Patents

Literature

54results about "Mixing/kneading with aerating apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

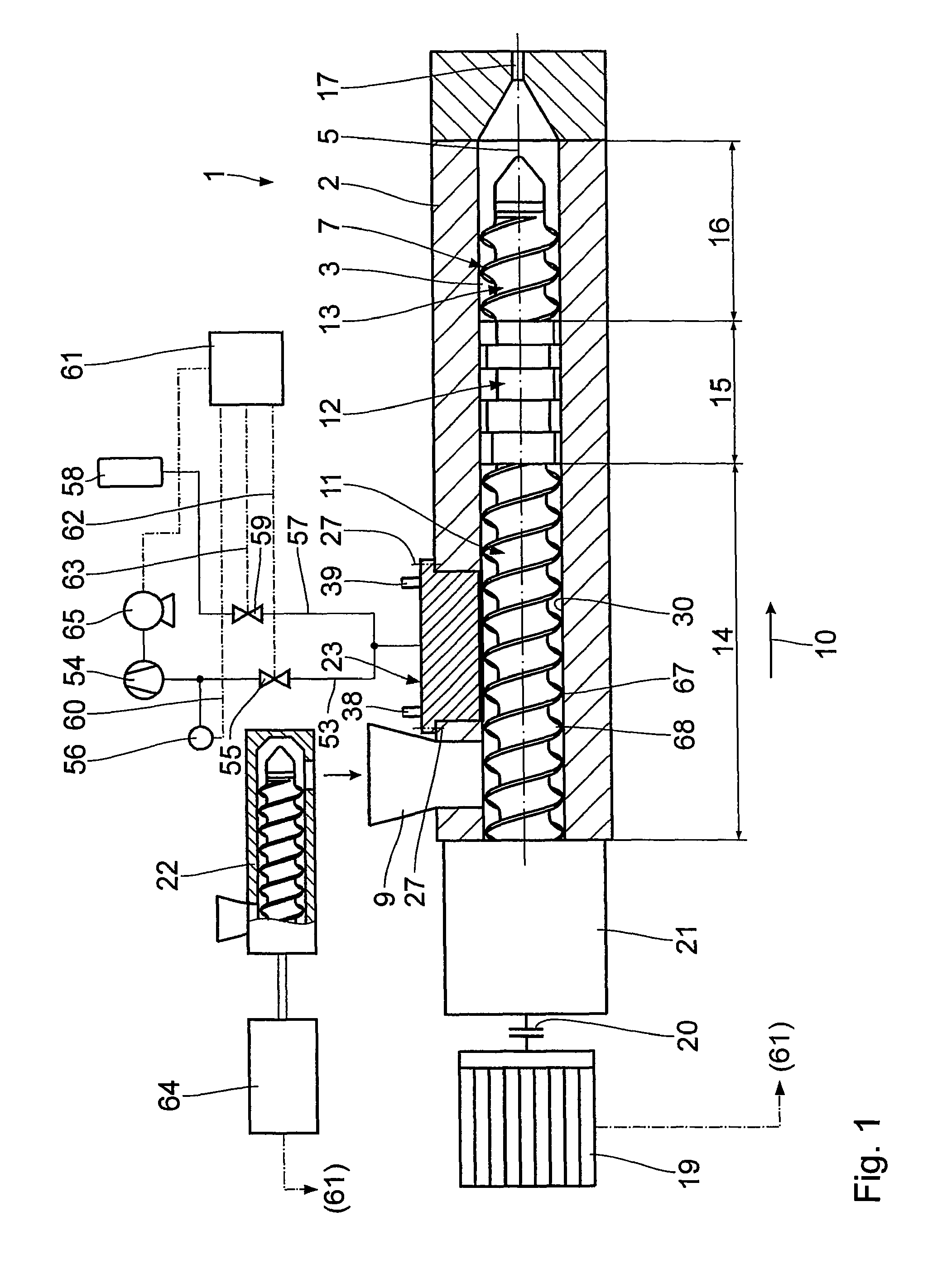

Screw machine

ActiveUS20100202243A1Eliminate cloggingRaise the possibilityRotary stirring mixersFrozen sweetsEngineeringMechanical engineering

A screw machine for treating at least partially powdery bulk material has a housing with at least one housing bore and a screw arranged in the housing bore. A vacuum housing portion is provided, which is formed as a vacuum housing insert, which is releasably attached in the housing, in which a metal nonwoven is exchangeably held as a gas-permeable wall portion on a base body.

