Patents

Literature

111results about How to "Frictional" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

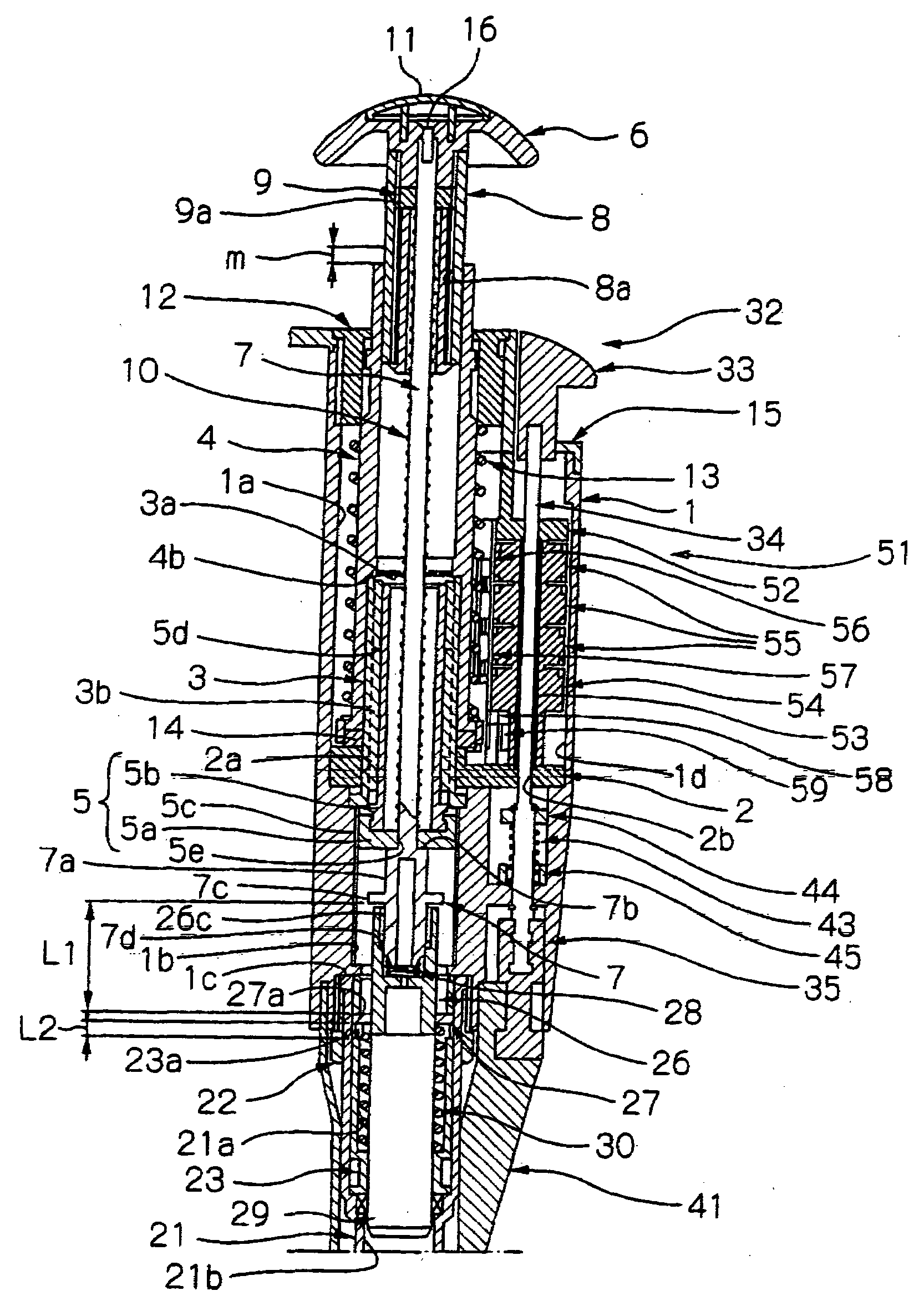

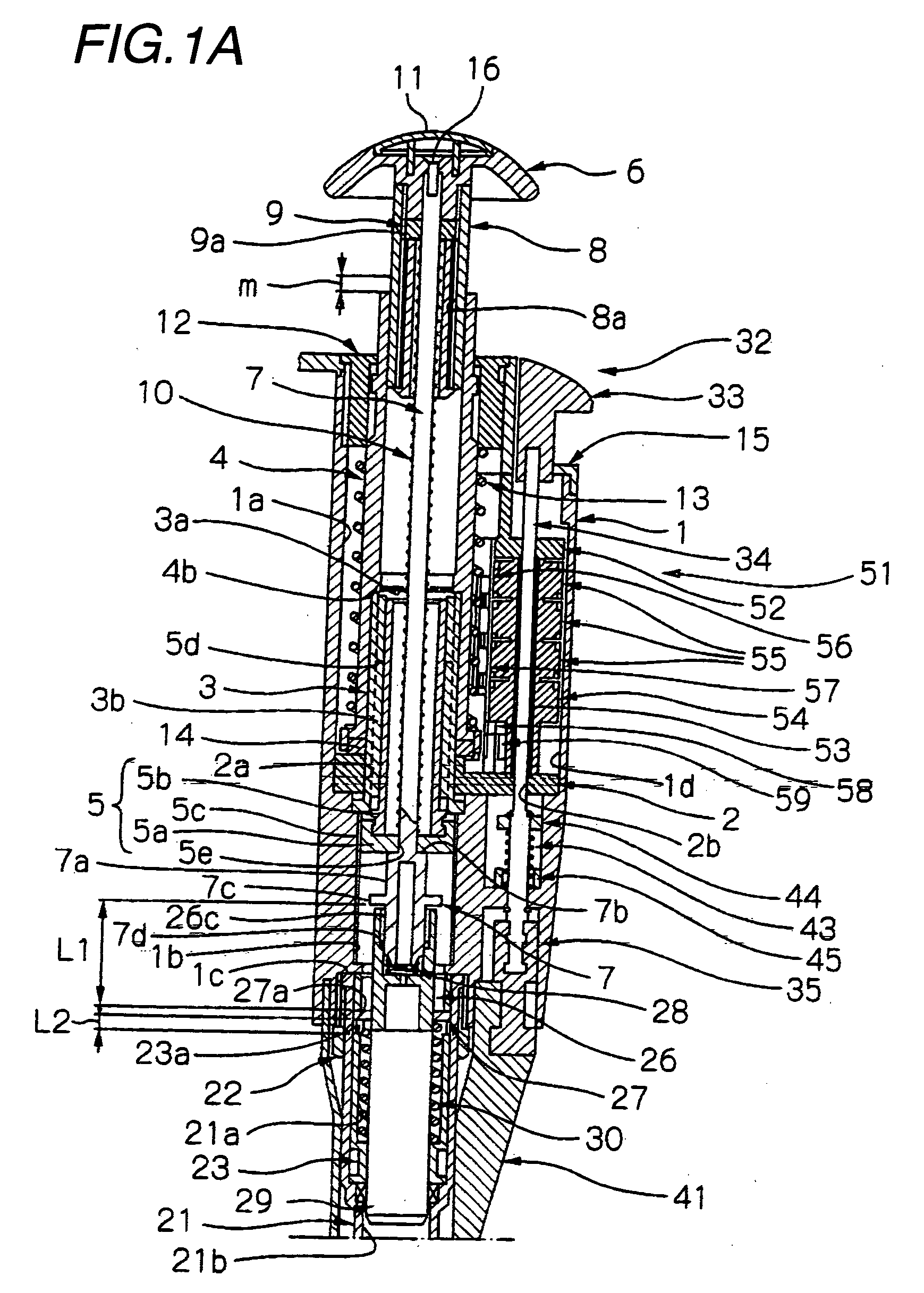

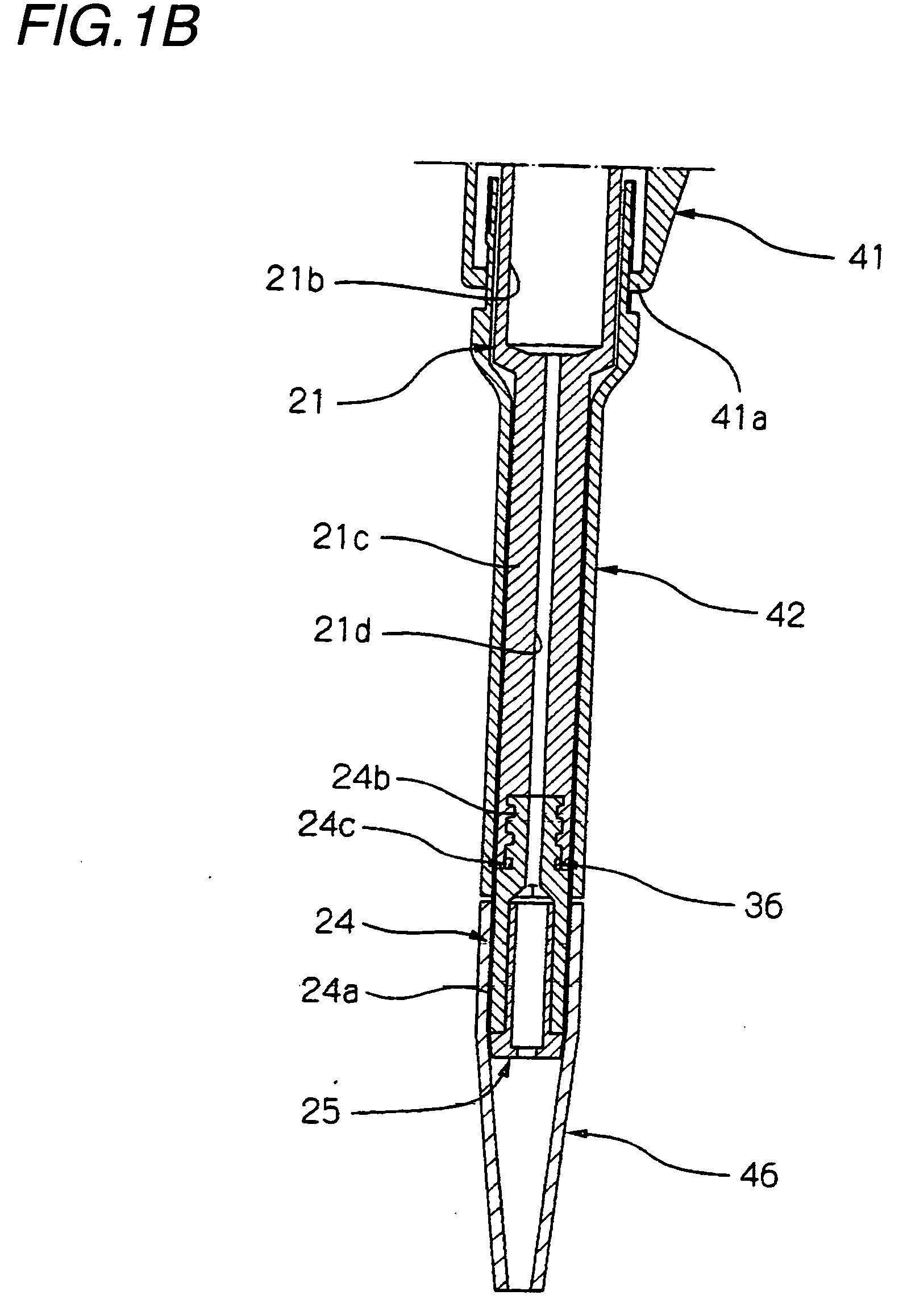

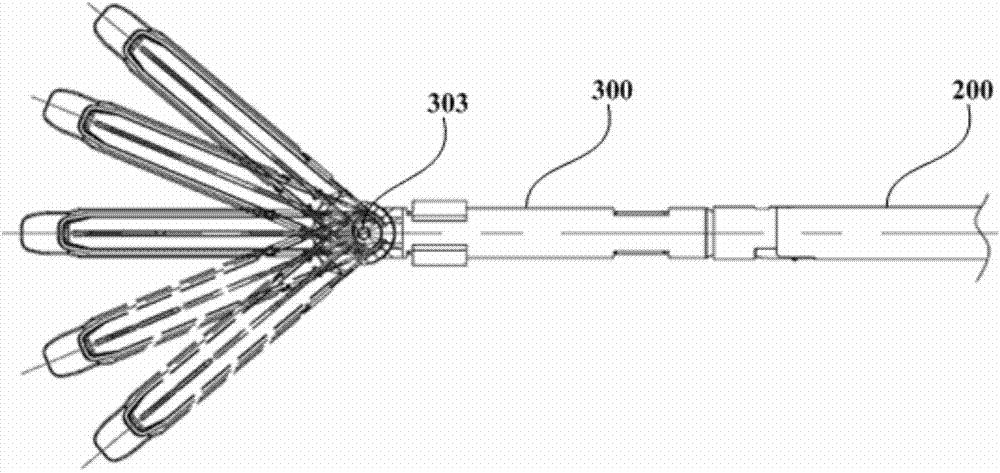

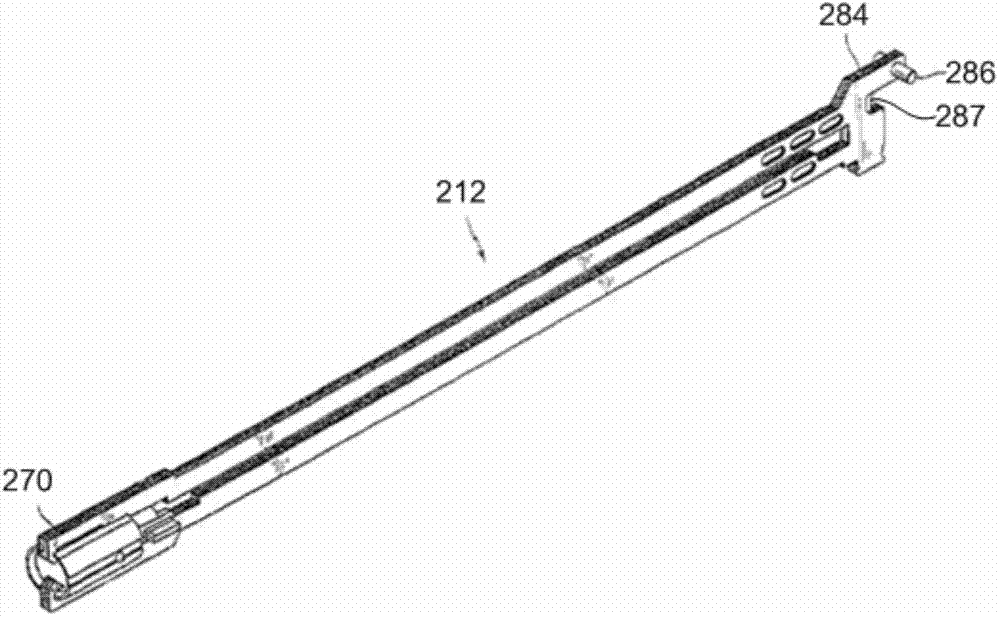

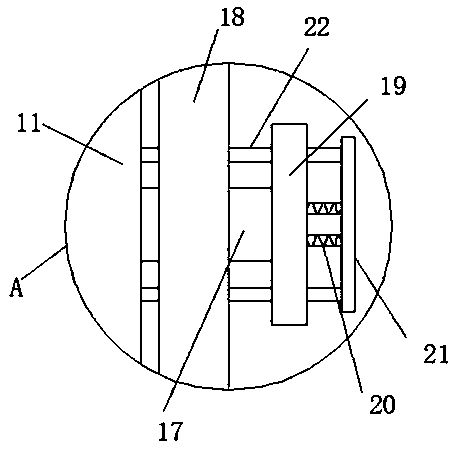

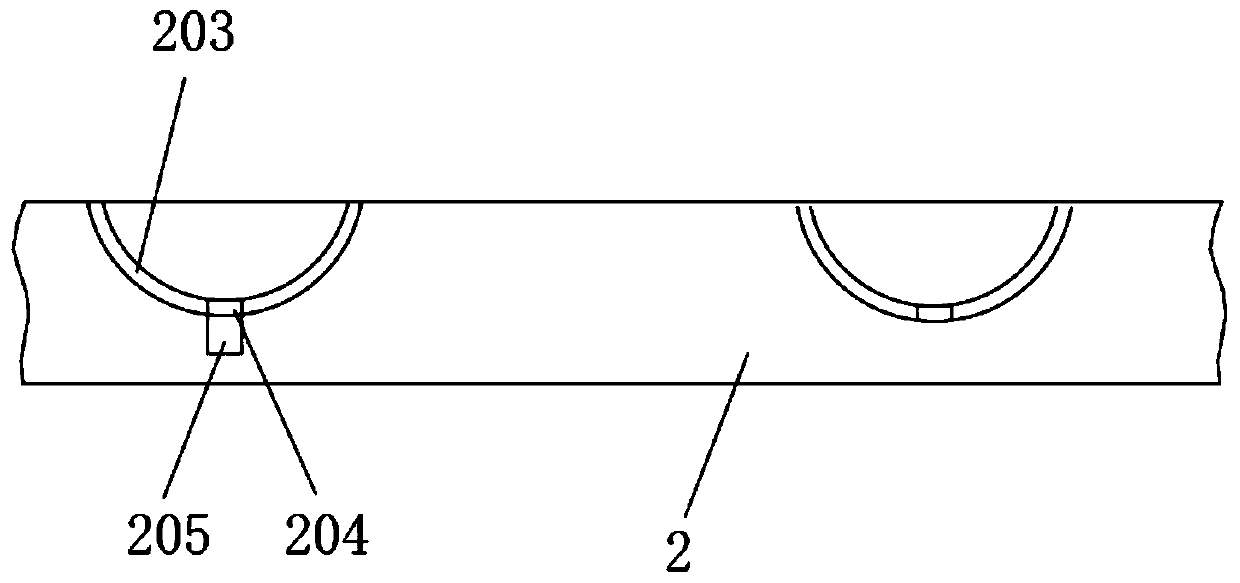

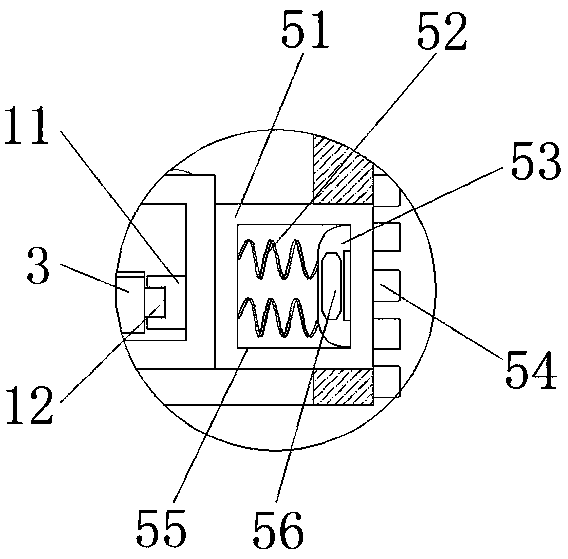

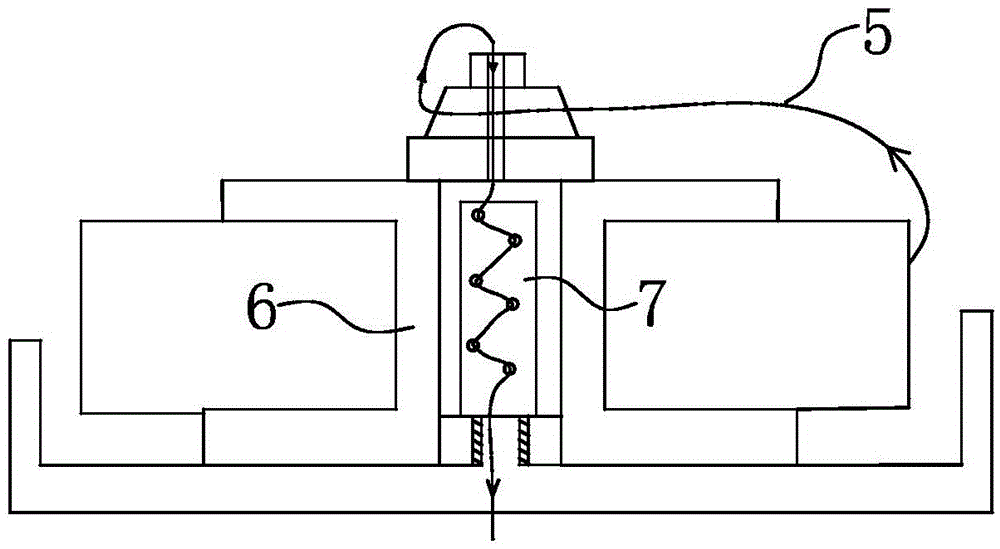

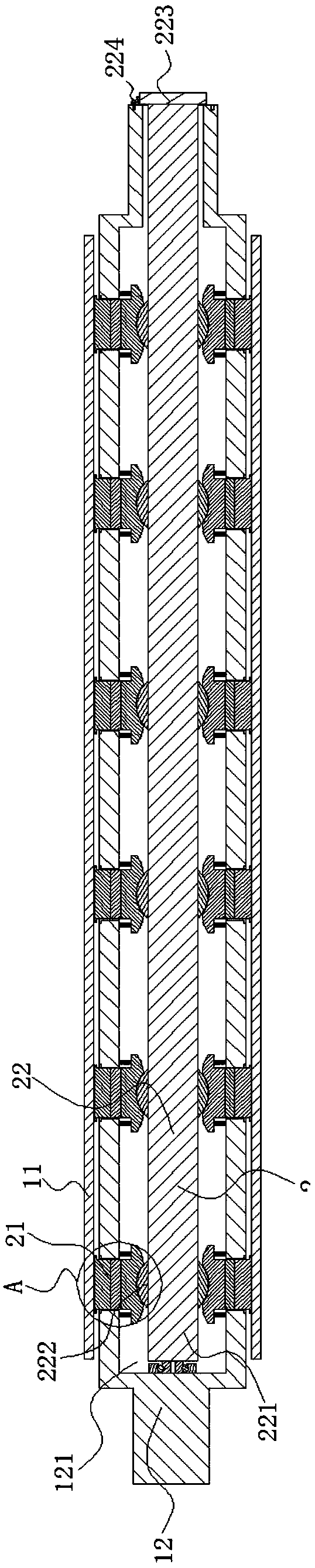

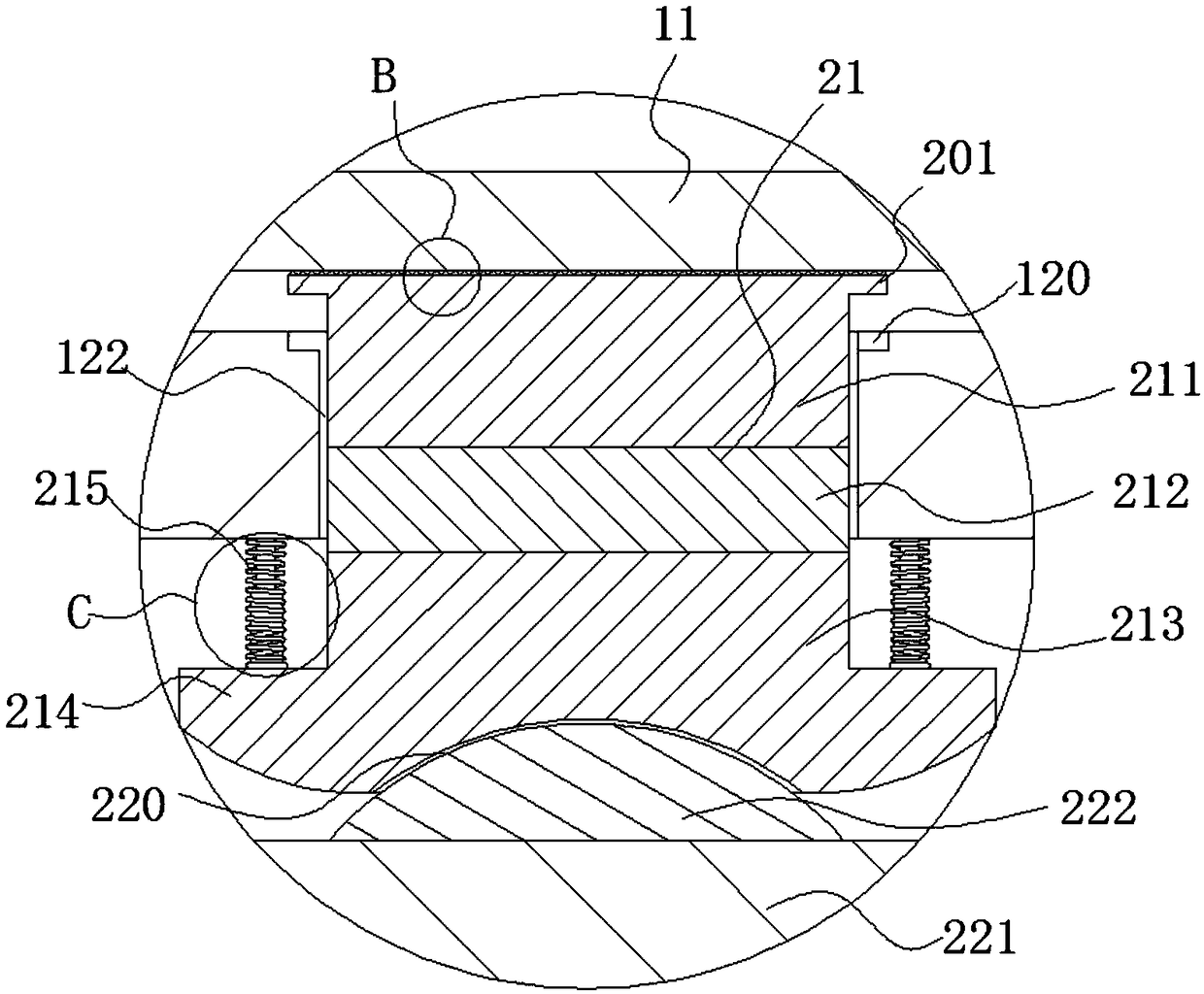

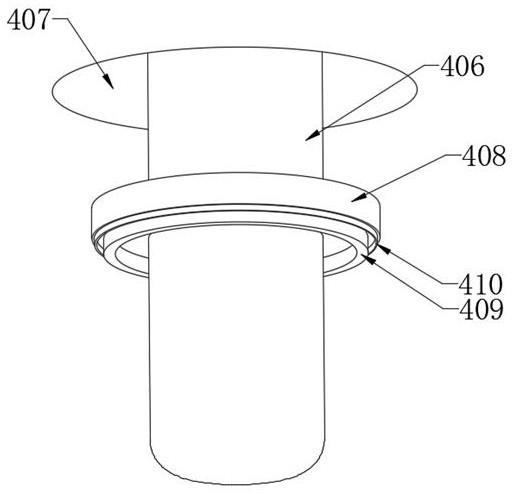

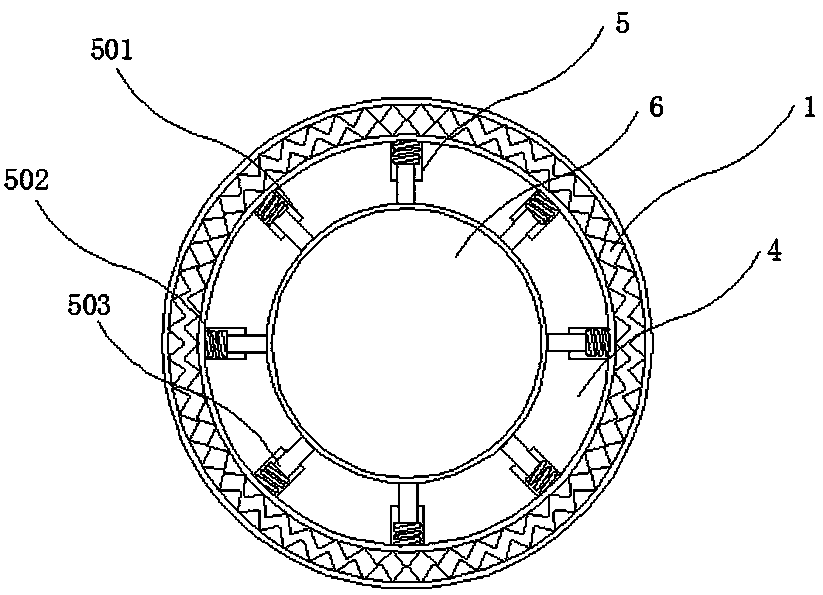

Pipette and sealing mechanism for plunger

InactiveUS20080223108A1Fluctuation in suction volumeSmooth ejecting operationTesting/calibration apparatusWithdrawing sample devicesPipetteMechanical engineering

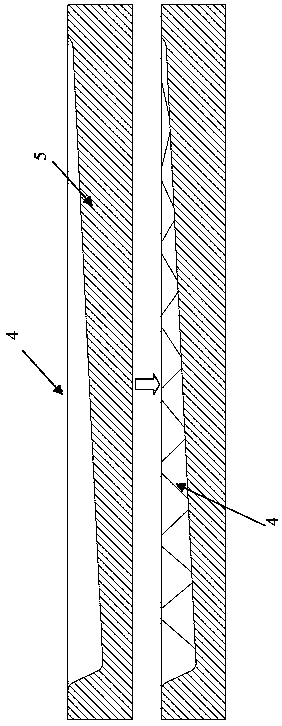

A pipette includes a tubular body (1) having an internal circumferential threaded portion (1b); a stroke screw (5) provided inside the body (1) and having an external circumferential threaded portion (5c) for thread-engaging said internal circumferential threaded portion (1b); a volume variably setting member (4) disposed to be rotatable together with the stroke screw (5) as one unit and axially slidable relative thereto; a central shaft (7) provided inside said tubular body (1), which is coupled to a plunger (29) and operable to be pushed down; and a first-stage spring (10) interposed between an upper portion of said central shaft (7) and said stroke screw (5), which urges the central shaft (7) upward so that a predetermined portion (7b) thereof urgingly abuts against the stroke screw (5), wherein, by rotating said volume variably setting member (4) as appropriate, the stroke screw (5) is caused to rotate together therewith as one unit relative to the body (1) so that said stroke screw (5) and said central shaft (7) axially slide together as one unit apparently by a predetermined amount, thereby variably setting a suction volume of said pipette.A plunger sealing mechanism includes an O-ring retention ring (101) fitted around said plunger (29); a seal ring (102) fitted around said plunger (29); an O-ring (103) interposed between said O-ring retention ring (101) and said seal ring (102); and an O-ring pressing spring (104) which axially presses said O-ring retention ring (101) with a predetermined force to press said O-ring (103) against an inclined inner surface (121a) of a tubular cylinder member (121) so that said seal ring (102) is radially inwardly pressed against an outer peripheral surface of said plunger (29) by a component of said predetermined force that is in a direction perpendicular to the axis of the pipette, wherein an inclination angle α of said inclined inner surface (121a) is 40° to 65° relative to the direction perpendicular to the axis of the pipette.

