Soilless lawn and preparation method of soilless lawn

A soilless lawn and pulping technology, which is applied in the field of agricultural environmental engineering and biology, can solve the problems of soil pollution, increase manpower and material resources, non-degradable, etc., and achieve the effect of avoiding soil pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The rice stalk fiber bundles and water hyacinth obtained after silk rubbing and separation are separated by a fiber separator, and then refined by a high-consistency refiner to form a physical mechanical pulp, then added to a yellow cardboard, and pulped through a beating tank , add water-retaining agent, fertilizer-retaining agent and turfgrass seeds, stir and mix to form a slurry with a mass concentration of 0.8%, and mold it through pulp molding equipment to directly produce the semi-finished product of the bottom plate of the turf board. After air-drying or 10~ Drying at a low temperature of 25°C can produce a finished bottom plate. Wherein 35 parts by weight of rice stalks, 40 parts by weight of water hyacinth, 8 parts by weight of yellow cardboard, 5 parts by weight of lawn grass seeds, 6 parts by weight of water-retaining agent, and 6 parts by weight of fertilizer-retaining agent.

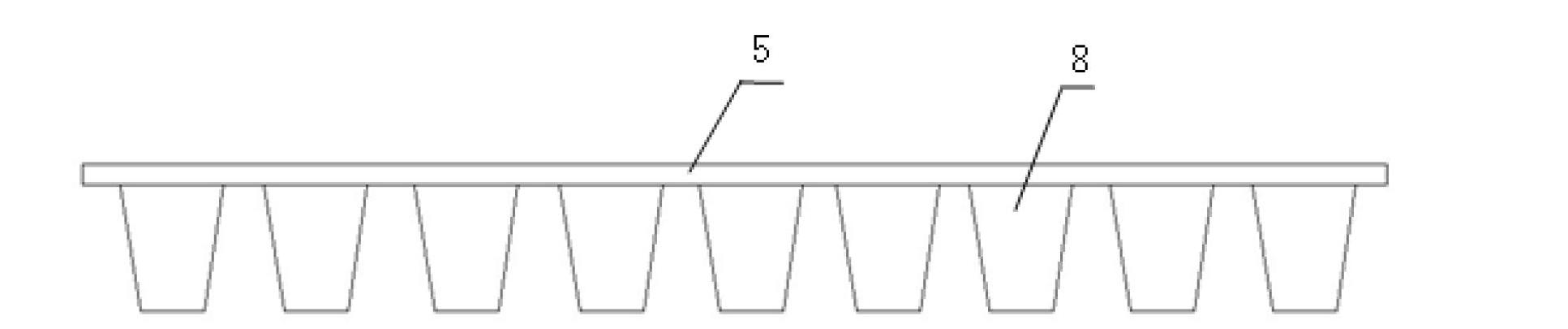

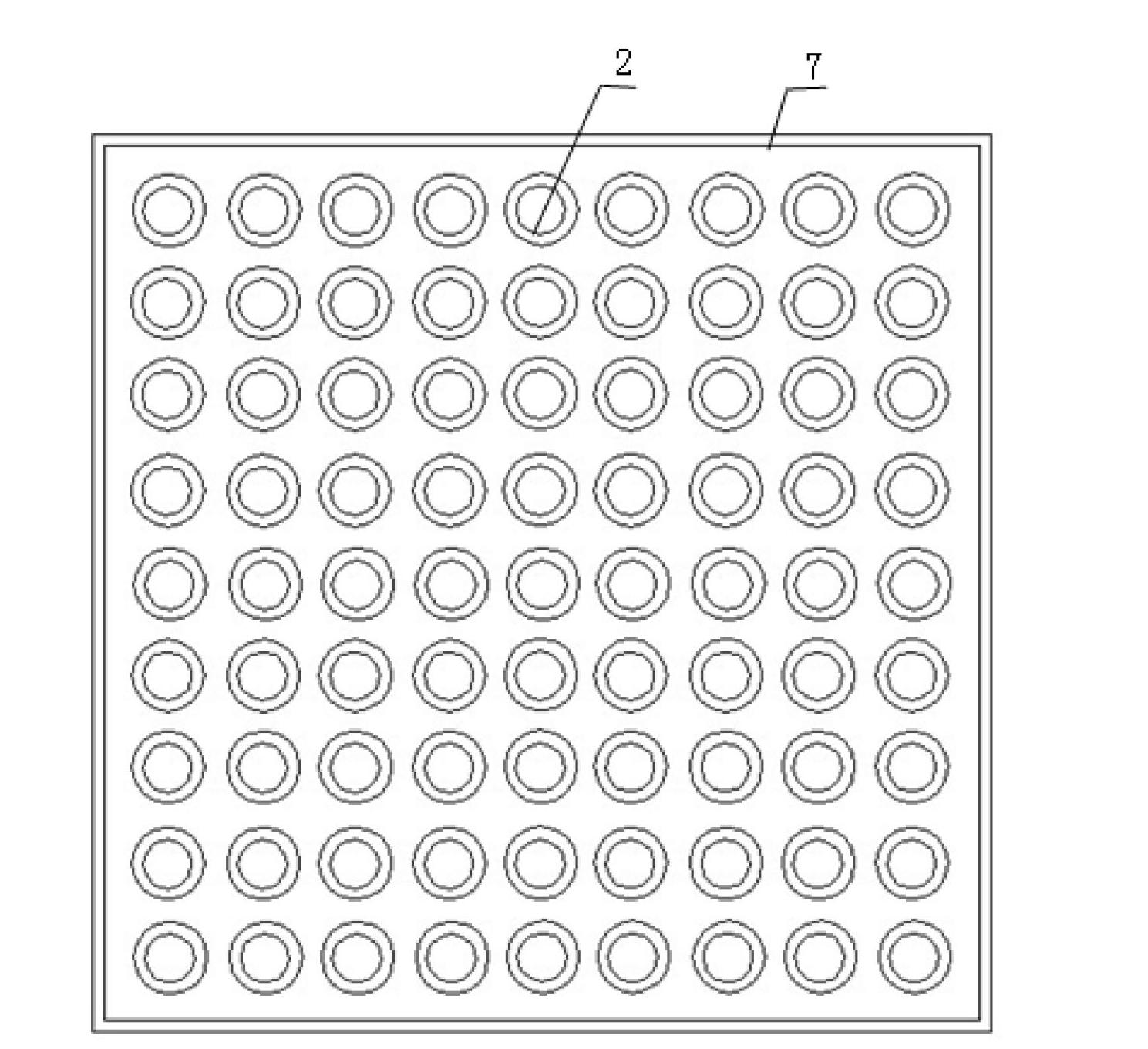

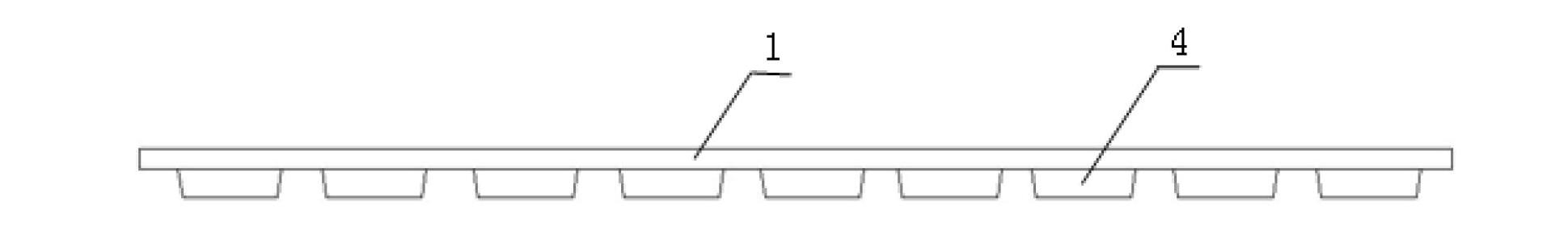

[0034] Figure 1~2 The bottom plate 5 of the soilless lawn is given, which is a ...

Embodiment 2

[0040] Mix soybean stalk fiber bundles and reed stalk fiber bundles obtained after silk rubbing and separation, and then use a high-consistency refiner to refine pulp to form physical mechanical pulp, then add yellow cardboard and pass through the beating tank Pulping forms