Composite membrane and electrochemical device

A technology of composite diaphragm and polymer film, which is applied in the direction of electrochemical generators, circuits, electrical components, etc., can solve the problem of thermal bonding coating, shrinkage performance and interface bonding performance of the diaphragm, and it is difficult to take into account the high energy density of the battery And high safety, reduce battery energy density and other issues, to achieve the effect of improving interface adhesion, high strength, and increasing energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

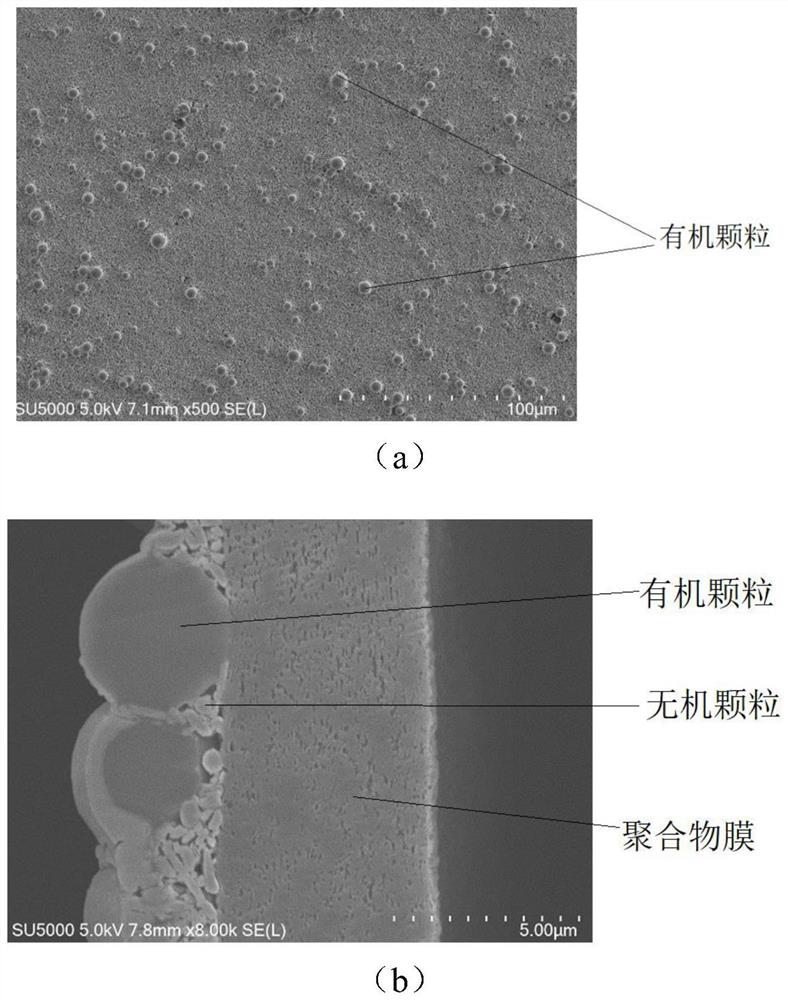

[0034] The method of preparing the composite diaphragm provided by the present invention, comprising: mixing inorganic particles and organic particles to form a mixed coating, coating the mixed coating on at least one surface of the polymer film, after drying, forming a functional coating to obtain a composite diaphragm .

[0035] In the specific implementation process of the present invention, the inorganic particles are first dispersed in the solvent to form a first mixture; the organic particles are dispersed in the solvent to form a second mixture; and then the first mixture and the second mixture The stirring is uniform, form a third mixture; the third mixture is evenly applied to at least one surface of the polymer film, and the functional coating is formed after drying, and the composite diaphragm is obtained.

[0036] Specifically, the coating method includes a gravure coating, a wire coating, a spray coating, and the like. The mixed coating was coated with one or both sur...

