Method for manufacturing T-shaped grid of GaN microwave device

A microwave device and manufacturing method technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of reducing the reliability of GaN-based power devices, demanding process conditions, and poor process repeatability and stability. , to achieve the effect of improving gate characteristics and noise characteristics, optimizing gate morphology, and high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

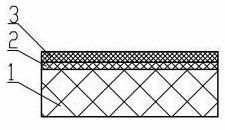

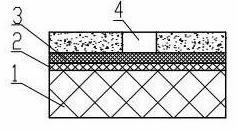

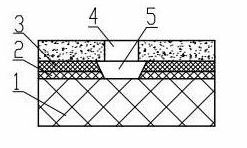

[0018] see Figure 1-Figure 7 , the steps of preparing the T-shaped grid of the present invention are as follows:

[0019] ①Grow a high-temperature dielectric layer 2 on the GaN substrate 1, and the composition of the high-temperature dielectric layer 2 is Si 3 N 4 .

[0020] First, the surface of the GaN substrate 1 is cleaned, and the cleaning steps are: soak in trichloroethane for 5-10 minutes; soak in acetone for 5-10 minutes; soak in isopropanol for 5-10 minutes; finally rinse with deionized water for 5-10 minutes. minute.

[0021] Then use MOVCD (Metal-organic Chemical Vapor DePosition, metal organic compound chemical vapor deposition method) growth process to make Si 3 N 4 , the growth temperature is 1000°C-1200°C, Si 3 N 4 The thickness is 100 angstroms ± 20 angstroms.

[0022] ②Grow a low-temperature dielectric layer 3 on the upper surface of the above-mentioned high-temperature dielectric layer 2, and the composition of the low-temperature dielectric layer 3 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com