Owner:NICHIRYO CO LTD

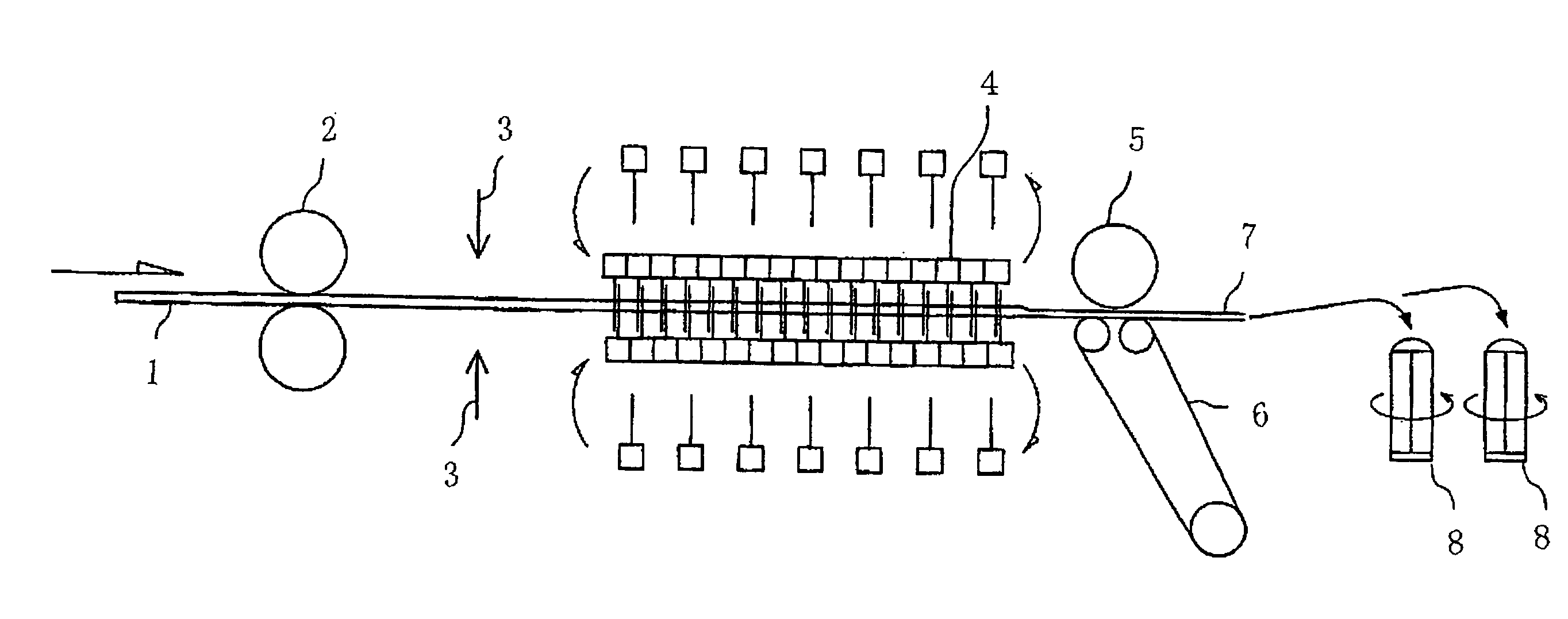

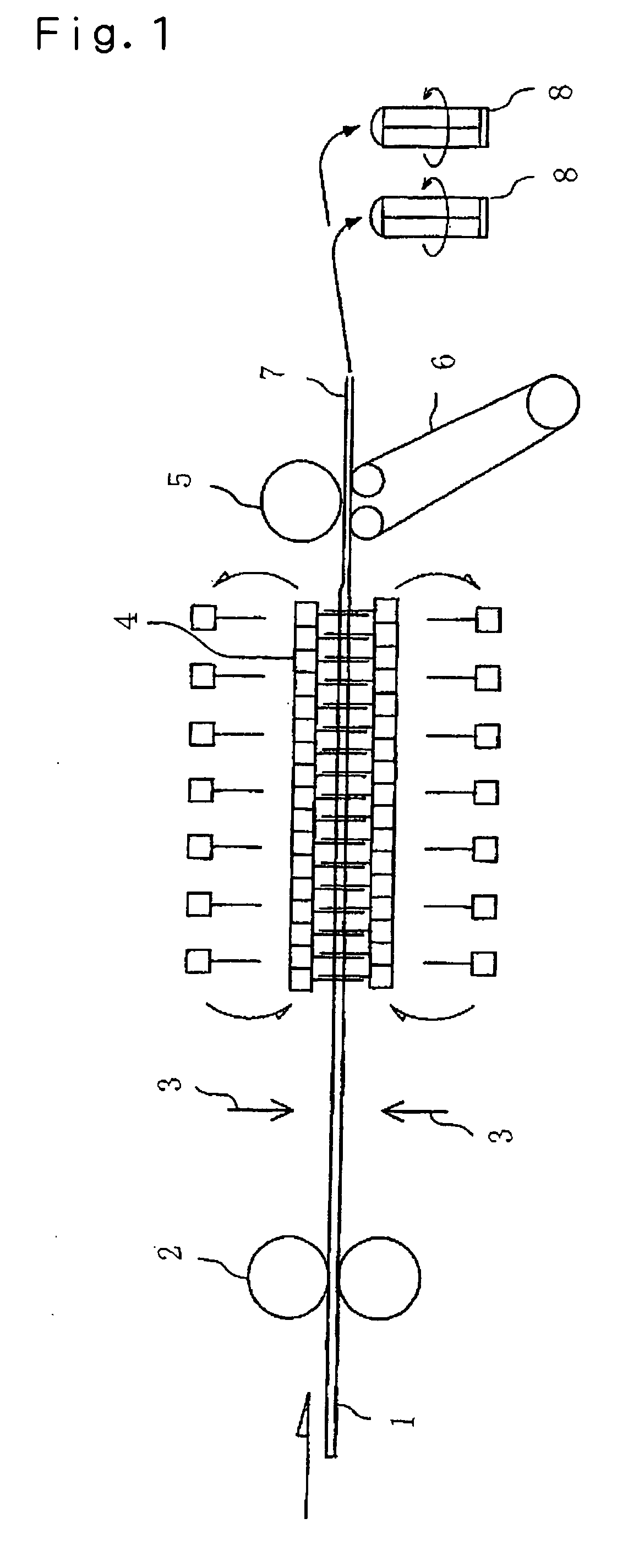

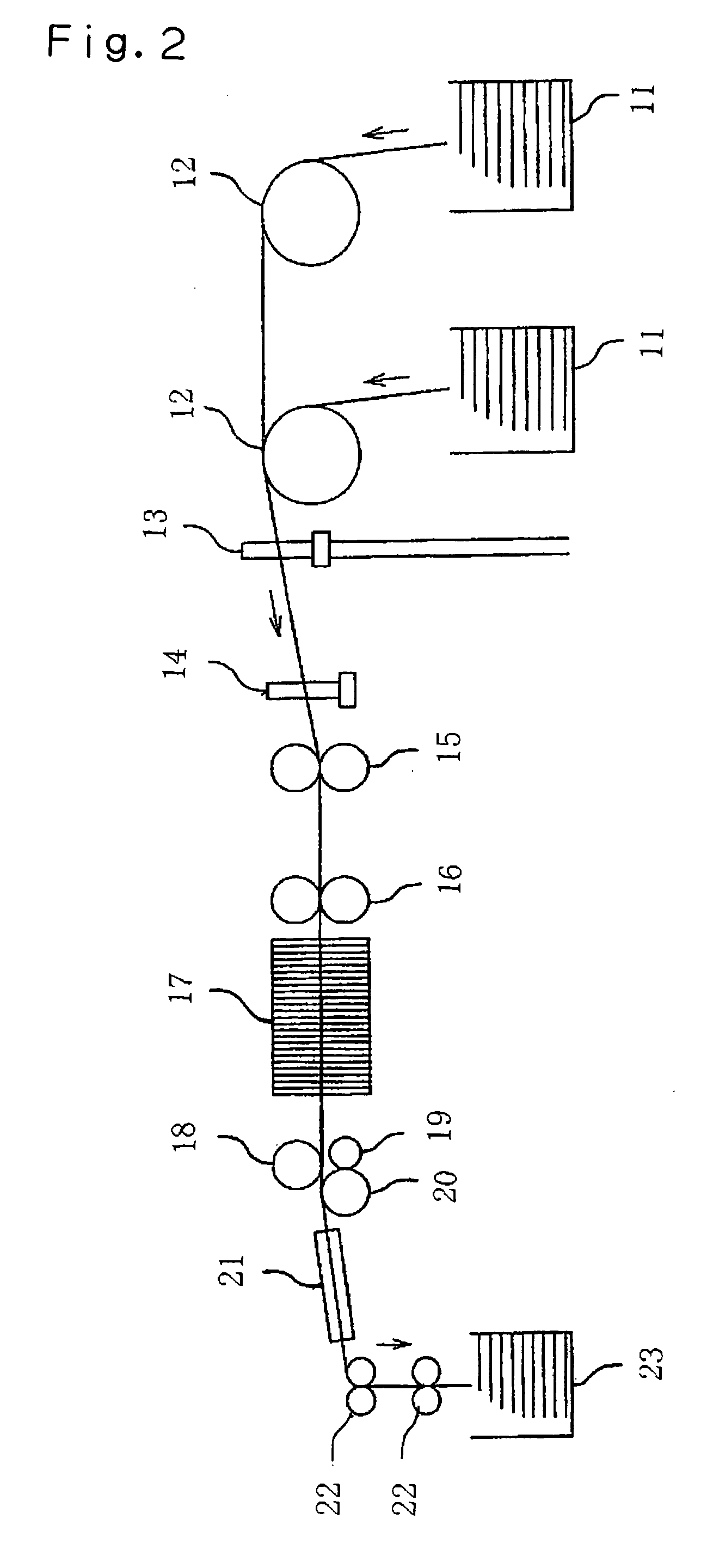

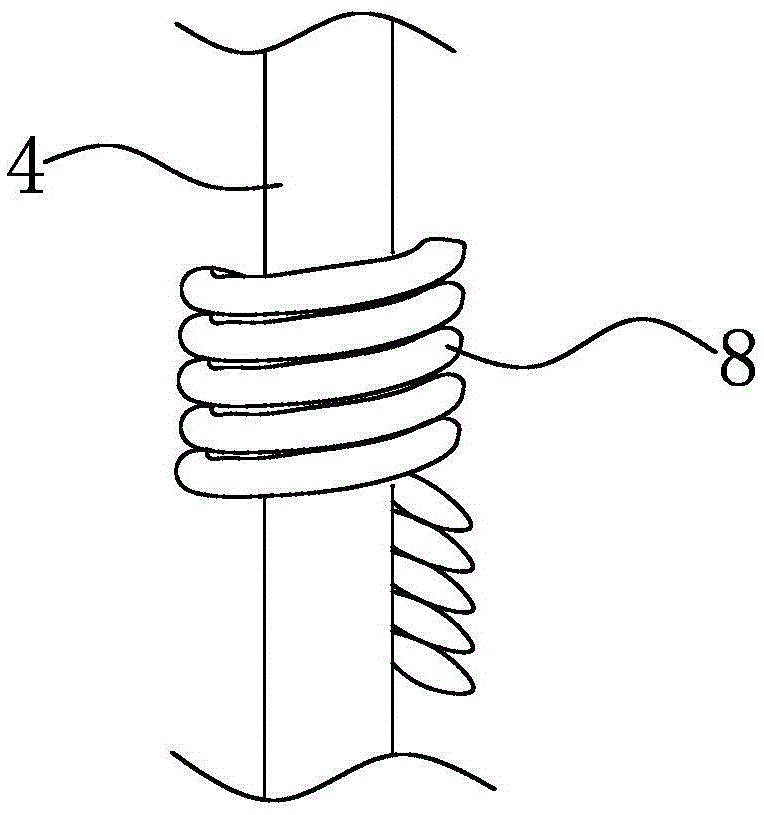

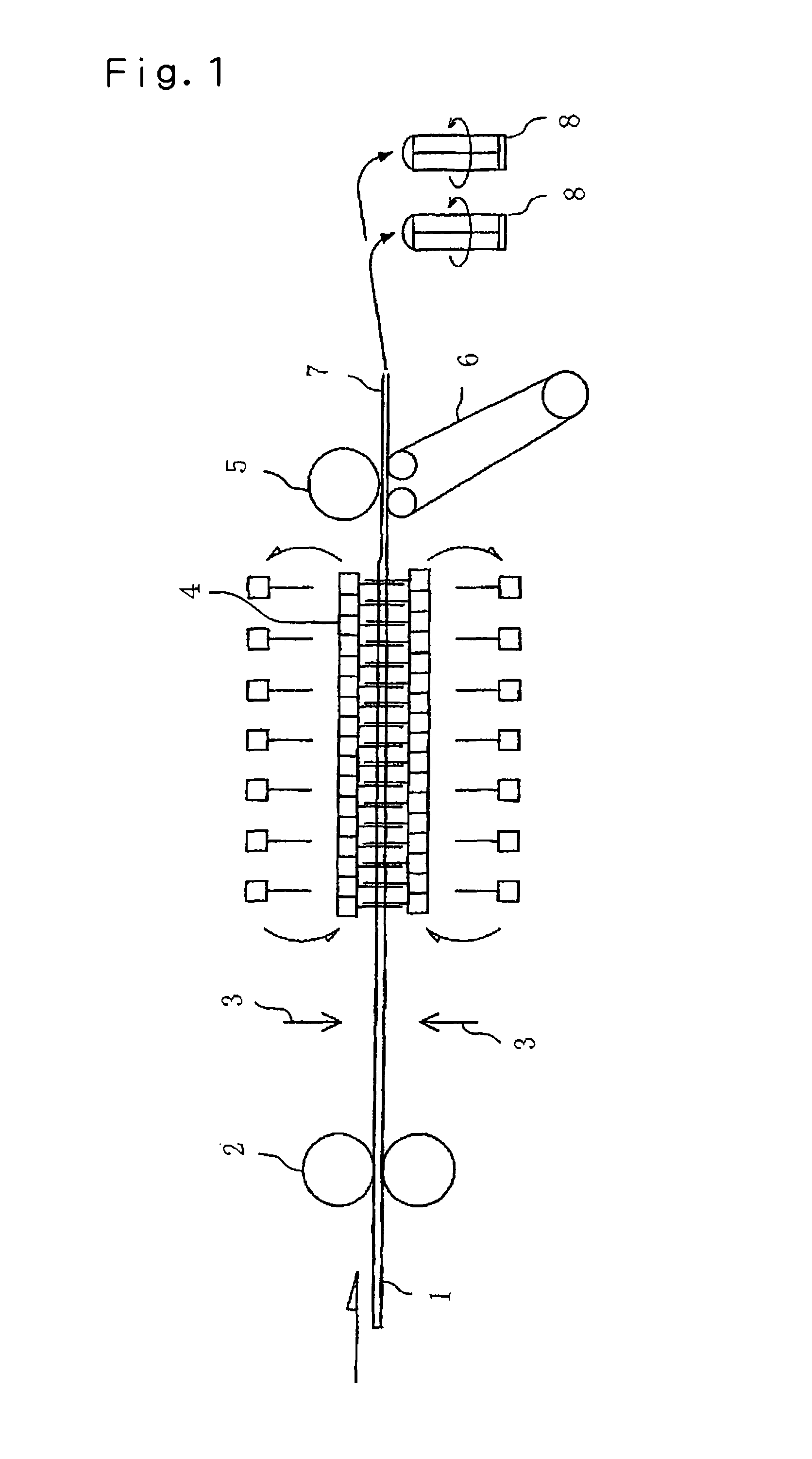

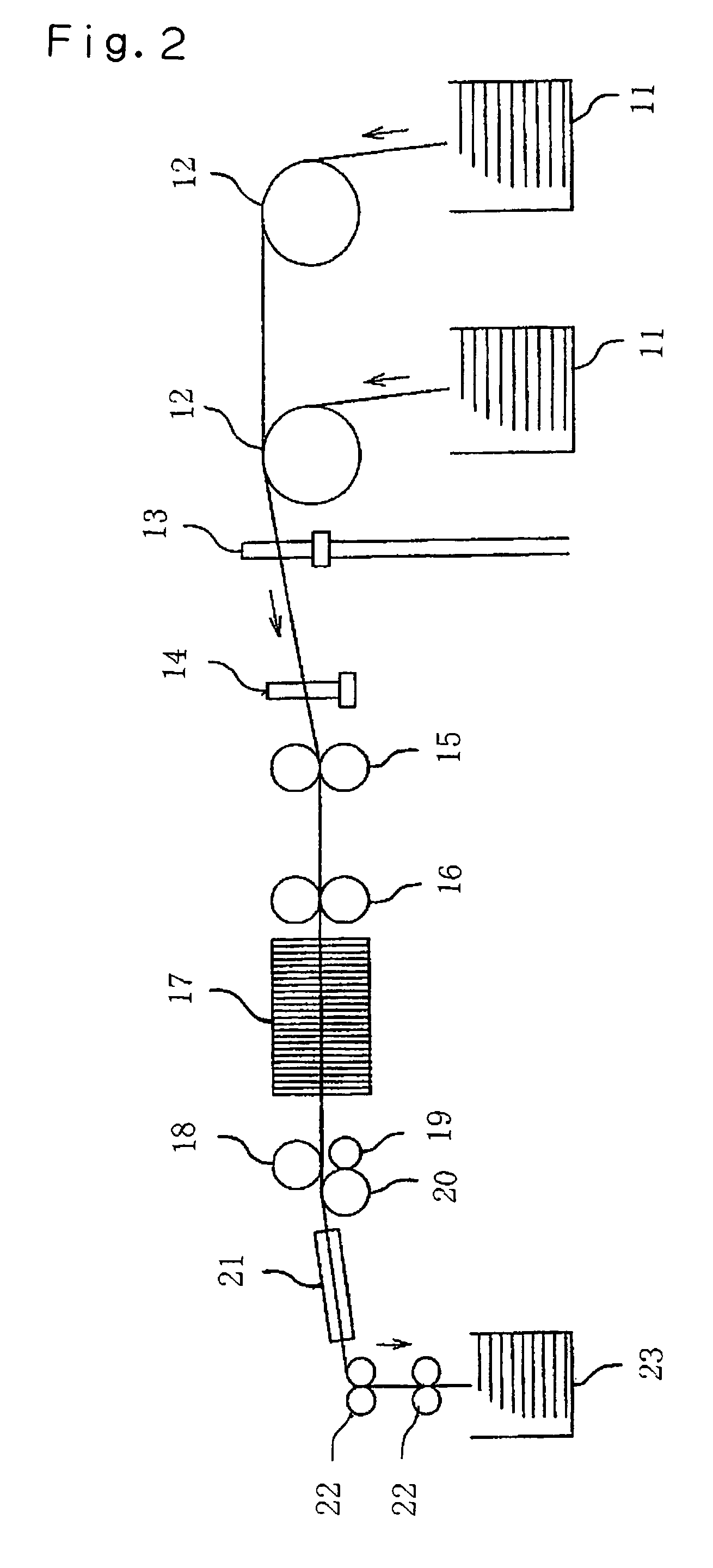

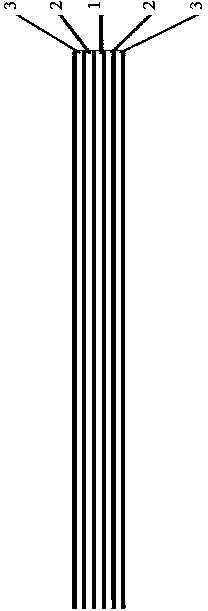

Hybrid Carbon Fiber Spun Yarn and Hybrid Carbon Fiber Spun Yarn Fabric Using the Same

ActiveUS20080152906A1High tensile strengthReduce adhesionFinal product manufactureLayered productsYarnCarbon fibers

A hybrid carbon fiber spun yarn comprising a core region which comprises carbon fibers as a main component, and a surrounding region which comprises carbon fibers as a main component and covers an outer peripheral surface of the core region;wherein 20% by mass or more of fibers forming the core region are long carbon fibers having a fiber length of 500 mm or longer,80% by mass ormore of fibers forming the surrounding region are short carbon fibers having a fiber length of less than 500 mm, anda mass ratio between the long carbon fibers and the short carbon fibers (long carbon fibers:short carbon fibers) is in a range of 20:80 to 80:20.