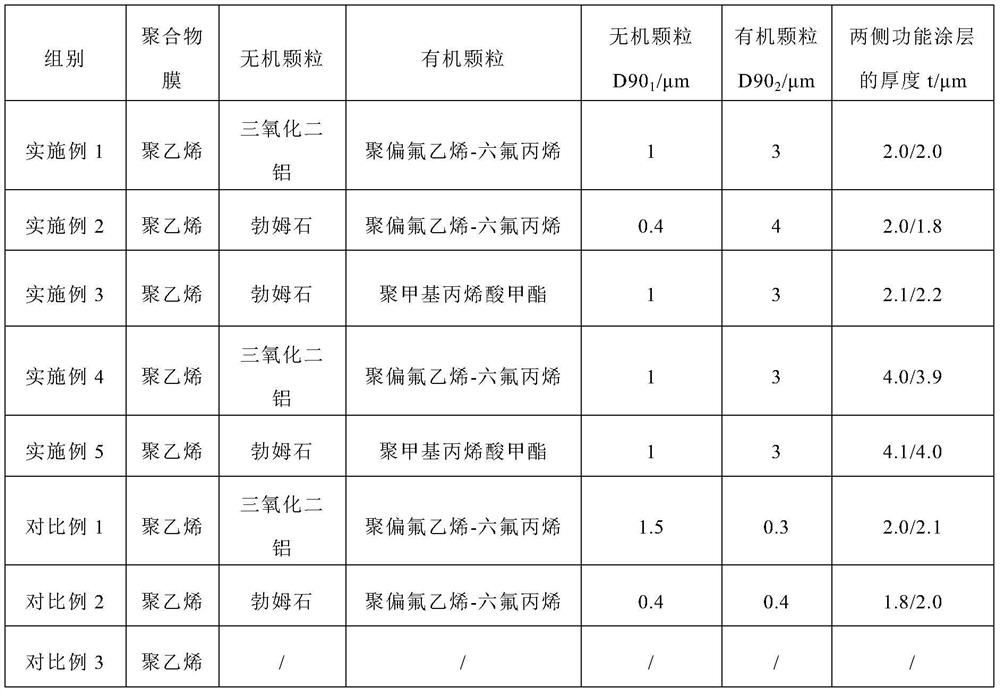

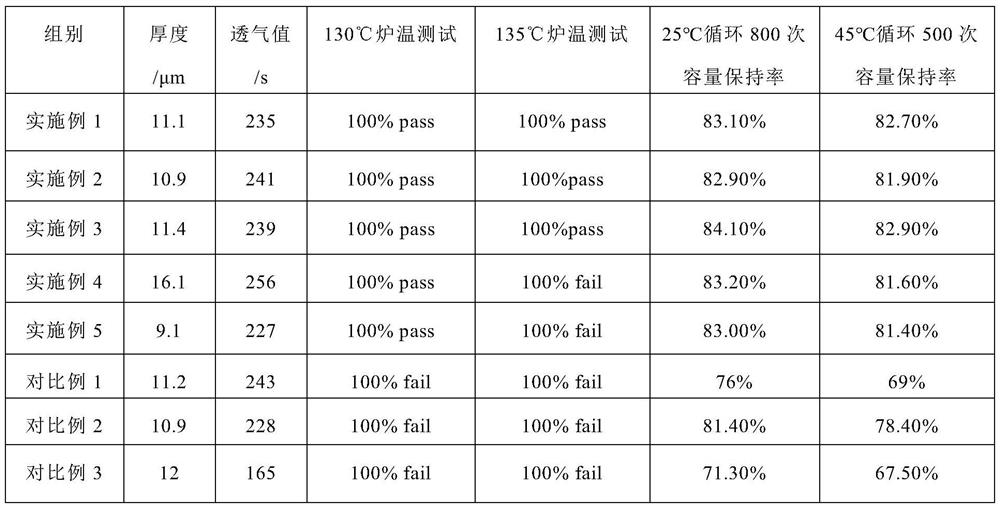

Embodiment 1

[0054] Preparation of composite diaphragm

[0055] Will D90 1 = 1.0 μm of the aluminum dioxide particles were added to deionized water, stirred for 30 minutes to obtain the first mixture; again D90 2 The polyvinylidene fluoride-hexafluoropropylene particles were added to deionized water, and the mixture was dispersed for 30 minutes to obtain a second mixture, and the first mixture was mixed with the second mixture, and the third mixture was uniformly obtained. The mass ratio of the oxide particles and polyvinylidene fluoride-hexafluoropropylene particles is 6: 4 (1.5: 1);

[0056]When the gravure coating is used, the third mixture is evenly applied to both surfaces of the polyethylene microporous membrane having a thickness of 7.1 μm. After drying, the thickness of the functional coating on both surfaces of the polyethylene microporous membrane is respectively. It was 2.0 μm, 2.0 μm, a composite diaphragm having a total thickness of 11.1 μm.

[0057] Preparation of lithium ion bat...

Embodiment 2

[0060] Put D90 1 = 0.4 μm Bumble particles were added to dendomethacolamide (DMAC), and the mixture was stirred for 30 minutes to obtain the first mixture. Put D90 2 The polyvinylidene fluoride-hexafluoropropylene particles of 4 μm were added to the DMAC, and the mixture was dispersed for 30 minutes to obtain a second mixture. The first mixture was added to the second mixture, and the distraction was mixed and dispersed evenly to obtain a third mixture, wherein the mass ratio of boehmite particles and polyvinylidene fluoride-hexafluoropropylene particles was 1.5: 1;

[0061] The third mixture is evenly applied to both sides of the polyethylene microporous membrane of 7.1 μm thick. After drying, the thickness of the polymer film is 2.0 μm, 1.8 μm, respectively. A composite diaphragm having a total thickness of 10.9 μm was obtained.

[0062] Preparation of lithium ion batteries

[0063] The complex diaphragm and the negative electrode sheet in Example 2 were laminated, and the bare ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com