Application of lignin in preparation of radial tires

A radial tire and lignin technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of endangering the health of workers, easy sublimation of resorcinol, environmental pollution, etc., to improve various performances, Effect of improving thermo-oxidative aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

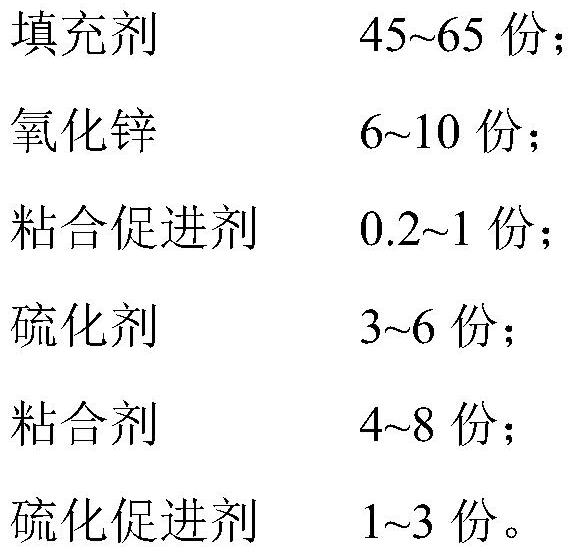

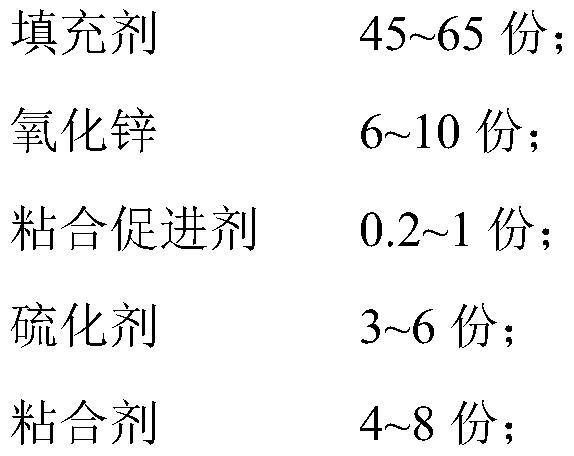

[0040] Basic formula: 100 parts of natural rubber; filler: 55 parts of carbon black N234; antioxidant: 0.3 parts of RD, 1 part of 40201; 10 parts of zinc oxide; adhesion promoter: 1 part of cobalt caprate; vulcanizing agent: 6 parts of sulfur OT20 Adhesive: 4 parts of RA-65; Vulcanization accelerator: 2 parts of MBTS (DM), which also contains resorcinol-80 and enzymatic lignin, the amount of both is shown in Table 1.

[0041] The preparation process is as follows:

[0042](1) One stage of mastication: according to the formula ratio, place the natural rubber in the mixing chamber of the internal mixer to press the weight for 40 seconds, the temperature of the rubber material is 160-170°C, and the rubber is discharged; the rotor speed is 50rpm, and the pressure is 0.7MPa;

[0043] (2) Two-stage mixing: the plasticized rubber obtained in step (1), filler, anti-aging agent, zinc oxide, adhesive, adhesion promoter and resorcinol, or enzymatically decomposed lignin and resorcinol ...

Embodiment 2

[0051] Example 2: Same as Example 1-2, only the enzymatic lignin is air-pulverized to different particle sizes, and the test results are shown in Table 2.

[0052] Table 2

[0053]

[0054] Note: The above particle size refers to d50.

[0055] It can be seen from Table 2 that the performance of the product is better as the particle size of lignin decreases; among them, when the particle size of lignin exceeds 8 μm, the performance drops significantly; when the particle size of lignin is 1.8 μm When the particle size of lignin is 3.8 μm, its performance is the best; when the particle size of lignin is 3.8 μm, its overall performance is not much different from that of 1.8 μm; in the course of the experiment, if the lignin is airflow crushed to 1.8 μm, every The hourly output is low and the energy consumption is high. Therefore, from the perspective of cost and performance, generally speaking, the particle size of lignin can be selected to be 1-5 μm.

Embodiment 3

[0057] 3.1 Same as Example 1-2, only the enzymatic lignin in 1-2 in the embodiment is replaced by alkali lignin (3-1), soda lignin (3-2), organic solvent lignin (acetic acid lignin prime) (3-3), the test results are shown in Table 5.

[0058] 3.2 Same as in Example 1-5, except that the enzymatic lignin in Example 1-5 was replaced with acetate lignin (3-4), the test results are shown in Table 3.

[0059] table 3

[0060]

[0061] As can be seen from Table 3, lignin acetate can effectively replace resorcinol, and after 5 parts of lignin acetate replaces 1 part of resorcinol, its tensile strength at break can be compared with that of Example 1-1 (completely resorcinol Diphenol, without lignin replacement) at the same level, and other properties are also better than Example 1-1, especially the steel drawing performance reaches 732N / mm, thereby opening up a new method for preparing radial tires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com