Owner:COPERION

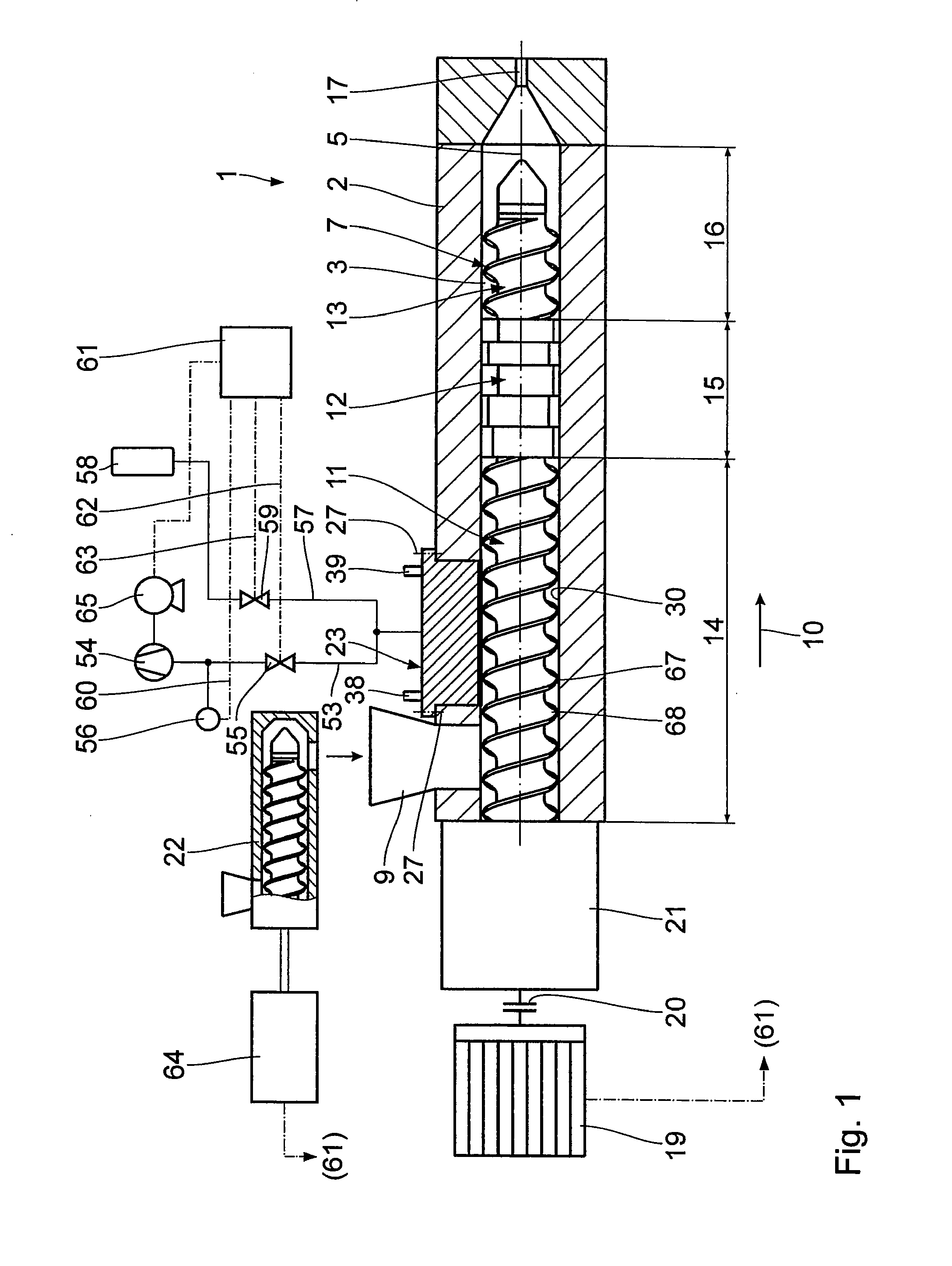