a slurry with a mass percentage of 1.0%. Add a water-retaining agent to the slurry, stir and mix it, and mold it through a pulp molding equipment to directly produce a semi-finished lawn bottom plate. After air-drying or 10 ~25℃ low temperature drying can make the finished bottom plate. Among them, 40 parts by weight of soybean stalk fiber bundles, 40 parts by weight of reed stalk fiber bundles, 5 parts by weight of yellow cardboard, and 6 parts by weight of water-retaining agent.

[0041] In the same way, the wheat stalk fiber bundles and dried cow dung obtained after silk rubbing and separation are separated and pulped, added with yellow cardboard for beating, added with water retaining agent, mixed evenl...

Embodiment 3

[0044] Cut the dry reed stalks into small pieces of about 5cm, soak them in lime water for 45 minutes, rinse them twice with clean water, add dry cow dung, mix them, and then process them with a wire separator, and use a high-consistency refiner to refine After the physical mechanical pulp is formed, the yellow cardboard is added, and the pulp is made through the beating tank. Add water-retaining agent, fertilizer and ryegrass seeds to the slurry, stir and mix to form a slurry with a mass concentration of 2.5%, and mold it through pulp molding equipment to directly produce the semi-finished product of the bottom plate of the lawn board. After air drying or low temperature drying at 10~25℃, the finished bottom plate can be obtained. Wherein, 30 parts by weight of reed stalks, 30 parts by weight of dry cow dung, 5 parts by weight of yellow cardboard, 5 parts by weight of water-retaining agent, 8 parts by weight of ryegrass seeds, and 2 parts by weight of fertilizer-preserving ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com