Efficient drilling device for pearl processing design and using method thereof

A drilling device and pearl technology, applied in stone processing equipment, stone processing tools, working accessories, etc., can solve problems such as low efficiency, difficult stable operation, time-consuming, etc., to achieve improved connection stability, improved positioning effect, improved The effect of slip resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

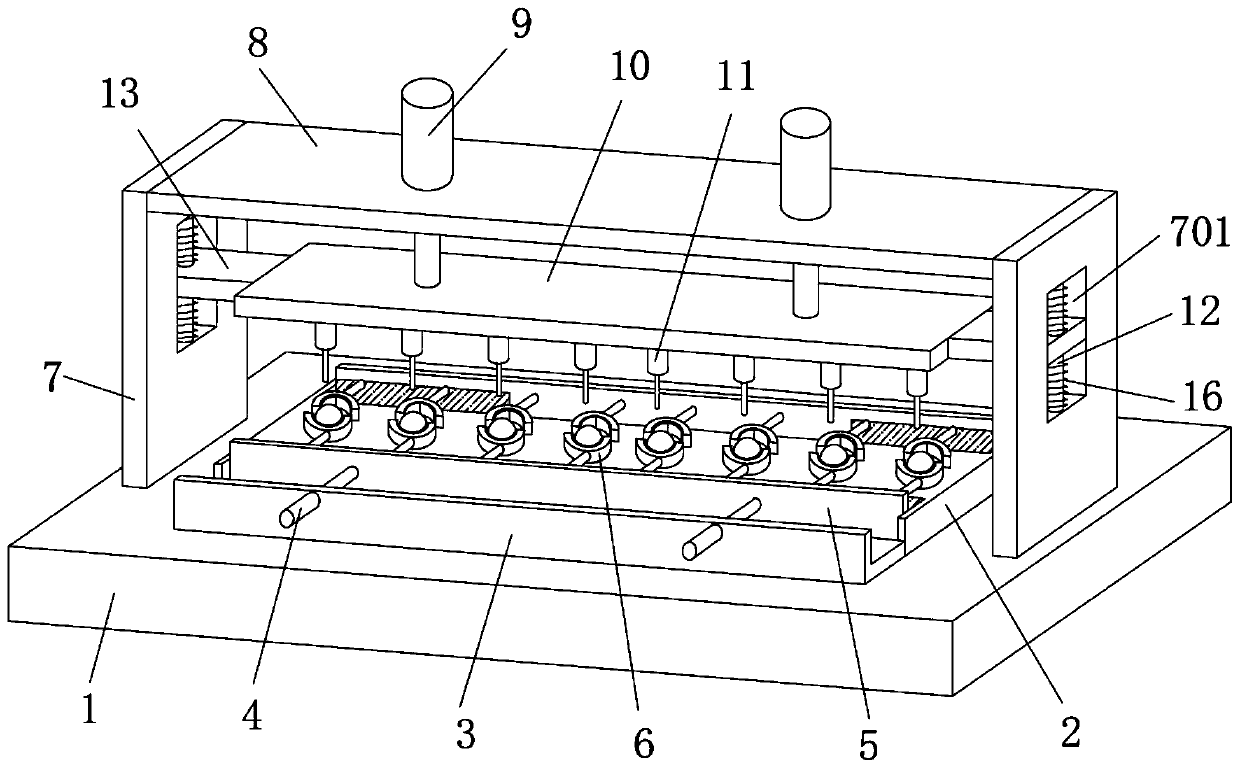

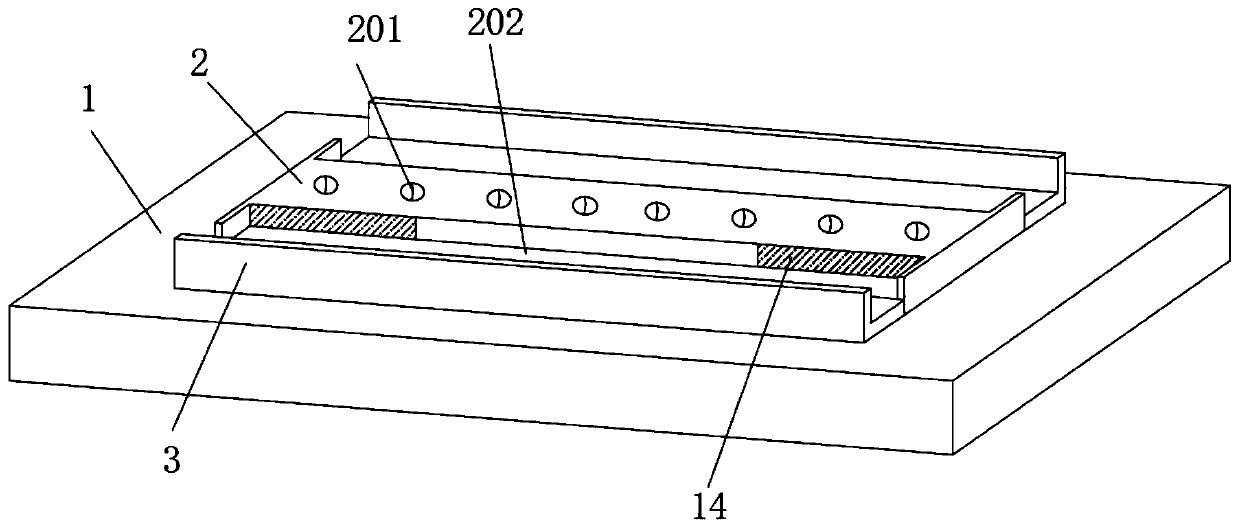

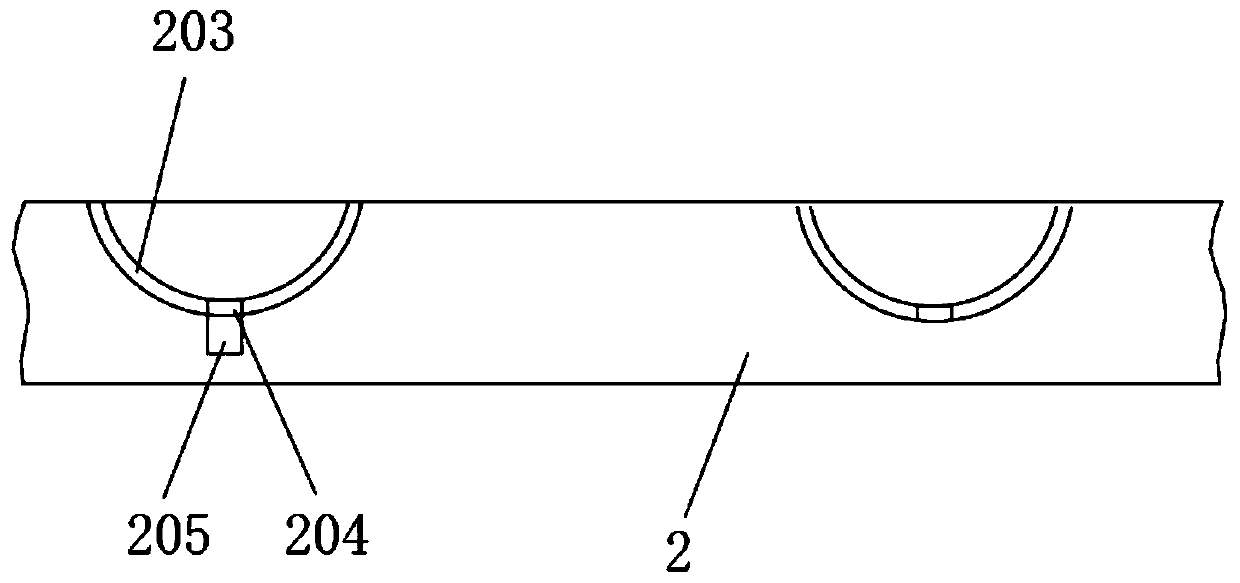

[0036] see Figure 1-3, a high-efficiency drilling device for pearl processing and design, including an operating table 1 and a positioning table 2 arranged on the upper end of the operating table 1, the upper end of the positioning table 2 is provided with a plurality of positioning holes 201 along its horizontal direction, and the positioning holes 201 are used for It plays a certain role in limiting the position of the pearl. The upper end of the pearl exposes the upper end surface of the positioning hole 201. The inner walls of the multiple positioning holes 201 are covered with rubber wear-resistant pads 203. The bottom end of the rubber wear-resistant pad 203 is provided with an upper through hole 204. , the inner bottom of the positioning hole 201 is provided with a lower through hole 205 communicating with the upper through hole 204, and the setting of the rubber anti-wear pad 203 effectively protects the pearl, and at the same time, it has a certain friction force with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com