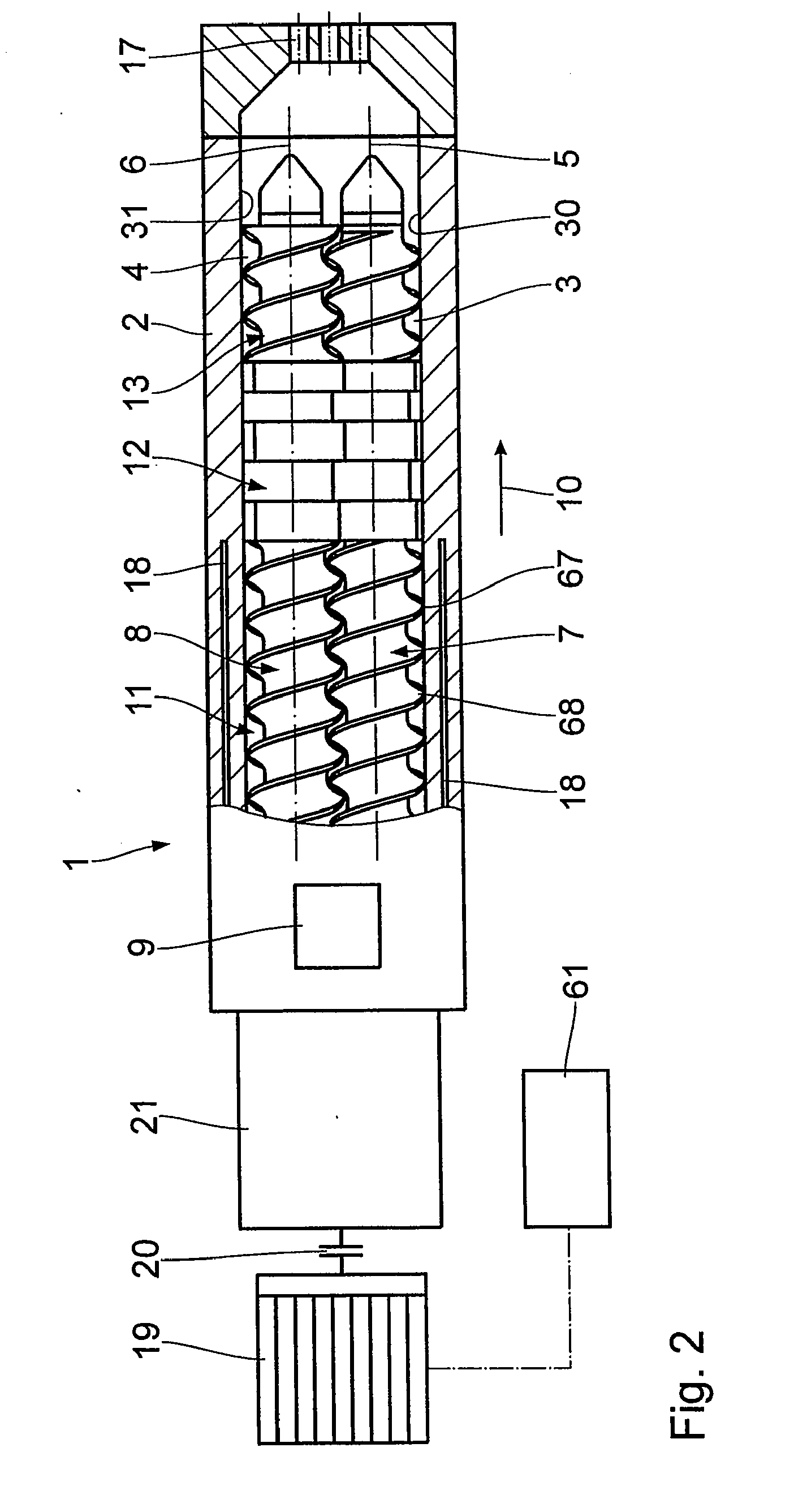

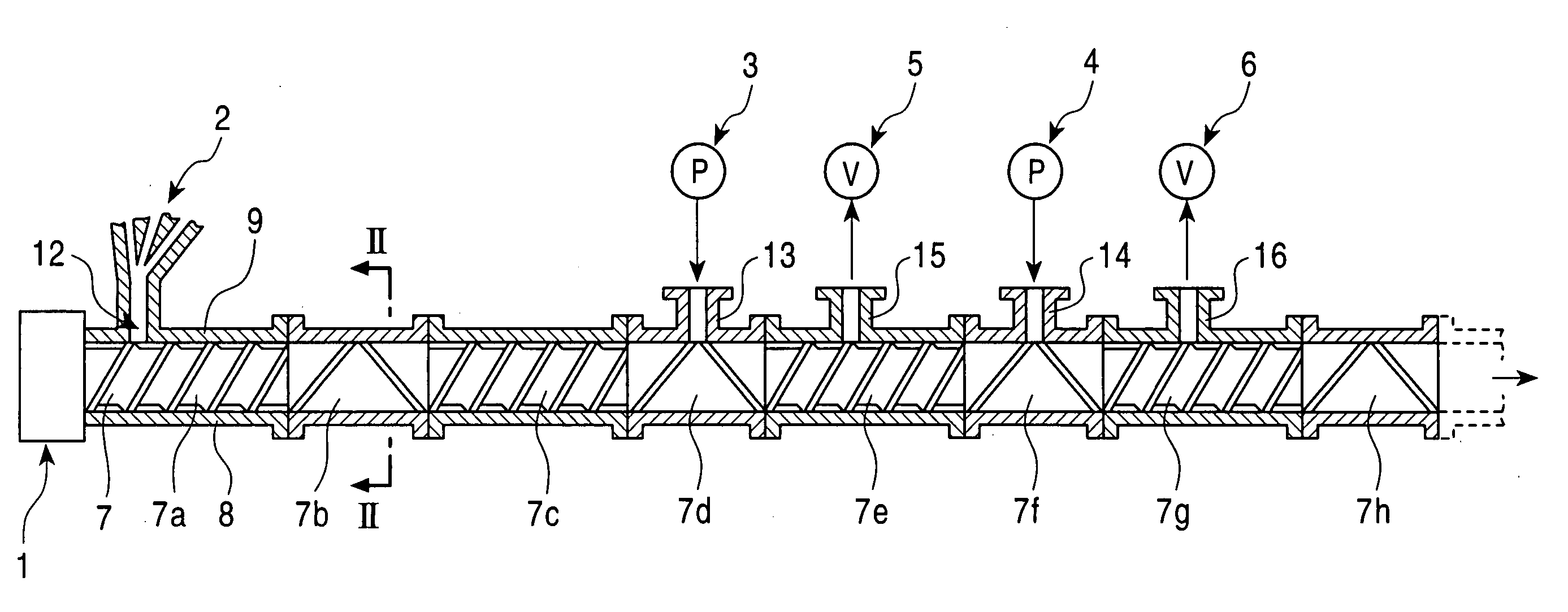

