Coaxial electrospun injectable fibers and preparation method thereof

A coaxial electrospinning and fiber technology, which is applied in fiber processing, fiber chemical characteristics, cellulose/protein conjugated artificial filaments, etc., can solve problems such as invasive operations, achieve faster release speed, and reduce the number of administrations , good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

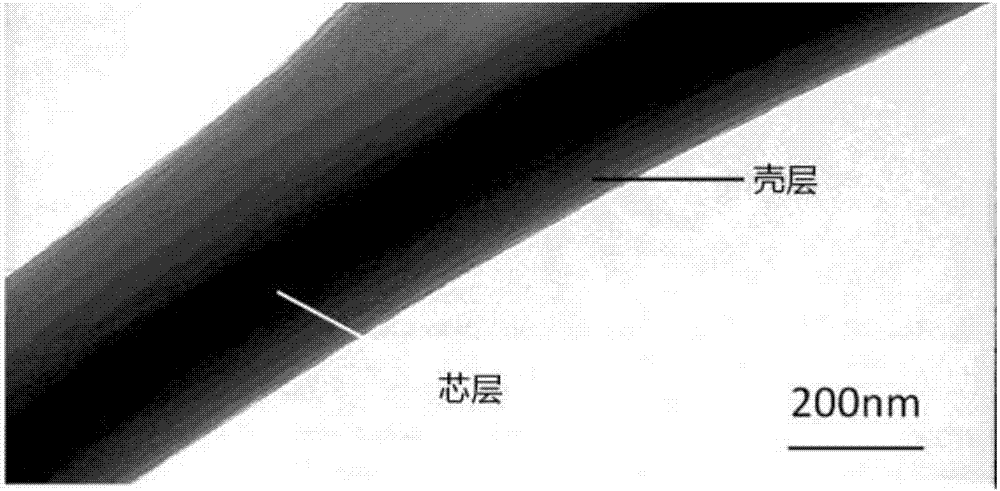

[0037] A preparation method for coaxial electrospinning injectable fibers, comprising the following steps:

[0038] (1) dissolving chitosan in a mixed solution with a volume ratio of trifluoroacetic acid and dimethyl carbonate of 8:2, adjusting the pH value of the mixed solution with 1% acetic acid to 5, stirring evenly, then adding Kang Pretin, stirred evenly, to obtain the shell solution; wherein, the weight-to-volume ratio of chitosan and the mixed solution is 0.1:2, and the weight-to-volume ratio of compretin and the mixed solution is 0.1:5;