Owner:KUREHA KAGAKU KOGYO KK

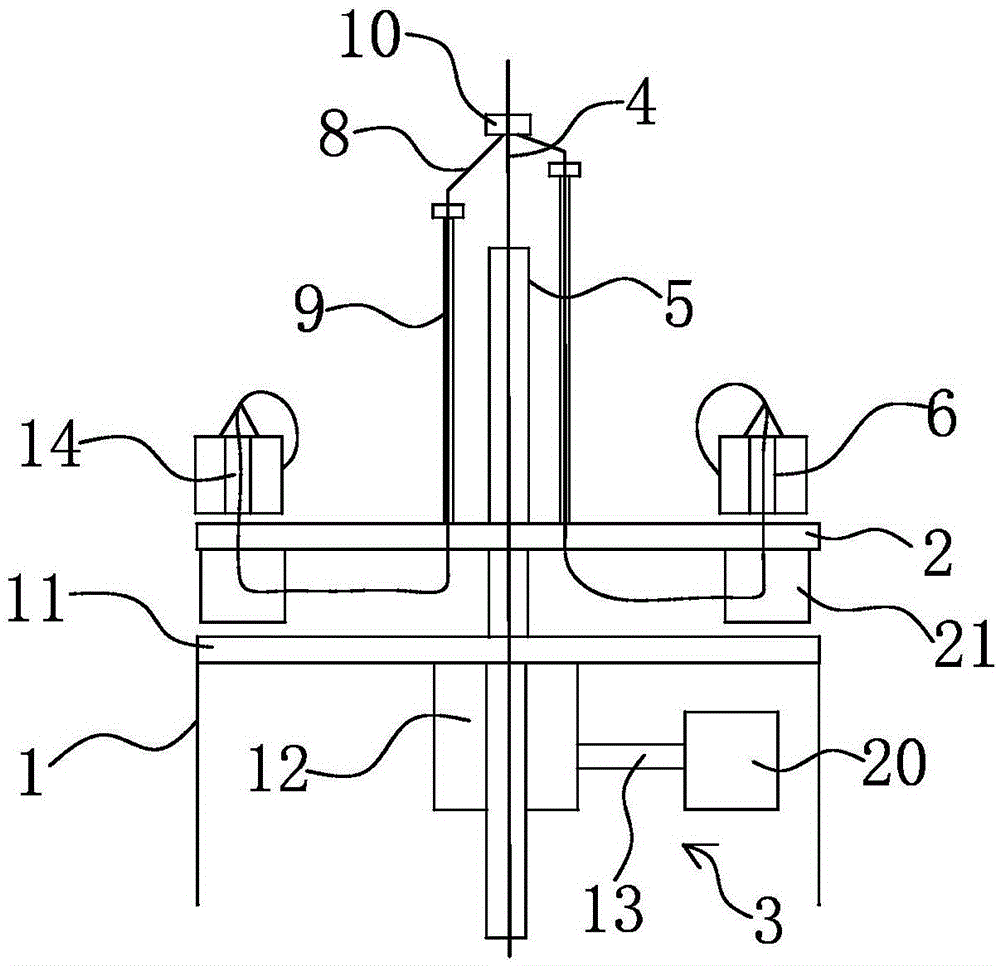

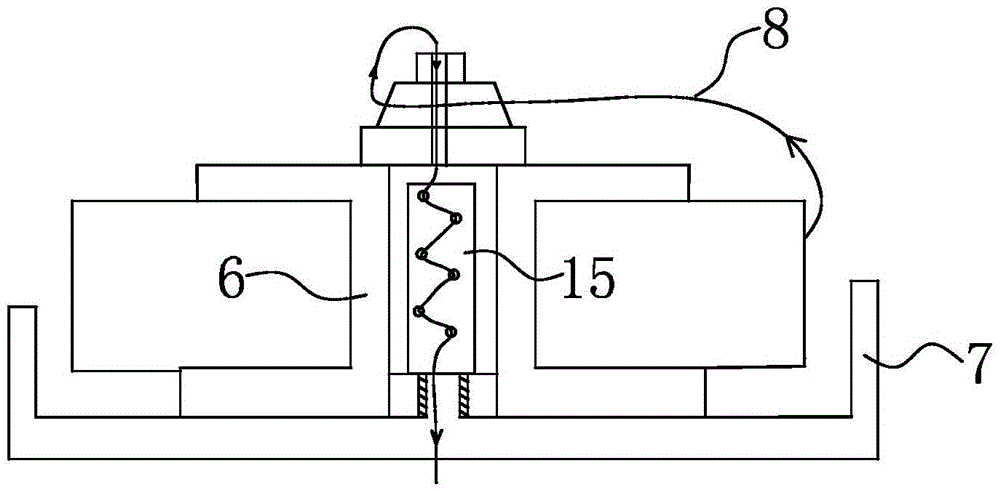

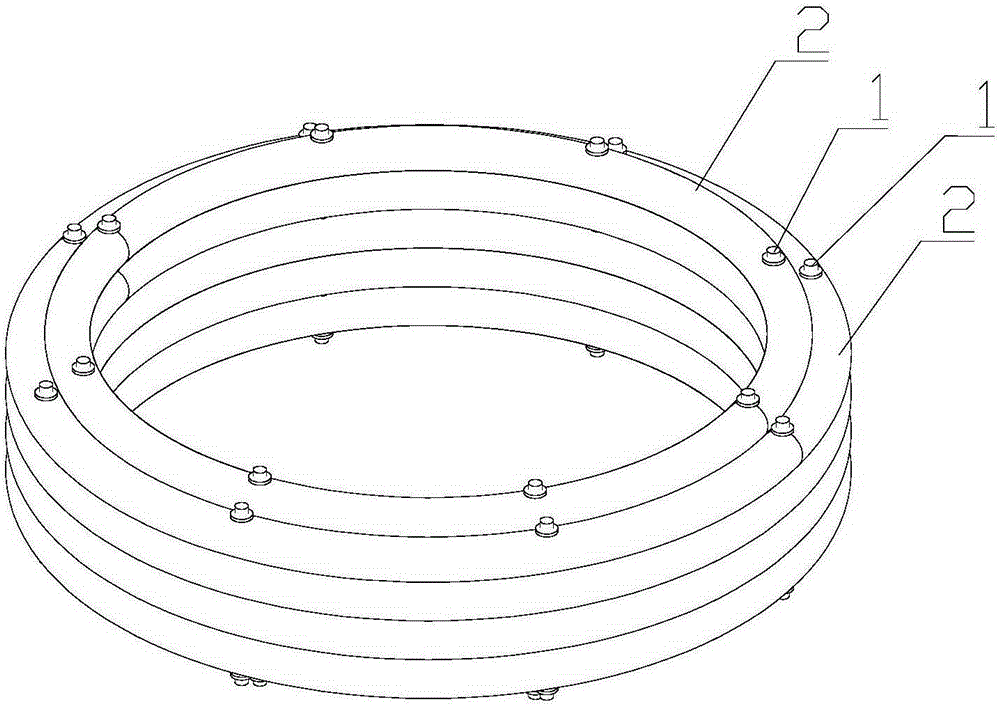

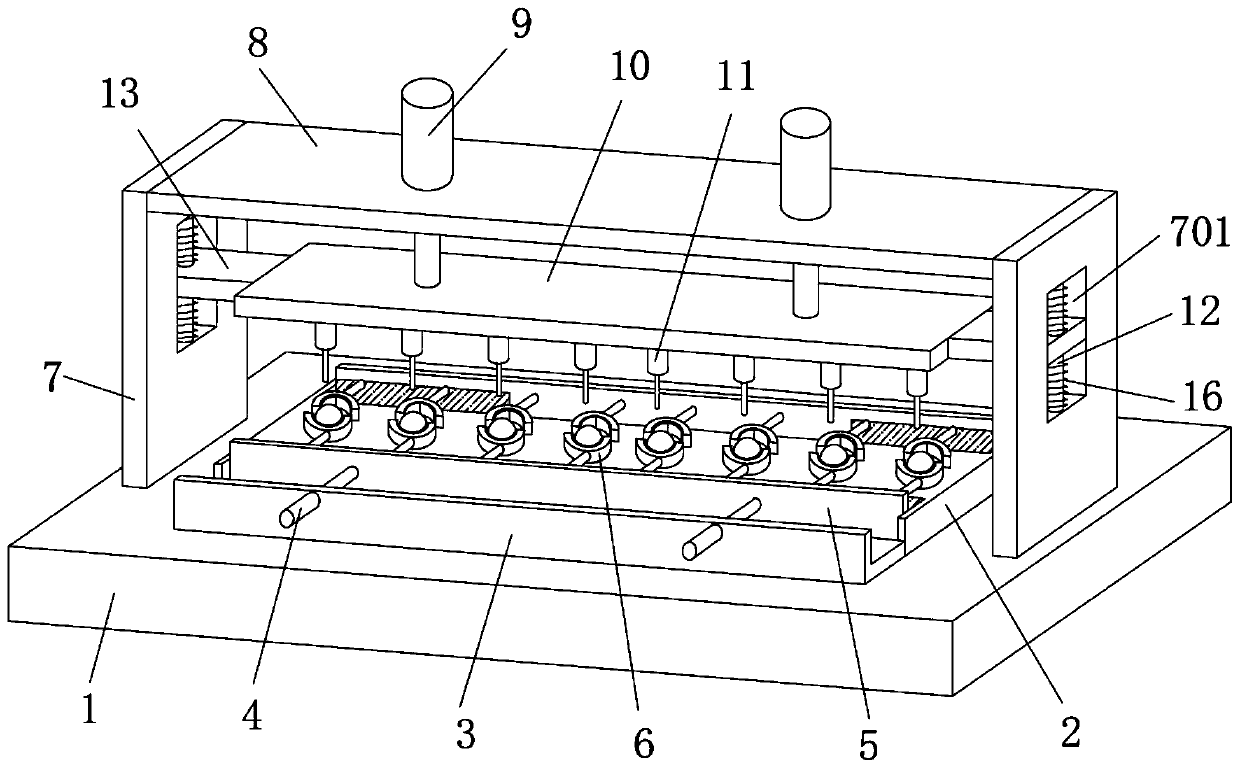

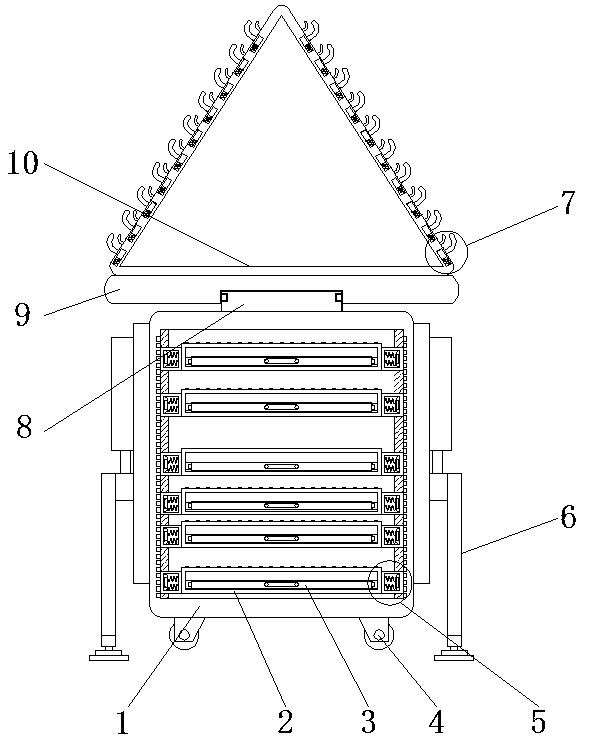

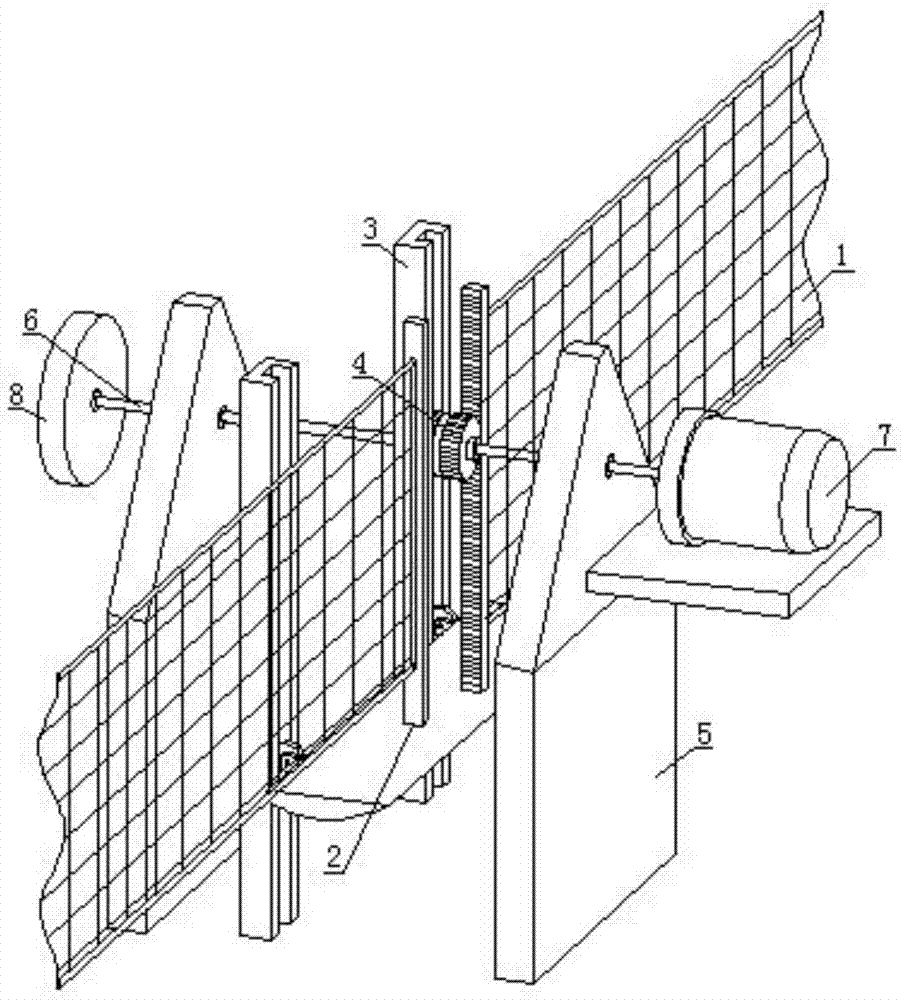

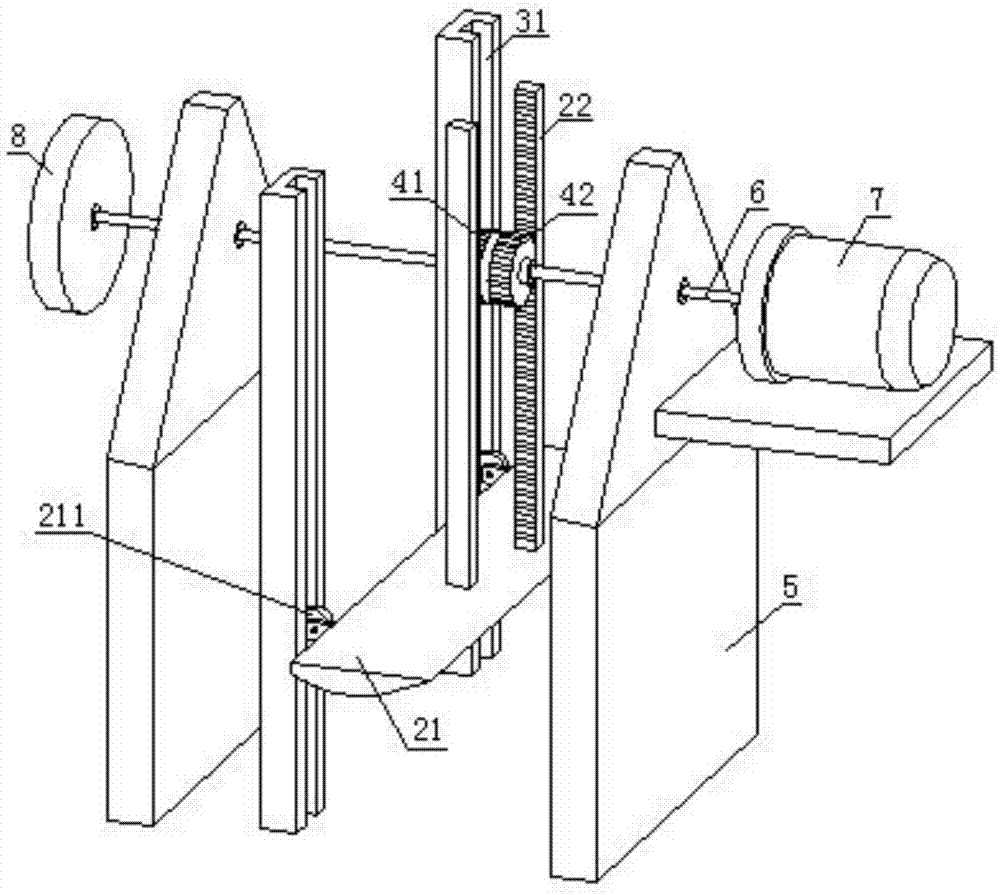

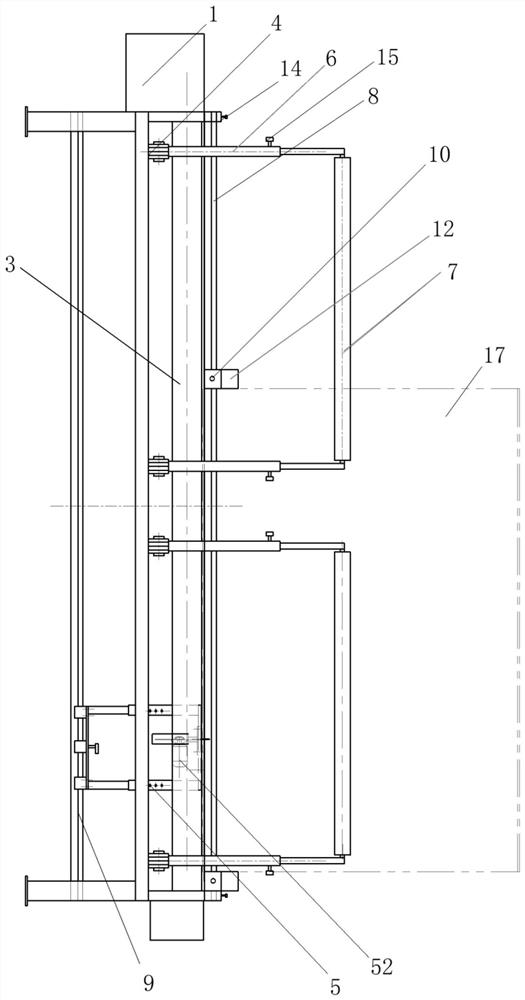

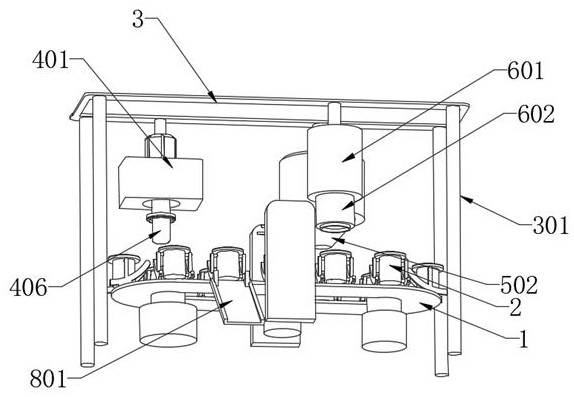

Multi-coating core-spun yarn and preparing machine thereof

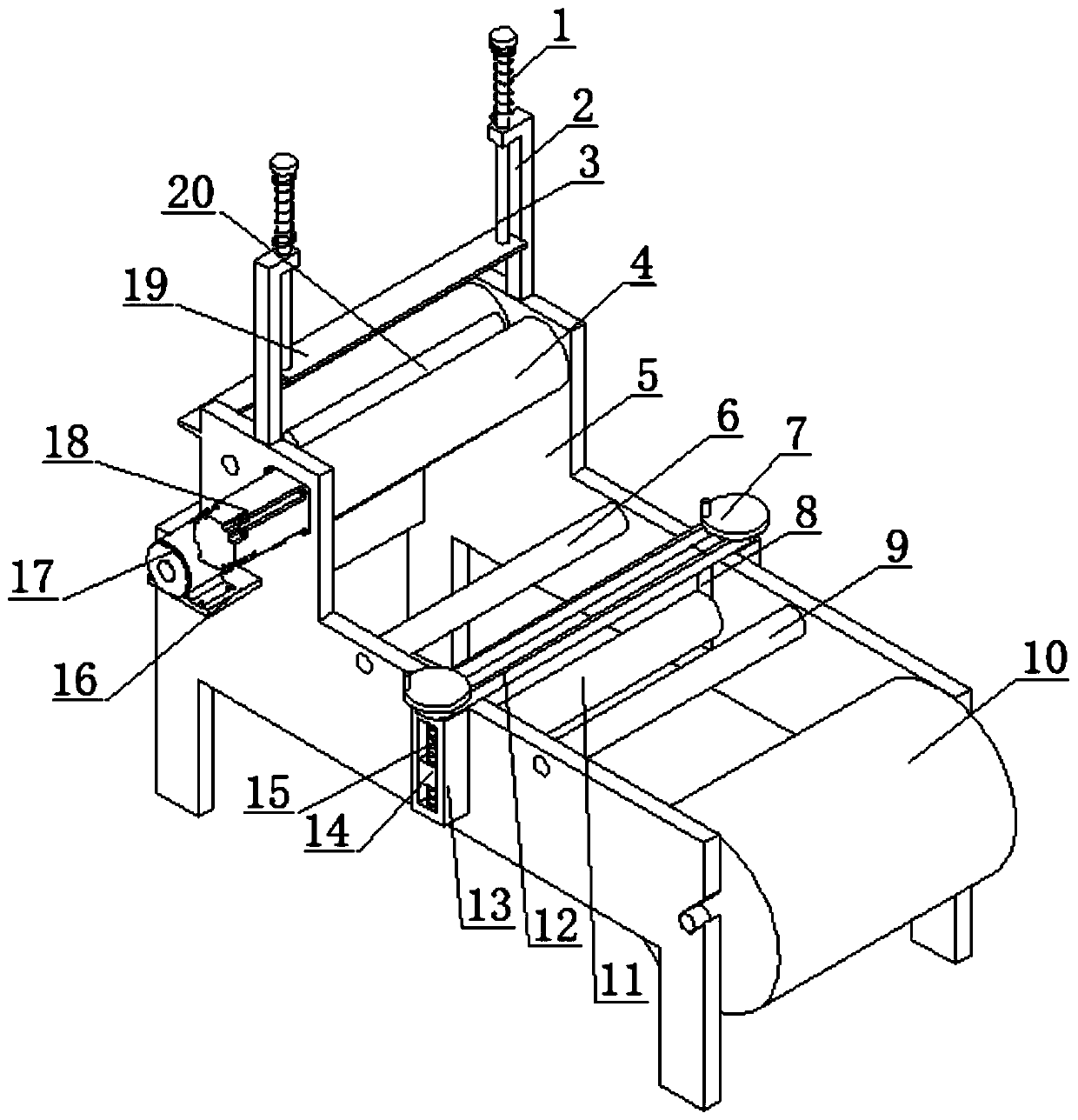

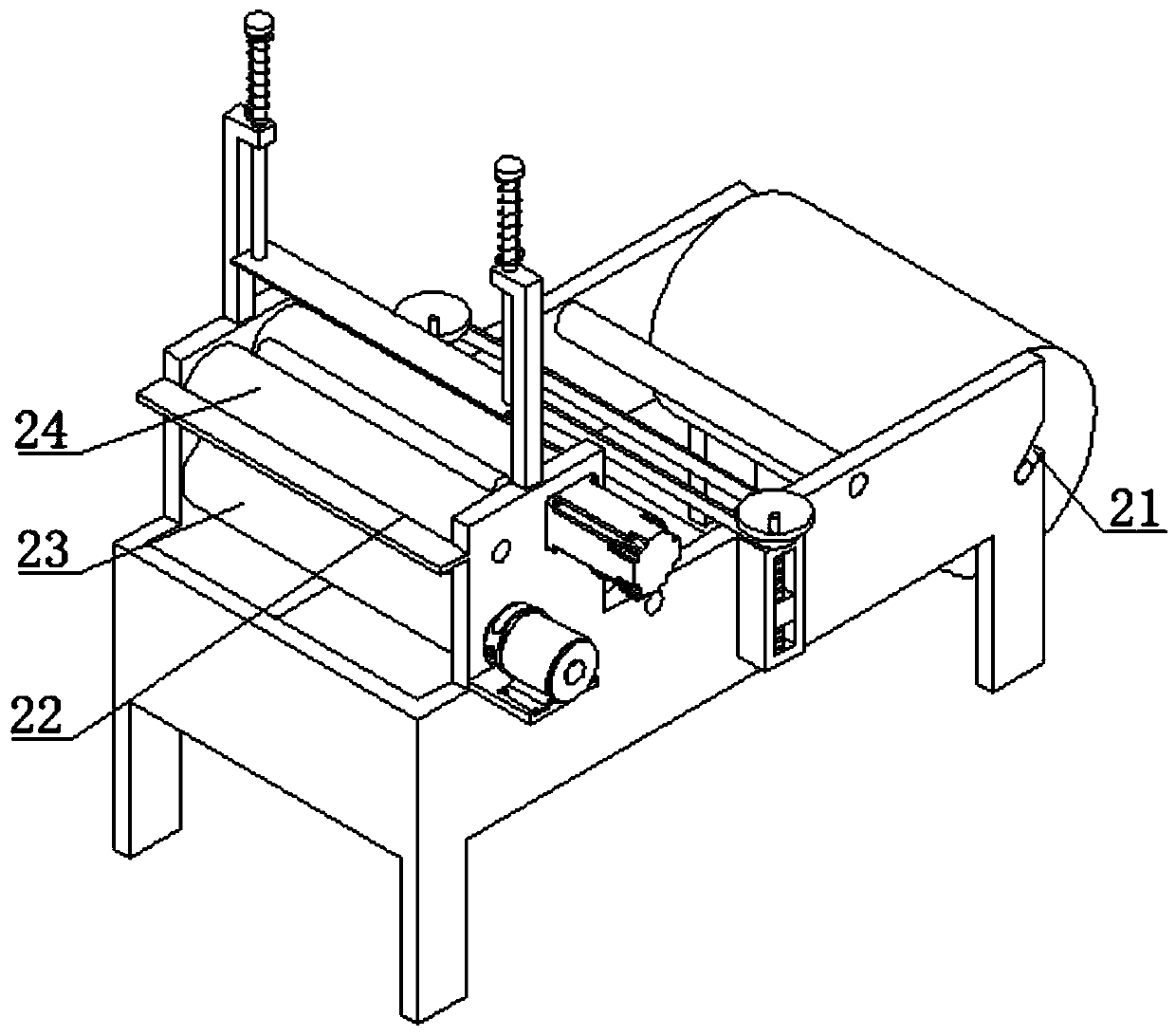

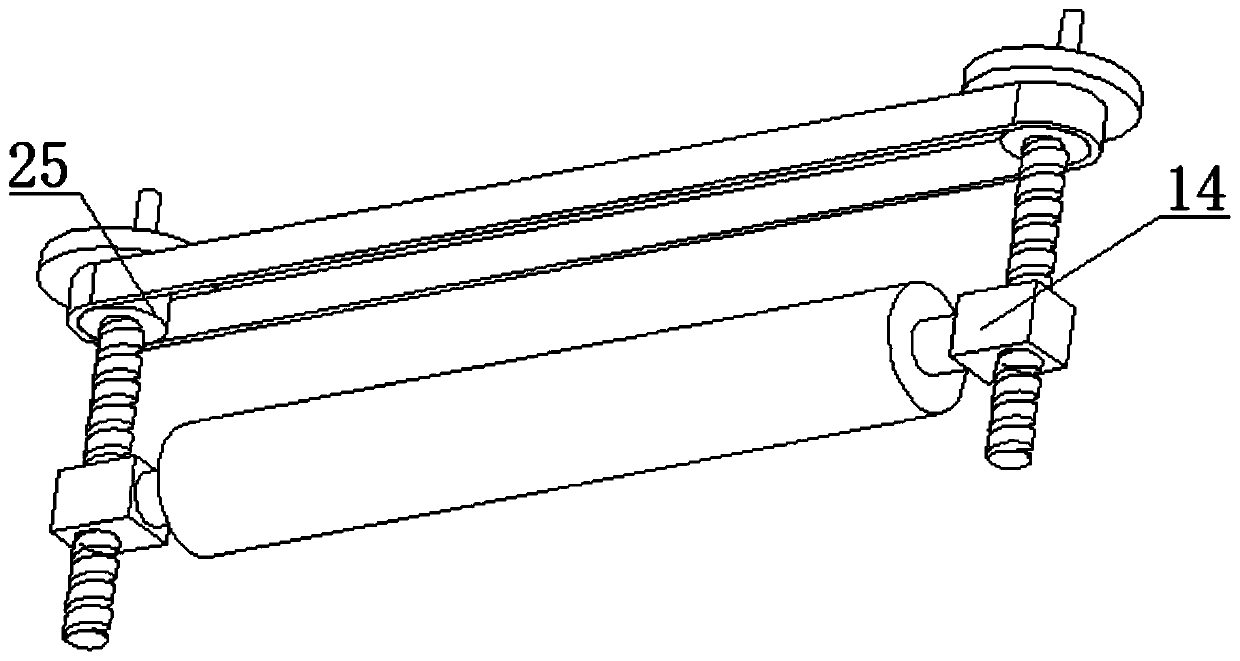

The invention belongs to the technical field of core-spun yarns and particularly relates to a multi-coating core-spun yarn and a preparing machine thereof. The preparing machine comprises a rack, a rotating disc is rotationally connected to the rack and connected with a driving mechanism, a central yarn tube is fixedly arranged on the rotating disc in a penetrating mode, at least one spindle located on the periphery of the central yarn tube is arranged on the rotating disc, and the spindles are used for carrying bobbins. The rotating disc is further fixedly provided with a plurality of yarn passing needle tubes for covering yarns released from the bobbins to penetrate through from bottom to top in a penetrating mode, the yarn passing needle tubes correspond to the spindles one by one and are located between the spindles and the central yarn tube, and the heights of the yarn passing needle tubes are gradually increased or decreased clockwise or anticlockwise in the circumferential direction so that the covering points of the covering yarns and a core yarn can be sequentially arranged side by side in the axial direction of the core yarn. The multi-coating core-spun yarn and the preparing machine thereof have the advantages that the yarn passing needle tubes are arranged in the circumferential direction, the heights of the yarn passing needle tubes are sequentially increased or decreased, a strip shape is formed after all the covering yarns are arranged side by side together, it is ensured that no gap appears between the covering yarns, the production efficiency can be easily improved, and energy consumption can be reduced.

Owner:浙江可羽纺织科技有限公司

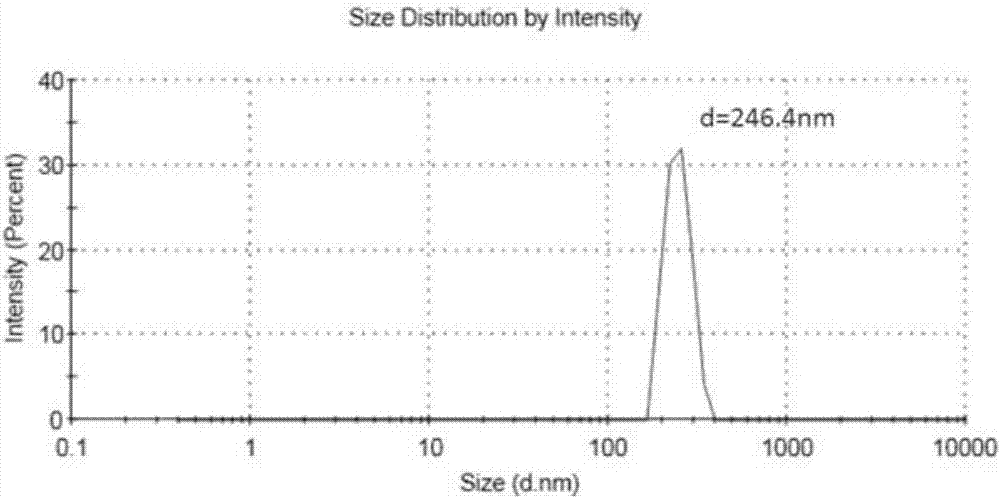

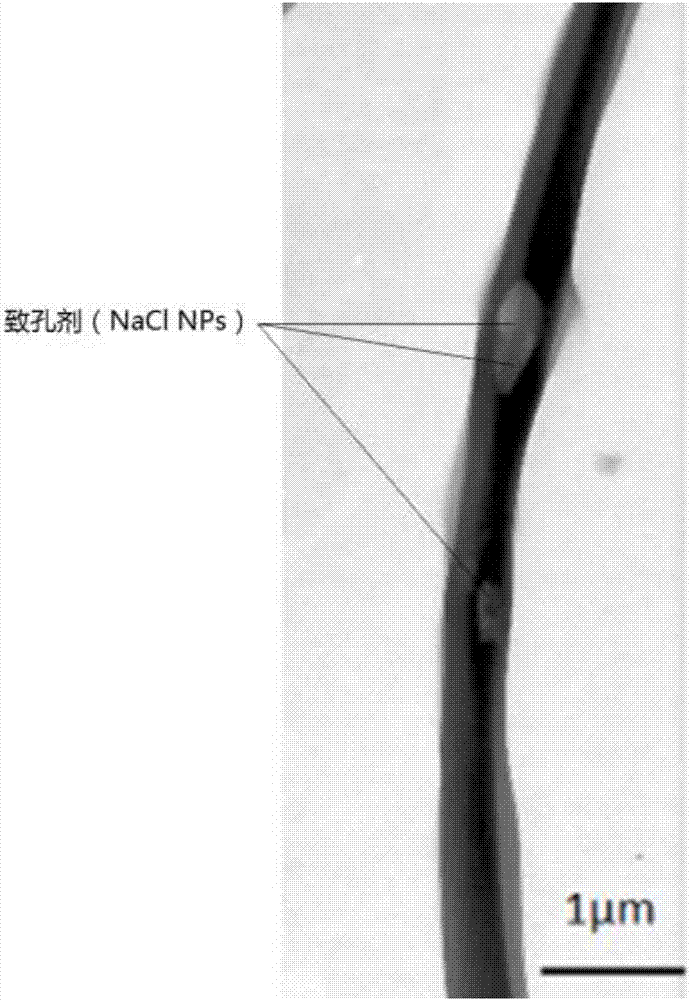

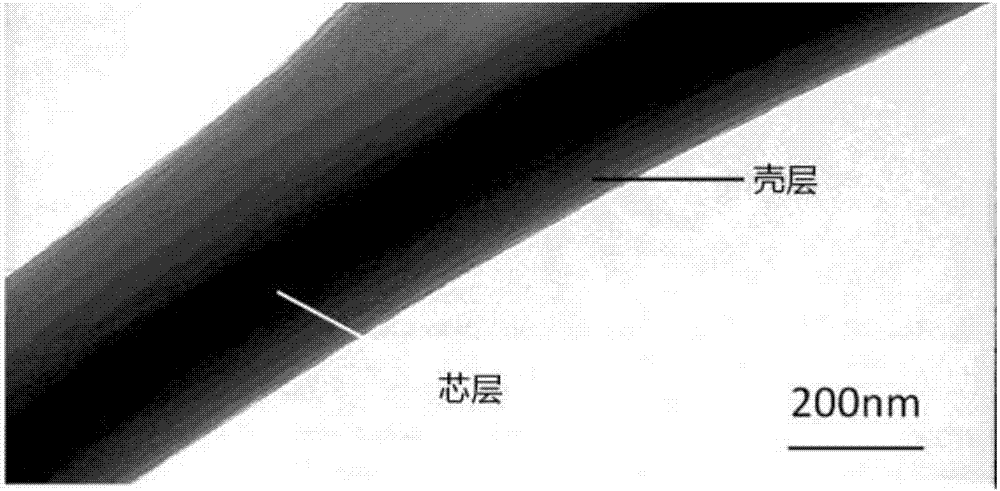

Coaxial electrospun injectable fibers and preparation method thereof

ActiveCN107115268AQuick releaseGood solution dispersibilityPharmaceutical delivery mechanismEther/acetal active ingredientsFiberUltrasonic oscillation

The invention discloses coaxial electrospun injectable fibers and a preparation method thereof. Each fiber comprises a core-layer fiber and a shell-layer fiber covering the core-layer fiber; the preparation method of the injectable fibers comprises the following steps: (1) preparing a shell layer solution; (2) preparing a core layer solution; (3) preparing by adopting a coaxial electrospinning technology to obtain coaxial electrospun fiber membranes; putting the fiber membranes into ultrapure water at 0 to 4 DEG C, and standing for 2min to 5min; then putting the fiber membranes into an ice bath and carrying out ultrasonic oscillation for 20 to 36 times and for 4min to 6min; then centrifuging at the speed of 1200r / min to 2000r / min for 5min to 8min; collecting sediment and drying in vacuum to obtain the coaxial electrospun injectable fibers. According to the coaxial electrospun injectable fibers prepared by the preparation method, the injectable characteristic is added on the basis of a time sustained-release property, intramuscular administration can be positioned, and a medicine sustained-release phase and the like are controlled, so that the effect of minimally invasive treatment is realized, the treatment difficulty and risks are reduced, the invasive operation is reduced, and treatment pains are prevented.

