Perovskite photoelectric detector based on composite electron transport layer and preparation method of perovskite photoelectric detector

An electron transport layer, photodetector technology, applied in the direction of electric solid device, semiconductor/solid state device manufacturing, circuit, etc., can solve the problems of short life, high device dark current, poor stability of inorganic photodetector devices, etc., to achieve good barrier Effects of water oxygen, dark current reduction, and carrier transport capability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

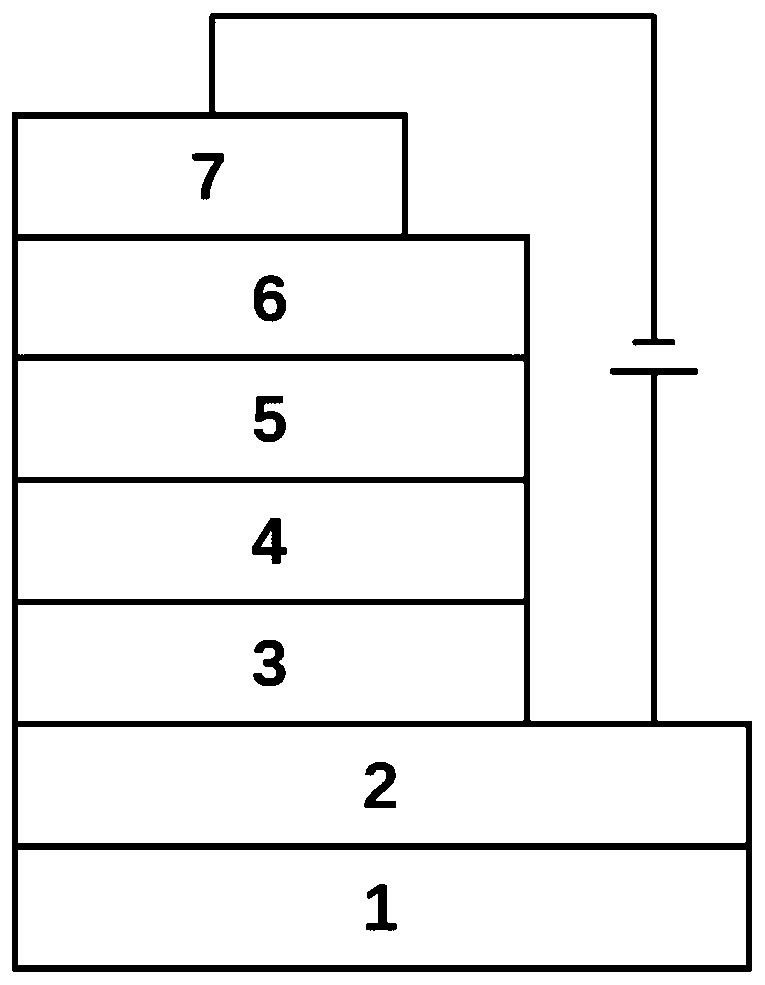

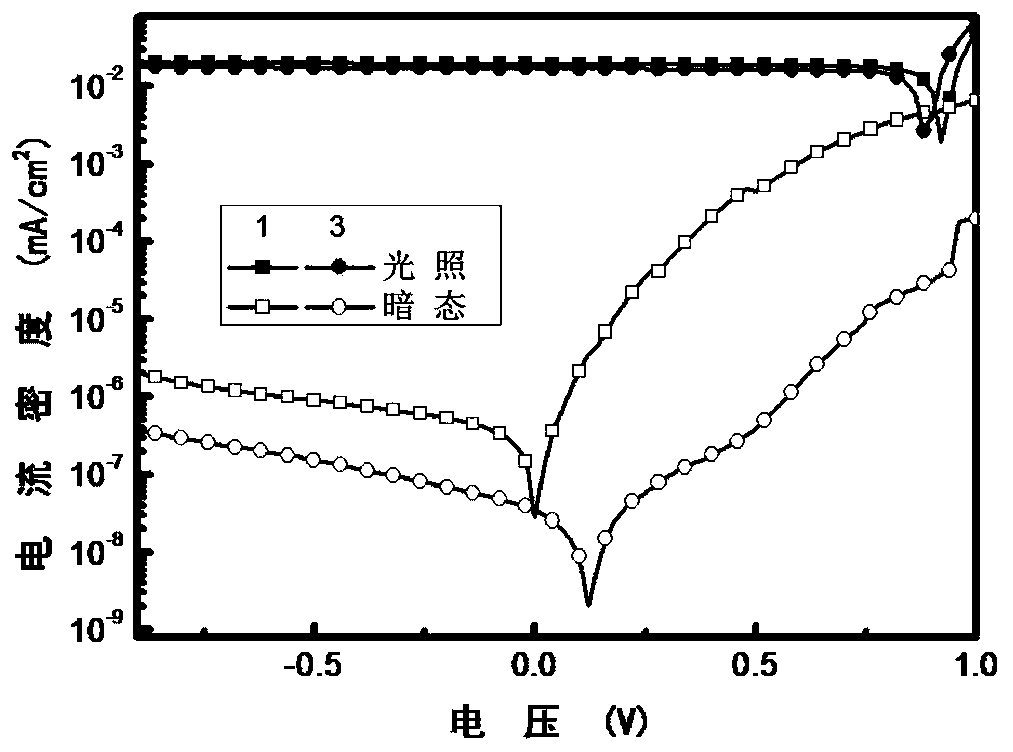

[0053] The substrate composed of the substrate and the transparent conductive anode ITO is cleaned, and dried with nitrogen after cleaning; the surface of the transparent conductive anode ITO is spin-coated with PEDOT:PSS (water dispersion, containing 1 to 3 wt% of PEDOT:PSS, spin-coating time 60s, thickness 15nm) prepare hole transport layer, and the formed film is carried out thermal annealing (annealing temperature 150 ℃, annealing time 15min); Spin-coat MAPbl on hole transport layer 3 (using DMF as a solvent to form a mixed solution with a solute concentration of 800mg / mL, the spin-coating speed is 4000rpm, the spin-coating time is 30s, and the thickness is 500nm) to prepare the perovskite photoactive layer. The carbon layer was quickly added dropwise with chlorobenzene solution to inhibit the disordered crystallization of perovskite, and then annealed at 120 °C for 20 min; the surface of perovskite photoactive layer was spin-coated with PCBM solution (aqueous dispersion so...

Embodiment 2