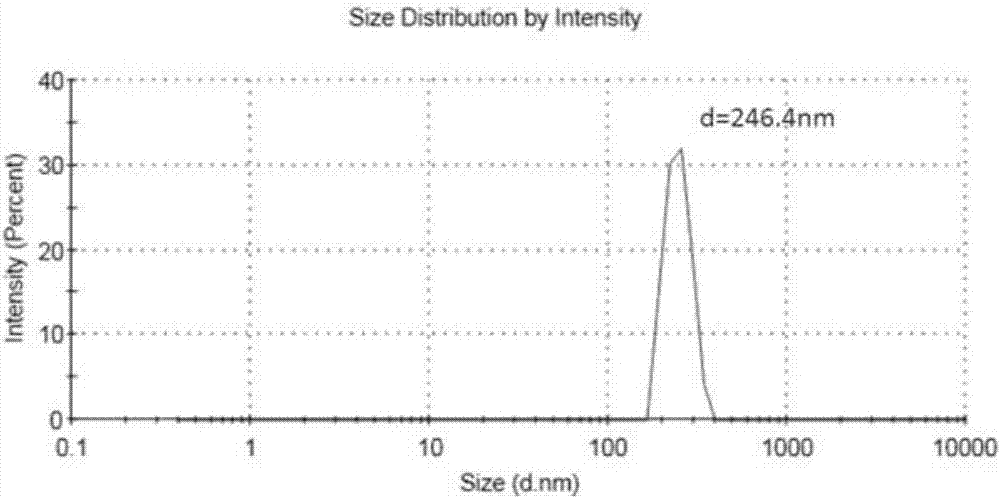

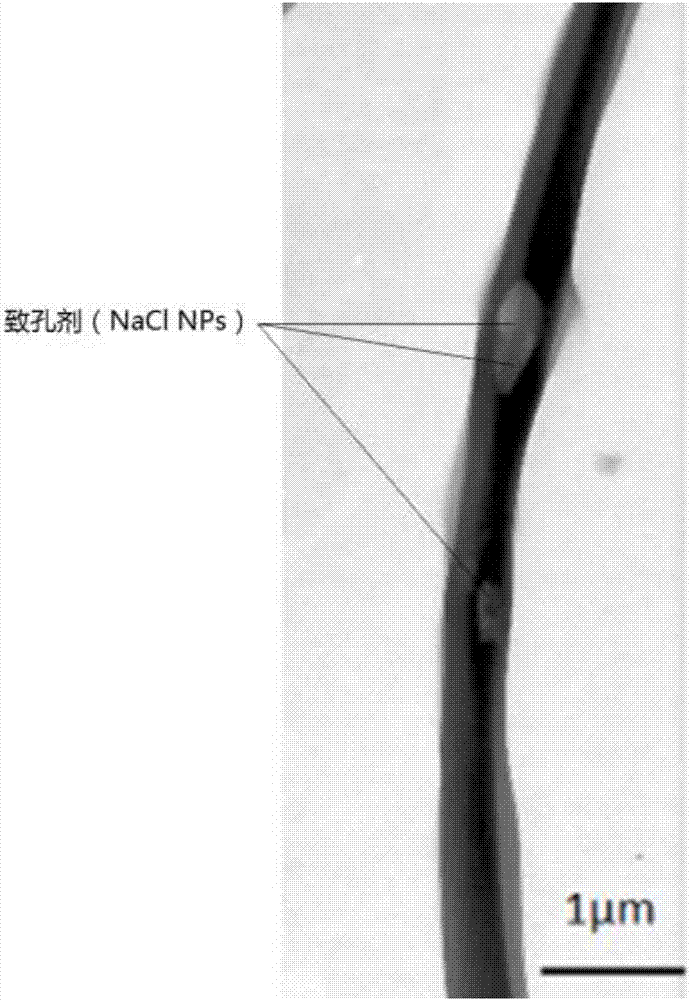

[0039] (2) Dissolve polylactic acid-glycolic acid copolymer in a mixed solution of dichloromethane and N,N-dimethylamide with a volume ratio of 7:3, stir evenly, add hydroxycamptothecin, continue stirring, and then add Sodium chloride particles with a particle size of 250nm are uniformly mixed to obtain a core layer solution; wherein, the weight-to-volume ratio of the mixed solution of polylactic acid-glycolic acid copolymer to dichl...

Embodiment 2

[0049] A preparation method for coaxial electrospinning injectable fibers, comprising the following steps:

[0050] (1) Dissolving chitosan in a mixed solution with a volume ratio of 7:3 between trifluoroacetic acid and dimethyl carbonate, adjusting the pH value of the mixed solution to 4.5 with 3% acetic acid, stirring evenly, then adding Kang Pretin, stirred evenly, to obtain the shell solution; wherein, the weight-to-volume ratio of chitosan and the mixed solution is 0.3:2, and the weight-to-volume ratio of compretin and the mixed solution is 0.4:5;

[0051] (2) Dissolve polylactic acid-glycolic acid copolymer in a mixed solution with a volume ratio of methylene chloride and N,N-dimethylamide of 8:2, stir evenly, add hydroxycamptothecin, continue stirring, and then add Sodium chloride particles with a particle size of 248nm are uniformly mixed to obtain a core layer solution; wherein, the weight-to-volume ratio of the mixed solution of polylactic acid-glycolic acid copolyme...

Embodiment 3

[0061] A preparation method for coaxial electrospinning injectable fibers, comprising the following steps:

[0062] (1) Chitosan is dissolved in trifluoroacetic acid and dimethyl carbonate volume ratio in the mixed solution that is 7.5:2.5, is that the pH value of 2% acetic acid adjustment mixed solution is 3 with concentration, stirs, then adds Kang Pretin, stirred uniformly to obtain a shell solution; wherein, the weight-to-volume ratio of chitosan and the mixed solution is 0.2:2, and the weight-to-volume ratio of compretin to the mixed solution is 0.35:5;

[0063] (2) Dissolve polylactic acid-glycolic acid copolymer in a mixed solution of dichloromethane and N,N-dimethylamide with a volume ratio of 9:1, stir evenly, add hydroxycamptothecin, continue stirring, and then add Sodium chloride particles with a particle size of 250nm are uniformly mixed to obtain a core layer solution; wherein, the weight-to-volume ratio of the mixed solution of polylactic acid-glycolic acid copol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com