Owner:SICHUAN UNIV

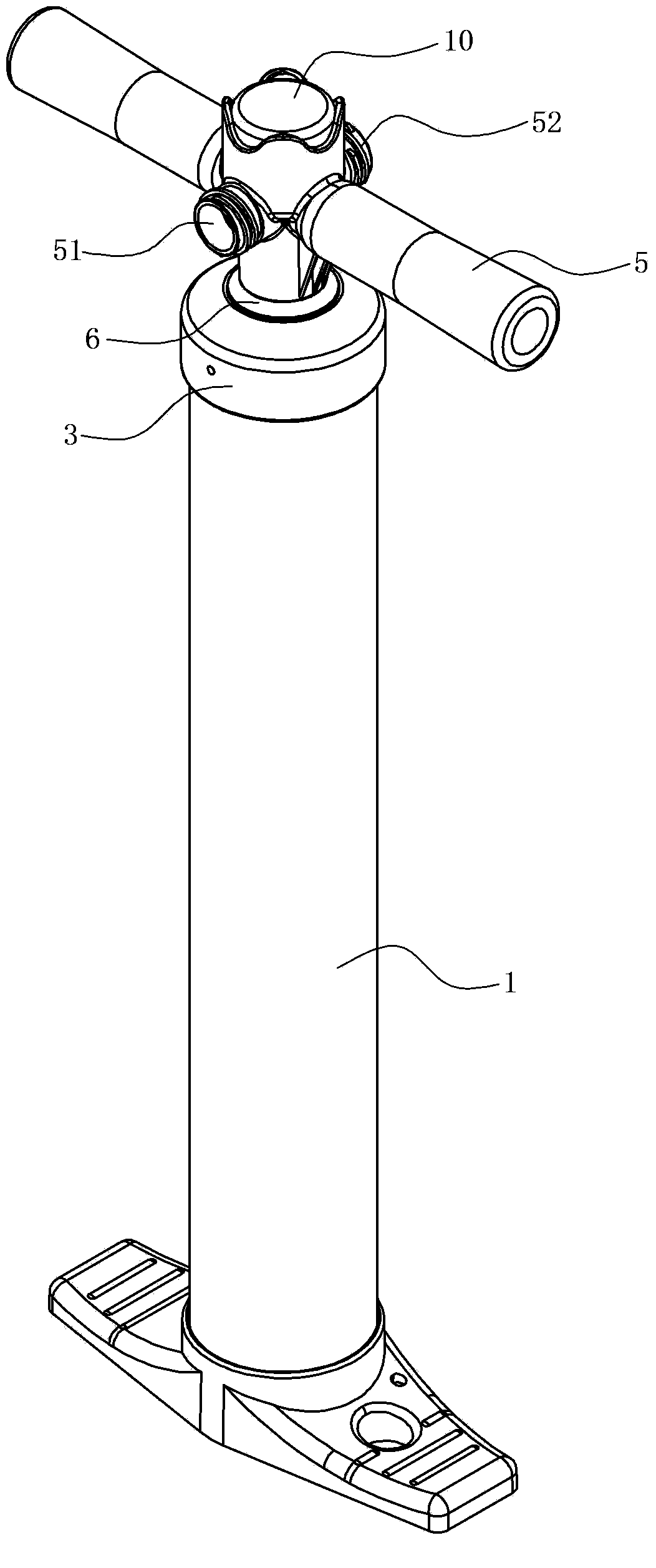

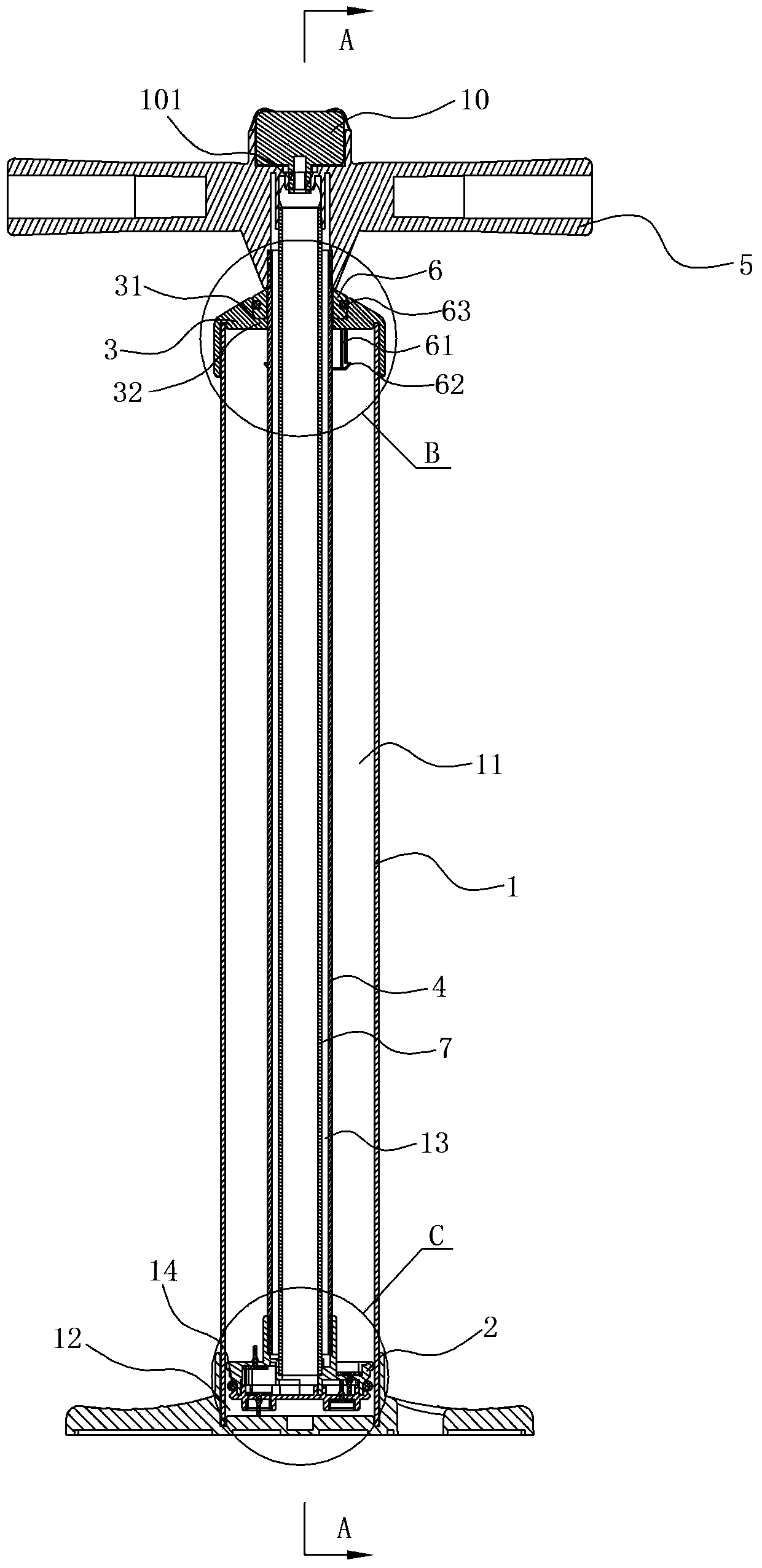

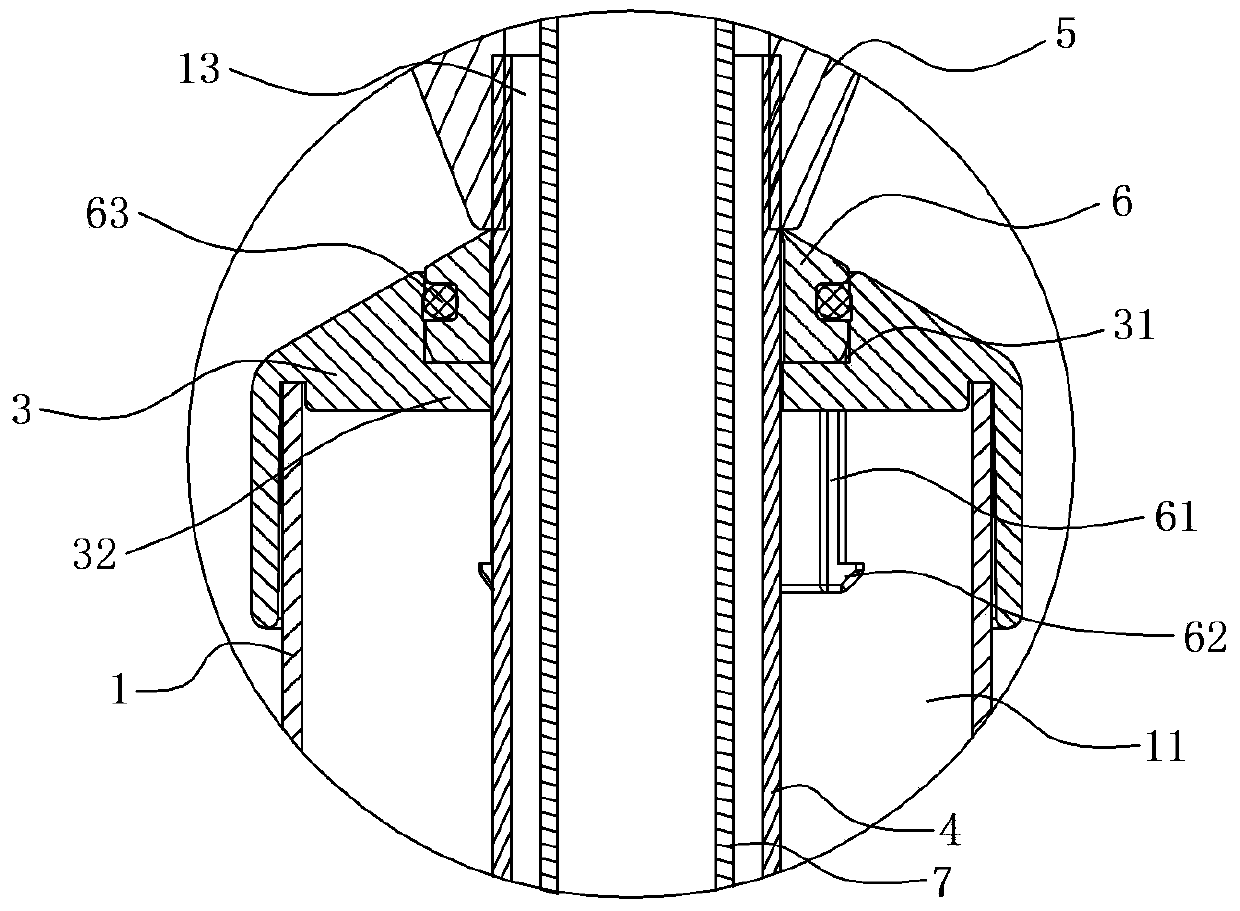

Bi-directional aerating high pressure inflator

The invention relates to a bi-directional aerating high pressure inflator, which comprises an inflator body and a piston, wherein the piston divides an internal space of the inflator body into an upper air chamber and a lower air chamber; and an upper cover is arranged on an upper part of the inflator body. The bi-directional aerating high pressure inflator is characterized in that a valve hole communicated with the upper air chamber and outside is formed in the upper cover; a plurality of fillets arranged at intervals along the circumference are formed on an inner hole wall of the valve hole along a radial direction; a valve cover capable of sliding up and down is arranged in the valve hole; a plurality of downwards extending guiding bars arranged at intervals along the circumference are arranged under the valve cover; and a hook part tapped with an inner top wall of the upper cover is arranged on the outer sides of the bottom parts of the guiding bars. When pressure generated by air pressure of the upper air chamber on a valve cover is larger than frictional force between the valve cover and an inner wall of the valve hole, the valve cover is pushed to move upwards, the valve hole is at an open state, a grip is pulled upwards in a labor saving manner, without a support force of a spring, the valve cover is at a loosening state, the grip is pulled upwards again, the valve cover can be opened easily, the inflator is changed to be in a one-way inflating mode, and when the inflator is inflated to be with a certain pressure by inflating equipment, the way that the grip is pulled upwards is still labor-saving.

Owner:NINGBO BRAVO MFG OF INFLATORS & ACCESSORIES

Natural Bama mineral white mud facial mask, and preparation method thereof

InactiveCN103585030AFrictionalImprove textureCosmetic preparationsToilet preparationsWrinkle skinSide effect

The invention relates to a natural Bama mineral white mud facial mask and a preparation method thereof, and belongs to the field of beauty skin care products. The natural Bama mineral white mud facial mask is prepared by taking an ore (mainly contains algae dolomite) that comes from karst landform in Changshou country, Bama, Guangxi province as a main raw material, and auxiliary materials, which are used for cosmetic production, as the balance. The preparation method is relatively simple and convenient, and no environmental pollution is caused. The mud particles of the natural Bama mineral white mud facial mask are fine; the natural Bama mineral white mud facial mask contains no large particles, is soft for smearing, and possesses no toxic or side effects; and no friction on skin is caused. The natural Bama mineral white mud facial mask is capable of increasing elasticity of skin, delaying skin senescence, adjusting human body metabolism, activating blood circulation and dissipating stasis, avoiding wrinkle, realizing skin whitening, diminishing inflammation, sterilizing, and protecting skin from ultraviolet light; and is suitable for people of all ages and people with various skin types, and is especially suitable for people with sensitive skin.

Owner:长沙可滋泉生物科技有限公司

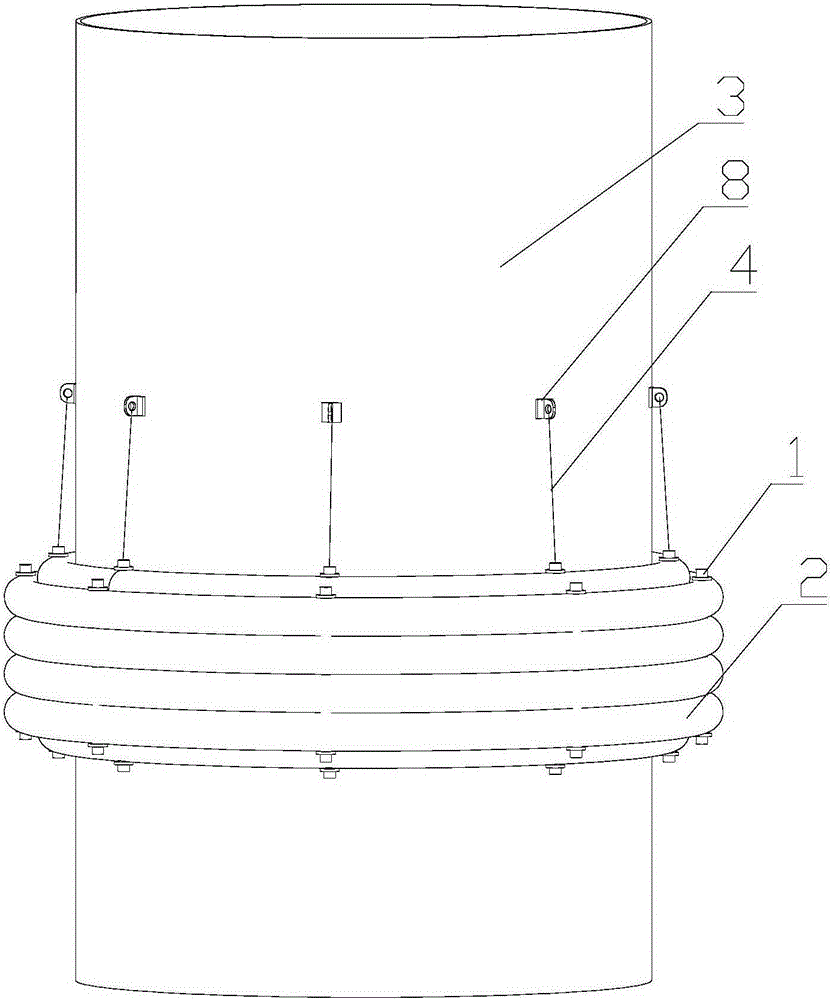

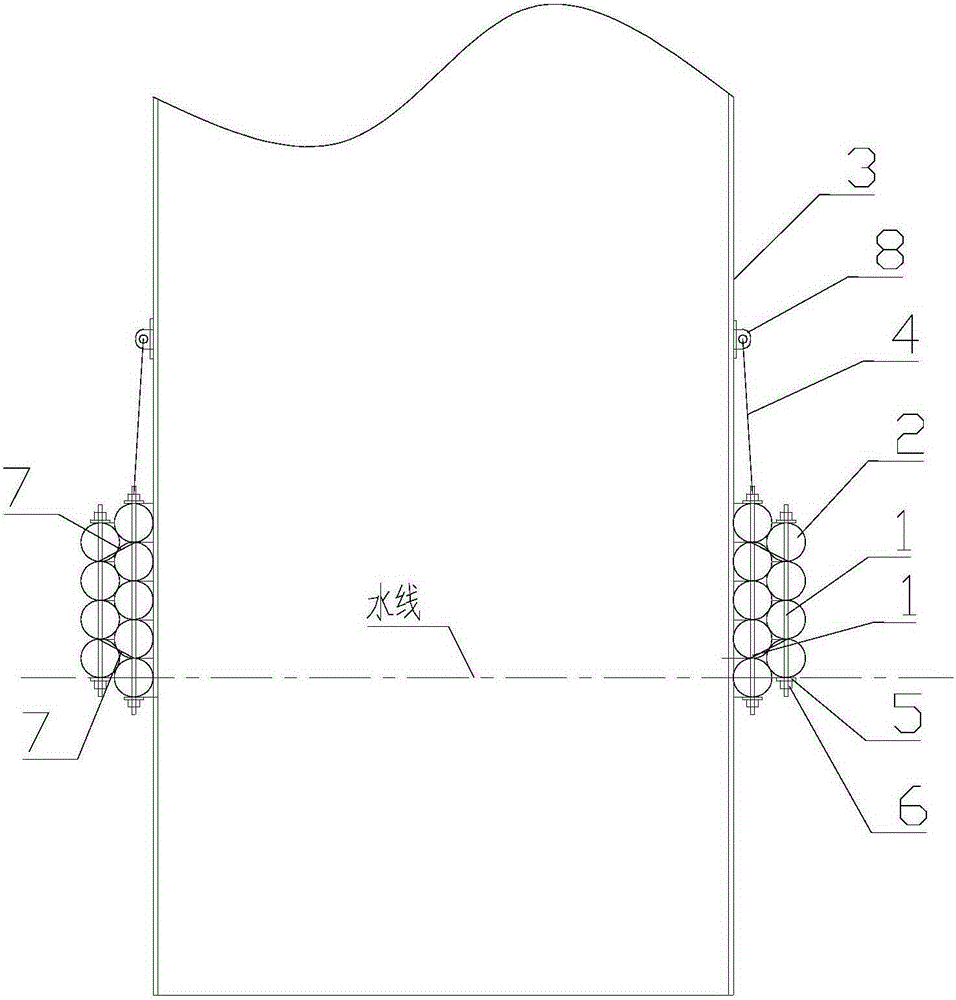

Collision and ice preventing device of sea fan

ActiveCN105297681AEasy to transportReduce weightClimate change adaptationShipping equipmentSea iceEngineering

The invention relates to a collision and ice preventing device of a sea fan. The device comprises collision preventing cylinder structures with two or more layers, wherein the collision preventing cylinder structure consists of more than two collision preventing rings; the collision preventing rings are vertically laminated; multiple serial connecting rods are vertically inserted in the peripheral direction of the collision preventing cylinder structure; the serial connecting rods penetrate through the collision preventing rings one by one to serially connect the collision preventing rings; the collision preventing rings are spliced by collision preventing rubber pipes passing through the serial connecting rods; the spliced ports of the collision preventing rings are staggered from one another; clamping parts are arranged at the two ends of the serial connecting rods exposed on the collision preventing cylinder structure; the adjacent collision preventing cylinder structures are mutually connected through connecting pieces; and the collision preventing cylinder structures coat a fan foundation, and are lifted with the fan foundation through lifting cables. The collision and ice preventing device has the advantages of easy installation and low manufacturing cost. The structure can effectively buffer the impact of operation and maintenance ships to the fan foundation and the squeezing effect of ice layers in the winter sea icing season on the fan foundation, and can effectively weaken the scouring effect of seawater on the fan foundation.

Owner:NEW UNITED GROUP

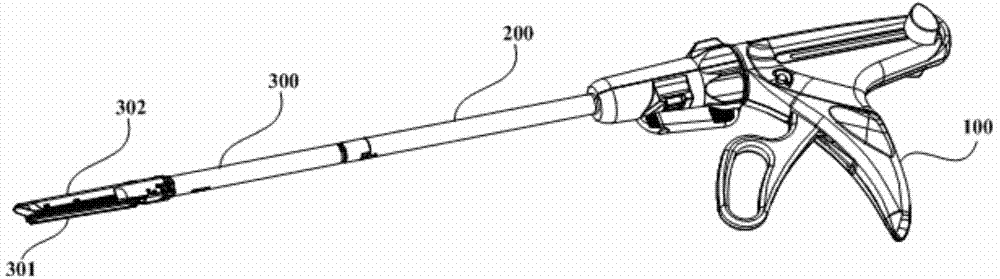

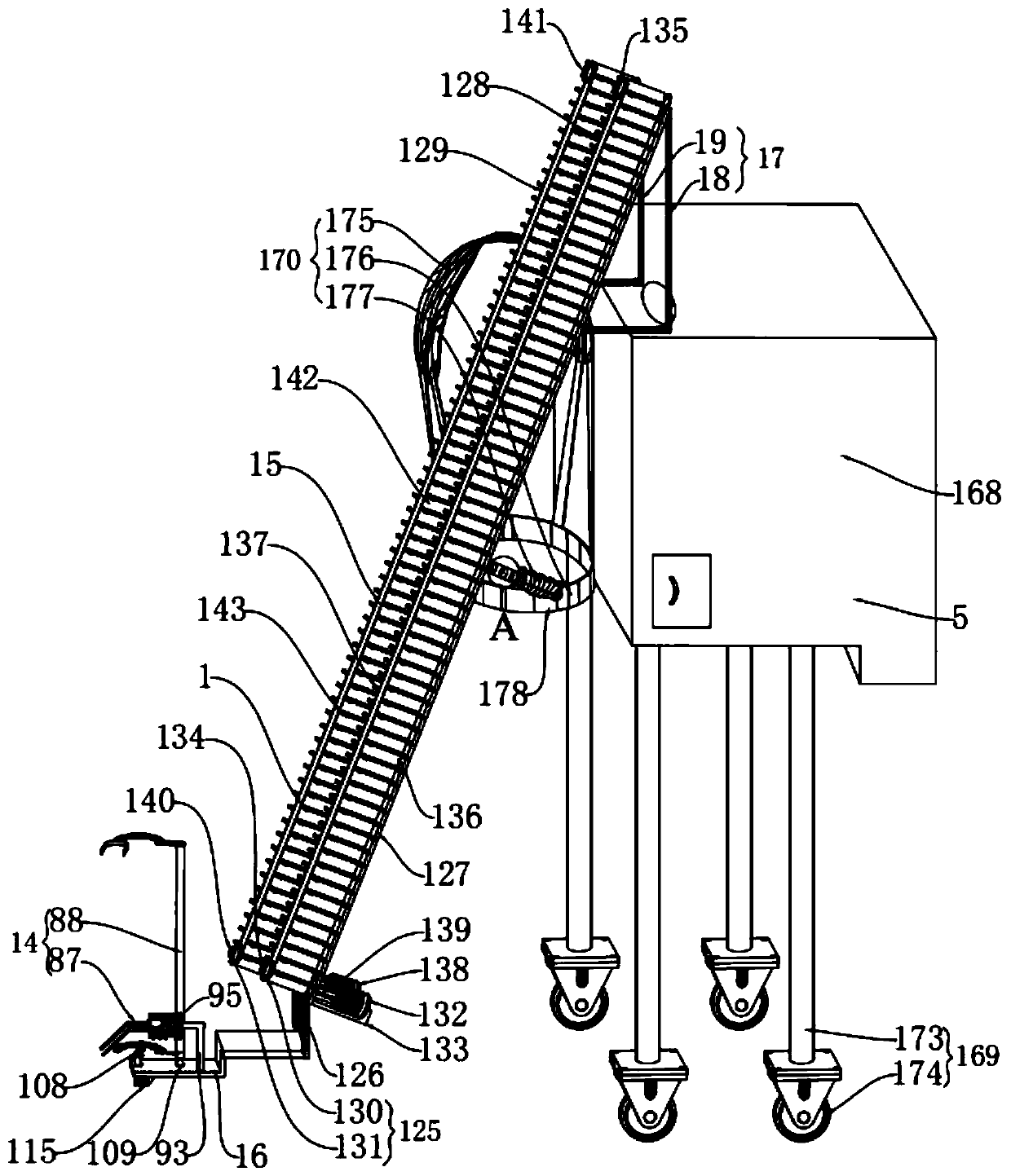

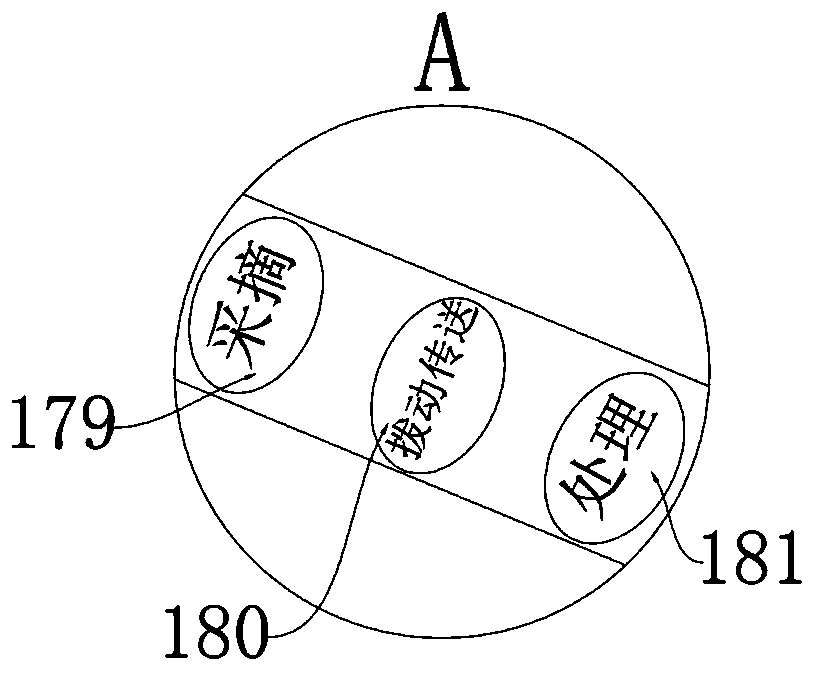

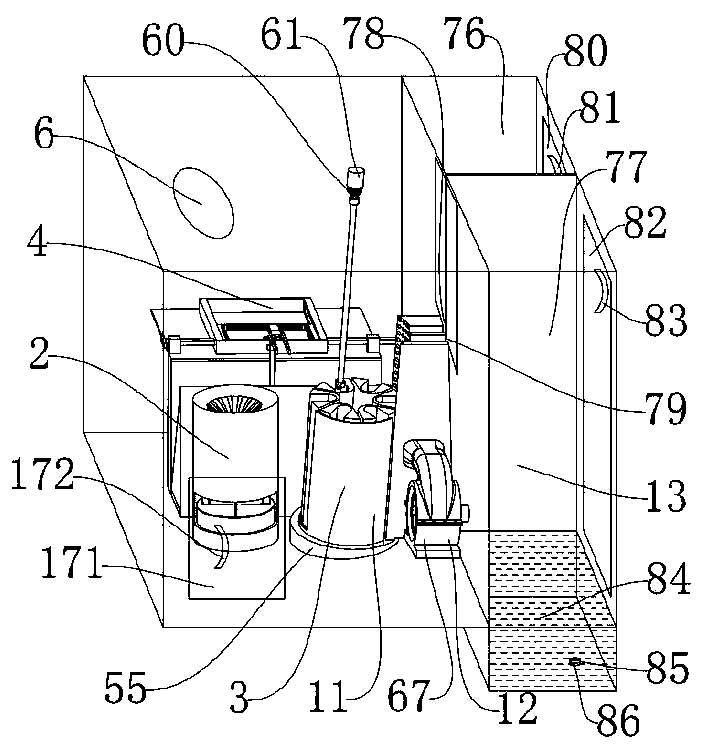

Flexible drive element, end effector and surgical operating instrument

The invention relates to the technical field of medical instruments and discloses a flexible drive element, an end effector and a surgical operating instrument. The flexible drive element comprises a head portion, a tail portion and a plate stress bending portion, the plate stress bending portion between the head portion and the tail portion and comprises a plurality of metal filaments and a flexible seal sleeve, and the flexible seal sleeve covers the plurality of metal filaments which extend along the length direction of the flexible drive element. In the technical scheme, the plurality of metal filaments enable the stress bending portion to have certain rigidity and flexibility and can be relatively fixed by the flexible seal sleeve, and accordingly surface friction of the flexible drive element can be reduced, and rigidity of the flexible drive element can be further improved. The flexible drive element is capable of effectively transferring driving forces required by instruments and less prone to destructive permanent deformation during turning, triggering and retracting, and accordingly difficulty in operation of surgical operating instruments is greatly lowered for surgeons, and simplicity and convenience in a machining process are achieved due to reduction of a welding procedure.

Owner:REACH SURGICAL

Integrated rotary-pull-leaf-removing air-flow-tilt-preventing precise-classification wearable traveling garment for antirrhinum majus harvesting

ActiveCN110366938AFrictionalImprove practicalityHarvestersFlower preserving apparatusEngineeringAntirrhinum majus

