test conditions: 50pphm×40℃×72h, tensile 20%;

[0046] Heat air aging test condition: 100℃×168h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com