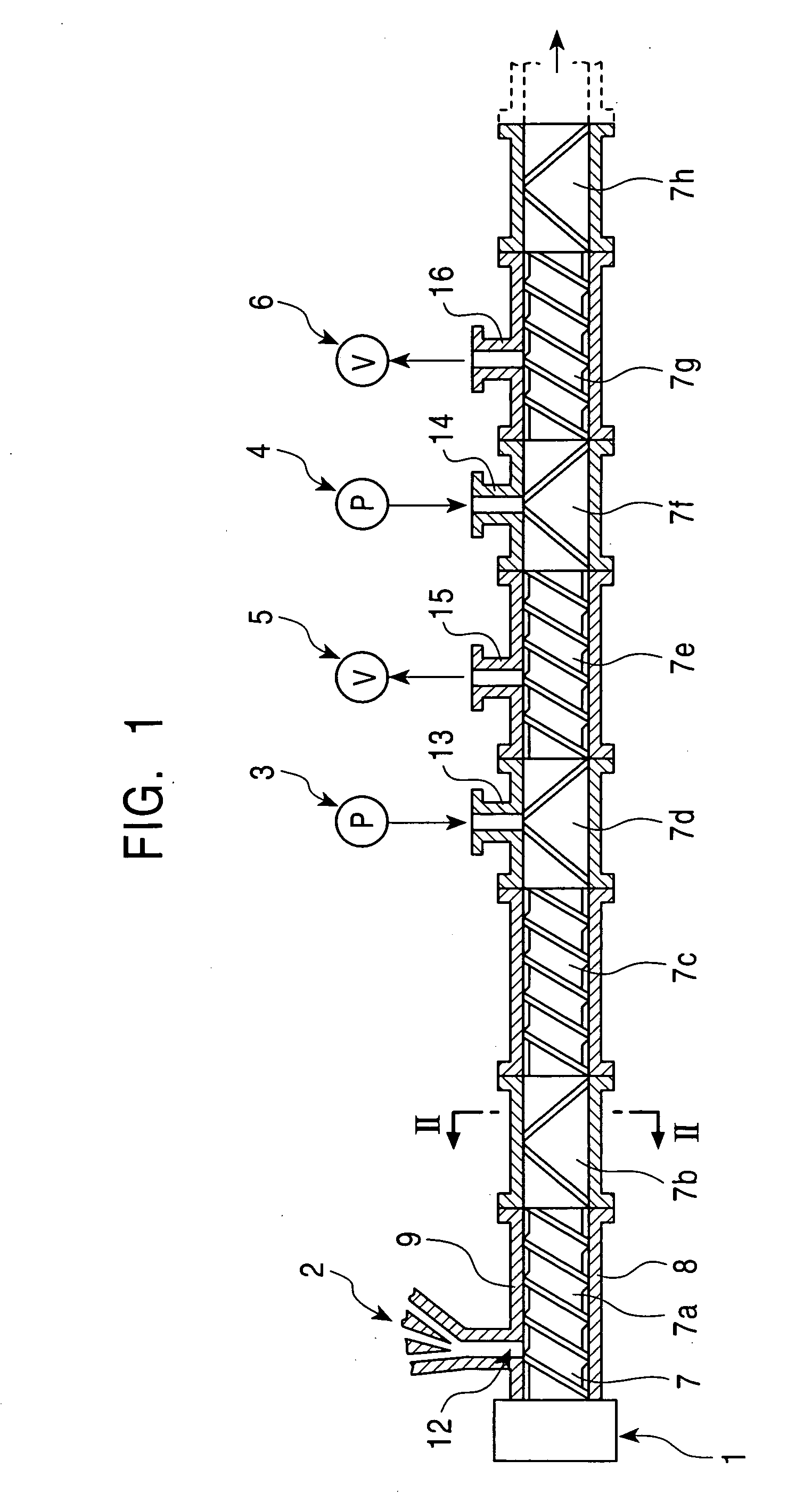

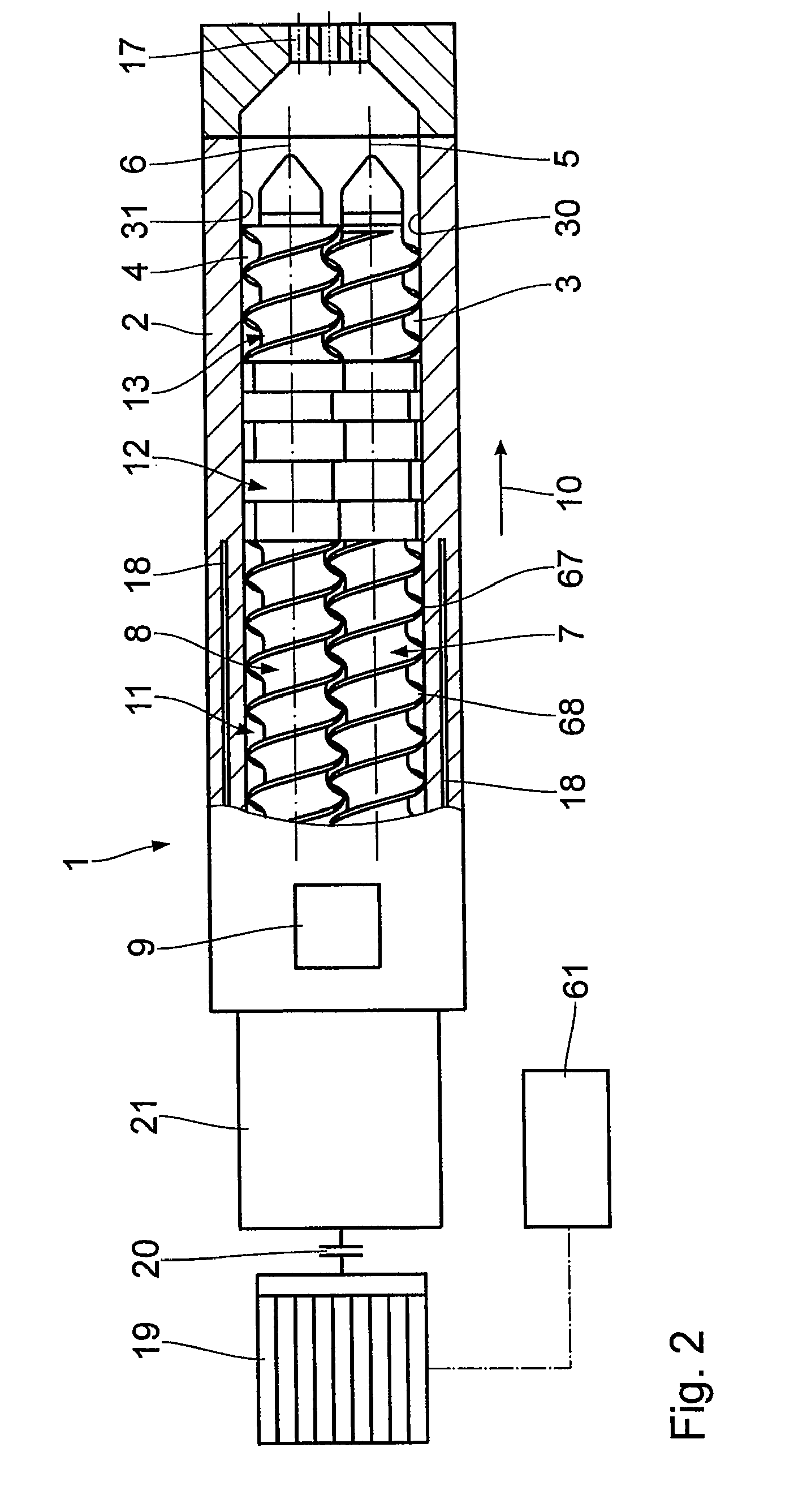

