Method for synthesizing special resin for PE100 pipe fitting

A synthetic method and resin technology, which is applied in the field of synthetic resin, can solve the problems of inability to meet the domestic market demand, high price, and unstable performance, and achieve the effects of increasing mutual binding ability, high pressure resistance, and improving thermal oxygen aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

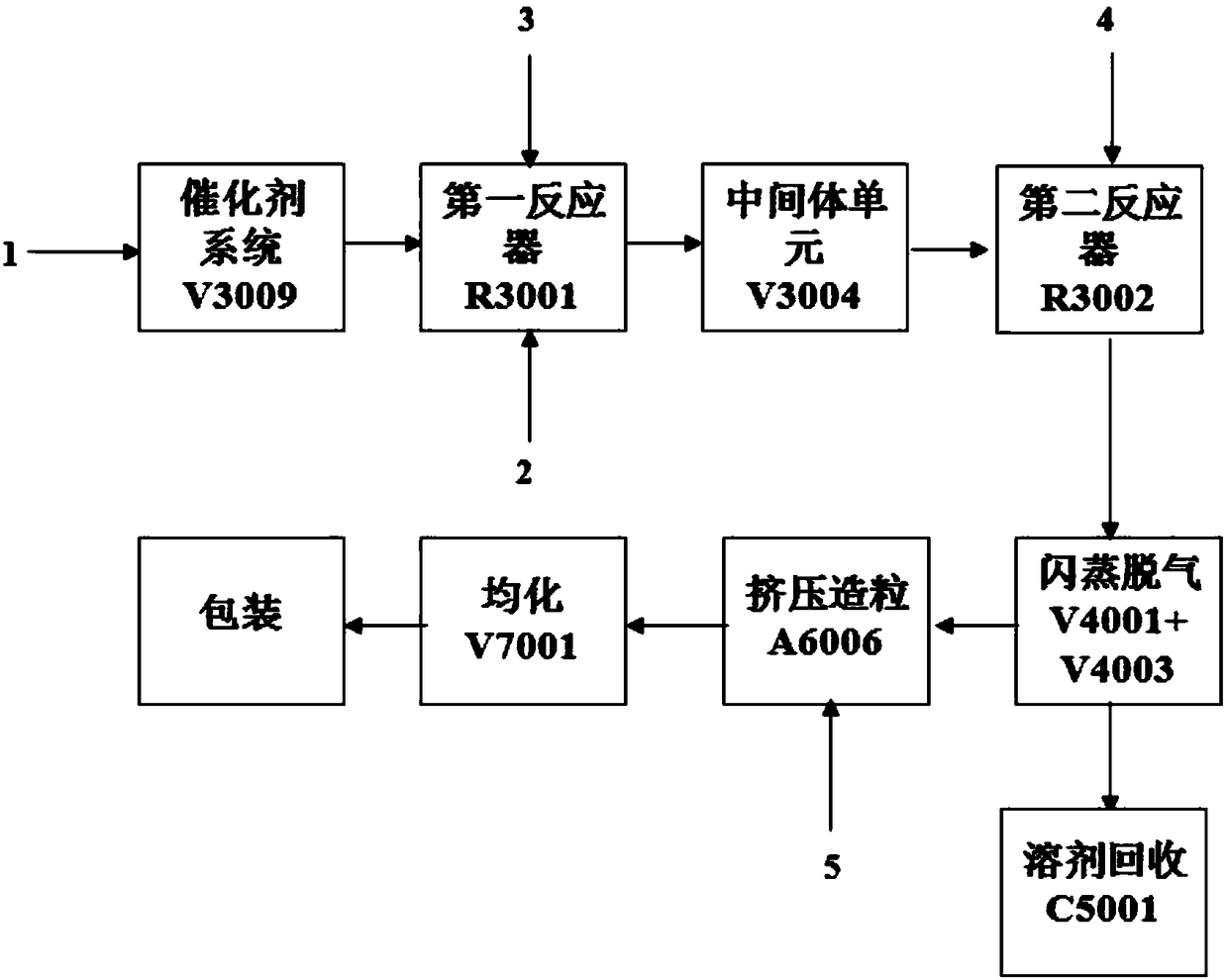

Method used

Image

Examples

Embodiment 1

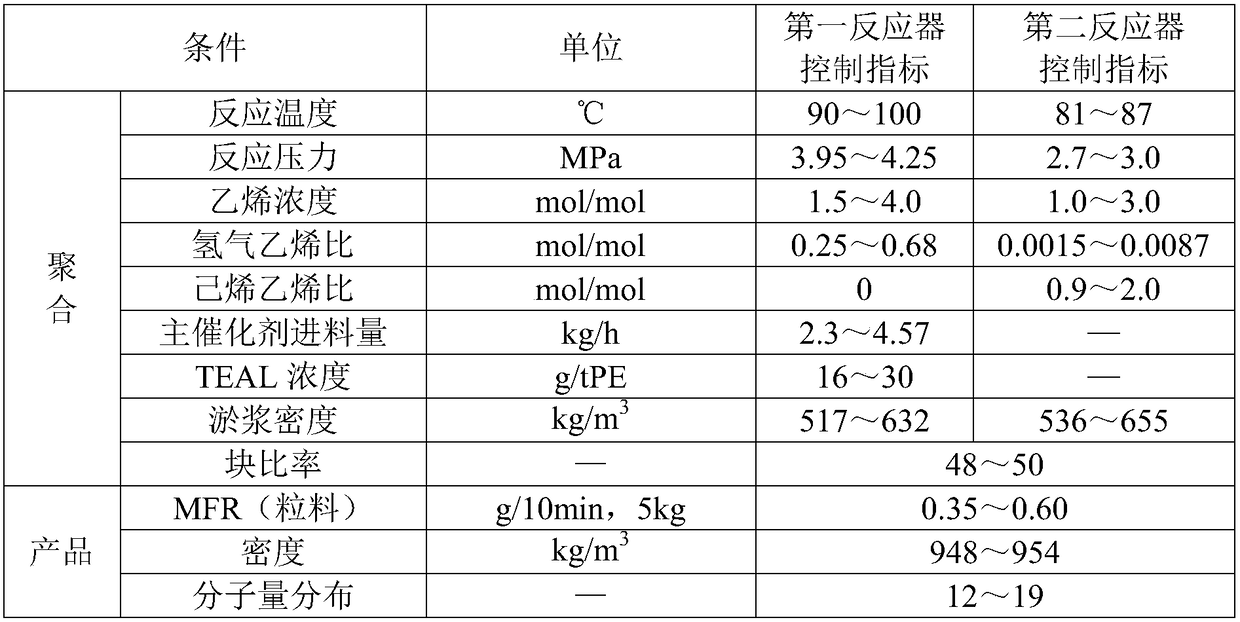

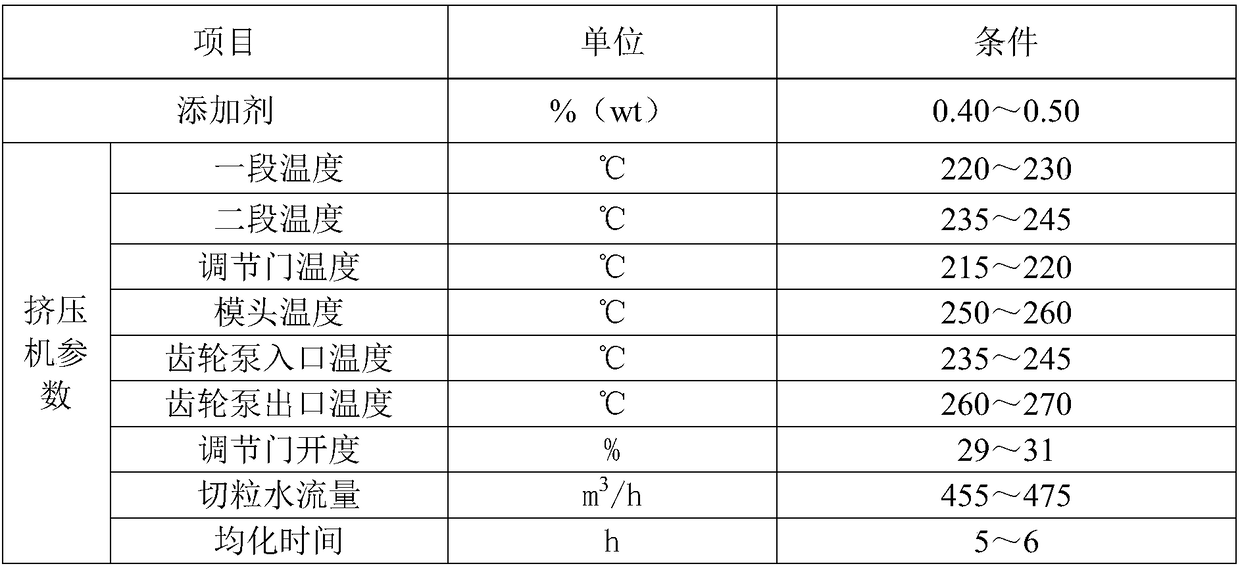

[0064] Using the Innovene S low-pressure slurry double-loop polyethylene device, after diluting the main catalyst in V3009, inject it into the first reactor R3001 at a concentration of 2.3kg / h together with triethylaluminum, and maintain the concentration of R3001 at 22kg / tPE to maintain the pressure 4.1MPa, reaction temperature 102°C, add hydrogen and ethylene with molar ratio of 0.68:1 to R3001, slurry density 517kg / m 3 , after the reaction, the above product is treated with intermediates to remove hydrogen, and then transported to the second reactor R3002, the pressure of R3002 is 2.8MPa, and the reaction