Preparation method of composite polyurethane waterproof coating

A composite polyurethane and waterproof coating technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of affecting waterproof durability, mechanical ultraviolet aging resistance and poor thermal oxygen aging performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

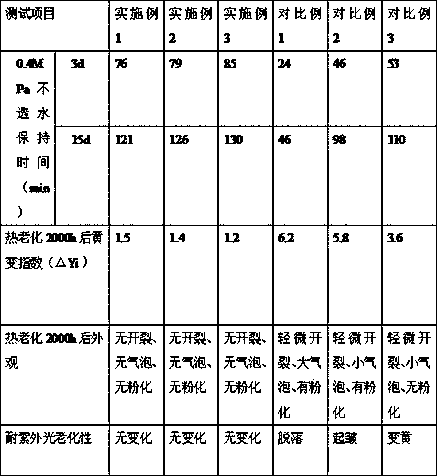

Examples

Embodiment 1

[0043] Preparation of silicone microcapsules:

[0044] According to the mass ratio of 1:4:20, polyvinyl alcohol, maltodextrin and water are mixed and placed in an ultrasonic oscillator, and dissolved by ultrasonic vibration at a frequency of 25kHz to obtain a coating solution, and then the mass ratio is 1:8. Methylcyclotetrasiloxane and coating liquid are mixed and placed in a high-speed disperser, and dispersed at a high speed of 3000r / min for 5 minutes to obtain an oil-in-water emulsion, and then the oil-in-water emulsion is sprayed with a spray dryer Dried to obtain organosilicon microcapsules for subsequent use;

[0045] Preparation of clear and transparent hydrolyzate:

[0046] According to the mass ratio of 1:2:5, mix ethyl orthosilicate with absolute ethanol and deionized water evenly, and dropwise drop into nitric acid solution with a concentration of 0.5mol / L, and stir until ethyl orthosilicate is hydrolyzed to obtain Clear and transparent hydrolyzate;

[0047] Pre...

Embodiment 2

[0058] Preparation of silicone microcapsules:

[0059] According to the mass ratio of 1:4:20, polyvinyl alcohol, maltodextrin and water are mixed and placed in an ultrasonic oscillator, and dissolved by ultrasonic vibration at a frequency of 30 kHz to obtain a coating solution, and then the mass ratio is 1:8. Methylcyclotetrasiloxane and coating liquid are mixed and placed in a high-speed disperser, and dispersed at a high speed of 3500r / min for 7.5 minutes to obtain an oil-in-water emulsion, and then the oil-in-water emulsion is sprayed with a spray dryer Spray drying to obtain organosilicon microcapsules for subsequent use;

[0060] Preparation of clear and transparent hydrolyzate:

[0061] According to the mass ratio of 1:2:5, mix ethyl orthosilicate with absolute ethanol and deionized water evenly, and dropwise drop into nitric acid solution with a concentration of 0.5mol / L, and stir until ethyl orthosilicate is hydrolyzed to obtain Clear and transparent hydrolyzate;

...

Embodiment 3

[0073] Preparation of silicone microcapsules:

[0074] According to the mass ratio of 1:4:20, polyvinyl alcohol, maltodextrin and water are mixed and placed in an ultrasonic oscillator, and dissolved by ultrasonic vibration at a frequency of 35kHz to obtain a coating solution, and then the mass ratio is 1:8. Methylcyclotetrasiloxane and coating liquid are mixed and placed in a high-speed disperser, and dispersed at a high speed of 4000r / min for 10 minutes to obtain an oil-in-water emulsion, and then the oil-in-water emulsion is sprayed with a spray dryer Dried to obtain organosilicon microcapsules for subsequent use;

[0075] Preparation of clear and transparent hydrolyzate:

[0076] According to the mass ratio of 1:2:5, mix ethyl orthosilicate with absolute ethanol and deionized water evenly, and dropwise drop into nitric acid solution with a concentration of 0.5mol / L, and stir until ethyl orthosilicate is hydrolyzed to obtain Clear and transparent hydrolyzate;

[0077] Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com