Owner:XUZHOU YUNCHUANG CATERING CO LTD

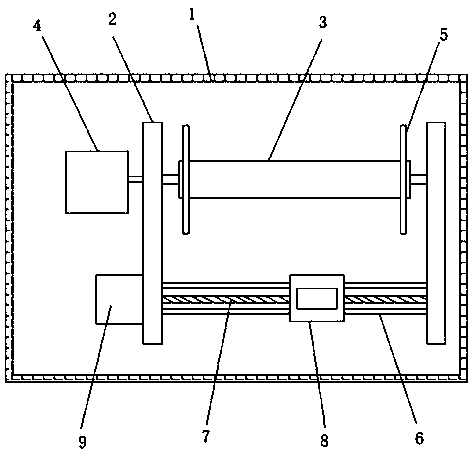

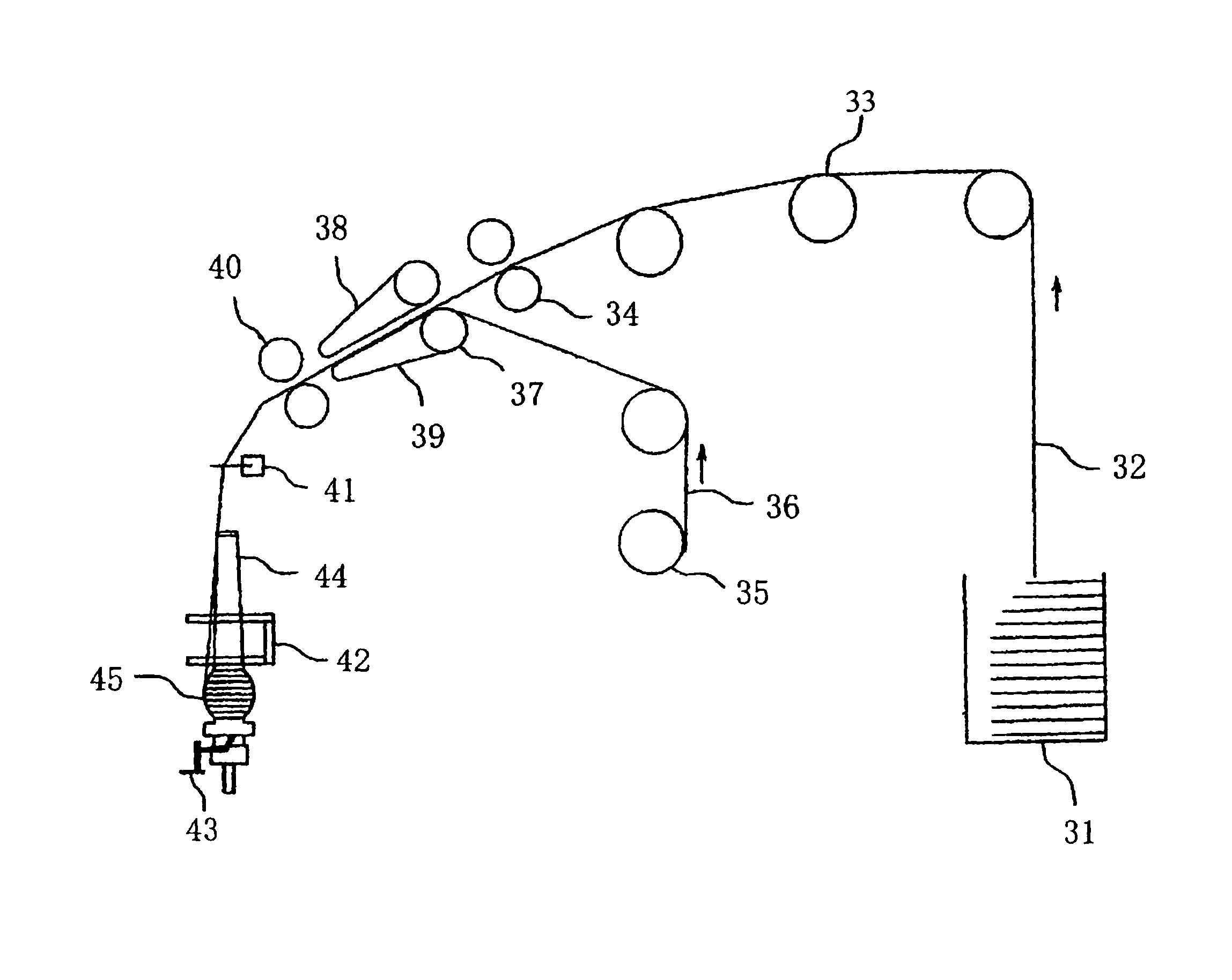

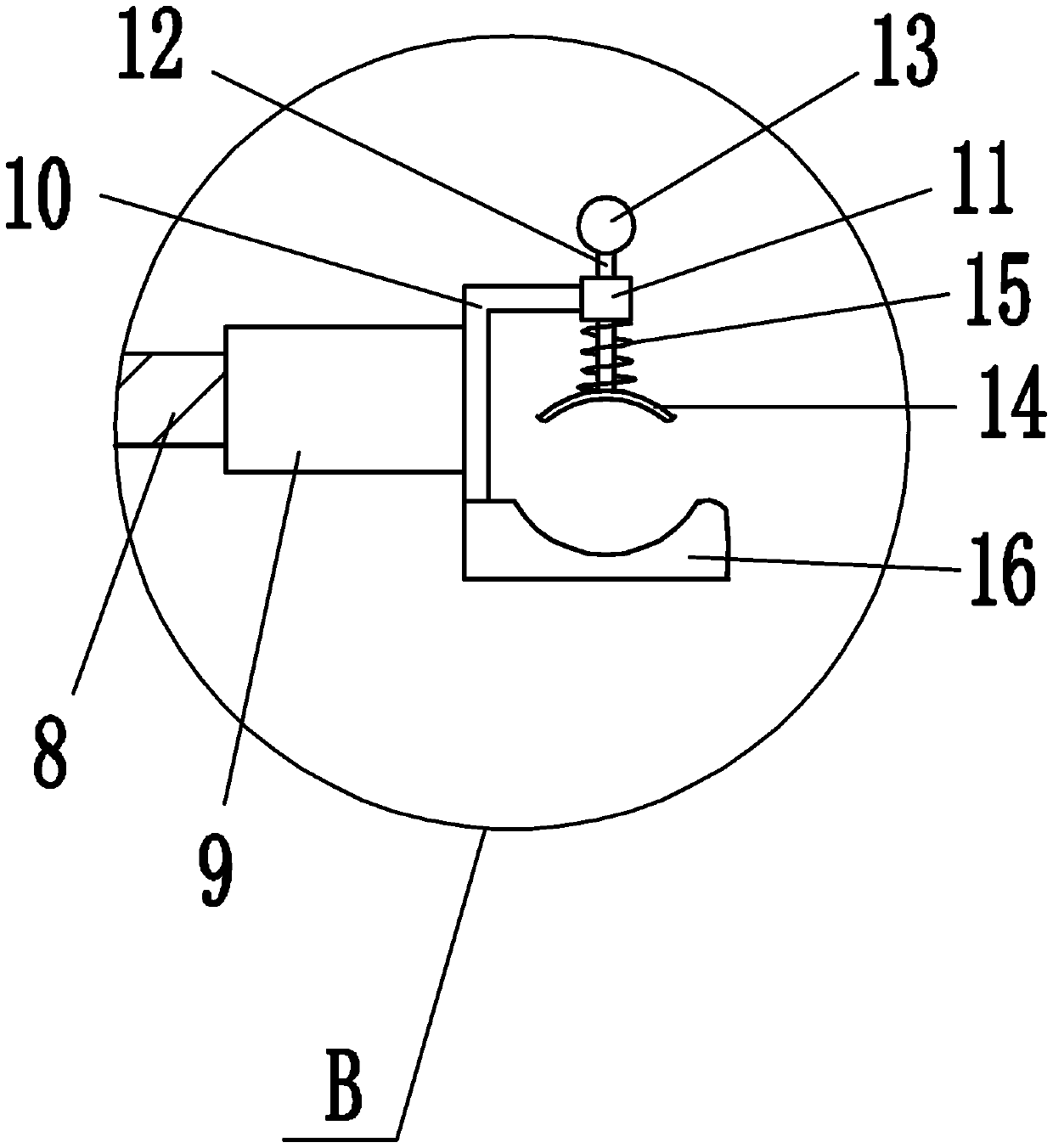

Pipe winding machine for condenser coil pipe

The invention discloses a pipe winding machine for a condenser coil pipe. The pipe winding machine for the condenser coil pipe comprises a bottom plate, wherein two supporting plates are welded to thetop of the bottom plate; a winding roller is rotatably installed between the two supporting plates; limiting plates sleeve two ends of the winding roller; the limiting plates are fixedly connected with the winding roller; a first bidirectional motor and a second bidirectional motor are fixedly installed on the bottom plate; an output shaft of the first bidirectional motor is fixedly connected with the winding roller; and two horizontally arranged guide rods are fixedly installed between the two supporting plates. A screw rod is rotatably installed between the two supporting plates, a moving plate is slidably installed on the guide rod, the moving plate is in threaded connection with the screw rod, an output shaft of the second bidirectional motor is fixedly connected with the screw rod, and the top of the moving plate is separately welded to a first side plate and a second side plate. According to the pipe winding machine for the condenser coil pipe, the uniform winding of a pipe is ensured, and meanwhile, the pipe is in a tight state in the winding process through a clamping mechanism, so that relaxation cannot occur, the pipe winding effect is good, the use is convenient, and the popularization is easy.

Owner:滁州雨博机电科技有限公司

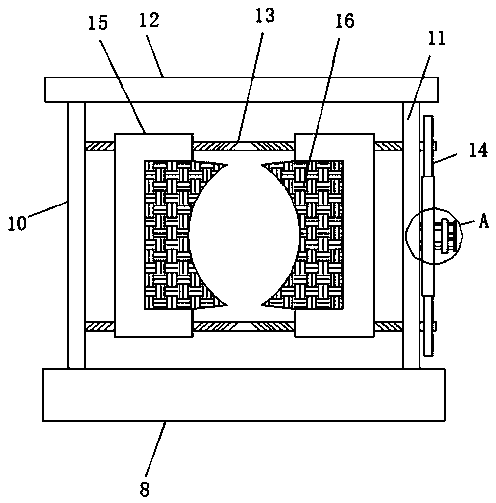

Efficient drilling device for pearl processing design and using method thereof

InactiveCN110871503AAvoid position shiftImprove processing efficiencyWorking accessoriesStone-like material working toolsControl engineeringDrill bit

The invention discloses an efficient drilling device for pearl processing design and a using method thereof, and belongs to the field of pearl processing design. An operation table and a positioning table arranged at the upper end of the operation table are involved in the efficient drilling device for the pearl processing design and the using method thereof, a plurality of positioning holes are formed in the upper end of the positioning table in the horizontal direction, and L-shaped fixing tables are fixedly connected to the side walls of the front side and the rear side of the positioning table correspondingly. According to the efficient drilling device and the using method, the plurality of positioning holes for limiting the pearls are formed in the positioning table, a group of pearllimiting mechanisms are symmetrically arranged on the two sides of each positioning hole, the pearl limiting mechanisms do opposite motion under the action of transverse electric push rods to limit and fix the pearls, and the positions of the pearls in the perforating process are effectively prevented from being shifted; and a plurality of electric drills corresponding to the positions of the positioning holes are arranged, so that the synchronous drilling operation of the plurality of pearls is achieved, the situation that the pearls need to be drilled one by one is avoided, and the processing efficiency and the processing quality are effectively improved.

Owner:SUZHOU CHINA PEARL & GEM CITY CO LTD

Hybrid carbon fiber spun yarn and hybrid carbon fiber spun yarn fabric using the same

ActiveUS8171711B2High tensile strengthReduce adhesionLayered productsFinal product manufactureYarnCarbon fibers

A hybrid carbon fiber spun yarn having a core region with carbon fibers as a main component, and a surrounding region with carbon fibers as a main component and covers an outer peripheral surface of the core region. 20% by mass or more of fibers forming the core region are long carbon fibers having a fiber length of 500 mm or longer. 80% by mass or more of fibers forming the surrounding region are short carbon fibers having a fiber length of less than 500 mm. A mass ratio between the long carbon fibers and the short carbon fibers (long carbon fibers:short carbon fibers) is in a range of 20:80 to 80:20.

Owner:KUREHA KAGAKU KOGYO KK

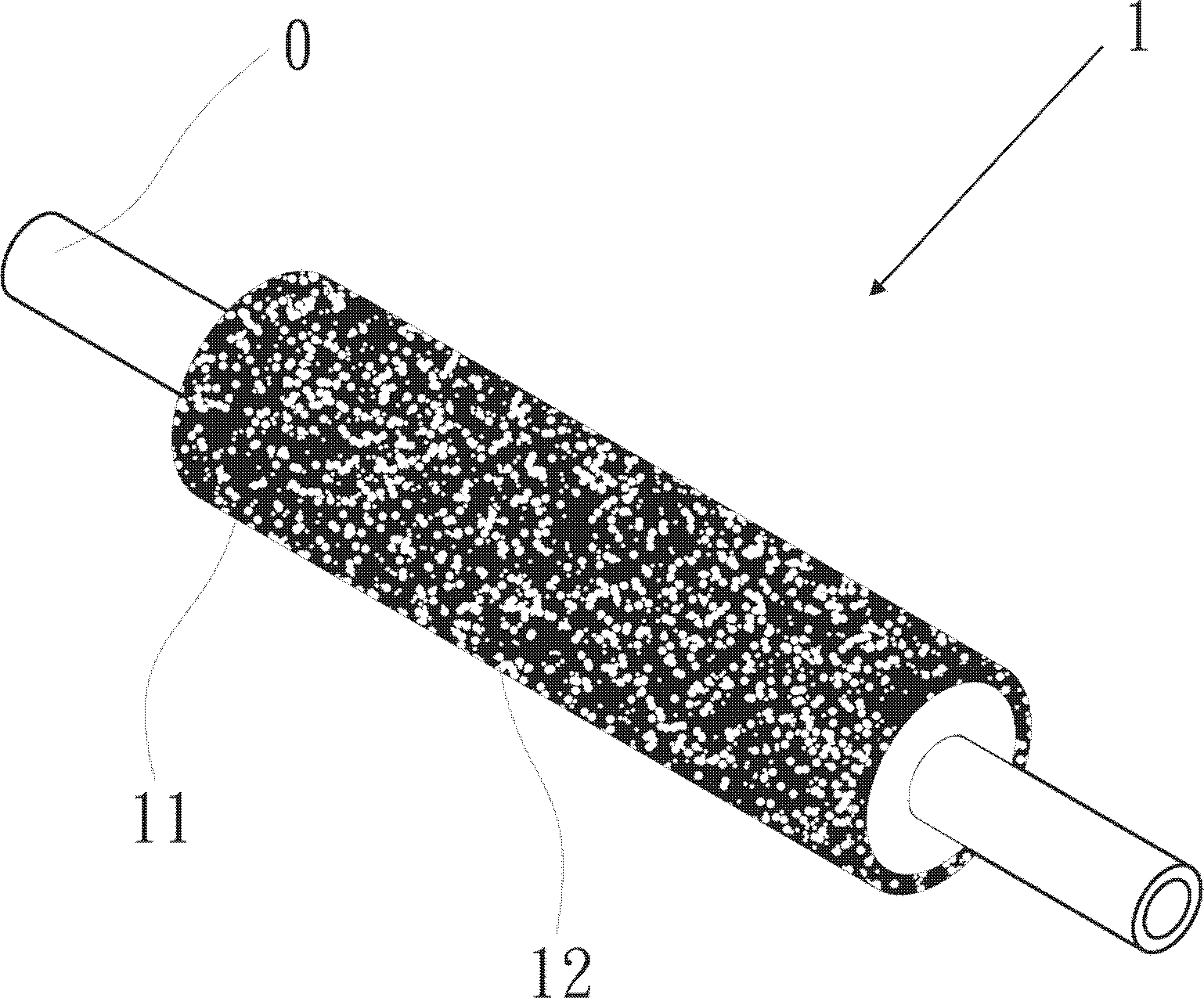

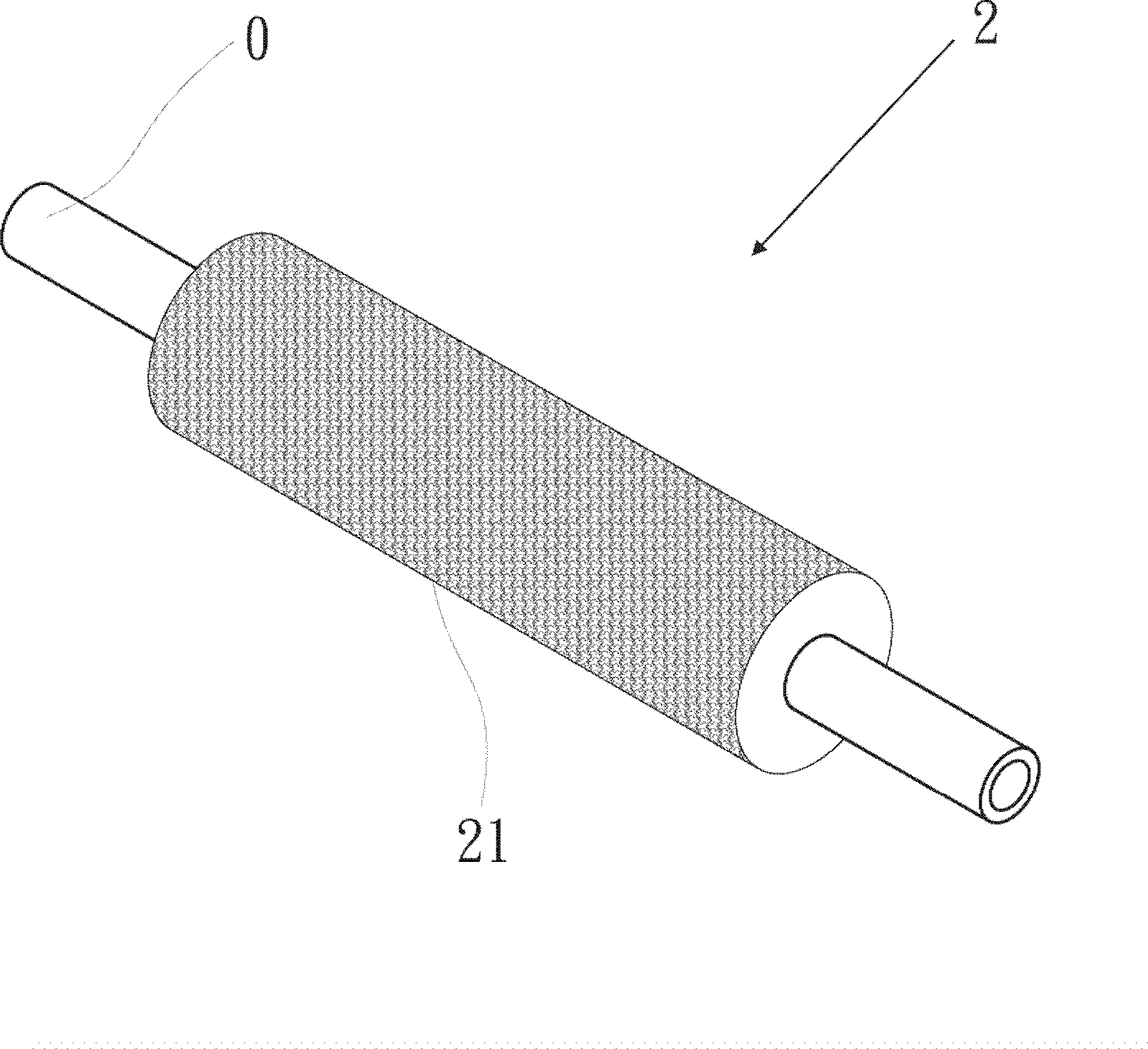

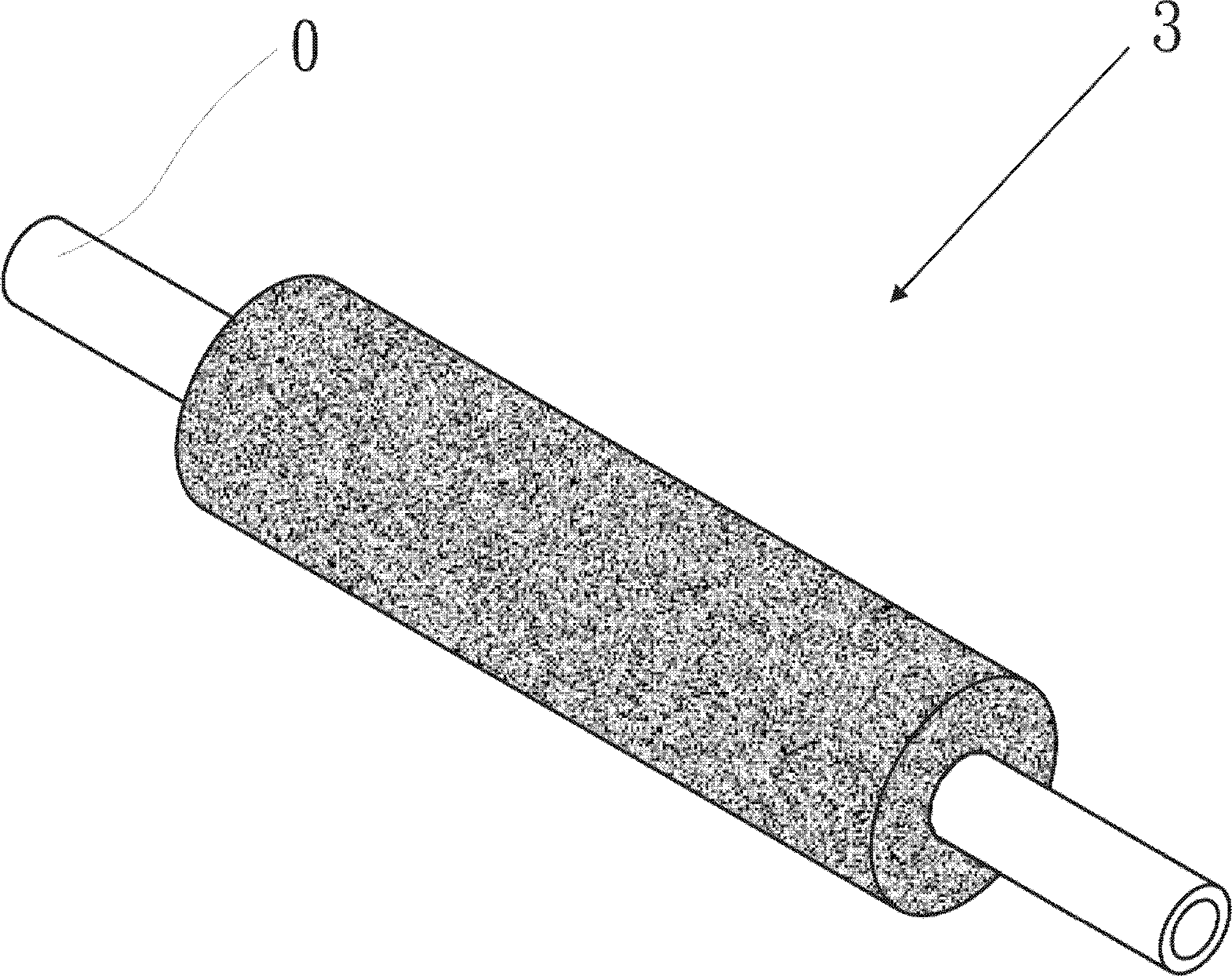

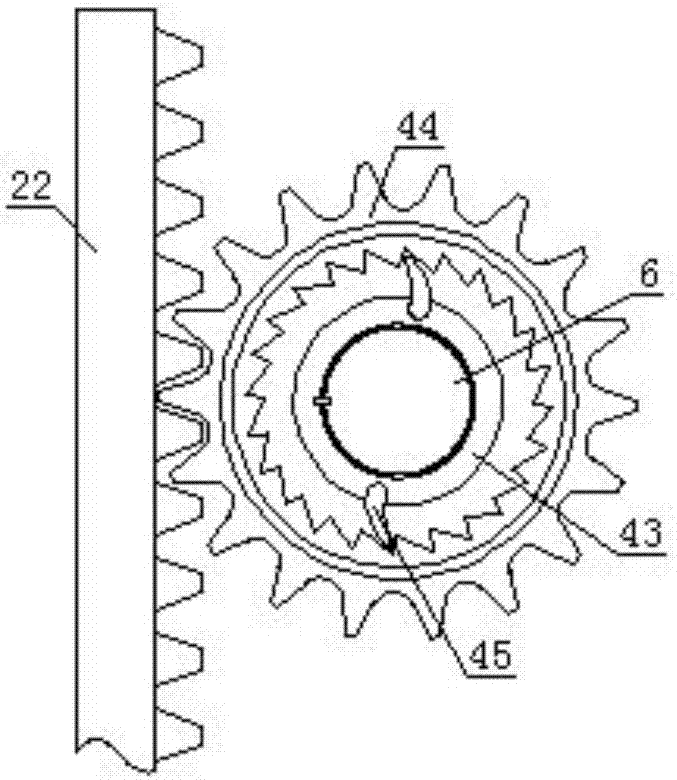

Improved rubber roll device and manufacturing method thereof

InactiveCN102758905AExtended service lifeLonger and more stable service lifePortable liftingGearing elementsPrepolymerRough surface

The invention discloses an improved rubber roll device and a manufacturing method thereof. The rubber roll device comprises a rotating shaft (0) and a rubber roll (3) which is coaxially and fixedly arranged outside the rotating shaft (0), wherein the rubber roll (3) is made of PU (Polyurethane) material and air pores (31) are uniformly and densely formed in the rubber roll (3). The manufacturing method of the rubber roll device comprises the following steps of: combining the axis (0) and a forming mould to form a heating mould assembly; mixing and stirring PU prepolymer, a hardening agent and water; filling mixture of a flow 20 into the heated mould; hermetically standing the mould assembly with filled mixture; and taking the rubber roll device comprising the axis (0) and the rubber roll (3) out of the mould. The rubber roll device and the manufacturing method thereof have the advantages that the rubber roll material is PU and the air pores are uniformly and densely formed in the rubber roll, so that the physical structure of the rubber roll is a tough anti-skid rough surface from inside to outside, i.e., the outer surface of the rubber roll is an anti-skid rough surface and has friction force in spite of the diameter of the worn rubber roll.

Owner:施瑞仁

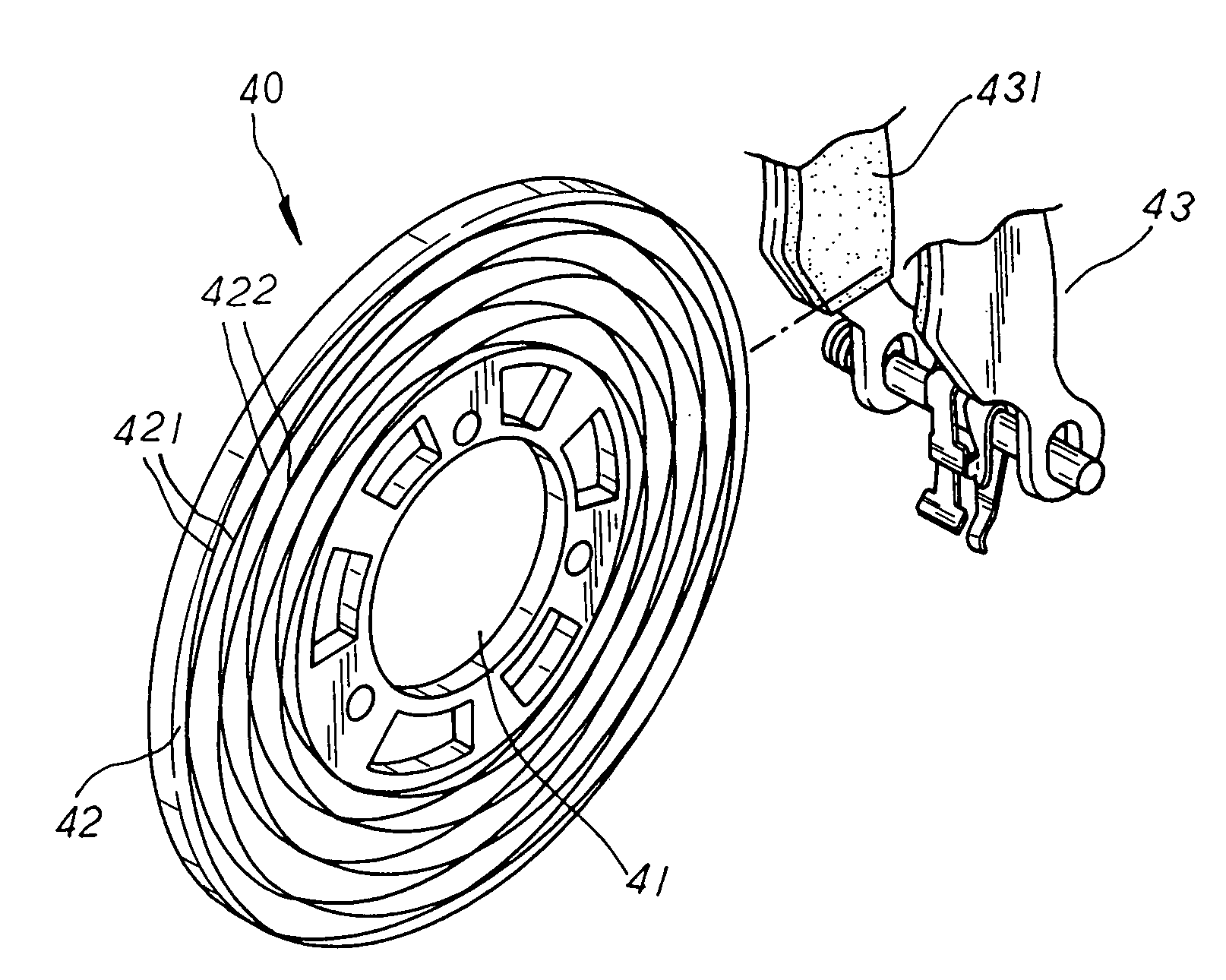

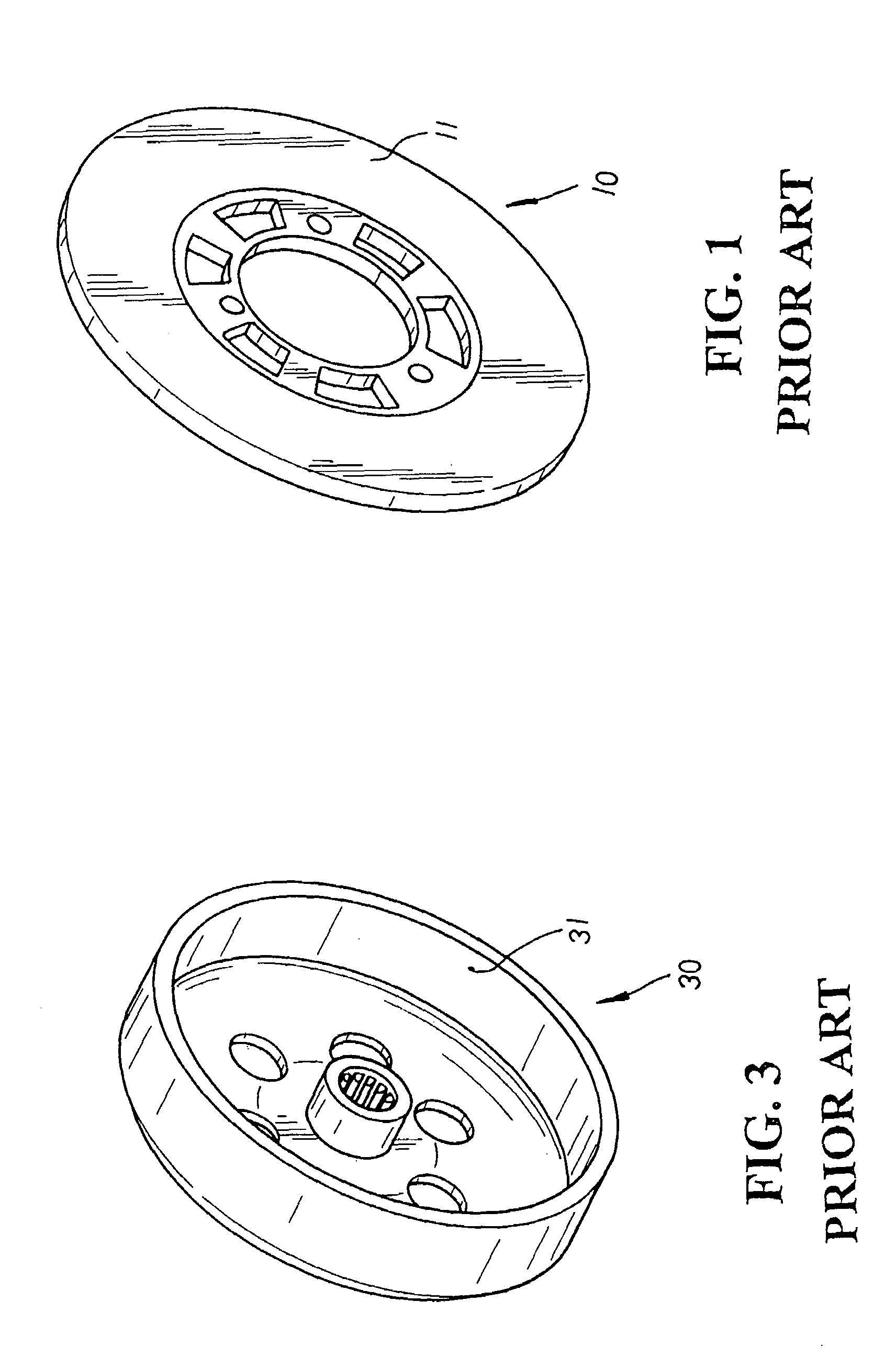

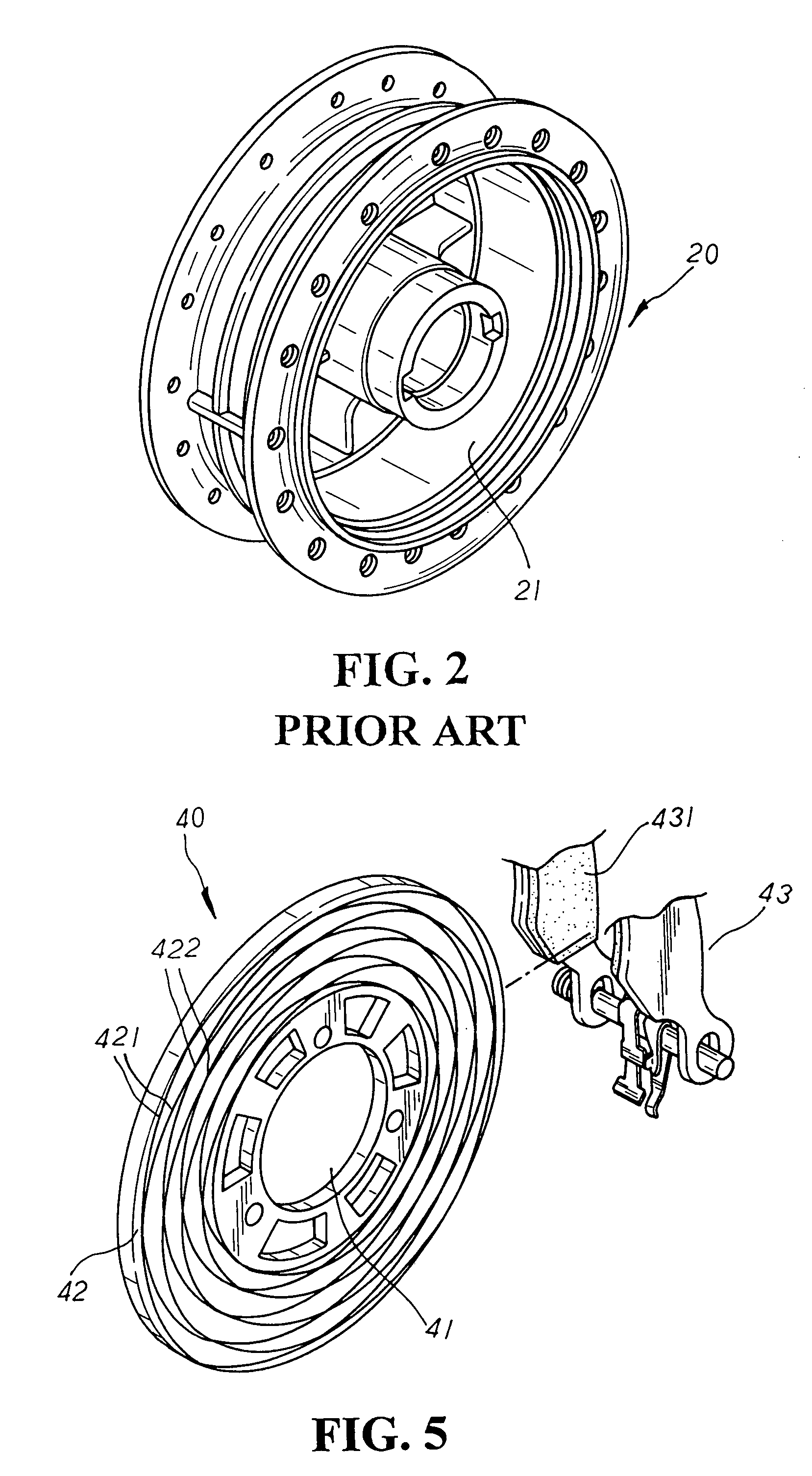

Brake structure of vehicle

InactiveUS6971490B2Increase coefficient of frictionImprove balanceAxially engaging brakesBraking drumsEngineeringVehicle braking