[0055] The substrate composed of the substrate and the transparent conductive anode ITO is cleaned, and dried with nitrogen gas after cleaning; the surface of the transparent conductive anode ITO is spin-coated with PEDOT:PSS (water dispersion, containing 1 to 3 wt% of PEDOT:PSS, spin-coating time 60s, thickness 15nm) prepare hole transport layer, and the formed film is carried out thermal annealing (annealing temperature 150 ℃, annealing time 15min); Spin-coat MAPbl on hole transport layer 3 (using DMF as a solvent to form a mixed solution with a solute concentration of 800mg / mL, the spin-coating speed is 4000rpm, the spin-coating time is 30s, and the thickness is 500nm) to prepare the perovskite photoactive layer. The carbon layer was quickly dripped with chlorobenzene solution to inhibit the disordered crystallization of perovskite, and then annealed at 120 ° C for 20 min; the surface of the perovskite photoactive layer was spin-coated with a PCBM solution doped with 2% gela...

Embodiment 3

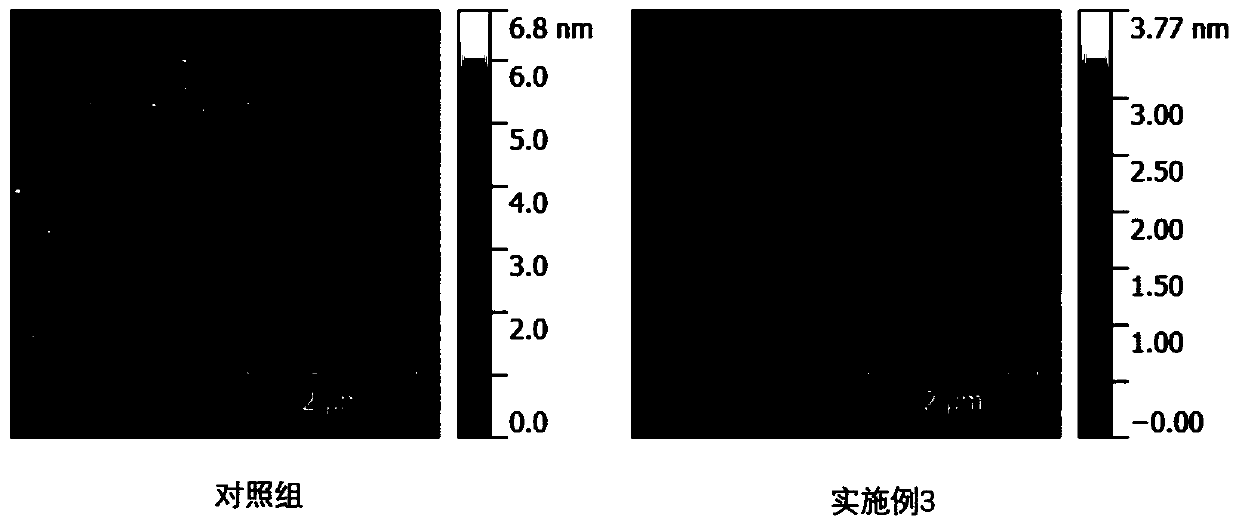

[0057] The substrate composed of the substrate and the transparent conductive anode ITO is cleaned, and dried with nitrogen after cleaning; the surface of the transparent conductive anode ITO is spin-coated with PEDOT:PSS (water dispersion, containing 1 to 3 wt% of PEDOT:PSS, spin-coating time 60s, thickness 15nm) prepare hole transport layer, and the formed film is carried out thermal annealing (annealing temperature 150 ℃, annealing time 15min); Spin-coat MAPbl on hole transport layer 3 (using DMF as a solvent to form a mixed solution with a solute concentration of 800mg / mL, the spin-coating speed is 4000rpm, the spin-coating time is 30s, and the thickness is 500nm) to prepare the perovskite photoactive layer. The carbon layer was rapidly dripped with chlorobenzene solution to inhibit the disordered crystallization of perovskite, and then annealed at 120 ° C for 20 min; the surface of the perovskite photoactive layer was spin-coated with a PCBM solution doped with 3% gelatin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com