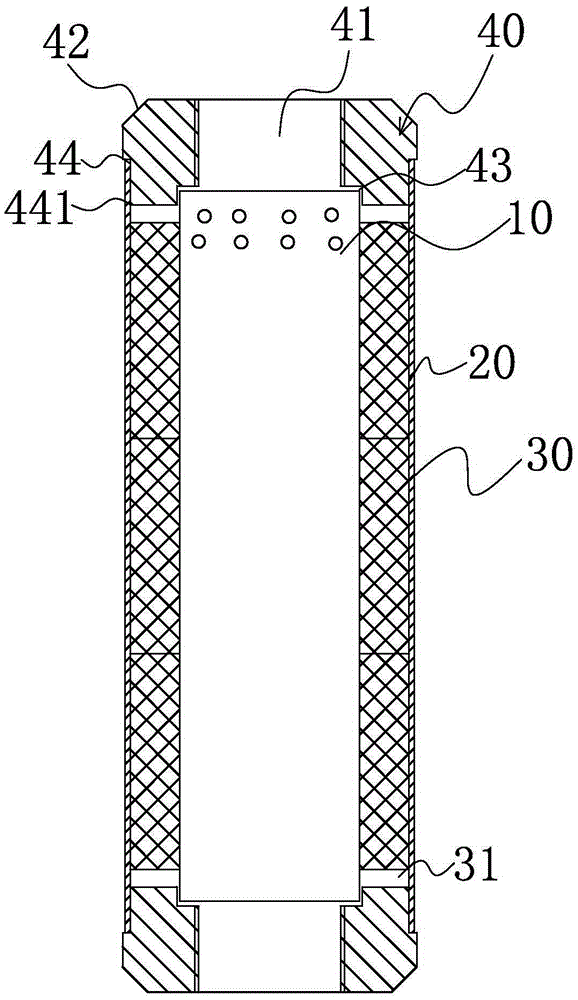

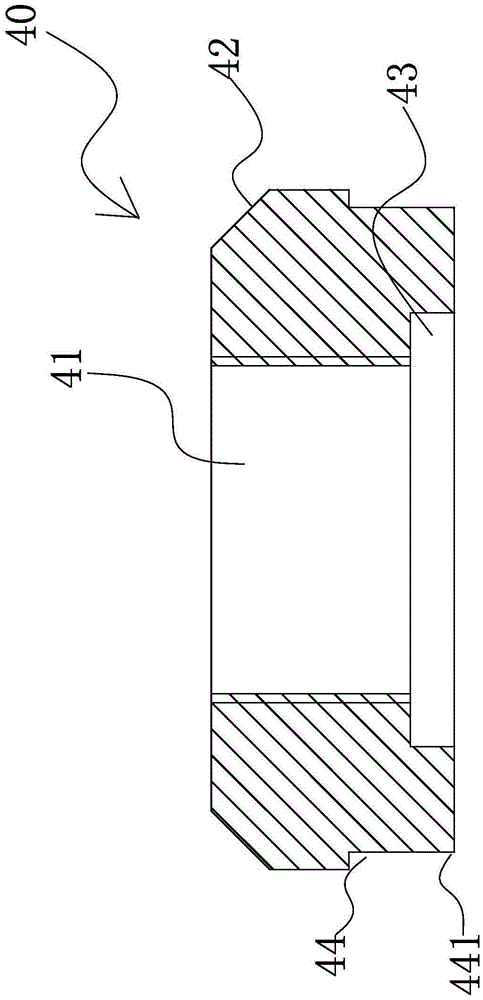

Muffler

A technology of muffler and muffler mesh is applied in the direction of machine/engine, liquid fuel engine, mechanical equipment, etc., which can solve the problems of inconvenient installation and disassembly of the machine, insufficient corrosion resistance, and large volume of the muffler, and can improve the room temperature and high temperature. Mechanical properties, improved processing properties, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