Owner:LIN YU HUAN

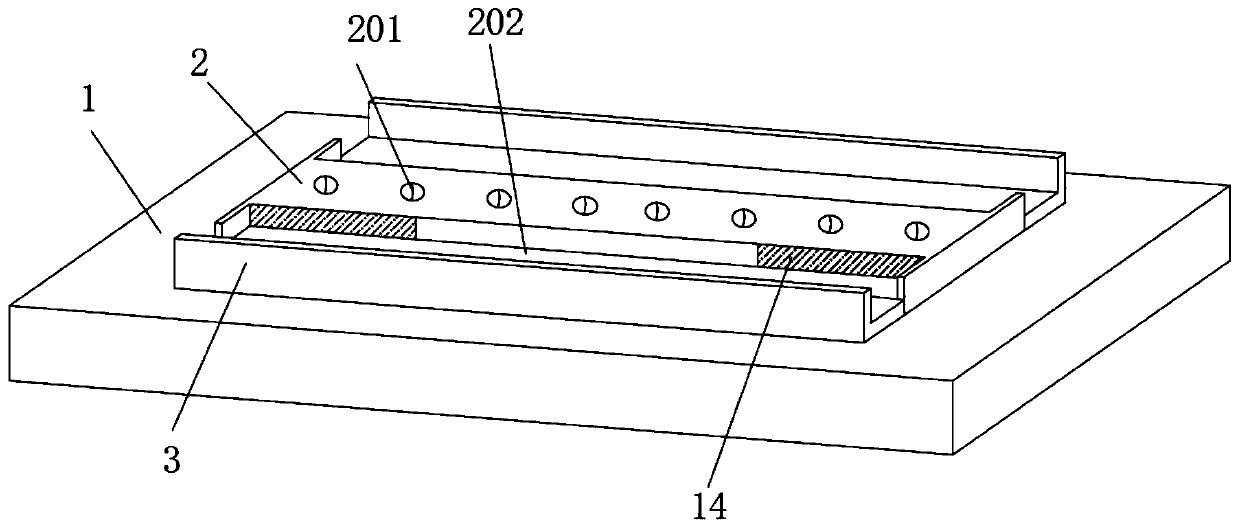

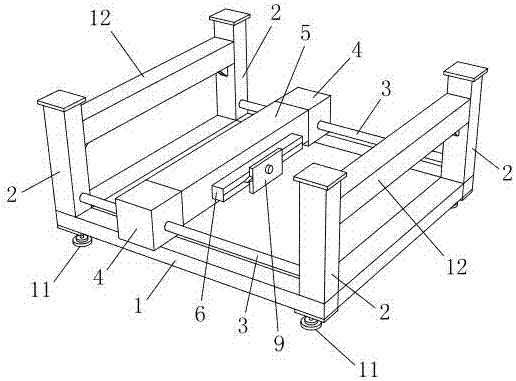

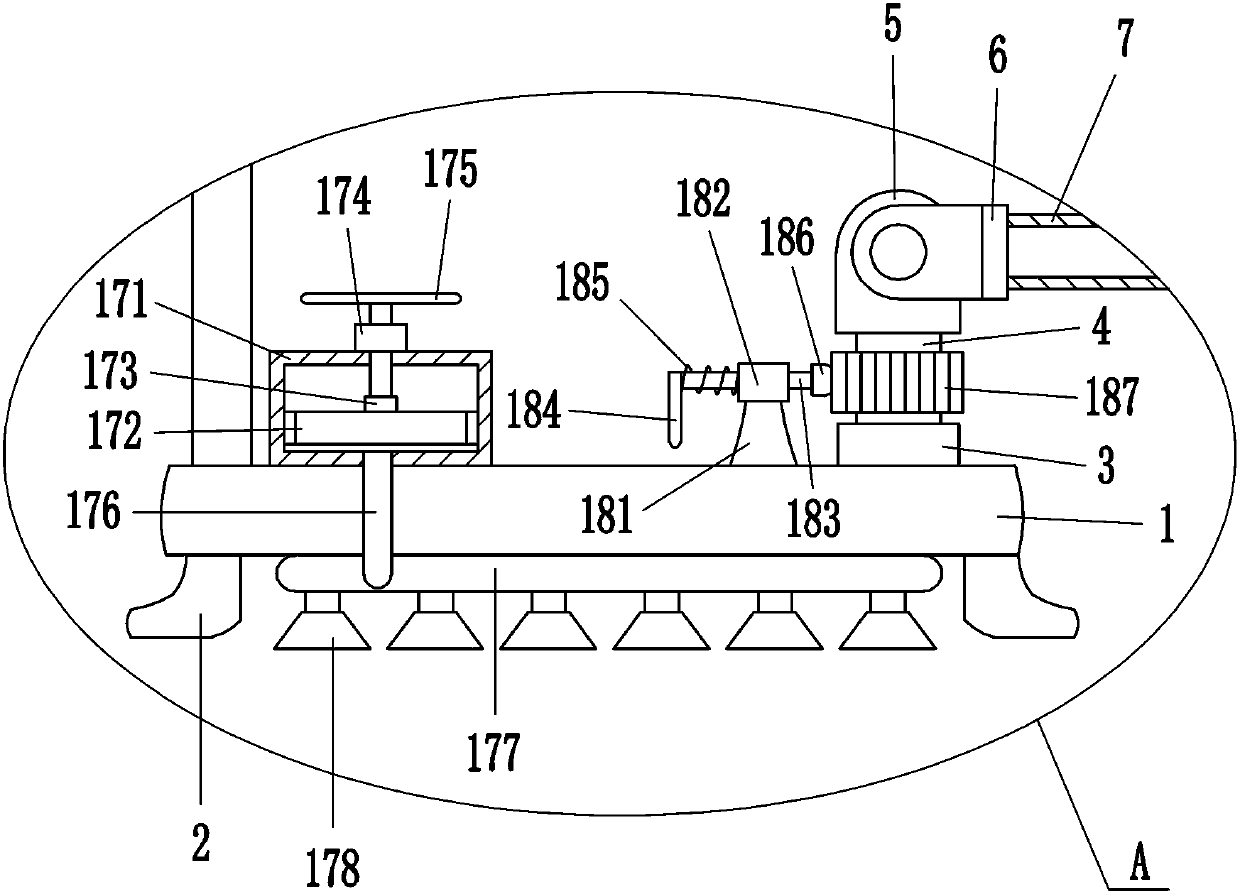

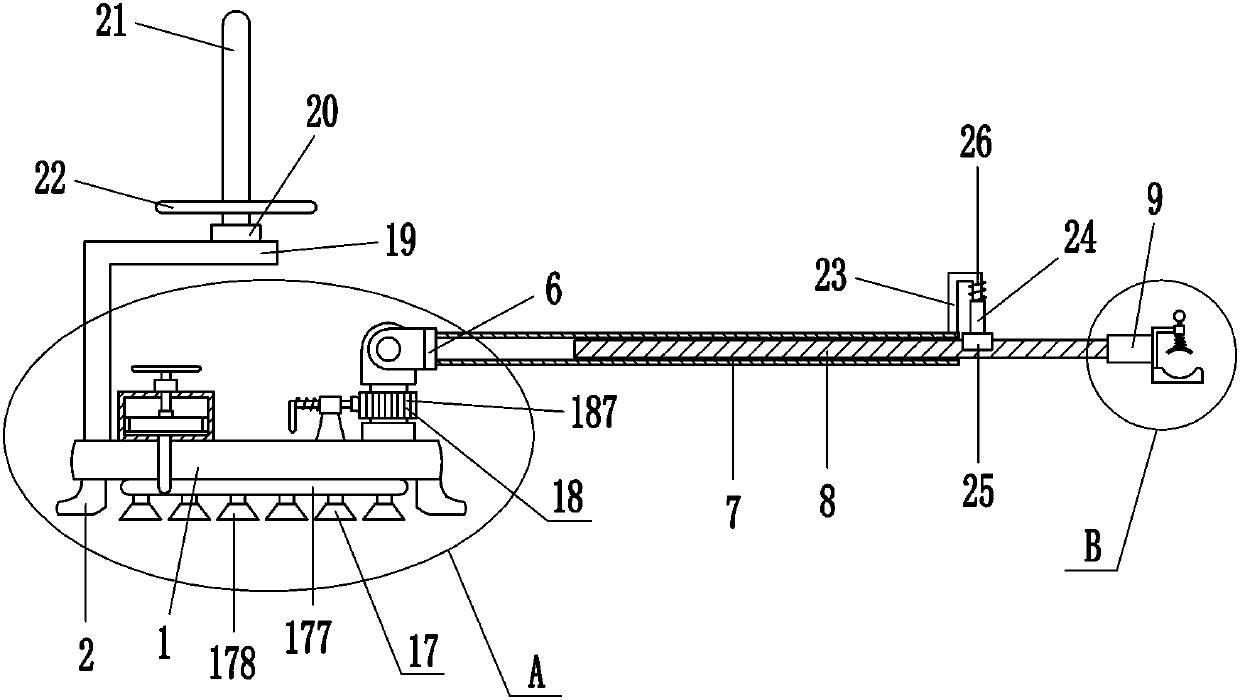

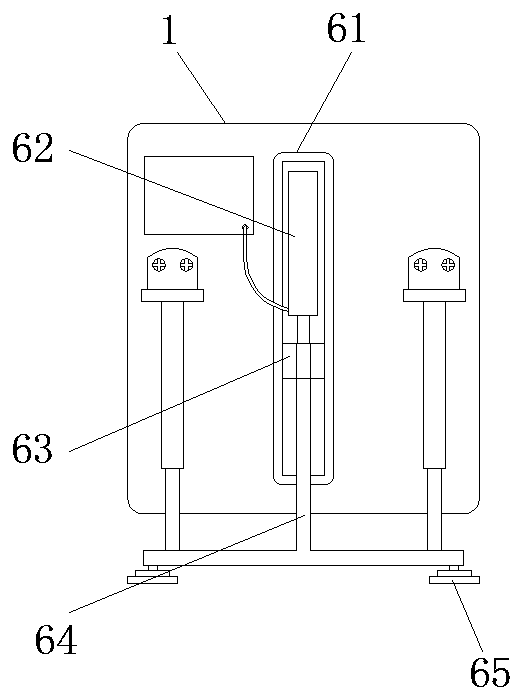

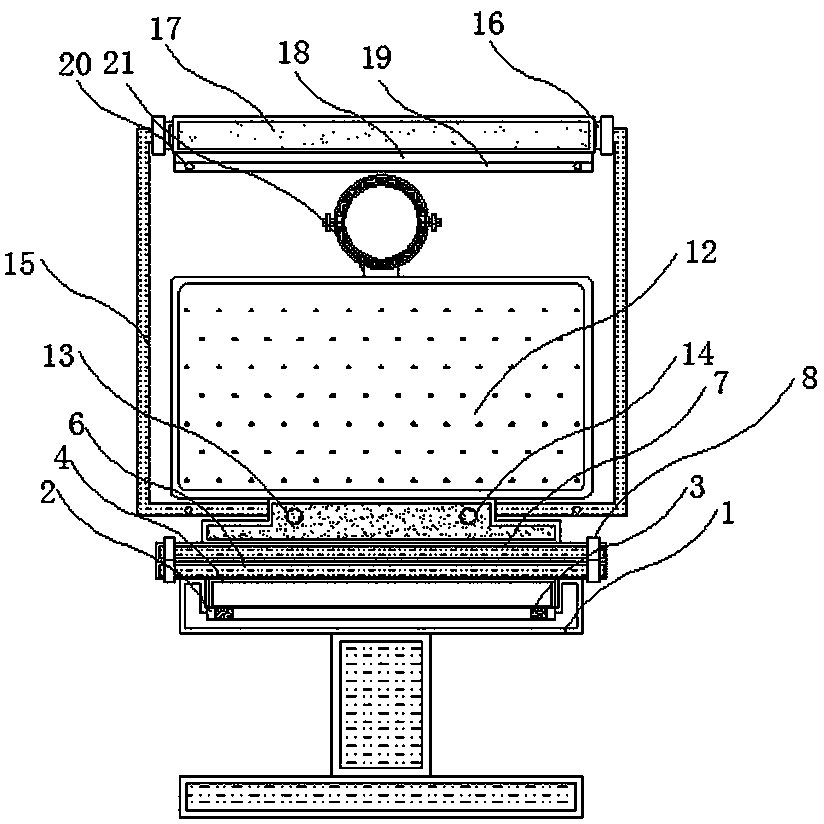

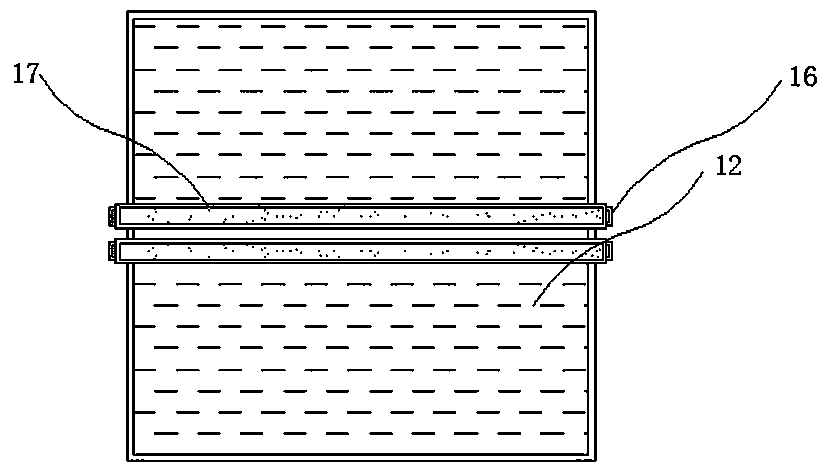

Board flatness detection device

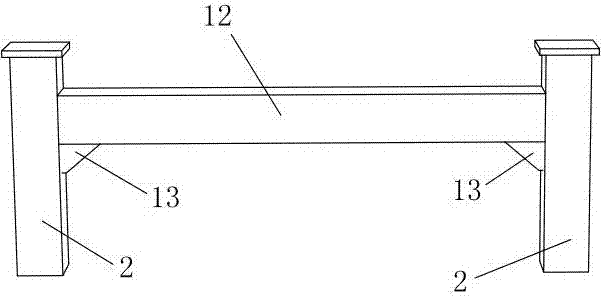

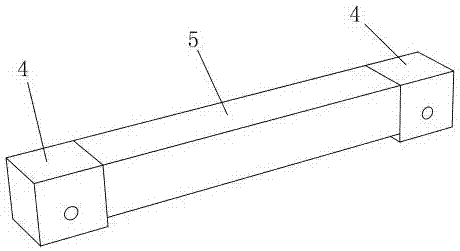

InactiveCN106885506APrevent movementFrictionalMechanical roughness/irregularity measurementsEngineeringHorizontal bar

The invention discloses a plank flatness detection device, which comprises a base, on which a support rod is arranged, and a cross bar is arranged between two adjacent support rods along the length direction of the base, and the adjacent two cross bars are at the same On the plane; there is a moving block on the cross bar, the moving block and the base are attached to each other, a horizontal bar is set between two adjacent moving blocks, a detection plate is set on one side of the horizontal bar, and a center line is set on the side of the detection plate , the side of the detection board is provided with a fixed shaft, the fixed shaft is rotatably connected with an indicating plate, the indicating plate is arranged above the base, and an indicating arrow is arranged on the side of the indicating plate, and the indicating arrow points to the center line. The invention effectively eliminates unqualified wooden boards, effectively controls the flatness of the wooden boards, avoids cracks or falling off of the decorative paint on the wooden boards, improves the decorative effect, and directly displays the decorative surface in front of the user in the form of appearance, and has functional External performance and aesthetic function.

Owner:全南县韬寻机械设备开发有限公司

Clamping device for electronic element welding

ActiveCN110142479APrevent movementAvoid affecting workSoldering auxillary devicesEngineeringElectronic component

The invention relates to a clamping device, in particular to a clamping device for electronic element welding; the clamping device for electronic element welding solves the technical problem that a worker does not need to hold the electronic element by hands, the safety is high, the electronic element can be fixed, and the electronic element can be prevented from moving. The clamping device comprises a base, supporting legs, a first bearing block, a rotating shaft, a hinging seat, a connecting block, a hollow sleeve and a connecting rod; two supporting legs are connected to the left side and the right side of the bottom of the base; the first bearing block is arranged on the right side of the top of the base. According to the clamping device, the electronic element can be fixed through anarc-shaped clamping plate, so that the electronic element is prevented from moving; the electronic element does not need to be held by a worker by hands, and the safety is relatively high; the devicecan be fixed through the fixing mechanism, so that the influence of the work of workers caused by inclination of the device when the electronic element is welded is avoided.

Owner:山东伟新泽光电科技有限公司

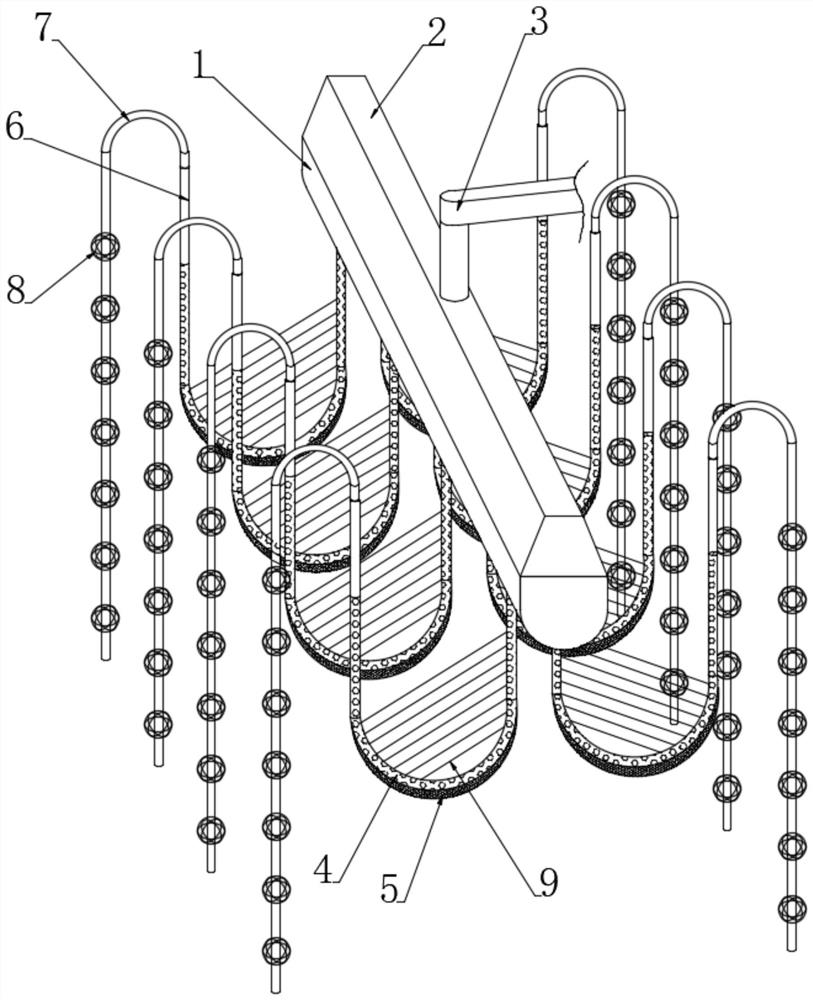

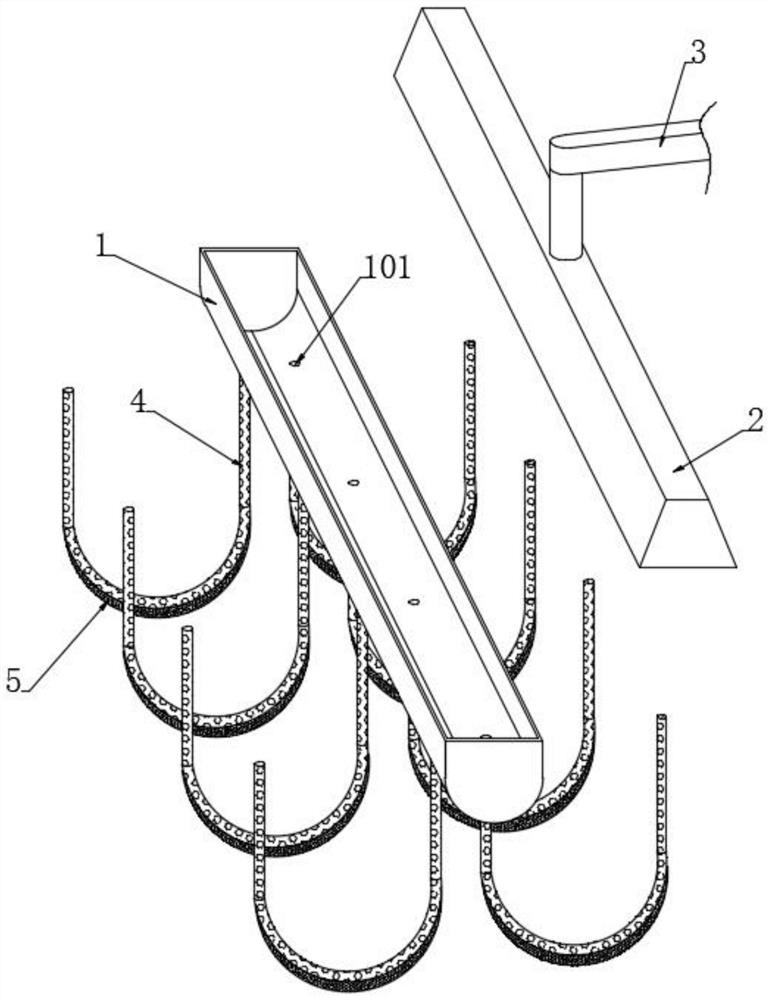

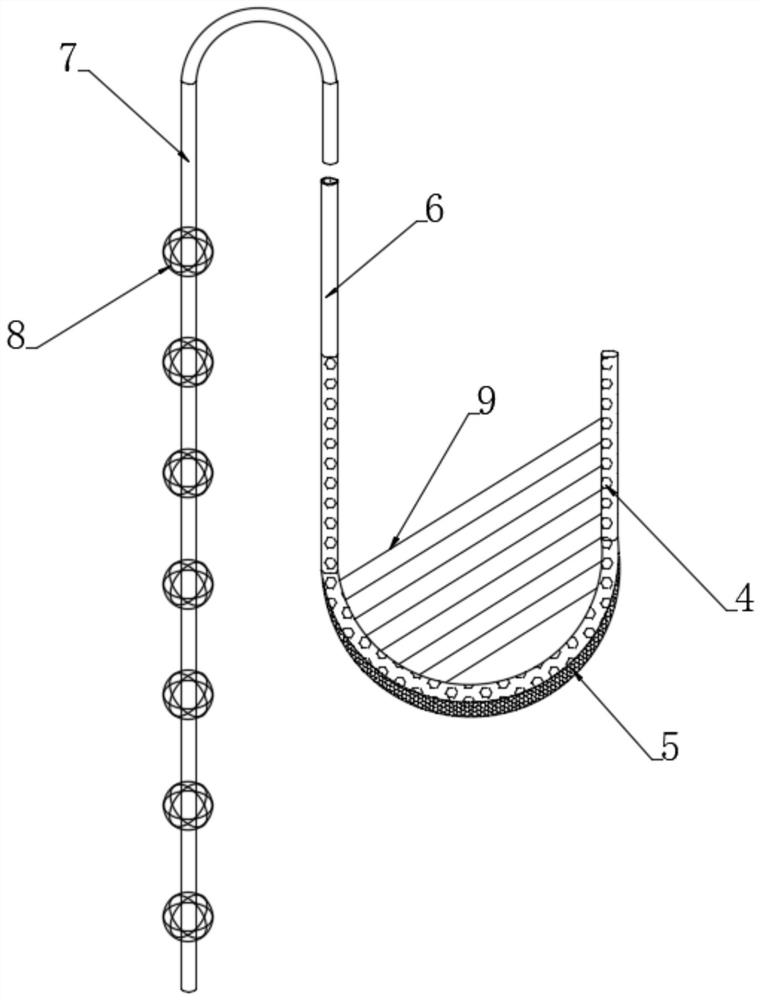

Embedded dual restorer for heavy metal soil improvement

The invention discloses an embedded dual restorer for heavy metal soil improvement, and belongs to the technical field of soil restoration, a microbial soil restoration agent can be periodically injected into an improver embedding box through cooperation of the improver embedding box and a plurality of U-shaped seepage rods, and the microbial soil restoration agent is guided into soil from a plurality of filter holes in the U-shaped seepage rods, so the diffusion balance degree of the microbial soil adsorbent is effectively improved; the microbial soil remediation agent has the effects of directly or indirectly improving soil, restoring soil fertility, preventing soil-borne diseases, maintaining rhizosphere microflora balance, degrading toxic and harmful substances and the like, and is matched with the attapulgite buried rod arranged on the outer side of the U-shaped material seeping rod; the attapulgite buried rod is matched with a plurality of heavy metal adsorption balls arranged outside the attapulgite buried rod in a sleeving mode, so the effects of gathering, adsorbing and passivating heavy metal in soil are achieved; the operation is easy, convenient and feasible, the improvement and adsorption are combined, and the remediation effect on the heavy metal soil is effectively improved to a certain degree.

Owner:王清水

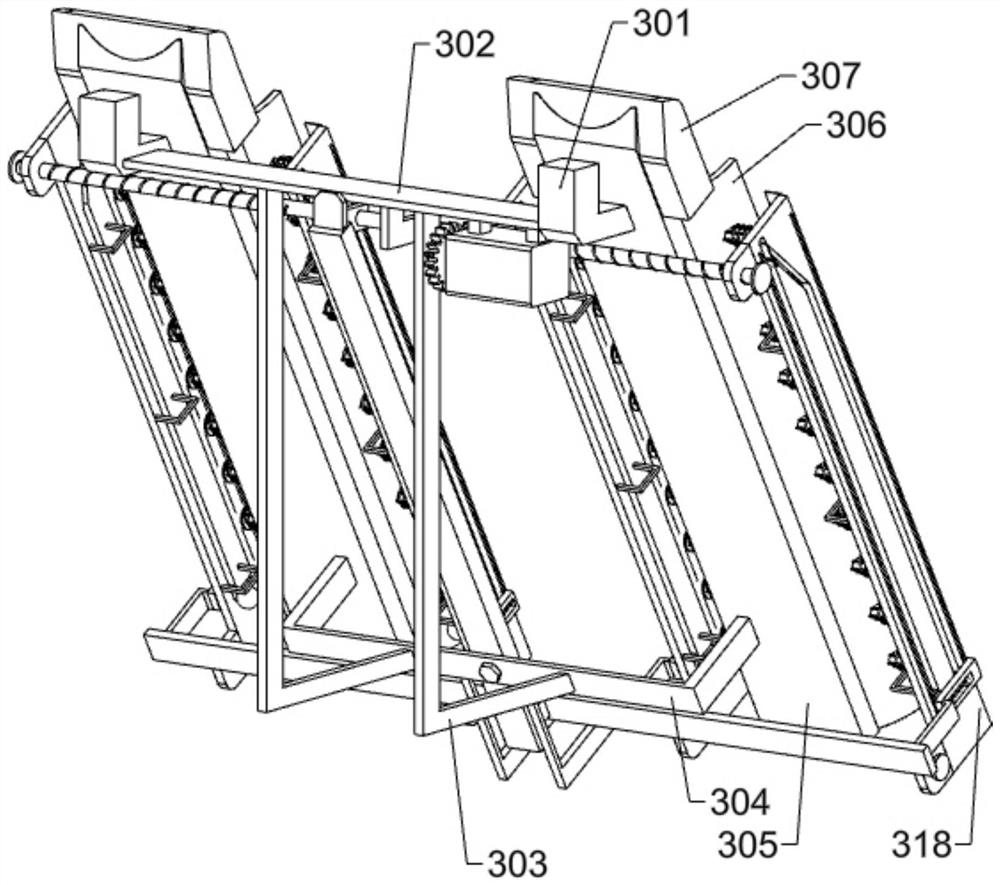

Stacking rack of required metal tubes in electric vehicle manufacturing

InactiveCN109648535AIncrease heightEasy to transportWork tools storageOther workshop equipmentElectric carsEngineering

The invention discloses a stacking rack of required metal tubes in electric vehicle manufacturing. The stacking rack comprises a box body and rectangular frames. By the aid of a lifting supporting mechanism, the whole box body can be supported to lift upwards or move downwards, the downward moving process can be stopped until universal wheels are in contact with the ground, then the height of thebox body is the lowest, the whole box body is supported to move by the universal wheels of the box body, so that a metal tube box body required by the electric vehicle can be conveniently transferredand stored; by the aid of a clamping connection device, the working efficiency is improved; by the aid of a rotary clamping connection mechanism, a certain friction force is achieved in the rotating process of a circular table, so that the circular table is placed with a certain firmness after being rotated, and is not prone to generate angle changes due to small collision; by the aid of the clamping connection device, the distance between every two adjacent rectangular frames can be adjusted, the stacking rack is suitable for storing metal tubes with different types, a drawer plates of the stacking rack is moved out to use, so that an assembly worker can pick and place the needed metal tubes conveniently; and by the aid of a clamping device, the stability of the metal tubes on the triangular frame can be improved, and slipping is not prone to occurrence.

