Styrenic thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and thermoplastic elastic technology, applied in the field of thermoplastic elastomer and its preparation, can solve the problems of harming the human body and the environment, and achieve the effects of avoiding harm, not obvious yellowing, and improving thermal oxygen aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

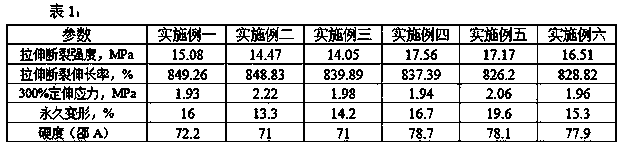

Embodiment 1

[0029] Get 2533g styrene-based thermoplastic elastomer glue, add 1000ppm primary antioxidant KD-A1080, 4500ppm secondary antioxidant 168 and 200g white naphthenic oil to it successively, use high-shear emulsifier to stir for 15 minutes, use water Steam stripping removes the organic solvent in the glue to obtain a rubber block, which is rolled on a double-roller rubber mixer to remove moisture, and the sample preparation method is tested according to the relevant mechanical properties, and mixed at a certain temperature. Use a flat vulcanizer to mold a 2mm thick sample at 165±0.5°C, place it in a constant temperature and humidity box for 24 hours, then cut it into a dumbbell-shaped rubber test sample, one part is used for mechanical performance testing, and the other part The specimens were placed in a thermo-oxidative aging test chamber for thermo-oxidative aging at 70±1°C, and samples were taken regularly to observe the changes of the specimens. The results are shown in Table ...

Embodiment 2

[0031] Take 2533g styrene thermoplastic elastomer glue, add 3000ppm primary antioxidant KD-A1080, 4450ppm secondary antioxidant and 200g white naphthenic oil to it successively. After using a high-shear emulsifier to stir for 15 minutes, steam stripping was used to remove the organic solvent in the glue to obtain a rubber block, which was rolled on a double-roller rubber mixer to remove moisture, and according to the relevant mechanics Performance test sample preparation method, kneading at a certain temperature, molded into a 2mm thick sample with a flat vulcanizer at 165±0.5°C, placed in a constant temperature and humidity box for 24 hours, and cut it into a dumbbell-shaped rubber test sample One part of the sample is used for mechanical performance testing, and the other part of the sample is placed in a thermo-oxidative aging test box for thermo-oxidative aging at 70±1°C. Regular sampling is performed to observe the changes of the sample. The results are shown in Table 1. ...

Embodiment 3

[0033]Take 2533g styrene thermoplastic elastomer glue, add 5000ppm primary antioxidant KD-A1080, 4450ppm secondary antioxidant and 200g white naphthenic oil to it successively. After using a high-shear emulsifier to stir for 15 minutes, steam stripping was used to remove the organic solvent in the glue to obtain a rubber block, which was rolled on a double-roller rubber mixer to remove moisture, and according to the relevant mechanics Performance test sample preparation method, kneading at a certain temperature, molded into a 2mm thick sample with a flat vulcanizer at 165±0.5°C, placed in a constant temperature and humidity box for 24 hours, and cut it into a dumbbell-shaped rubber test sample One part of the sample is used for mechanical performance testing, and the other part of the sample is placed in a thermo-oxidative aging test box for thermo-oxidative aging at 70±1°C. Regular sampling is performed to observe the changes of the sample. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com