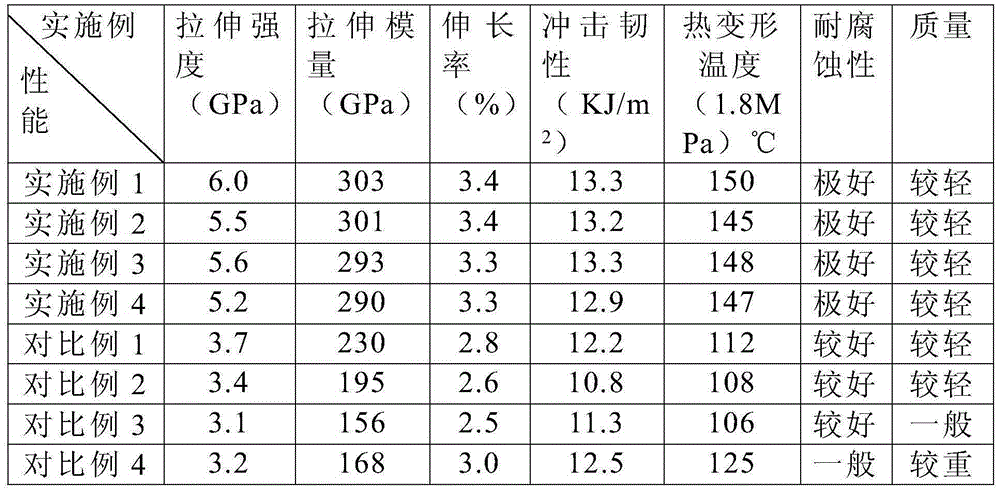

Embodiment 1

[0065] Mix epoxy resin, flow modifier, heat-resistant modifier, compatibilizer, primary antioxidant, auxiliary antioxidant, and processing aid in a high-speed mixer in the following percentages by weight: bisphenol A epoxy 45wt% resin; 5wt% flow modifier; 2wt% heat-resistant modifier; 5wt% compatibilizer; 0.4wt% primary antioxidant; 0.4wt% secondary antioxidant; The flow modifier is maleic anhydride grafted acrylate and styrene copolymer; the heat-resistant modifier is N,N'-(4,4'-methylenediphenyl)bis One or both of maleimide and maleic anhydride grafted polystyrene; the main antioxidant is antioxidant 1076, antioxidant 1098, antioxidant 1010, antioxidant 2246, One or more of the antioxidant 4010 or the antioxidant DNP; the auxiliary antioxidant is one or both of the antioxidant 168 or the antioxidant 626.

[0066] The mixed raw materials are melted by the twin-screw extruder, and at the same time, 15wt% of alkali-free glass fiber and 25wt% of mineral fiber are added to the s...

Embodiment 2

[0068] Mix epoxy resin, flow modifier, heat-resistant modifier, compatibilizer, primary antioxidant, auxiliary antioxidant, and processing aid in a high-speed mixer in the following percentages by weight: bisphenol A epoxy 48wt% resin; 1wt% flow modifier; 2wt% heat-resistant modifier; 3.4wt% compatibilizer; 0.4wt% primary antioxidant; 0.4wt% auxiliary antioxidant; The flow modifier is maleic anhydride grafted acrylate and styrene copolymer; the heat-resistant modifier is N,N'-(4,4'-methylenediphenyl)bis One or both of maleimide and maleic anhydride grafted polystyrene; the main antioxidant is antioxidant 1076, antioxidant 1098, antioxidant 1010, antioxidant 2246, One or more of the antioxidant 4010 or the antioxidant DNP; the auxiliary antioxidant is one or both of the antioxidant 168 or the antioxidant 626.

[0069] The mixed raw materials are melted by the twin-screw extruder, and at the same time, 18wt% of alkali-free glass fiber and 27wt% of mineral fiber are added to the...

Embodiment 3

[0071] Epoxy resin, flow modifier, heat-resistant modifier, compatibilizer, main antioxidant, auxiliary antioxidant, processing aid are mixed at high speed in a high-speed mixer according to the following weight percentage: TDE85 epoxy resin 50wt% 5wt% flow modifier; 3wt% heat-resistant modifier; 5wt% compatibilizer; 0.5wt% primary antioxidant; 0.5wt% secondary antioxidant; The flow modifier is maleic anhydride grafted acrylate and styrene copolymer; the heat-resistant modifier is N,N'-(4,4'-methylenediphenyl)bis One or both of maleimide and maleic anhydride grafted polystyrene; the main antioxidant is antioxidant 1076, antioxidant 1098, antioxidant 1010, antioxidant 2246, One or more of the antioxidant 4010 or the antioxidant DNP; the auxiliary antioxidant is one or both of the antioxidant 168 or the antioxidant 626.

[0072] The mixed raw materials are melted by the twin-screw extruder, and at the same time, 20wt% of alkali-free glass fiber and 15wt% of mineral fiber are ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com