Owner:HANDAN HAOTIAN MACHINERY EQUIP CO LTD

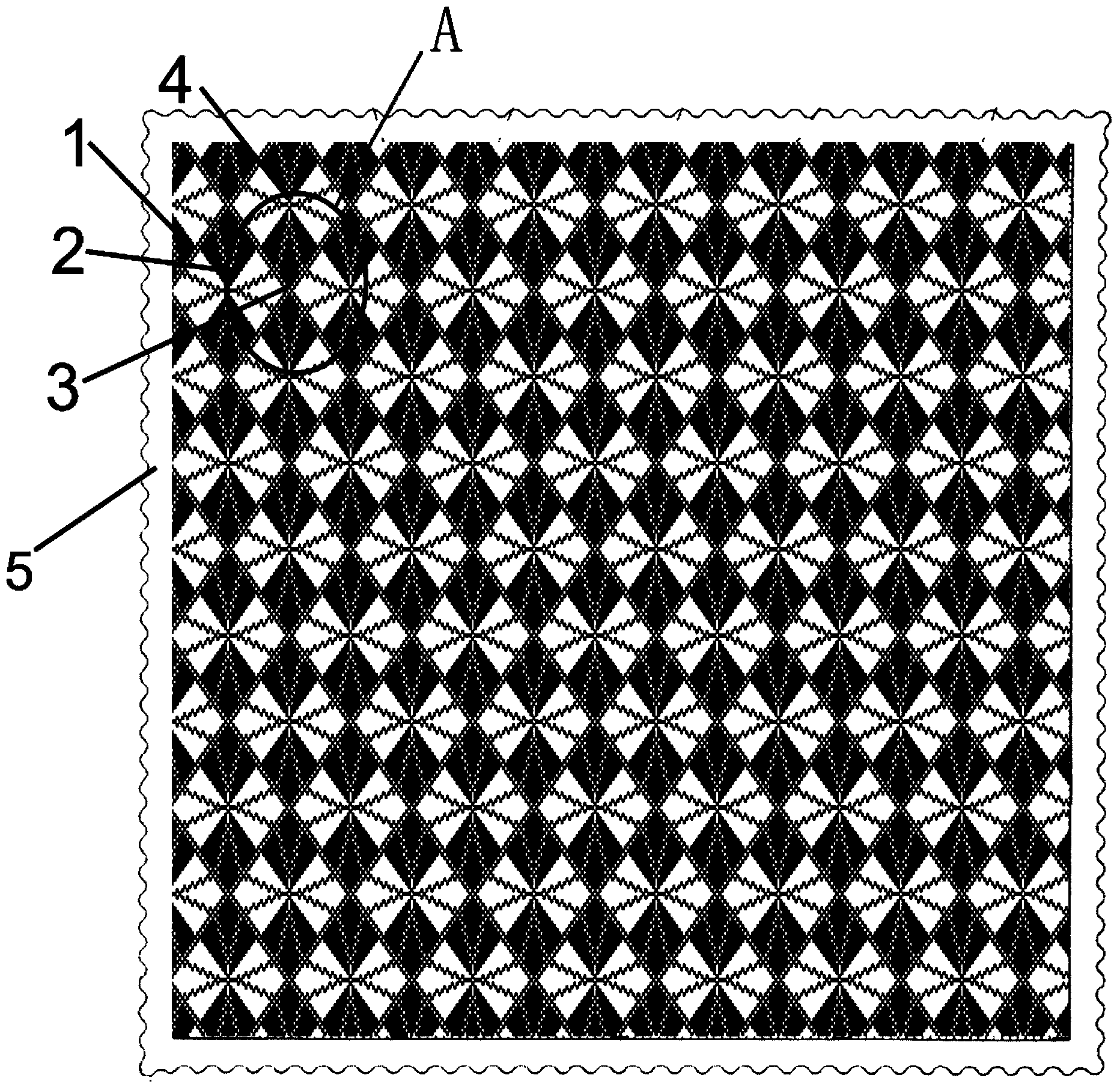

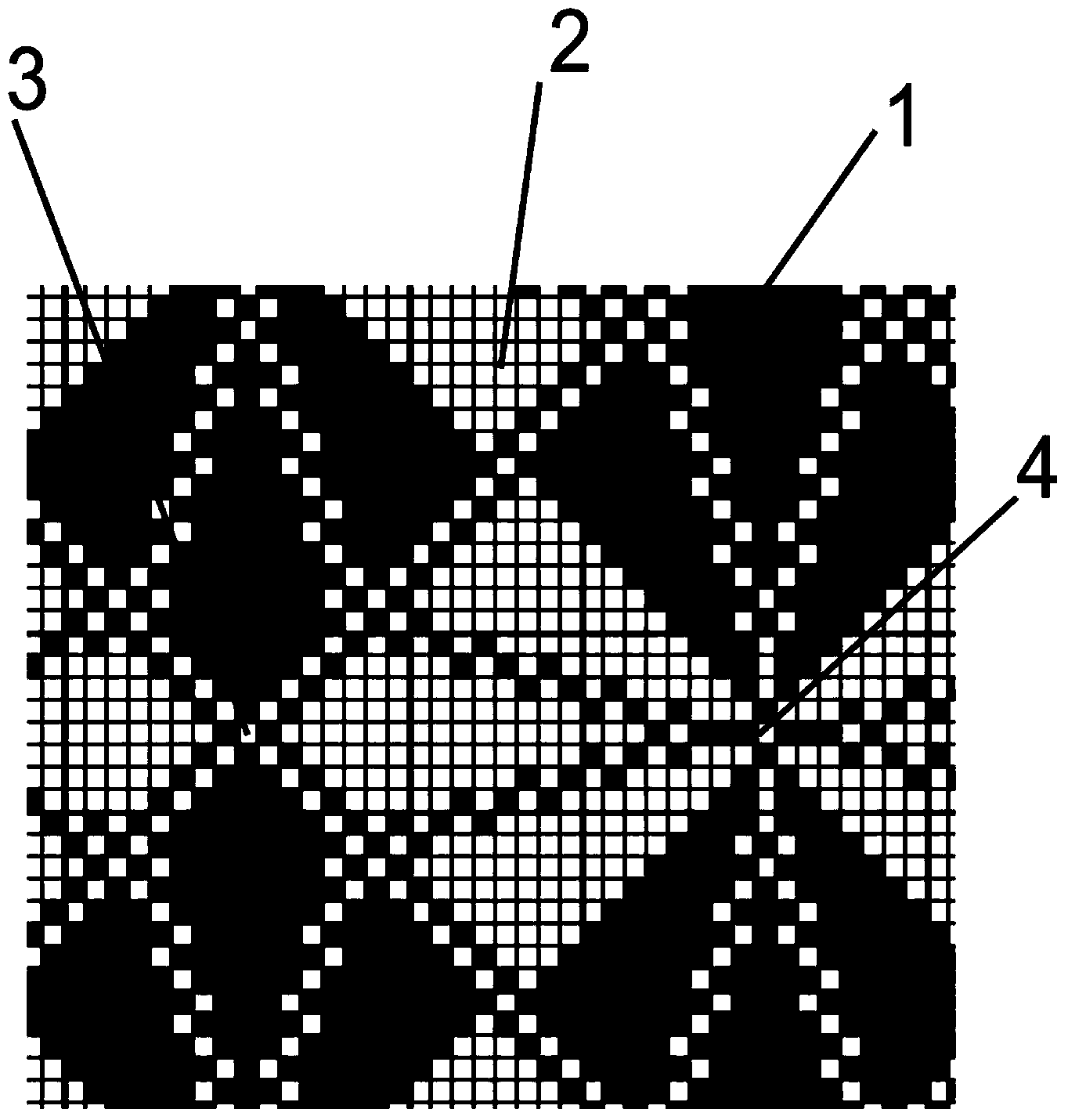

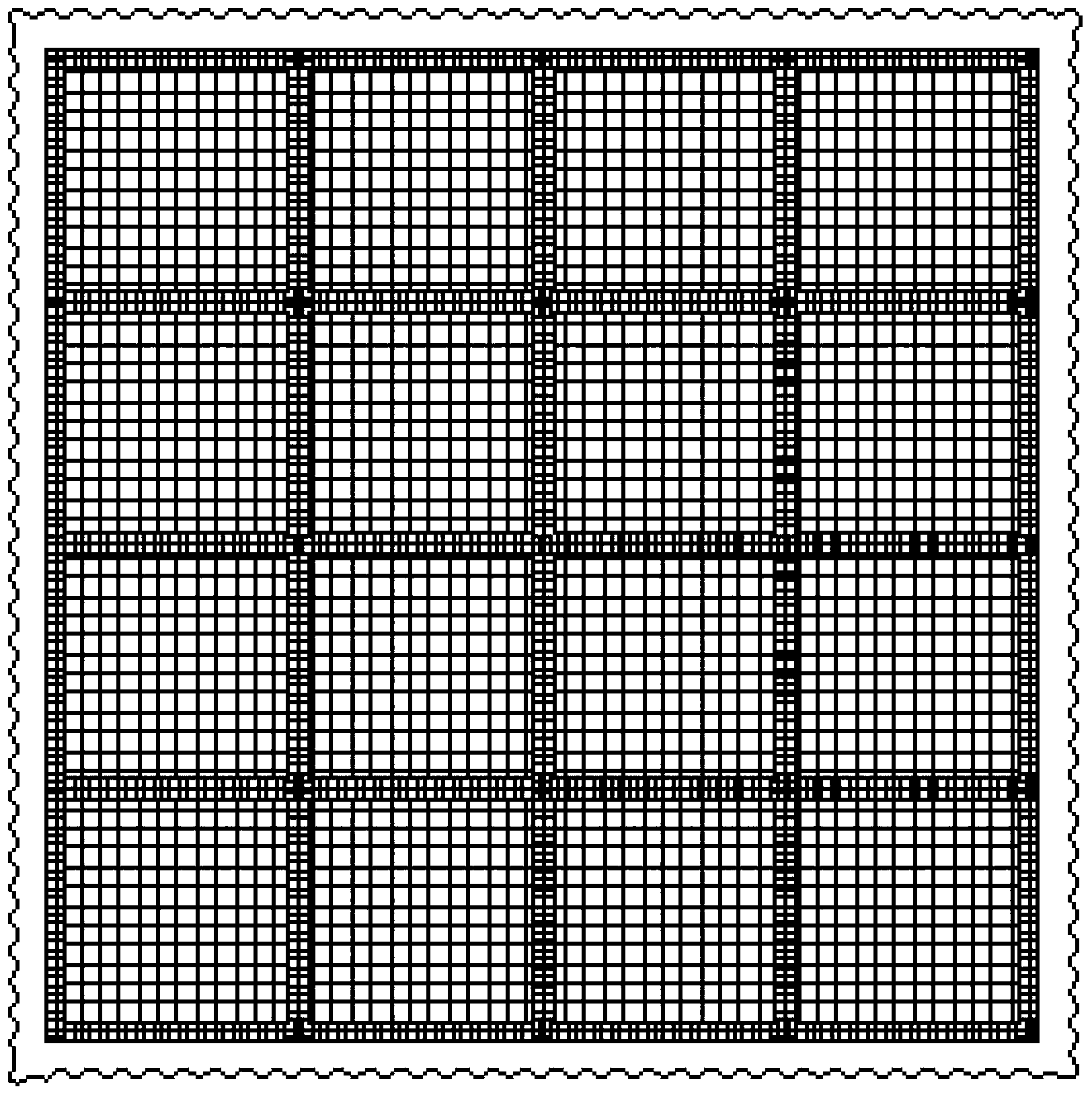

Stereoscopic scouring pad and a production method and applications thereof

InactiveCN103479314AIncrease coefficient of frictionFast water absorptionCarpet cleanersKitchenware cleanersEngineeringRepeat unit

The invention relates to a stereoscopic scouring pad comprising base cloth woven of warps and wefts. The scouring pad is characterized in that the base cloth is provided with weave repeat units composed of a floating zone of jacquard warps or wefts, and the weave repeat units are repeatedly arranged in the warp and weft directions to form a stereoscopic pattern; the base cloth is stacked on multiple mesh layers formed by single weaving; the base cloth is connected with the mesh layers through binding at the periphery. According to the scouring pad, the warps or wefts float to form different stereoscopic patterns, the patterns are combined with double mesh layers or multiple mesh layers formed by single weaving to form multilayer mesh fabric, with one side being abrasive and the other side absorbing water fast; the scouring pad is fine in water absorption and oil absorption, friction coefficient of the scouring pad is increased, the scouring pad rarely damages, and the service life of the scouring pad is prolonged.

Owner:于淞宏

Thin-walled three-layer hollow structure member and method for controlling surface groove defect

ActiveCN109202255AFrictionalReduce Surface GrooveNon-electric welding apparatusEngineeringMechanical engineering

The invention discloses a method for controlling a surface groove defect of a thin-walled three-layer hollow structure member. The method for controlling the surface groove defect of the thin-walled three-layer hollow structure member comprises the following steps that (1), the two sides of a core plate are coated with welding stop agent patterns according to a design shape, and the inner sides oftwo sleeves are separately coated with welding stop agents; (2), outer covering skins and the bag sleeves are separately superimposed on the two sides of the core plate in sequence, the peripheral ofthe superimposed assembly is sealed, and an air channel is reserved between the core plate and the outer covering skins on both sides of the core plate; (3), diffusion bonding between the core plateand the outer covering skins is carried out on the assembly; (4), first step progressive super plastic forming is implemented; (5), second step progressive super plastic forming is implemented; and (6), the sleeves are removed to obtain the thin-walled three-layer hollow structure member. Meanwhile, the thin-walled three-layer hollow structure member is further disclosed. The technology blank design of the sleeves and a progressive forming control method are adopted to effectively reduce a surface groove of a three-layer structure, and the hollow structure member with surface quality meeting design requirements is obtained.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

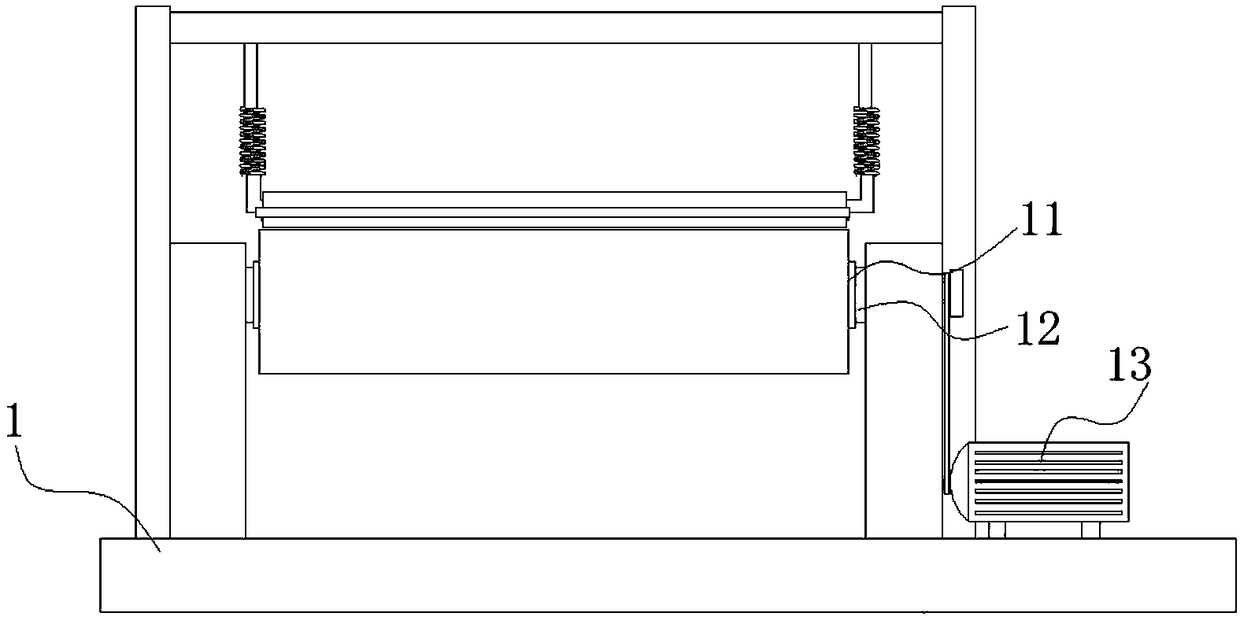

Small-roll cloth rolling machine

The invention relates to the field of cloth rolling machine equipment, in particular to a small-roll cloth rolling machine. The small-roll cloth rolling machine comprises symmetrical L-shaped supporting plates, and is characterized in that one ends of transverse plates of the symmetrical L-shaped supporting plates are provided with cloth roll shaft clamping grooves correspondingly; the two ends ofa cloth roll shaft of a cloth roll are clamped in the cloth roll shaft clamping grooves correspondingly; the ends, close to the cloth roll, of the transverse plates of the symmetrical L-shaped supporting plates are hinged to the two ends of a first cloth guide roller; the ends, close to a vertical plate, of the transverse plates of the symmetrical L-shaped supporting plates are hinged to the twoends of a second cloth guide roller; and the central axes of the first cloth guide roller and the second cloth guide roller are located in the same horizontal plane. According to the small-roll clothrolling machine, cloths can be quickly rolled, and thus the manpower resource is liberated.

Owner:钟方林

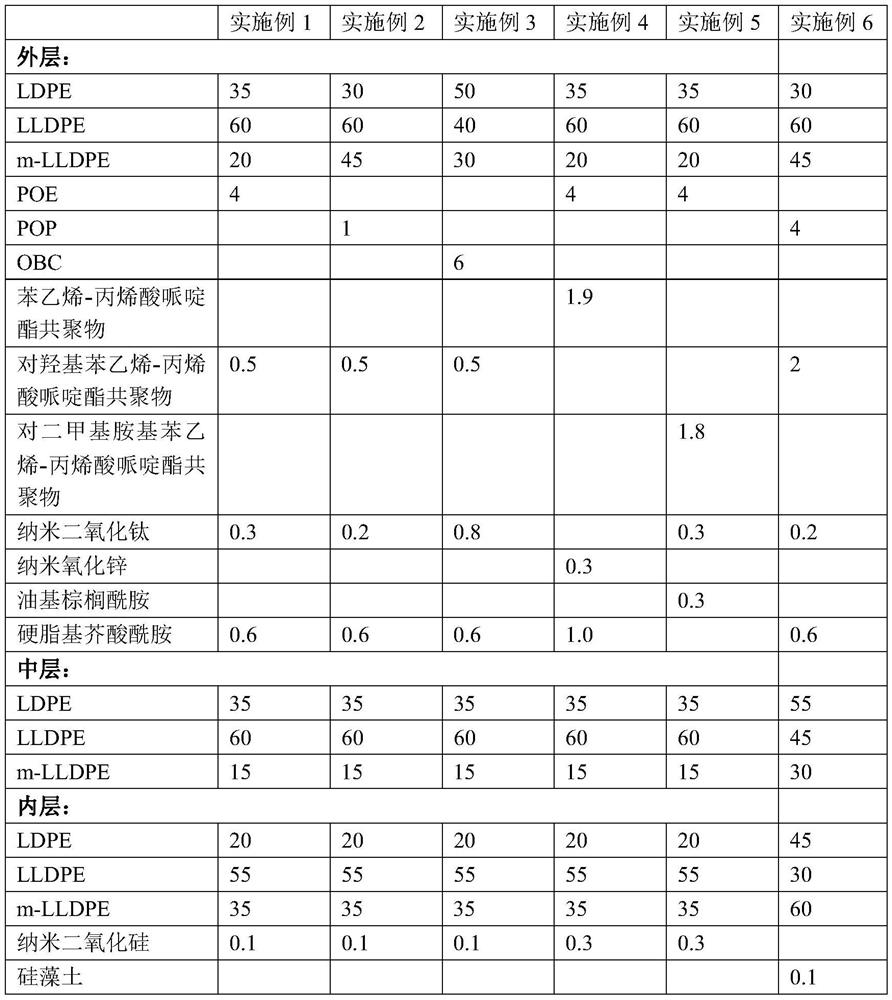

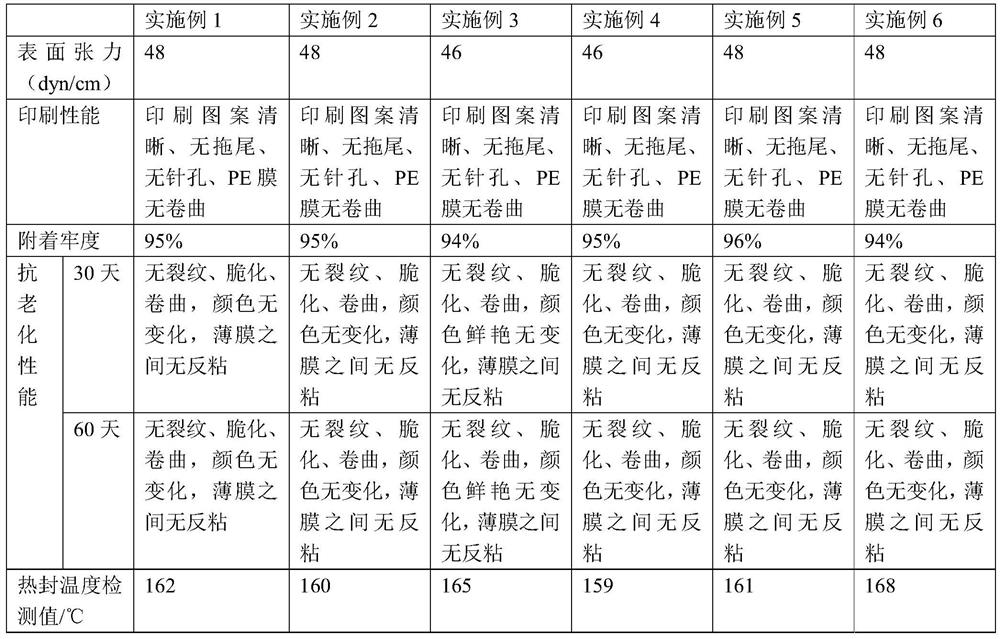

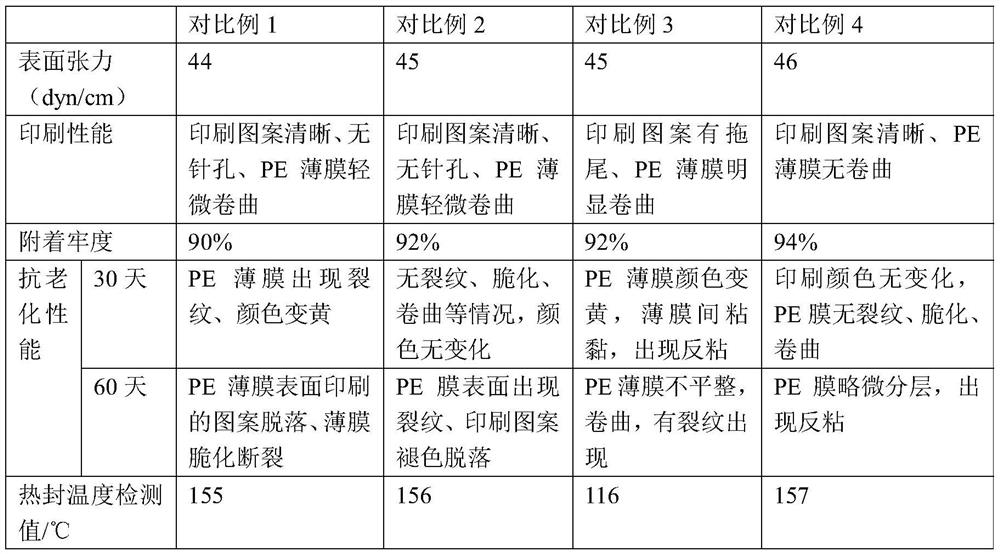

High-performance PE film as well as preparation method and application thereof

ActiveCN113635636AGood compatibilityGood light stabilityClimate change adaptationDuplicating/marking methodsLow-density polyethyleneElastomer

The invention discloses a high-performance PE film as well as a preparation method and application thereof. The high-performance PE film comprises an outer layer, a middle layer and an inner layer, and the outer layer is prepared from the following raw materials: low-density polyethylene, linear low-density polyethylene, metallocene linear low-density polyethylene, a polyolefin elastomer, a high-molecular-weight light stabilizer, a light screener and an organic anti-blocking agent; and the high molecular weight light stabilizer is one or more of a styrene-acrylic acid piperidine ester copolymer, a p-hydroxystyrene-acrylic acid piperidine ester copolymer or a p-dimethylamino styrene-acrylic acid piperidine ester copolymer. The inner layer is prepared from the following raw materials: low-density polyethylene, linear low-density polyethylene, metallocene linear low-density polyethylene and an inorganic anti-blocking agent. The high-performance PE film has excellent aging resistance and heat resistance, and when water-based ink is used for printing, the drying rate is high, and the anti-sticking phenomenon after false drying does not occur.

