Material and preparation method of damping spacer rubber parts for UHV transmission lines

A transmission line and spacer technology, applied in the field of rubber materials and their preparation, can solve the problems of corona discharge, poor comprehensive performance, affecting the safe use of wires, etc., and achieve excellent weather resistance, high elasticity and low compression set. The effect of excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

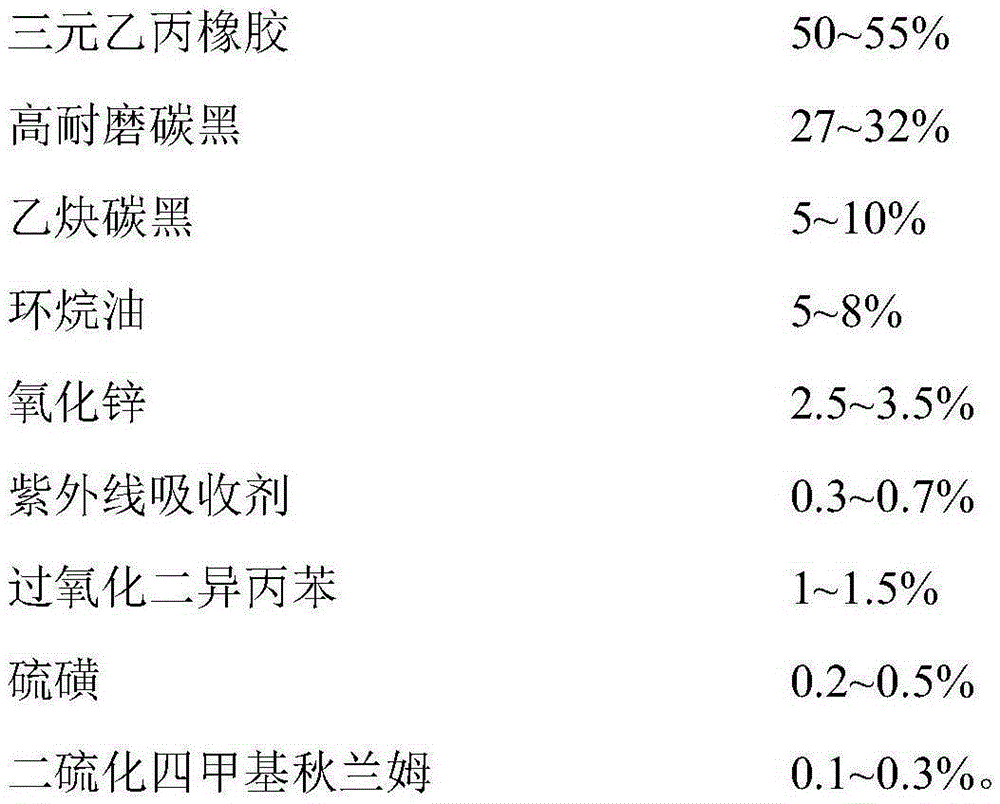

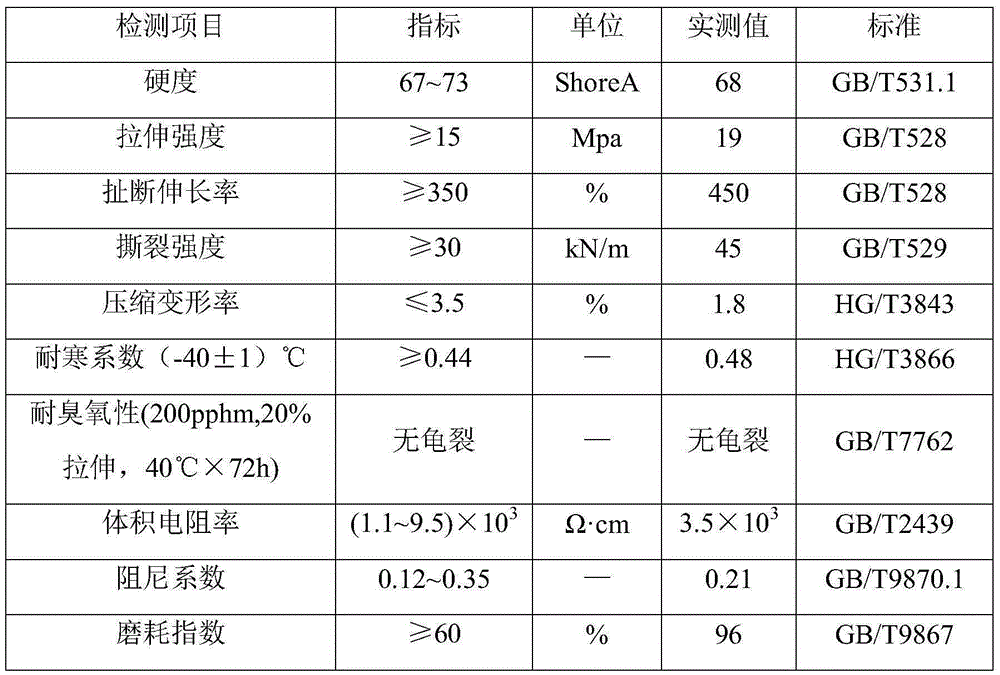

[0029] The material of a damping spacer rubber part for UHV transmission lines in this embodiment, its components and weight percentages are shown in Table 1.

[0030] Table 1 Embodiment 1 The material components and percentage content of the rubber parts

[0031] Raw material name

Percentage %

EPDM

55

High wear-resistant carbon black

27

Acetylene Black

8

naphthenic oil

5

2.5

0.5

1.5

0.3

0.2

[0032] The acetylene carbon black in this example is provided by Hebei Tengfei Carbon Black Chemical Co., Ltd. The main performance parameters are: iodine absorption value ≥ 90g / kg, resistivity ≤ 2.5Ω·m. The ultraviolet absorber is ultraviolet absorber UV-12, provided by Shanghai Wenhua Chemical Pigment Co., Ltd., its molecular weight is 326, and its melting point is 48~49°C. EPDM rubber is J-4...

Embodiment 2

[0043] Table 2 shows the components and weight percentages of the material of a damping spacer rubber part for UHV transmission lines in this embodiment.

[0044] The material composition and percentage content of table 2 embodiment 2 rubber parts

[0045] Raw material name

Percentage %

EPDM

50

High wear-resistant carbon black

32

Acetylene Black

5

naphthenic oil

8

2.5

0.3

1.4

0.5

0.3

[0046] The manufacturers and performance parameters of each component in this implementation are the same as in Example 1, and the material formula of the above-mentioned UHV transmission line damping spacer rubber part is adopted in this embodiment, and the steps of its preparation method are:

[0047] (1) Masterbatch mixing:

[0048] Put EPDM rubber, zinc oxide, and ultraviolet absorber in an interna...

Embodiment 3

[0055] Table 3 shows the components and weight percentages of the material of the damping spacer rubber parts for UHV transmission lines in this embodiment.

[0056] The material composition and percentage content of table 3 embodiment 3 rubber parts

[0057] Raw material name

Percentage %

EPDM

52

High wear-resistant carbon black

30

Acetylene Black

7

naphthenic oil

5.6

Zinc oxide

3

0.7

dicumyl peroxide

1.0

sulfur

0.4

0.3

[0058] The manufacturers and performance parameters of each component in this implementation are the same as in Example 1, and the material formula of the above-mentioned UHV transmission line damping spacer rubber part is adopted in this embodiment, and the steps of its preparation method are:

[0059] (1) Masterbatch mixing:

[0060] Put EPDM rubber, zinc oxide, and ultraviolet absorber in an inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com