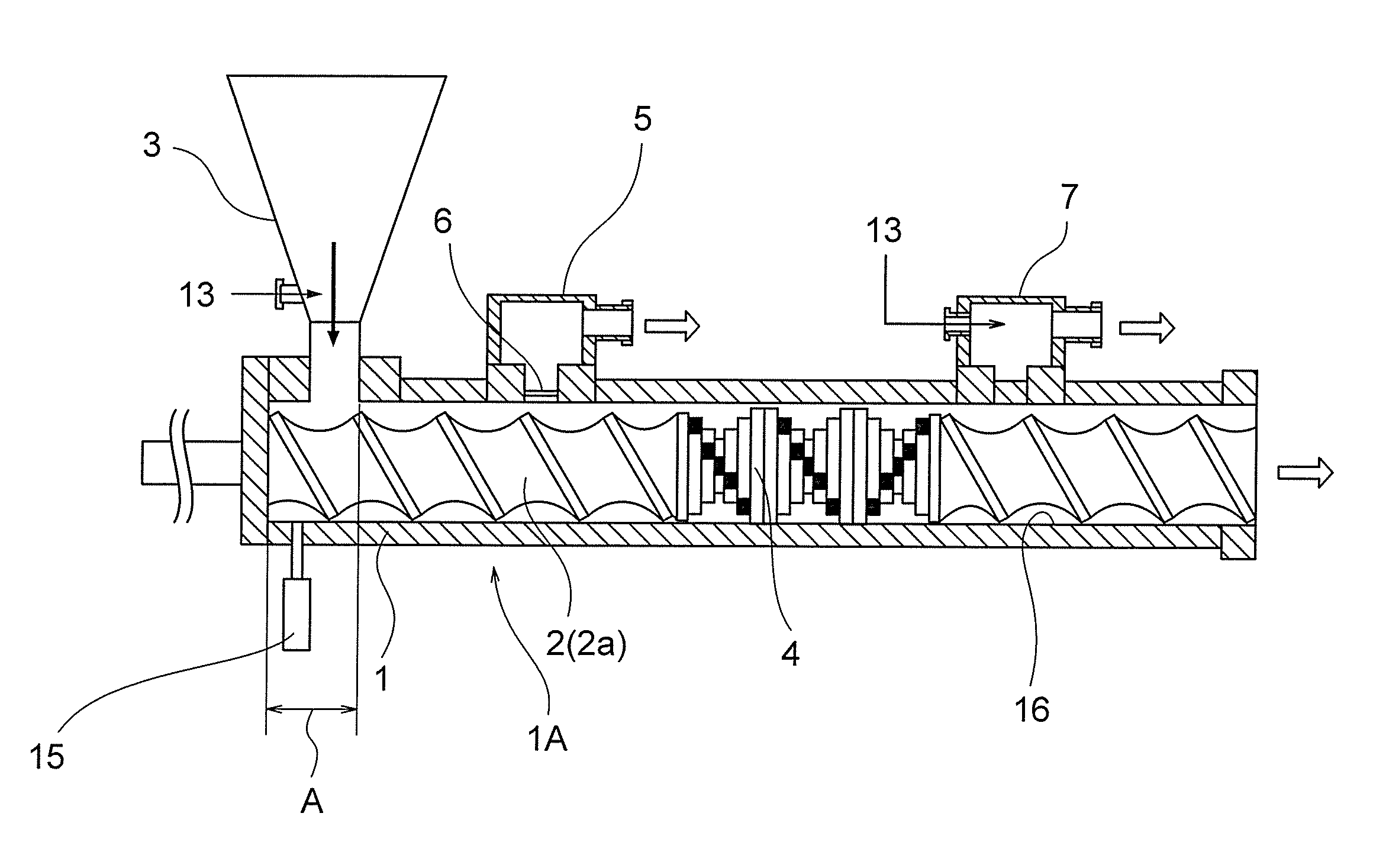

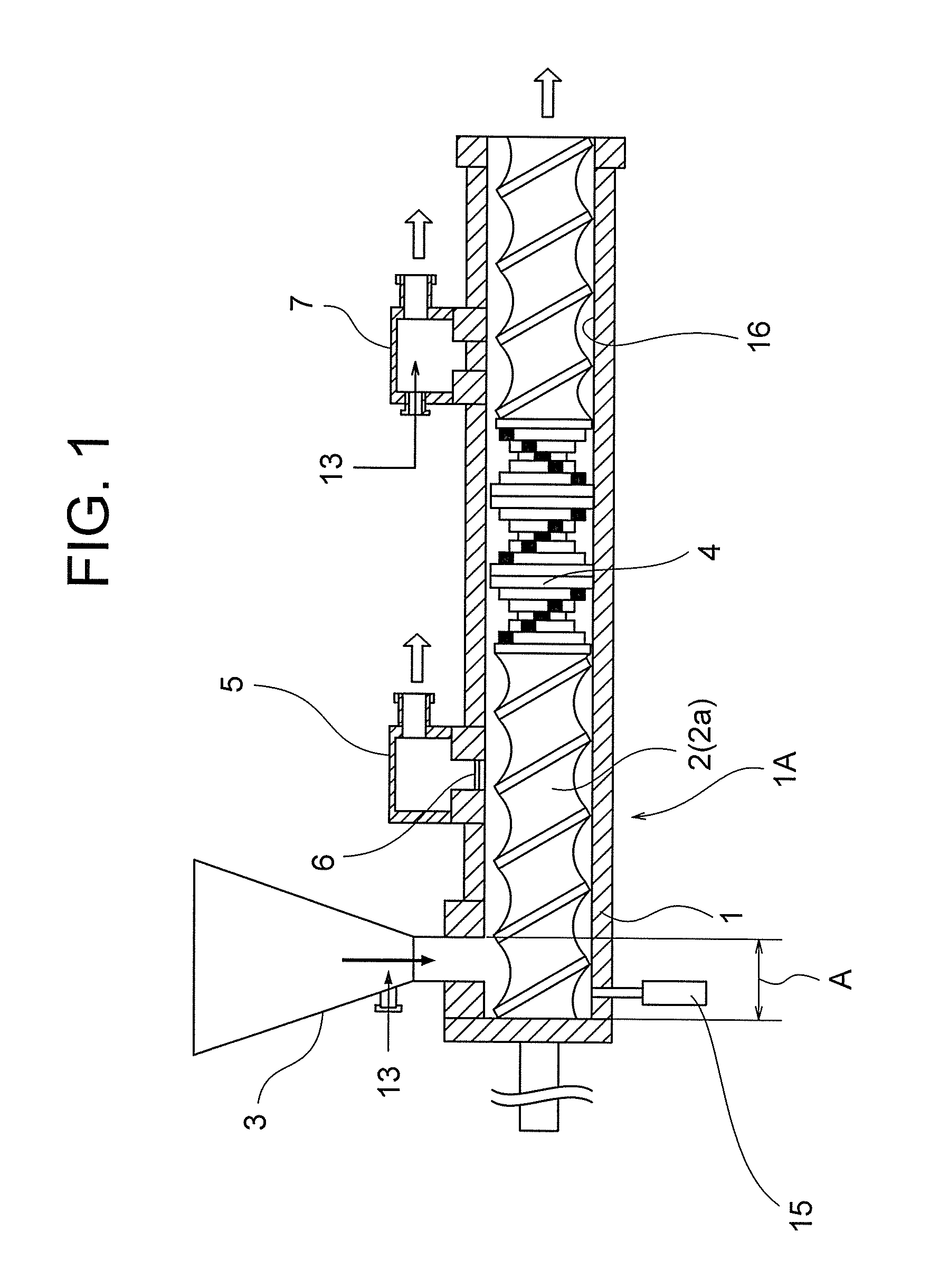