Owner:茂名联塑建材有限公司

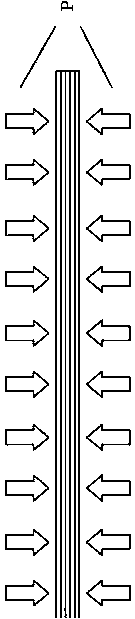

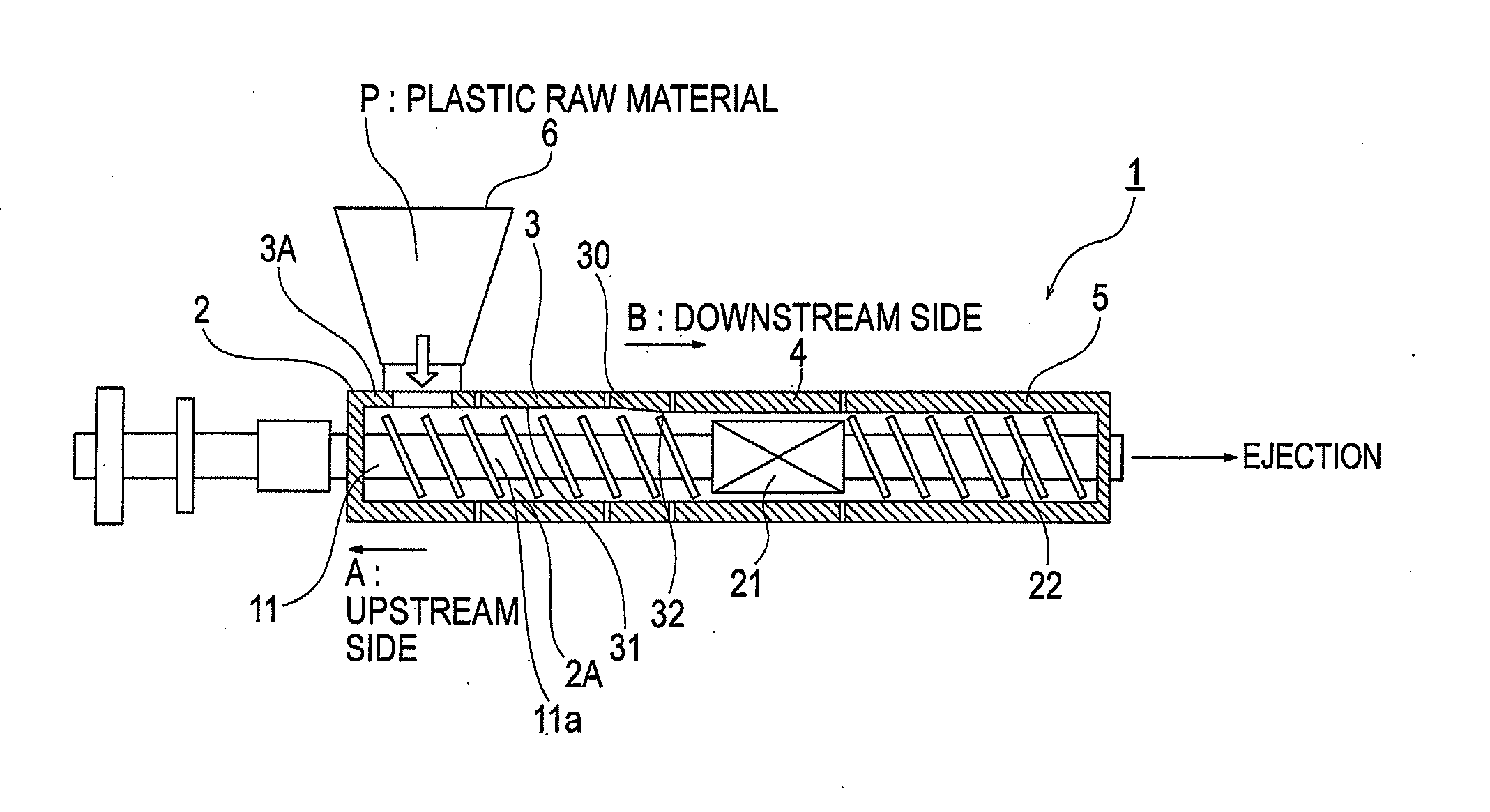

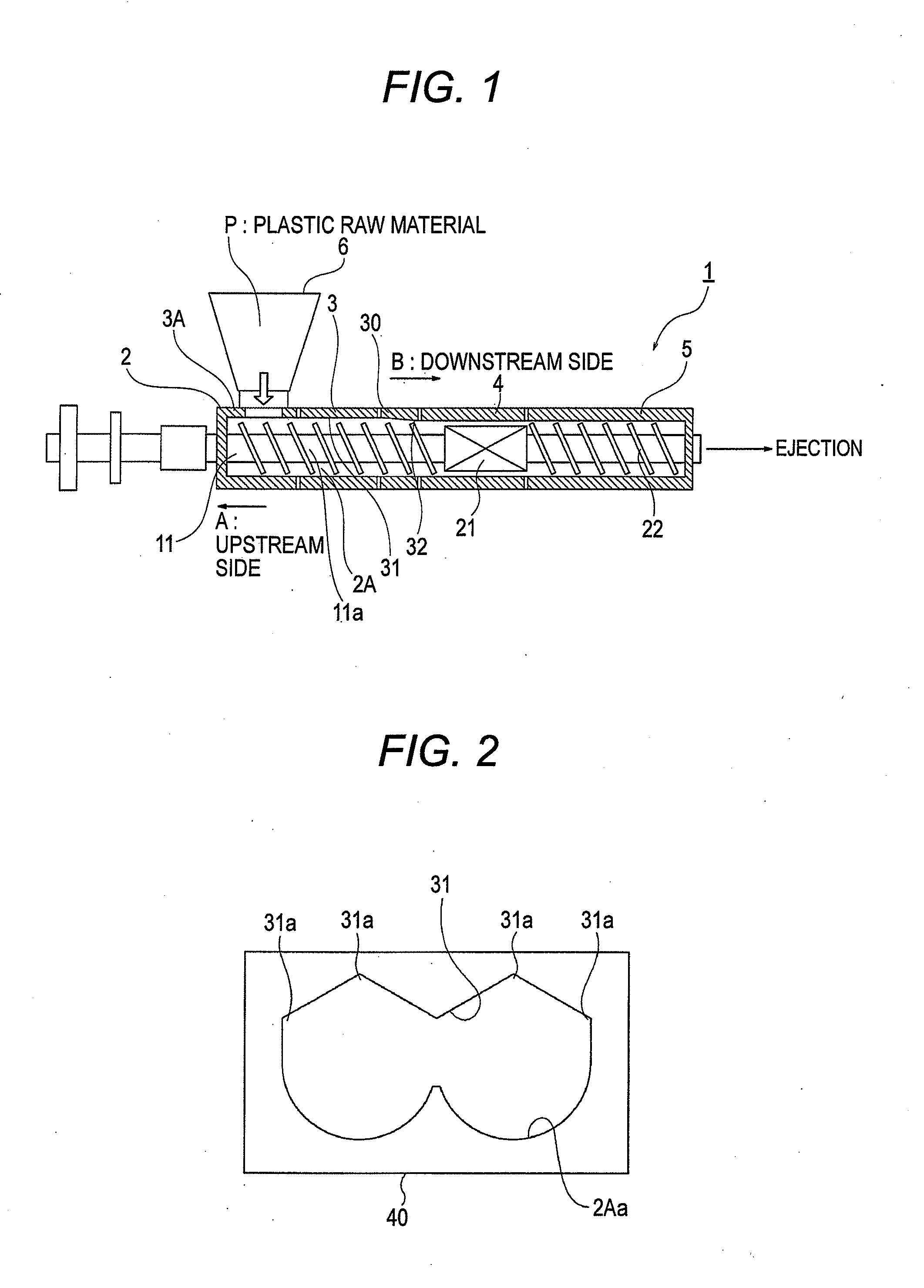

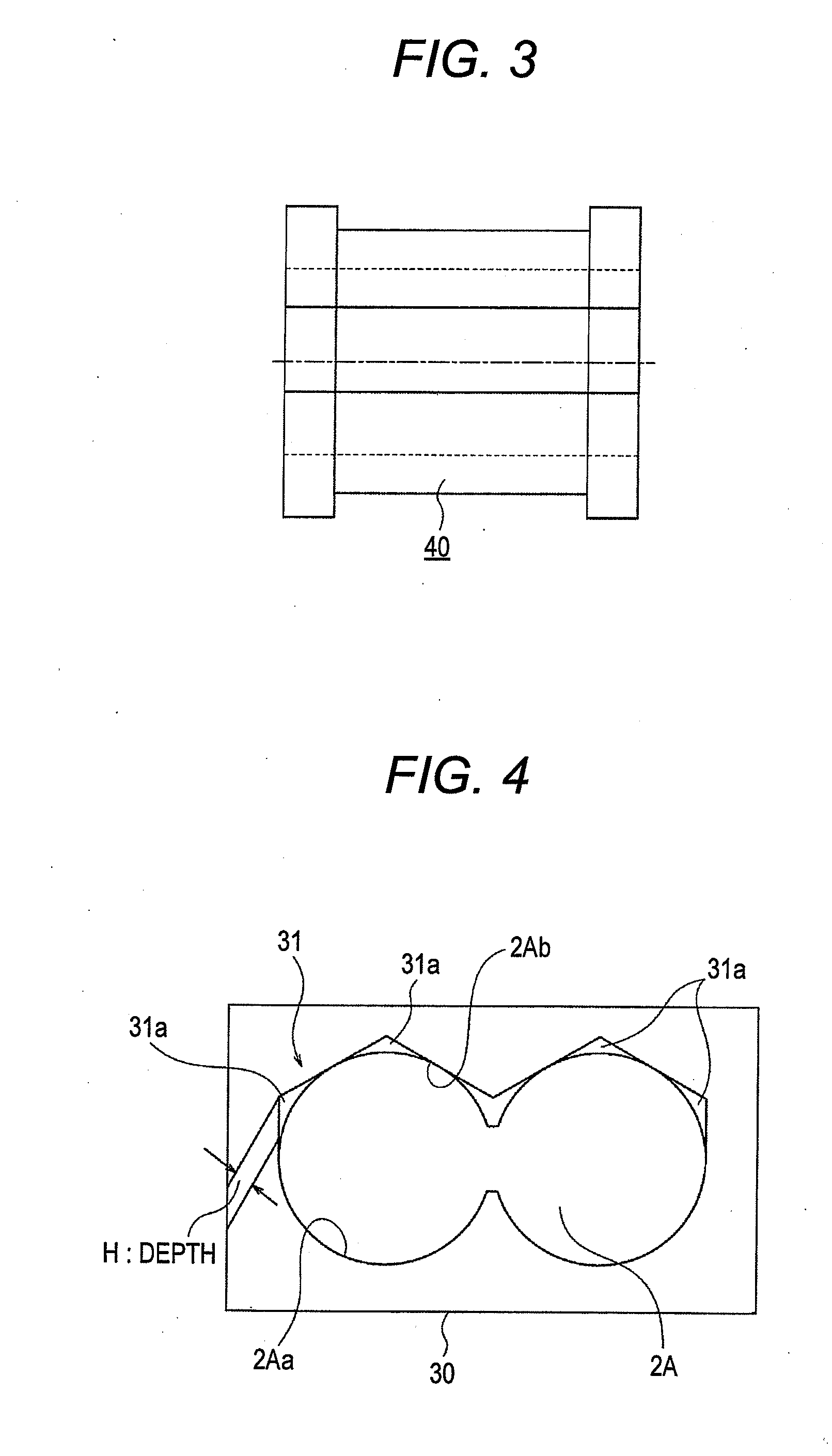

Apparatus and method for plastic extrusion

ActiveUS20120081989A1FrictionalImprove abilitiesRotary stirring mixersMixing/kneading with aerating apparatusFrictional coefficientEngineering

An object of the invention is to improve capacity of process and not require a vent portion by an upper polygonal groove and a transition portion provided to a transport cylinder.A plastic extrusion method and apparatus according to the invention is a method and a configuration, in which an upper polygonal groove and a transition portion are integrally or separately provided to a transport cylinder so as to increase a frictional coefficient of an inner wall of the cylinder, to increase transport efficiency of a plastic raw material by a screw, and to allow at least gas, etc., pass toward a hopper side without using a vent portion.

Owner:JAPAN STEEL WORKS LTD

Floating-raft-type river channel waste collection device

ActiveCN107299625AReduce omissionsIncrease collection rateWater cleaningRefuse collectionWaste collection

The invention relates to the field of water pollution treatment, in particular to a floating-raft-type river channel waste collection device, and is intended to solve the above technical problem. A technical scheme used herein refers to a floating-raft-type river channel waste collection device comprising a plurality of floating raft mechanisms across a river channel; an interceptor mesh for intercepting river channel waste is connected between every two floating raft mechanisms; each floating raft mechanism includes a floating frame fixedly connected with the corresponding interceptor mesh. The defects of the prior art are overcome; the floating-raft-type river channel waste collection device capable of moving correspondingly with changes in water level and having higher waste collection rate is provided, solving the problem that an existing river channel waste interceptor is unable to intercept wastes in case of water level changing.

Owner:成都首创环境工程有限公司

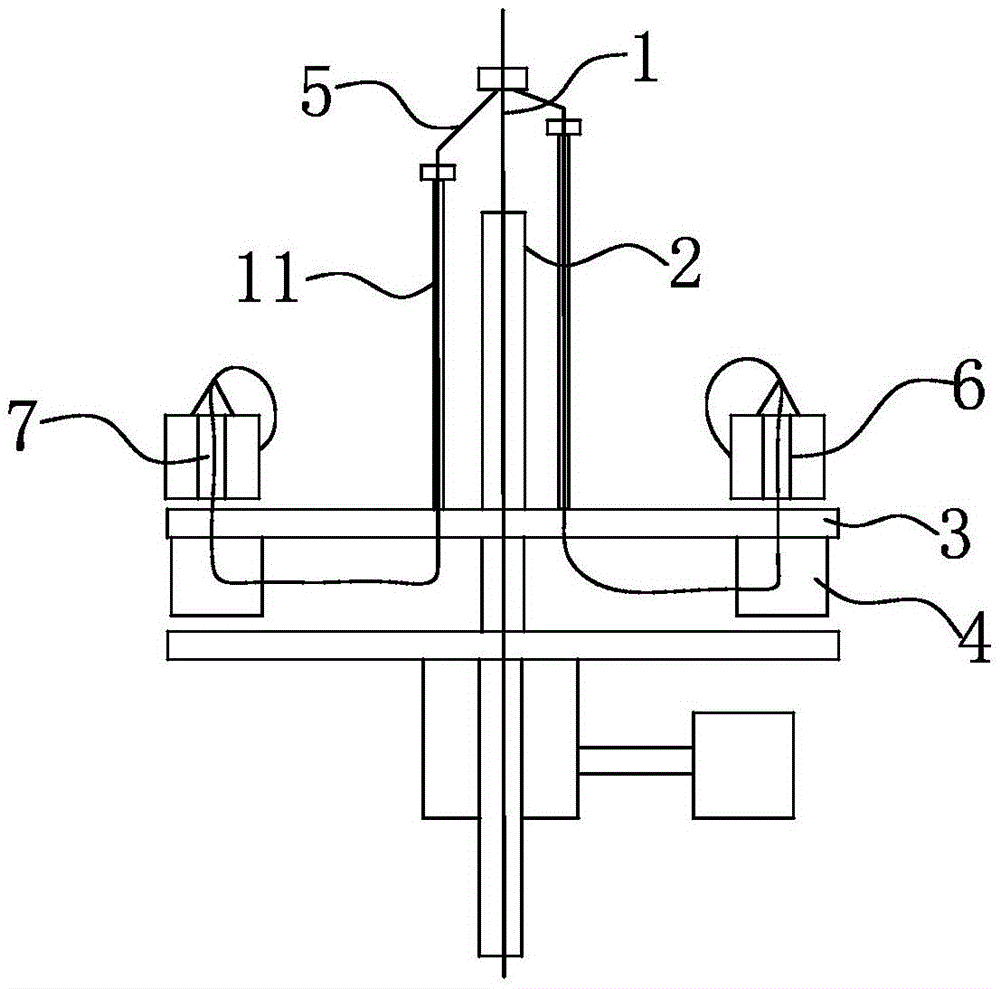

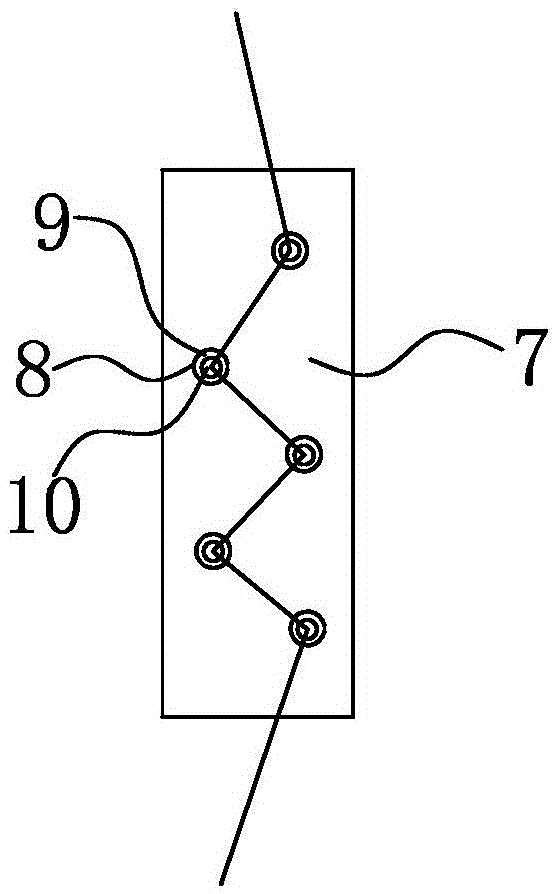

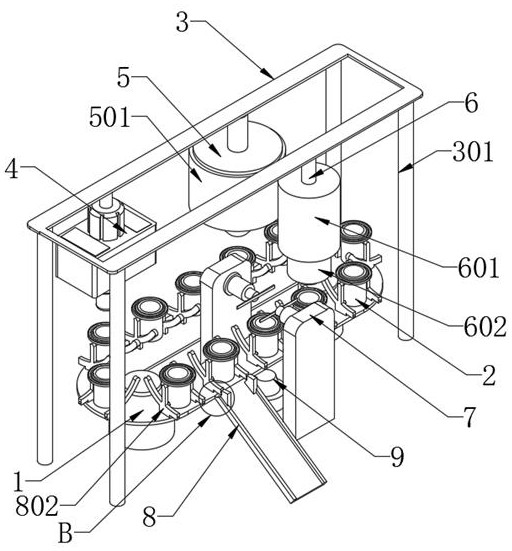

Yarn manufacturing mechanism with yarn tension adjusting function

The invention belongs to the technical field of yarn manufacturing devices, and particularly relates to a yarn manufacturing mechanism with a yarn tension adjusting function. The yarn manufacturing mechanism comprises a center bobbin for center yarn to penetrate through and is characterized in that the center bobbin is fixedly connected with a rotary disc, and at least one spindle located on the periphery of the center bobbin is arranged on the rotary disc; the mechanism further comprises adjusting plates, the adjusting plates are arranged on the spindles, located in bobbins, wound with yarn, on the spindles and each provided with multiple yarn passing through holes, the yarn passing through holes are distributed in each adjusting plate, and the number of the yarn passing through holes through which the yarn needs to penetrate through is determined by the yarn made of different materials. The yarn manufacturing mechanism has the advantages that all yarn passing bobbins are arrayed in the circumferential direction, the height of the bobbins is gradually increased or decreased, winding and covering points of all pieces of covered yarn threads and center yarn are sequentially arrayed in the axial direction of the center yarn, the multiple covered yarn threads are arrayed at the same time to form a strip shape, and it is ensured that no gap exists between the covered yarn threads, which is beneficial for improving the production efficiency of multi-coating covered yarn and reducing energy consumption and processing cost.

Owner:浙江可羽纺织科技有限公司

Cloth rolling equipment

The invention discloses cloth rolling equipment. The cloth rolling equipment comprises a frame body, a cloth winding barrel, a rotating part, a placing cavity and a driving part, wherein the rotatingpart is arranged in the cloth winding barrel in a penetrating mode, the placing cavity is arranged on the rotating part, and the driving part is used for driving the rotating part to rotate; a pressing mechanism for synchronously rotating the cloth winding barrel and the rotating part is arranged on the rotating part, and the pressing mechanism comprises a pressing component and a pushing component, wherein the pressing component is in rotation fit with the inner wall of the cloth winding barrel, and the pushing component is matched with the pressing component; and the pushing component is arranged in the placing cavity. Friction force is generated between the pressing part and the inner wall of the cloth winding barrel, the cloth winding barrel and the rotating part are kept relatively static, and the rotating part can drive the cloth coiling barrel to rotate synchronously, so that the cloth winding barrel is prevented from rotating relative to the rotating part; and a pushing component is arranged to push a pressing component to move, so that the pressure of the pressing component on the cloth winding barrel is improved, and the friction force between the cloth winding barrel andthe pressing component is improved.

Owner:HANGZHOU LESHOU TECH CO LTD

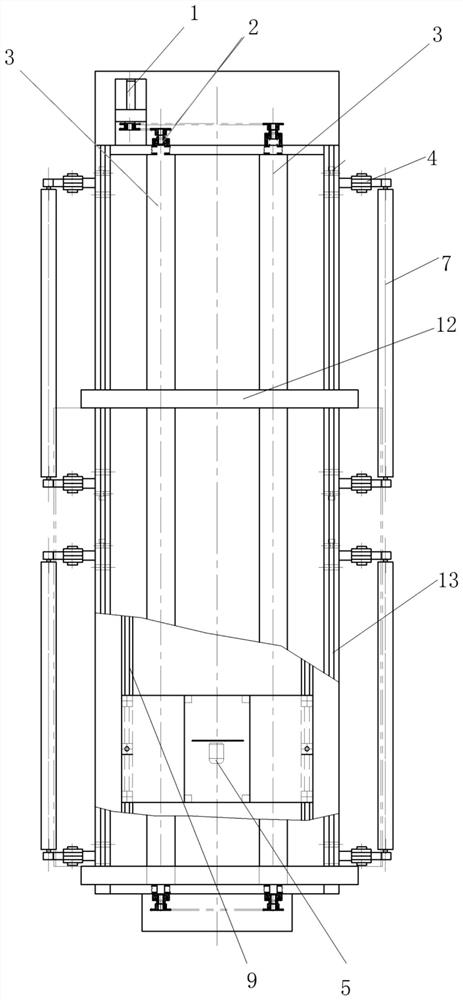

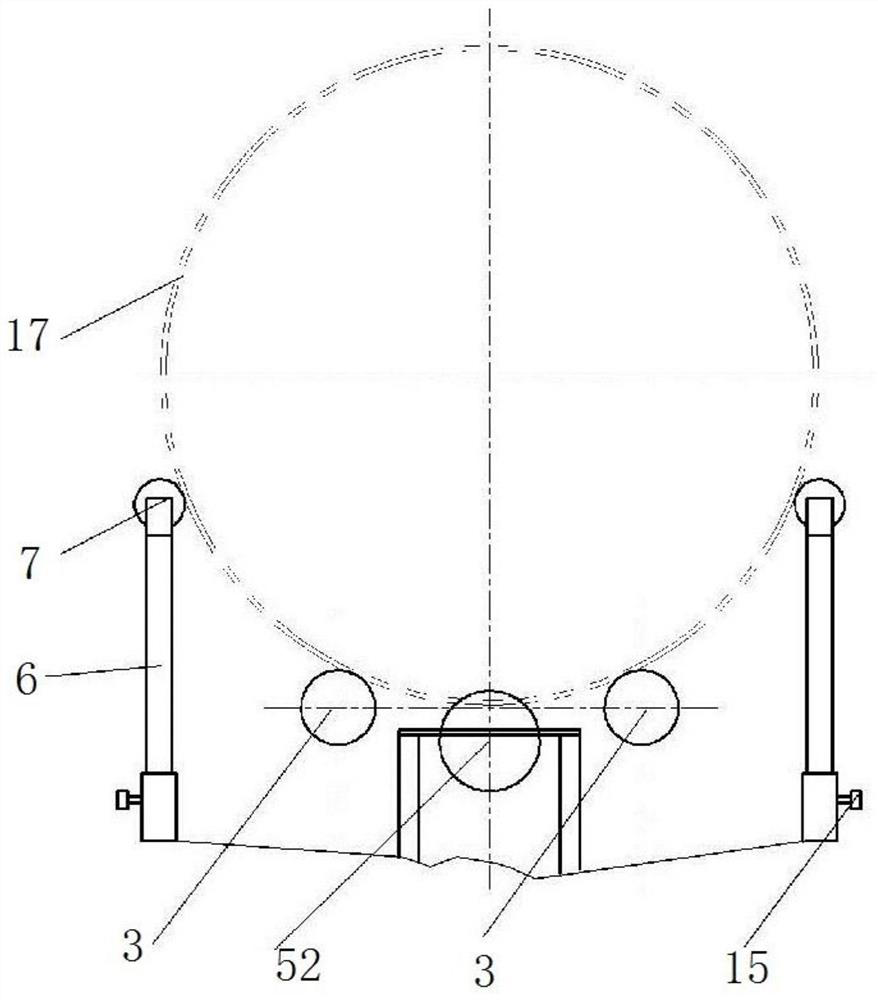

Transformer forming insulating cylinder cutting device

ActiveCN113488329AAdjustable positionReasonable and effective support rotationInductances/transformers/magnets manufactureDrive shaftTransformer

The invention belongs to the technical field of insulating cylinder cutting, and relates to a transformer forming insulating cylinder cutting device. The device comprises a working frame, a power mechanism, a transmission mechanism, a transmission shaft, a supporting device, a positioning device and a cutting mechanism. A first guide rail, a transmission shaft and a second guide rail are arranged in the longitudinal direction of the working frame from top to bottom, the positioning device comprises a first sliding block and a positioning guiding rule, the first sliding block is arranged on the first guide rail, and the positioning guiding rule is installed on the first sliding block; the cutting mechanism is arranged on the second guide rail; the transmission shaft is arranged on the working frame and connected with the power mechanism through the transmission mechanism. The supporting device comprises supporting rods and rollers, the bottom ends of the supporting rods are connected to the working frame, the top ends of the supporting rods are connected with the rollers, and the rollers make contact with the outer circle face of the insulating cylinder. The forming insulating cylinder continuously rolls on the transmission shaft through the power mechanism and the transmission mechanism, the supporting function is achieved through the supporting device, free positioning of the cutting position is achieved through the positioning device, and the cutting function of the forming cylinder is achieved through the cutting mechanism.

Owner:常州西电变压器有限责任公司 +1

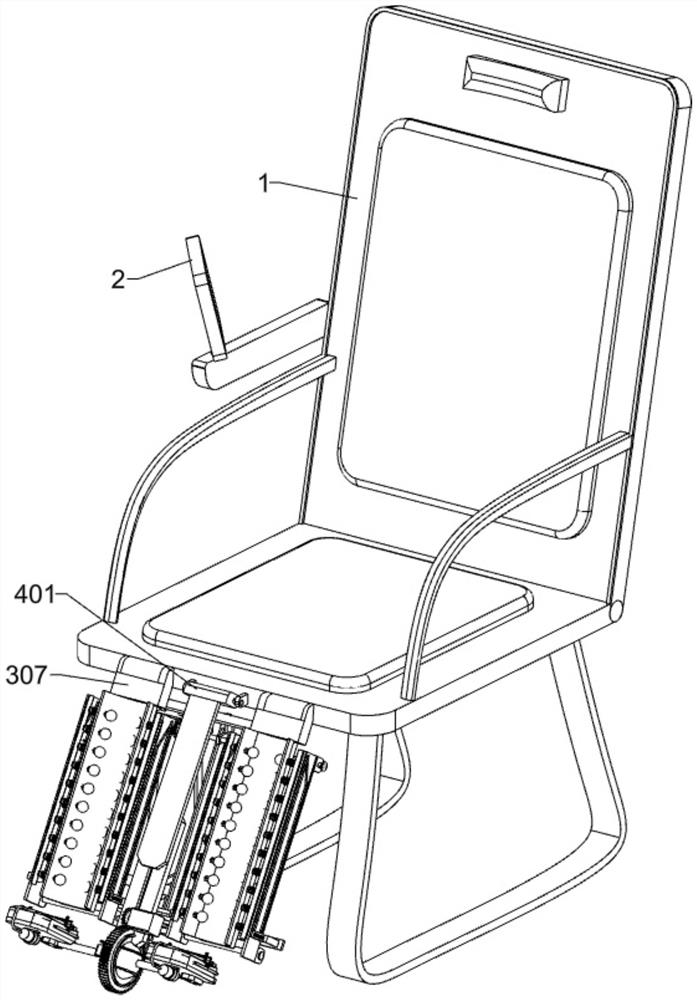

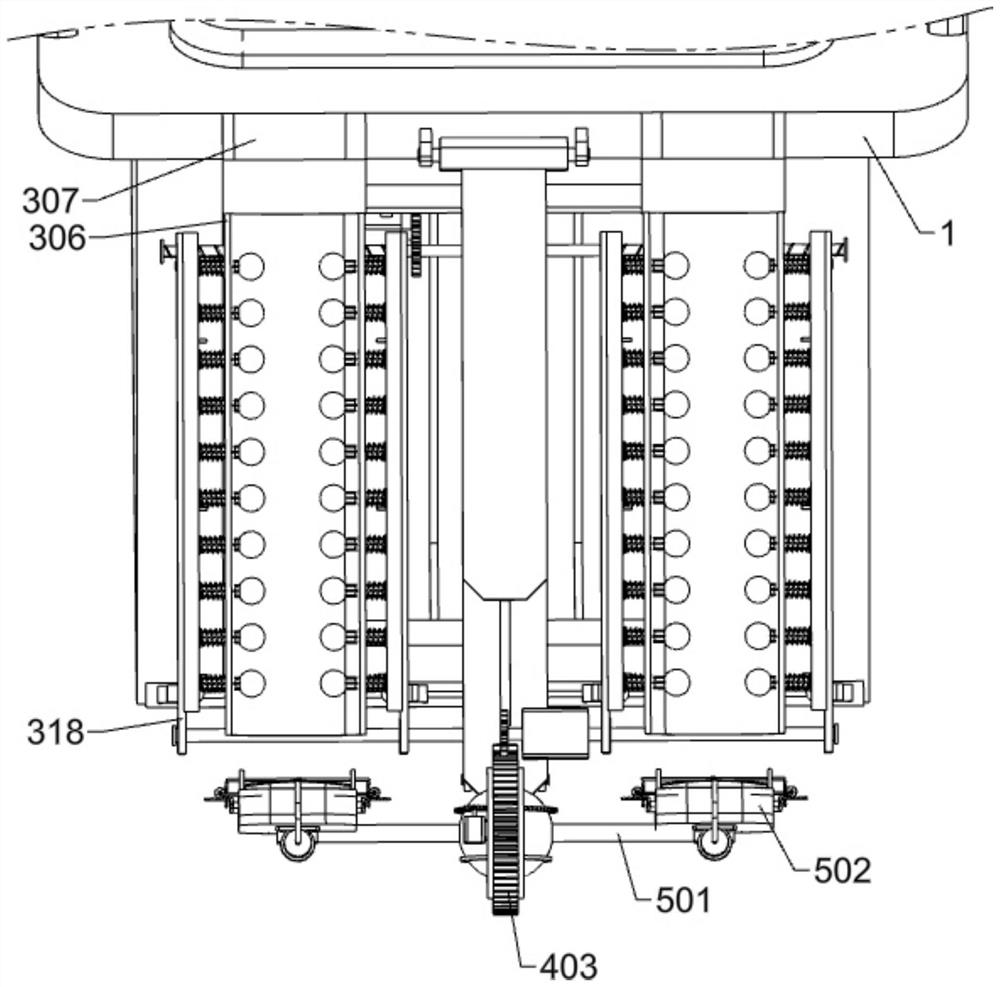

Adjustable postoperative leg intelligent nursing device for neurosurgery department

InactiveCN114681286AAvoid Physiological DeclineStrength trainingBlood stagnation preventionPneumatic massageDiseaseVenous blood

The invention relates to the technical field of intelligent leg nursing, in particular to an adjustable postoperative intelligent leg nursing device for the neurosurgery department. The technical problems that an existing leg nursing device can only conduct simple rehabilitation treatment on a patient, blood circulation of the legs of the patient cannot be improved, neuromuscular stimulation cannot be achieved, the legs of the patient cannot be comprehensively nursed, muscle, skeleton and the like of the patient suffer from disuse atrophy, and the physiological function of the leg declines are solved. According to the technical scheme, the adjustable postoperative leg intelligent nursing device for the neurosurgery department comprises a seat, a leg massage mechanism and an ankle moving mechanism, the leg massage mechanism is arranged on the front side face of a seat bottom plate, and the ankle moving mechanism is arranged on the front side face of the seat bottom plate. By arranging the leg massage mechanism, blood of the legs of a patient circularly flows from bottom to top, and diseases such as venous thrombosis of the lower limbs of the patient are avoided; by arranging the ankle moving mechanism, the phenomenon that the physiological function of the legs is declined due to the fact that the patient lies in bed for a long time is avoided.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

Device and method for packaging quick-frozen fruits and vegetables

ActiveCN114229088AWrapped firmlyImprove bagging efficiencyWrappingWrapper twisting/gatheringHydraulic cylinderHeat sealer

The invention discloses a device and method for packaging quick-frozen fruits and vegetables, and relates to the technical field of fresh food packaging. The device comprises a conveying belt, the conveying belt is provided with a plurality of charging buckets, and a suspension frame is arranged above the conveying belt; a bag placing mechanism, a feeding mechanism, a bouncing mechanism, a heat sealing mechanism and a discharging mechanism are sequentially arranged at the bottom of the suspension along a conveying line of the conveying belt, the bag placing mechanism comprises a first shell, a film barrel and a transmission wheel are symmetrically arranged in the first shell, a bag film is wound on the film barrel, and the end, away from the film barrel, of the bag film is fixedly connected with the transmission wheel. A first hydraulic cylinder is arranged over the bag film, the output end of the first hydraulic cylinder is fixedly connected with a push column, and a film outlet is fixedly formed in the bottom of the first shell. According to the fruit and vegetable bagging device, the shape of the bag film can be automatically controlled, the bag film is cylindrical, fruits and vegetables can be stably wrapped, the bagging stability is improved, manual operation is not needed, and the production efficiency is improved.

Owner:山东凯欣绿色食品股份有限公司

Remote unlocking device of telecommunication equipment function

InactiveCN109547869AAvoid swiping left and rightEasy maintenanceTelemetry/telecontrol selection arrangementsTelephonic communicationEngineeringClockwise

The invention discloses a remote unlocking device of a telecommunication equipment function, and relates to the technical field of the telecommunication equipment. The remote unlocking device is specifically composed of a computer base, a mounting plate, a computer, a support frame and a cushion block; a sliding chute is formed at an edge of a top end of the computer base, the mounting plate is arranged at an inner wall of a clamping mechanism; first connecting rods penetrate interiors of two sides of the mounting plate, and the computer is screwed on the upper end of a mounting base; the support frame is arranged at a left sidewall and a right sidewall of the mounting base, and a cross bar is welded at the top end of the support frame; a revolving drum is sleeved on the outer wall of thecross bar, and the cushion block is fixedly adhered on the top end of the computer. The invention provides the remote unlocking device of the telecommunication equipment function, since a cross section of the computer base is a concave-shaped structure, a rotating plate rotates in clockwise or reversely rotates in counterclockwise in the sliding chute through a sliding block in the process of rotating the rotating plate, and the computer can be rotated to an appropriate location.

Owner:LAIWU VOCATIONAL & TECHNICAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com