Polyolefin material with high thermal shrinkage resistance, high toughness and thermo-oxidative aging resistance as well as preparation method and application thereof

A high heat-resistant polyolefin technology, applied in the field of engineering plastics, can solve problems such as limited compatibility, decreased heat-oxidative aging resistance, poor compatibility, etc., and achieve the effect of improving toughness and thermal-oxidative aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~17

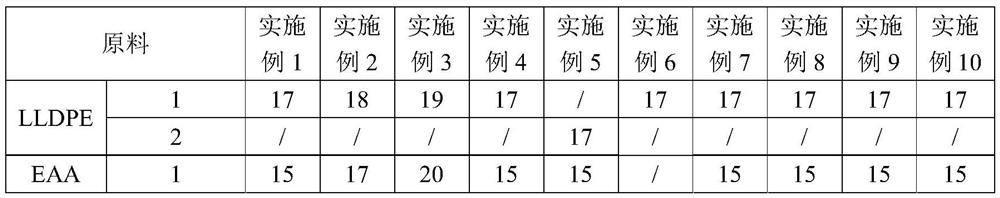

[0066] This embodiment provides a series of high heat-resistant shrinkage, high-toughness heat-resistant oxygen aging polyolefin materials, which are prepared according to the formulas in Tables 1-2 and according to the preparation method including the following steps:

[0067] The linear low density polyethylene LLDPE, ethylene-acrylic acid copolymer EAA, polyolefin elastomer POE, ammonia modified halogen-free flame retardant, compatibilizer, dispersant, antioxidant and other additives are listed in Tables 1-2. The ratio is added to the high-speed mixer and mixed for 5min, and the rotating speed of the high-speed mixer is 1000~3000 rev / min, and the mixture is obtained after mixing evenly; ), at 175-200°C (the temperature of the ten zones of the twin-screw extruder from the feeding section to the die head is 175°C, 175°C, 180°C, 180°C, 180°C, 190°C, 190°C, 190°C °C, 200 °C, 200 °C), melt extrusion and granulation at 350-450 rpm rotating speed.

[0068] Table 1 Content (parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com