Cloth rolling equipment

A kind of equipment and cloth rolling technology, which is applied in the field of cloth manufacturing, can solve the problems that affect the efficiency of cloth rolling, the rolling of the paper tube and the rotating shaft, and the difficulty of pressing and fitting the rotating shaft and the paper tube.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

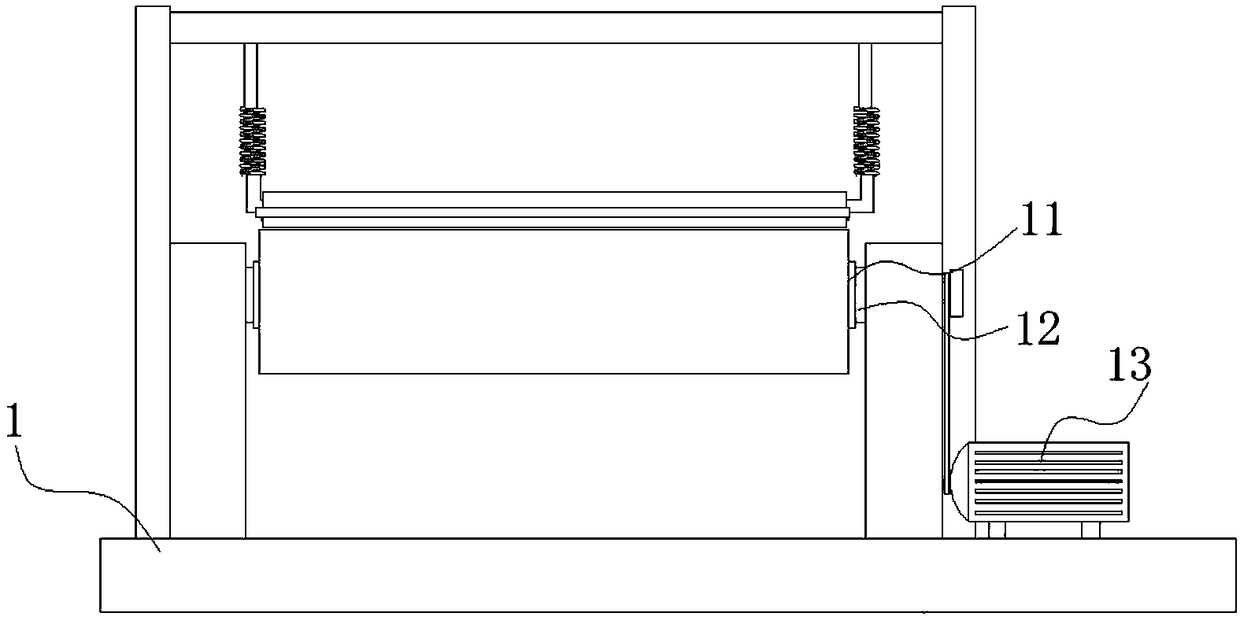

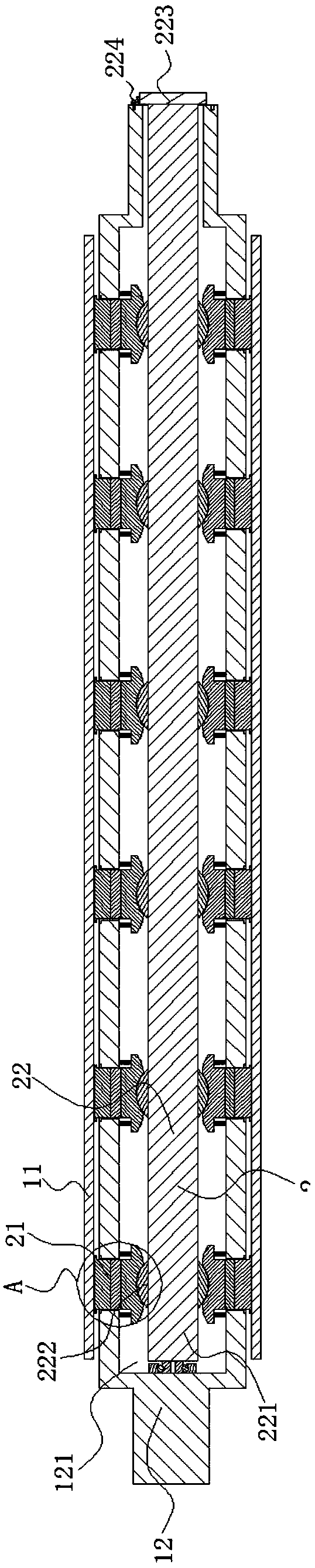

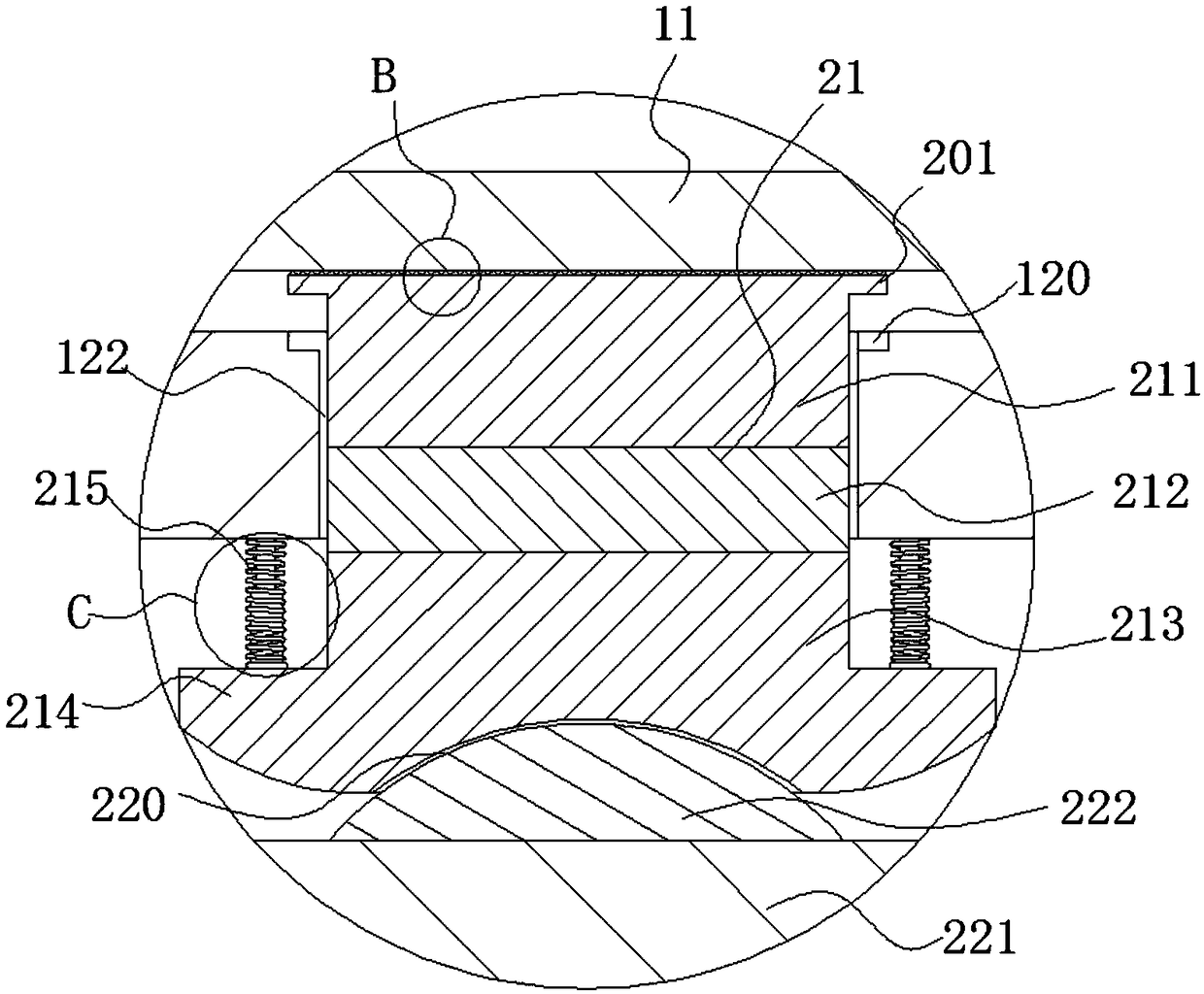

[0020] Such as Figure 1-5 As shown, a cloth rolling device includes a frame body 1, a cloth rolling drum 11, a rotating part 12, a placement cavity 121 and a driving part 13; the frame body 1 is a metal frame, and the driving part 13 is a motor. The cloth rolling drum 11 is an existing paper drum in the market, so it will not be repeated here; the rotating member 12 is a metal tube with a hollow inside, and the cavity formed by the hollow inner wall of the rotating member 12 is the The above-mentioned placement chamber 121; the rotating member 12 is provided with a plurality of movable openings 122 arranged at intervals, and the described movable openings 122 communicate wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com