temperature is 82°C. Add R3002 at a molar ratio of 0.0077:1 to control the slurry density to 574g / m 3 The ratio of polymer block is 48.5. After the reaction, the product is desolventized by high-pressure flash evaporation and low-pressure flash evaporation, and the solvent containing hexene enters the solvent recovery system C5001 for recovery. Add the product after dehyd...

Embodiment 2

[0066] Using the Innovene S low-pressure slurry double-loop polyethylene device, after diluting the main catalyst in V3009, inject it into the first reactor R3001 at a concentration of 3.1kg / h together with triethylaluminum, and maintain the concentration of R3001 at 30kg / tPE to maintain the pressure 4.0MPa, reaction temperature 95°C, add hydrogen and ethylene with a molar ratio of 1.25:1 to R3001, slurry density 555kg / m 3 , after the reaction, the above product is treated with intermediates to remove hydrogen, and then transported to the second reactor R3002, the pressure of R3002 is 2.9MPa, and the reaction temperature is 81°C. Add R3002 at a molar ratio of 0.0039:1 to control the slurry density to 536kg / m 3 , The ratio of polymer blocks is 48. After the reaction, the product is desolventized by high-pressure flash evaporation and low-pressure flash evaporation, and the solvent containing hexene enters the solvent recovery system C5001 for recovery. Add the product after de...

Embodiment 3

[0068] Using the Innovene S low-pressure slurry double-loop polyethylene device, after diluting the main catalyst in V3009, inject it into the first reactor R3001 at a concentration of 4.57kg / h together with triethylaluminum, and maintain the concentration of R3001 at 16kg / tPE to maintain the pressure 3.9MPa, reaction temperature 93°C, add hydrogen and ethylene with molar ratio of 0.93:1 to R3001, slurry density 632kg / m 3 , after the reaction, the above product is treated with intermediates to remove hydrogen, and then transported to the second reactor R3002, the pressure of R3002 is 2.7MPa, and the reaction temperature is 87°C. Add R3002 at a molar ratio of 0.0015:1 to control the slurry density to 580kg / m 3 The ratio of polymer block is 50. After the reaction, the product is desolventized by high-pressure flash evaporation and low-pressure flash evaporation, and the solvent containing hexene enters the solvent recovery system C5001 for recovery. Add the product after dehydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com