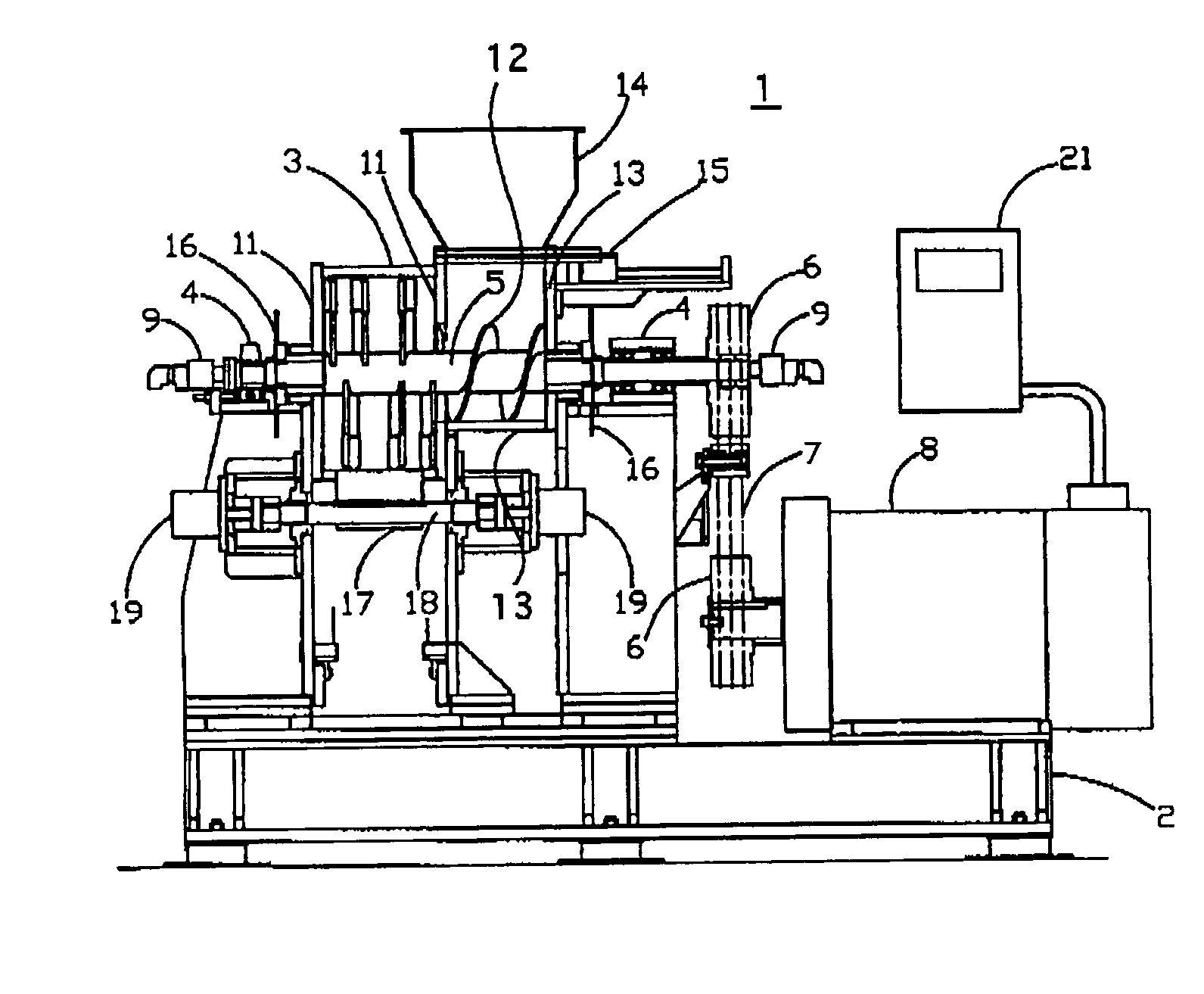

