Ultrahigh-temperature polyimide heat-conducting insulating material and preparation method thereof

A heat-conducting insulating material and polyimide technology are applied in the field of ultra-ultra-high temperature polyimide heat-conducting insulating material and its preparation, which can solve the problems of low heat resistance level and aggravated thermal-oxidative aging failure of organic materials, and reduce thermal expansion. coefficient, excellent high temperature thermo-oxidative/thermal stability, the effect of eliminating negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

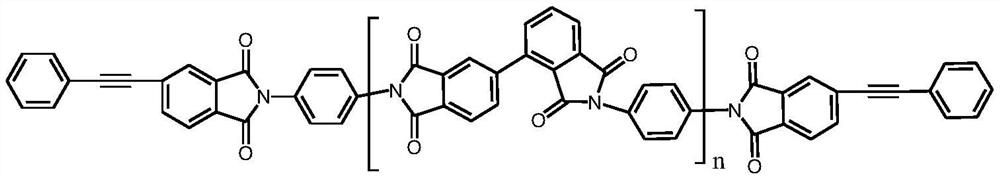

[0037] A method for preparing an extremely ultra-high temperature polyimide thermally conductive insulating material, comprising the following steps:

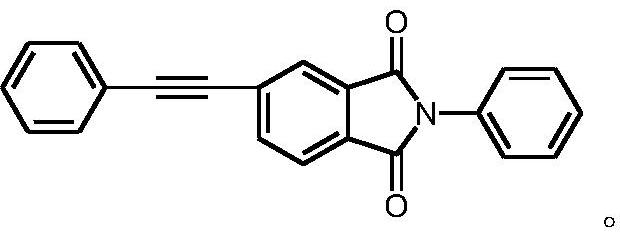

[0038] 100 parts of reactive polyimide resin synthesized from 2,3',3,4'-biphenyltetracarboxylic dianhydride, p-phenylenediamine and phenylethynyl phthalic anhydride, 10 parts of micron boron nitride Add powder, 3 parts of micron-sized PEEK particles, 1 part of lanthanum trioxide, and 5 parts of active diluent synthesized from phenylethynyl phthalic anhydride and aniline into a closed pressure-resistant kettle and stir evenly. Heat the mixed powder to 300°C and stir Vacuumize and degas for 30 minutes to obtain perfusion resin glue;

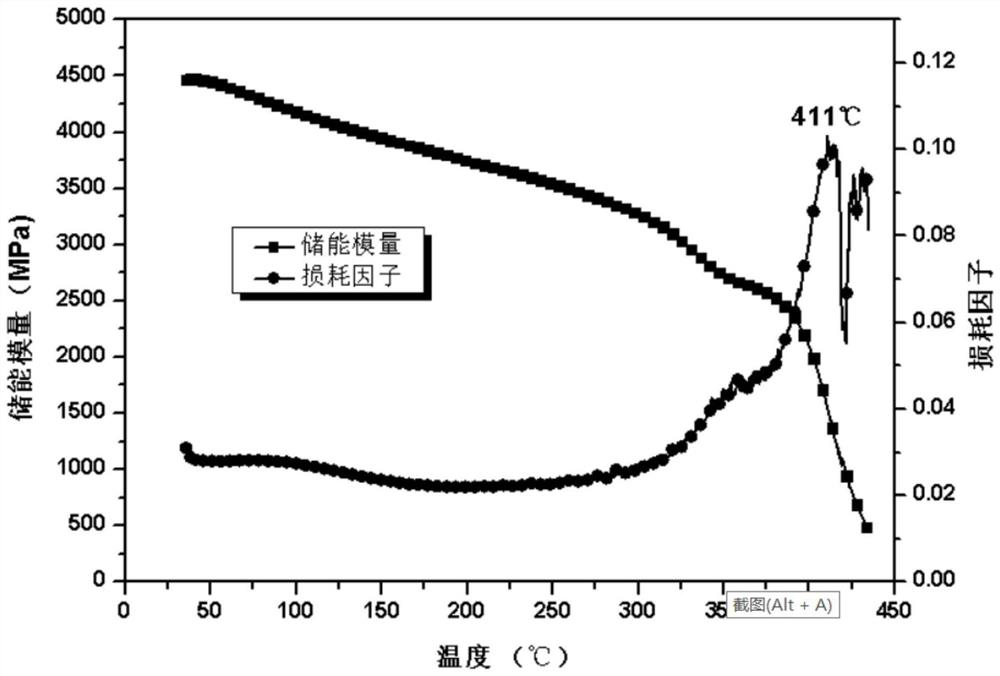

[0039] Pour the pouring resin glue into the mold, and cure it in a multi-stage gradient temperature program of 300°C / 1h+350°C / 2h+380°C / 2h to obtain a cured product of an ultra-ultra-high temperature polyimide thermally conductive insulating material. The DMA curve of the cured product of extremely ...

Embodiment 2

[0045] A method for preparing an extremely ultra-high temperature polyimide thermally conductive insulating material, comprising the following steps:

[0046] 100 parts (by mass) of a reactive poly Add imide resin, 5 parts of micron-sized boron nitride powder, 3 parts of micron-sized PEEK particles, 1 part of dilanthanum trioxide, and 5 parts of reactive diluent synthesized from phenylethynyl phthalic anhydride and aniline into a closed pressure-resistant kettle and stir Evenly, heat to 280°C, stir, vacuum and degas for 60 minutes to obtain the perfusion resin glue; pour the perfusion resin glue into the mold, and cure according to the multi-stage gradient heating program of 280°C / 1h+330°C / 2h+370°C / 2h , to obtain a cured product of an extremely ultra-high temperature polyimide thermally conductive insulating material. The cured product of ultra-ultra-high temperature polyimide thermal insulation material has a glass transition temperature of 390°C, an initial thermal decompos...

Embodiment 3

[0052] A method for preparing an extremely ultra-high temperature polyimide thermally conductive insulating material, comprising the following steps:

[0053] 100 parts of reactive polyimide resin synthesized by hexafluoroisopropyl phthalic anhydride, m-phenylenediamine and ethynyl phthalic anhydride, 10 parts of micron-sized boron nitride powder and 5 parts of micron-sized alumina powder , 5 parts of micron-sized PEEK particles, 0.5 parts of lanthanum trioxide, and 5 parts of active diluent synthesized from ethynyl phthalic anhydride and 1-naphthylamine were added to a closed pressure-resistant kettle and stirred evenly, heated to 200 ° C, stirred and vacuumed for degassing After 30 minutes, the perfusion resin glue was obtained; the perfusion resin glue was poured into the mold, and cured according to the temperature rise program of 250°C / 1h+310°C / 2h+360°C / 2h to obtain a cured product of the insulating material. The glass transition temperature of the cured product is 376°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com