150 DEG C thermoplastic halogen-free flame-retardant polyolefin thin-wall insulation material and preparation method thereof

A thin-wall insulation and thermoplastic technology, applied in the field of 150°C thermoplastic halogen-free flame-retardant polyolefin thin-wall insulation materials and its preparation, can solve the problems of high processing cost, poor wear resistance, poor insulation performance, etc., and achieve improved thermal oxygen aging Performance, wide range of applications, effect of increasing flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

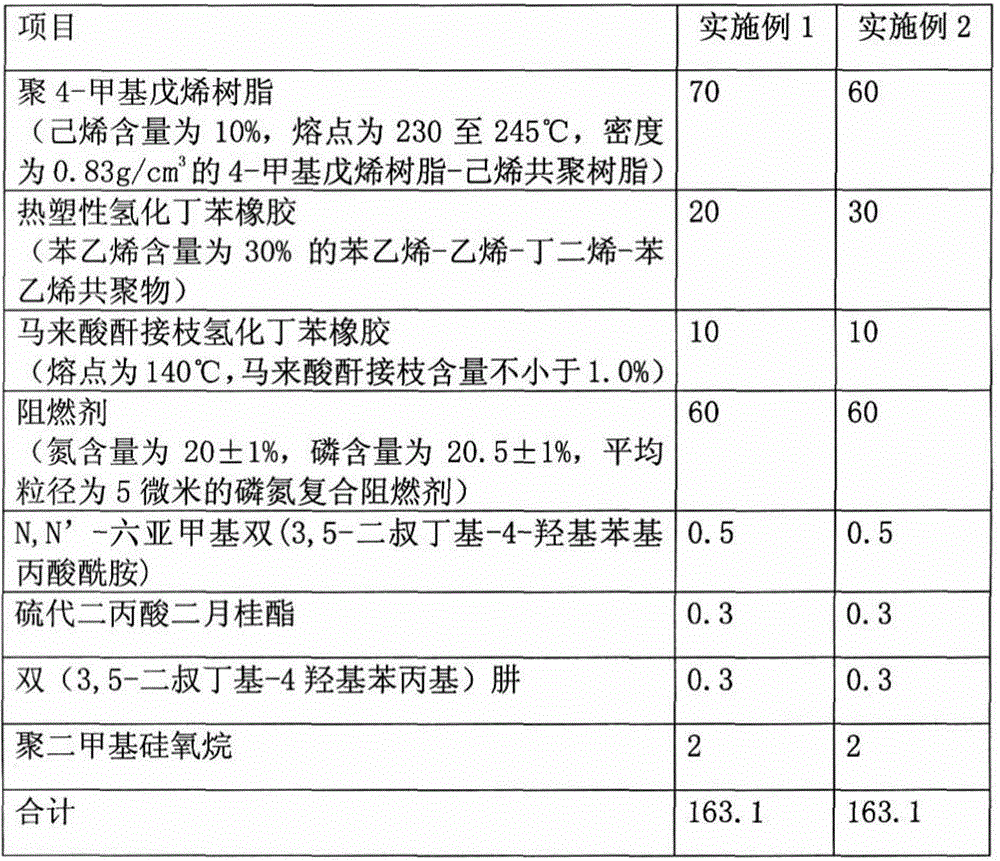

[0019] Embodiment 1 and embodiment 2 are prepared according to the parts by weight of each component shown in table 1:

[0020] Table 1 is the parts by weight table of each component of the embodiment of the present invention

[0021]

[0022] The preparation of embodiment 1:

