High-speed grinding machine

A grinding machine, high-speed technology, used in grinding machines, grinding/polishing equipment, grinding/polishing safety devices, etc. Low failure rate and good dustproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

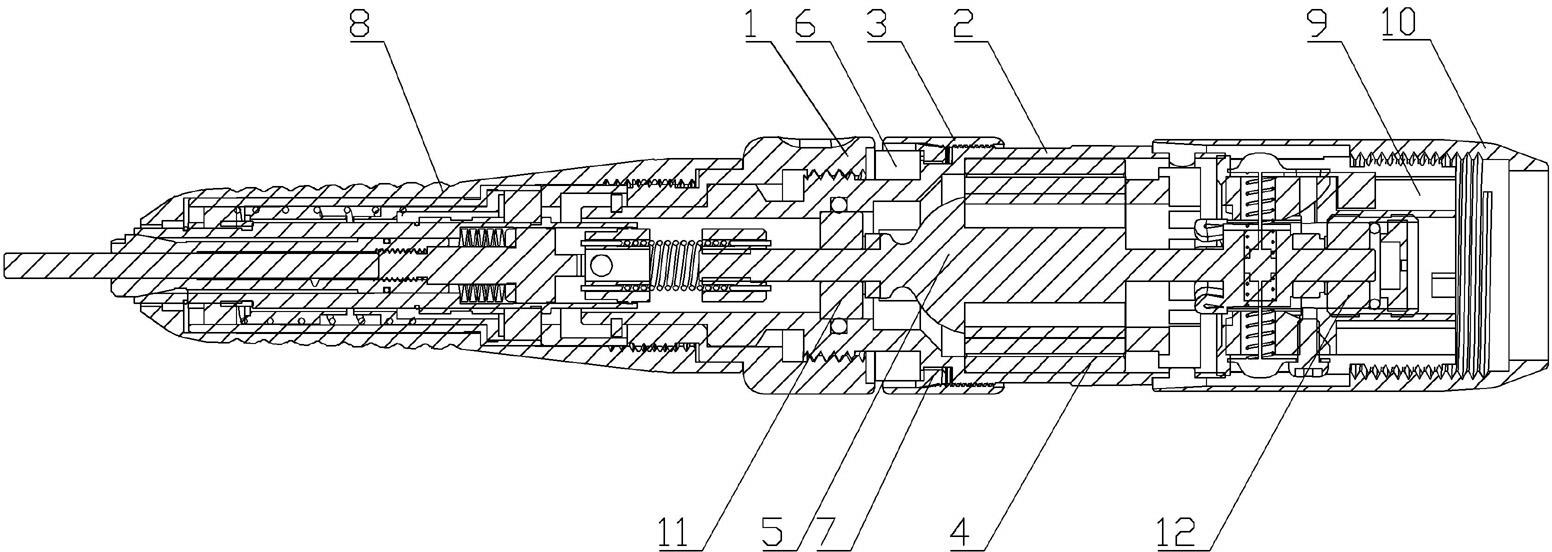

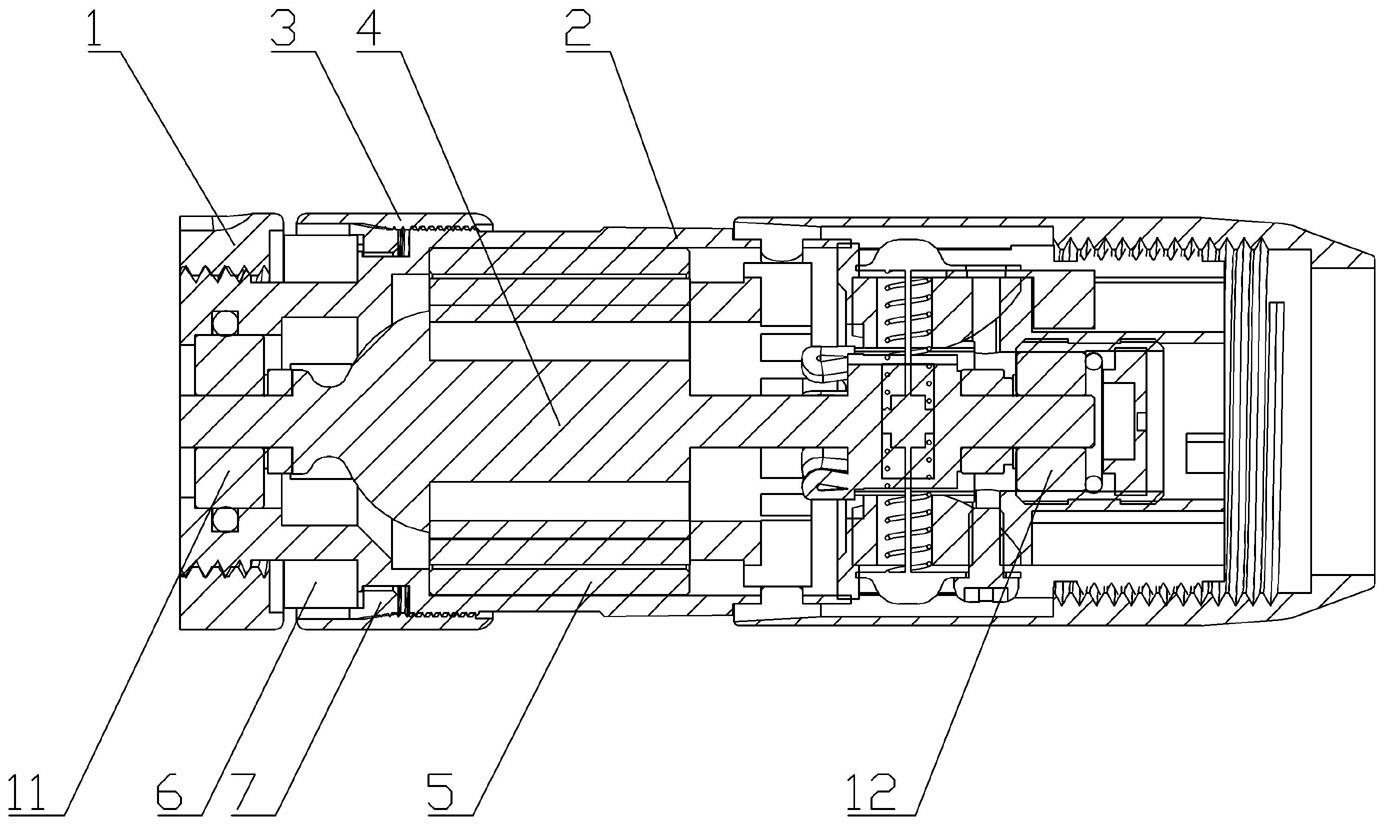

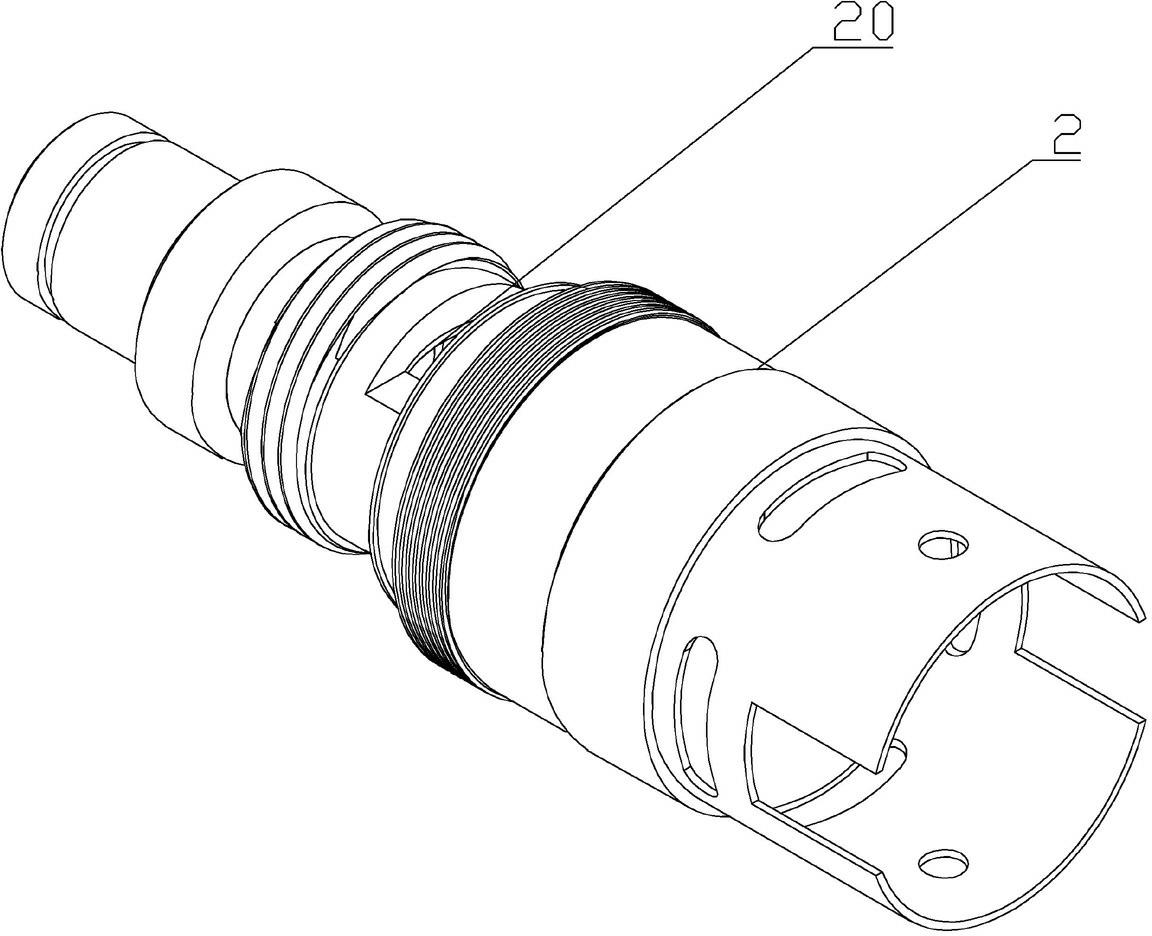

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the present invention includes a front end shell 8, an inner core, a spring connection device, an adjustment seat 1, a motor shell 2, a shield 3, a carbon brush seat 9, and a tail cap 10. The rear end of the front end shell 8 is provided with an internal thread, The front end of the adjustment seat 1 is provided with the external thread connected by the internal thread, the motor housing 2 is provided with a magnetic ring 4 and a rotor 5 matching the magnetic ring 4, and the inner core is located in the In the front end casing 8, and connected with the rotor 5 through the spring connection device, the carbon brush holder 9 is arranged at the tail end of the motor casing 2, and the tail cover 10 wraps the carbon brush holder 9 And it is threadedly connected and fixed with the carbon brush holder 9, the tail of the adjustment seat 1 is provided with an internal thread, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com