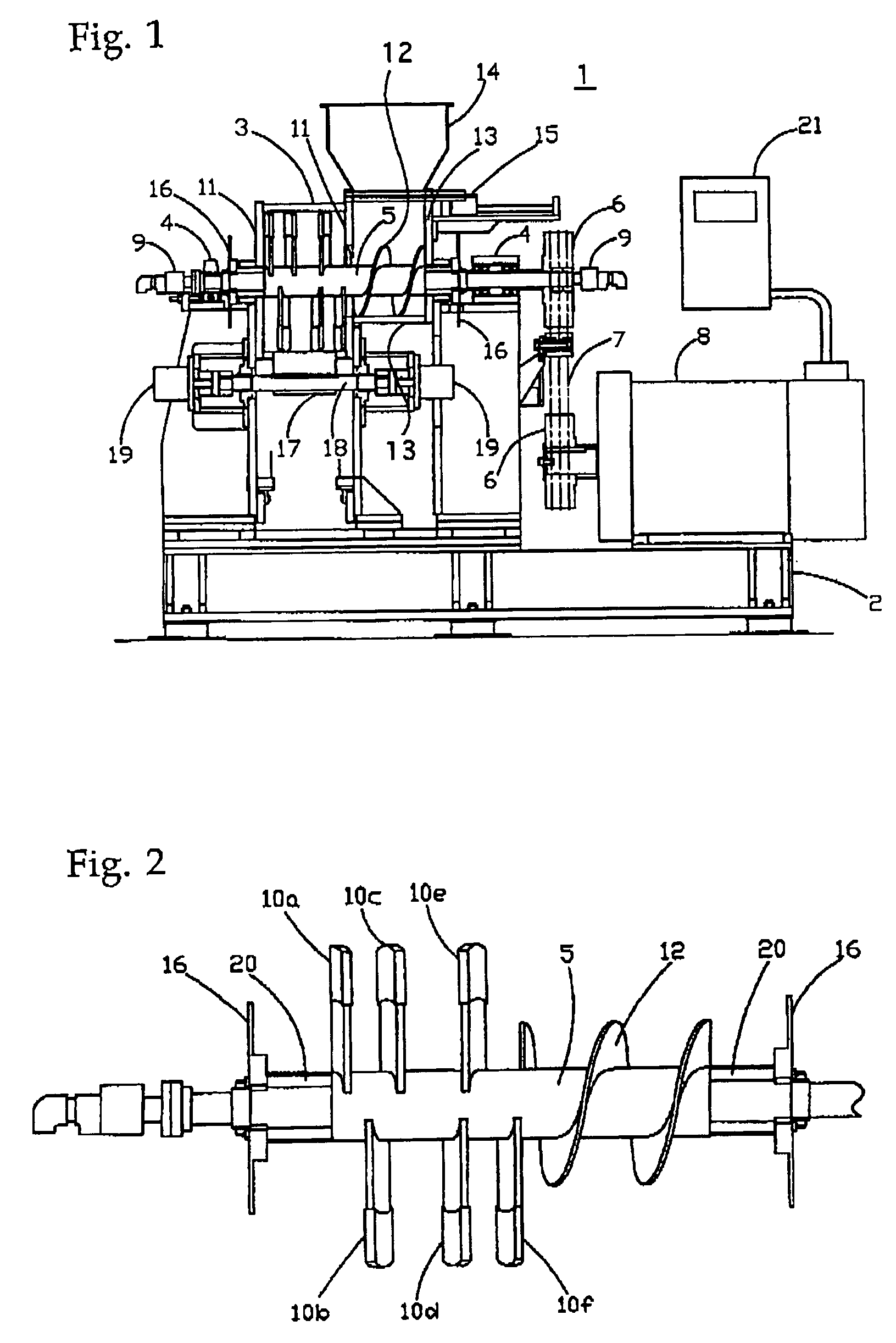

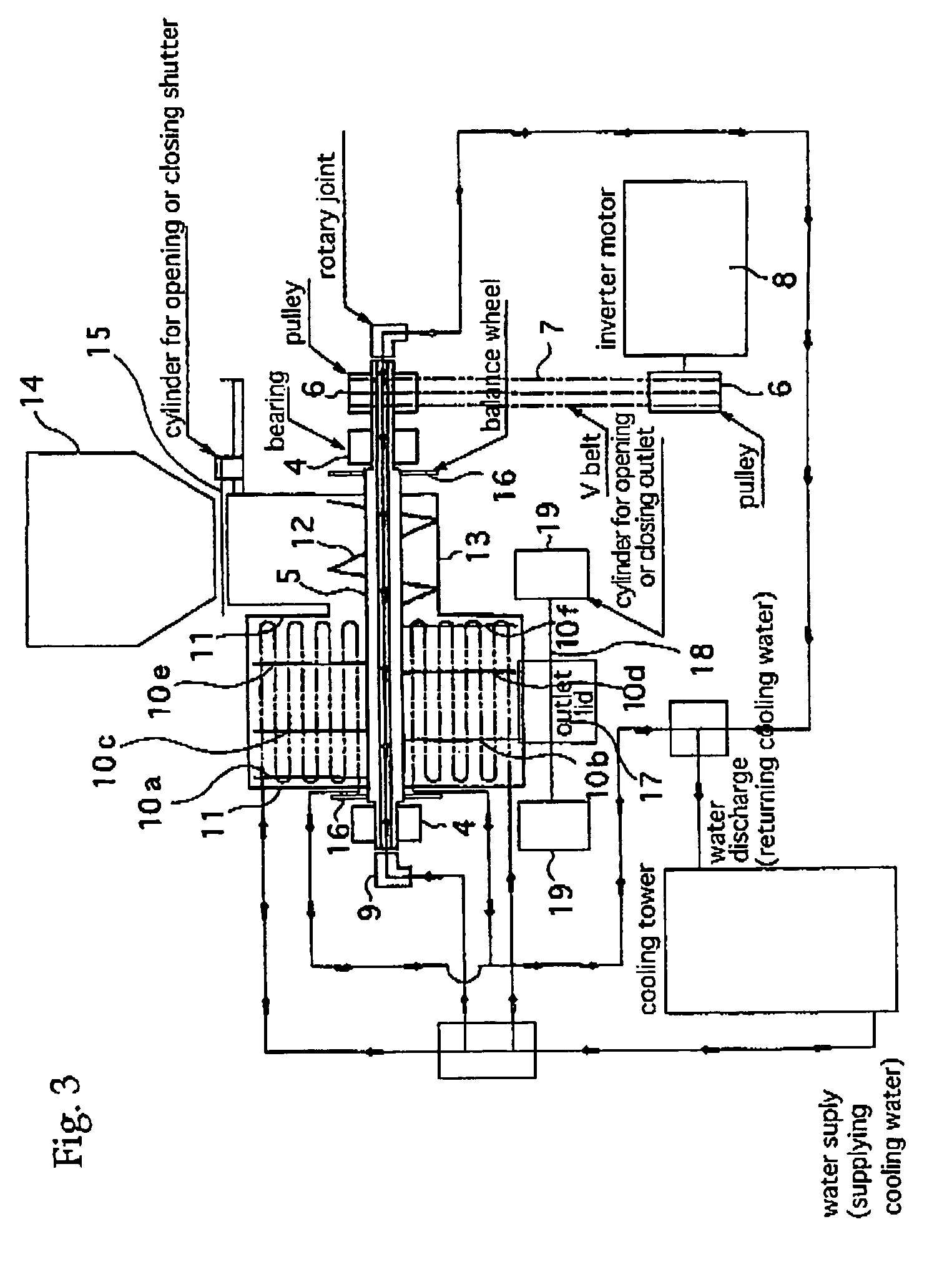