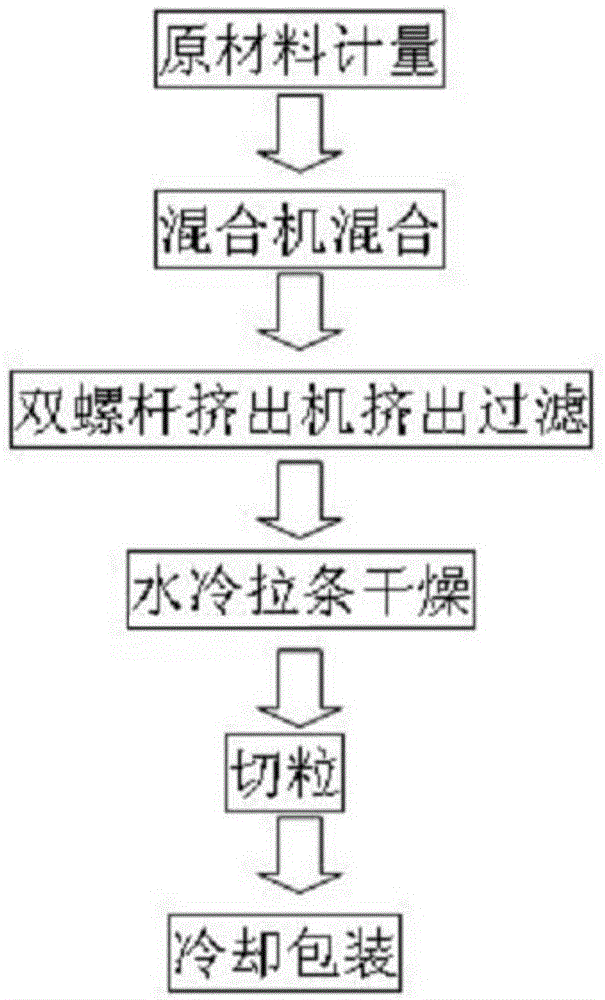

[0023] The raw materials described in Table 1 are prepared according to their respective parts by weight, and then put into a mixer and mixed evenly. The mixing time is 5 to 10 minutes, and then sent into a twin-screw extruder with a diameter of 50mm for blending, filtering, extrusion and pulling. Strips, the extrusion temperature is 180°C to 260°C, the extrusion speed is 200 rpm, and then cooled in a cooling water tank, dried by a blower, and then entered into a pelletizer to cut into pellets, and finally cooled to below 50°C for packaging , to get the finished product.

Embodiment 2

[0024] The preparation of embodiment 2:

[0025] The raw materials described in Table 1 are prepared according to their respective parts by weight, and then put into a mixer and mixed evenly. The mixing time is 5 to 10 minutes, and then sent into a twin-screw extruder with a diameter of 50mm for blending, filtering, extrusion and pulling. The extrusion temperature is 180°C to 260°C, the extrusion speed is 300 rpm, then it is cooled in a cooling water tank, dried by a blower, and then enters a pelletizer to cut into granules, and finally cooled to below 50°C for packaging , to get the finished product.

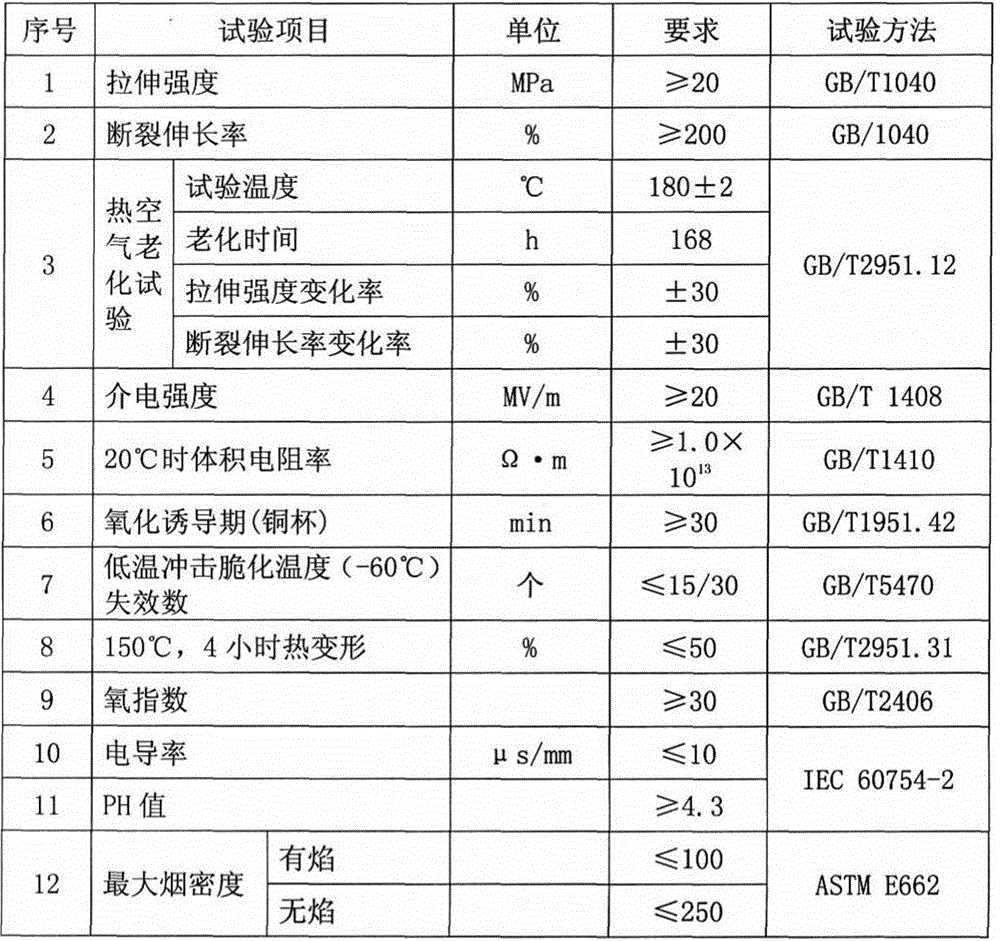

[0026] Examples of the present invention are prepared as shown in Table 2 below:

[0027] Table 2 shows the main performance requirements of the 150°C thermoplastic halogen-free flame-retardant polyolefin insulation material and its preparation method prepared by the embodiment of the invention

[0028]

[0029] The 150°C thermoplastic halogen-free flame-retardant polyolef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com