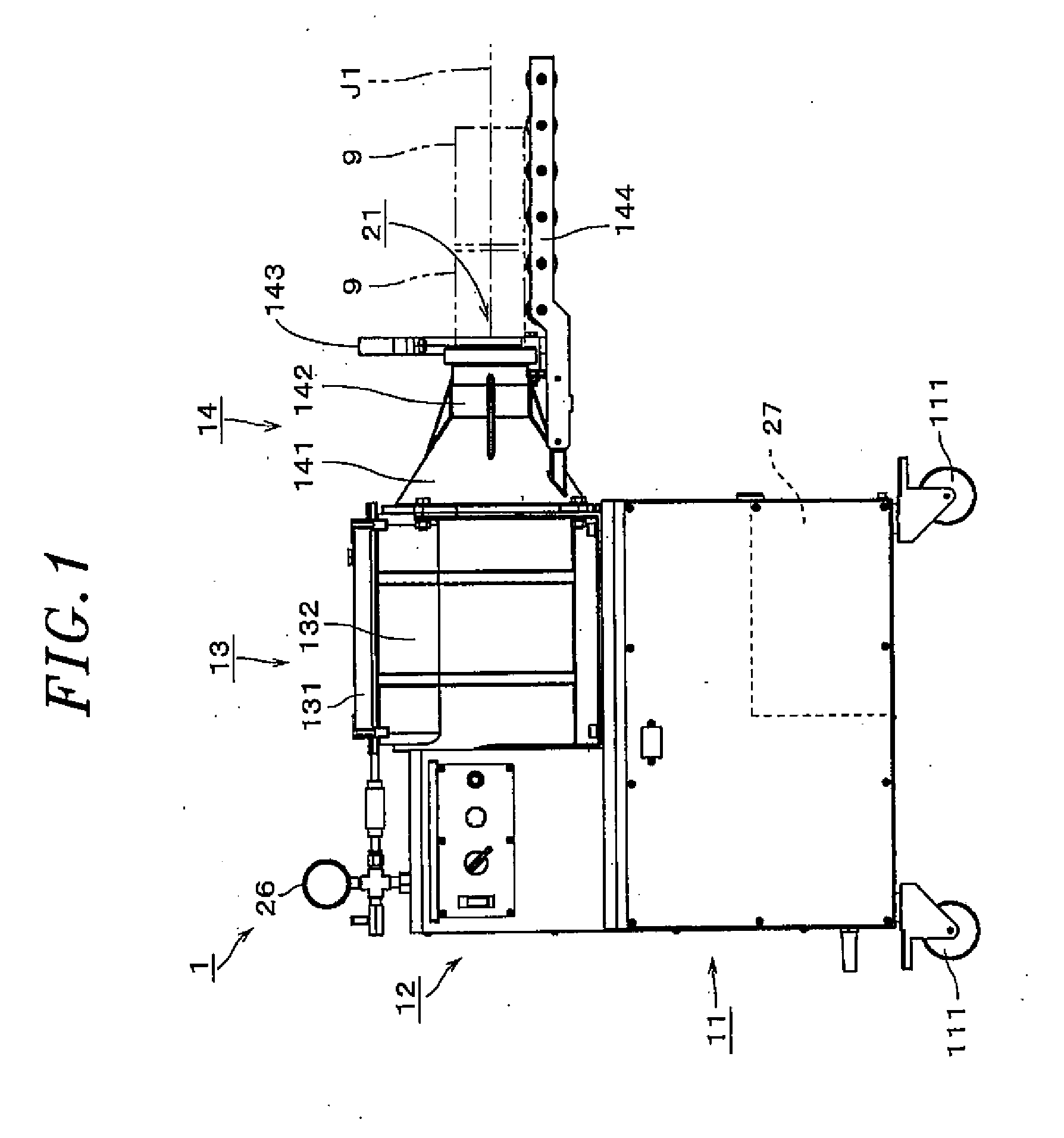

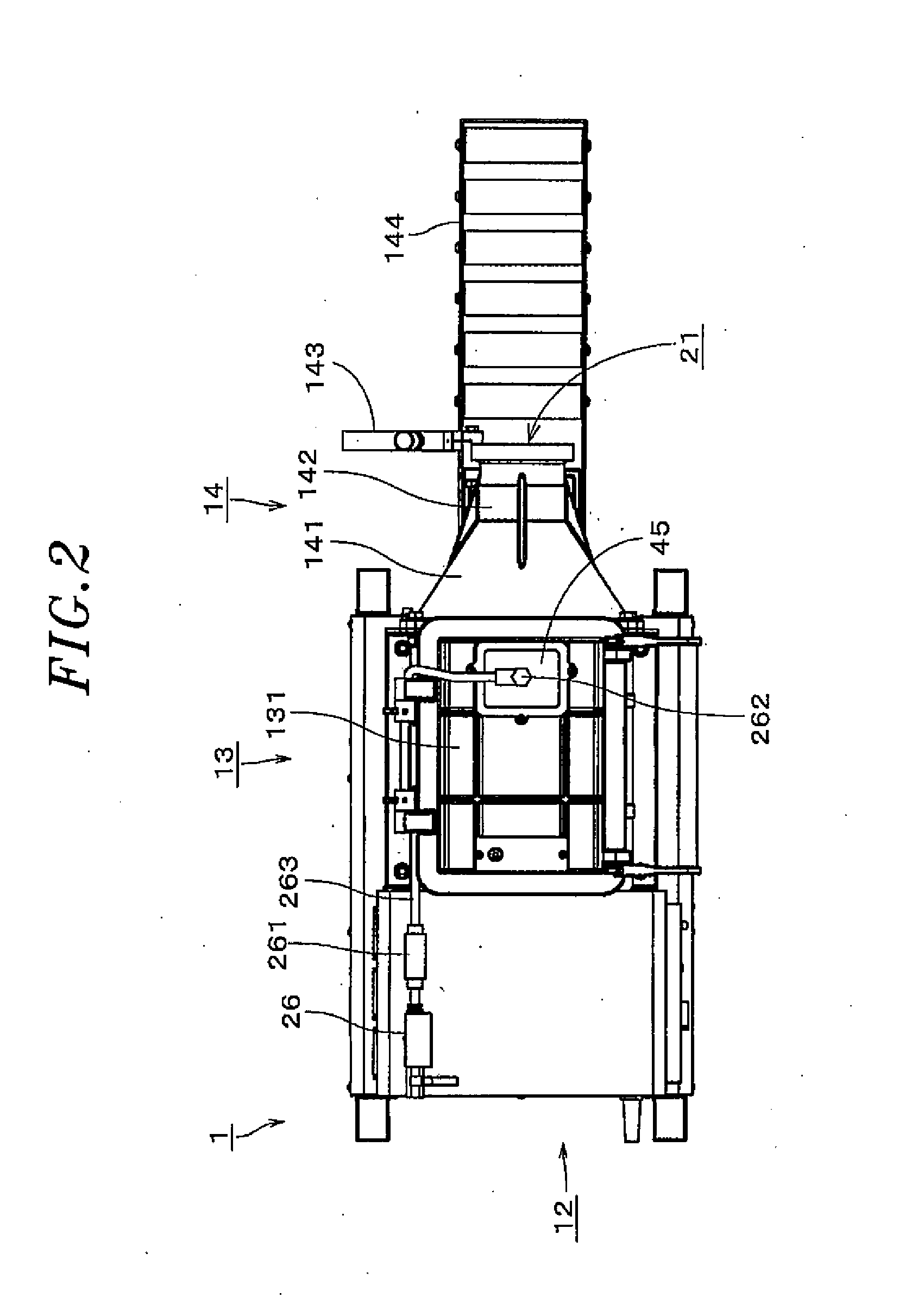

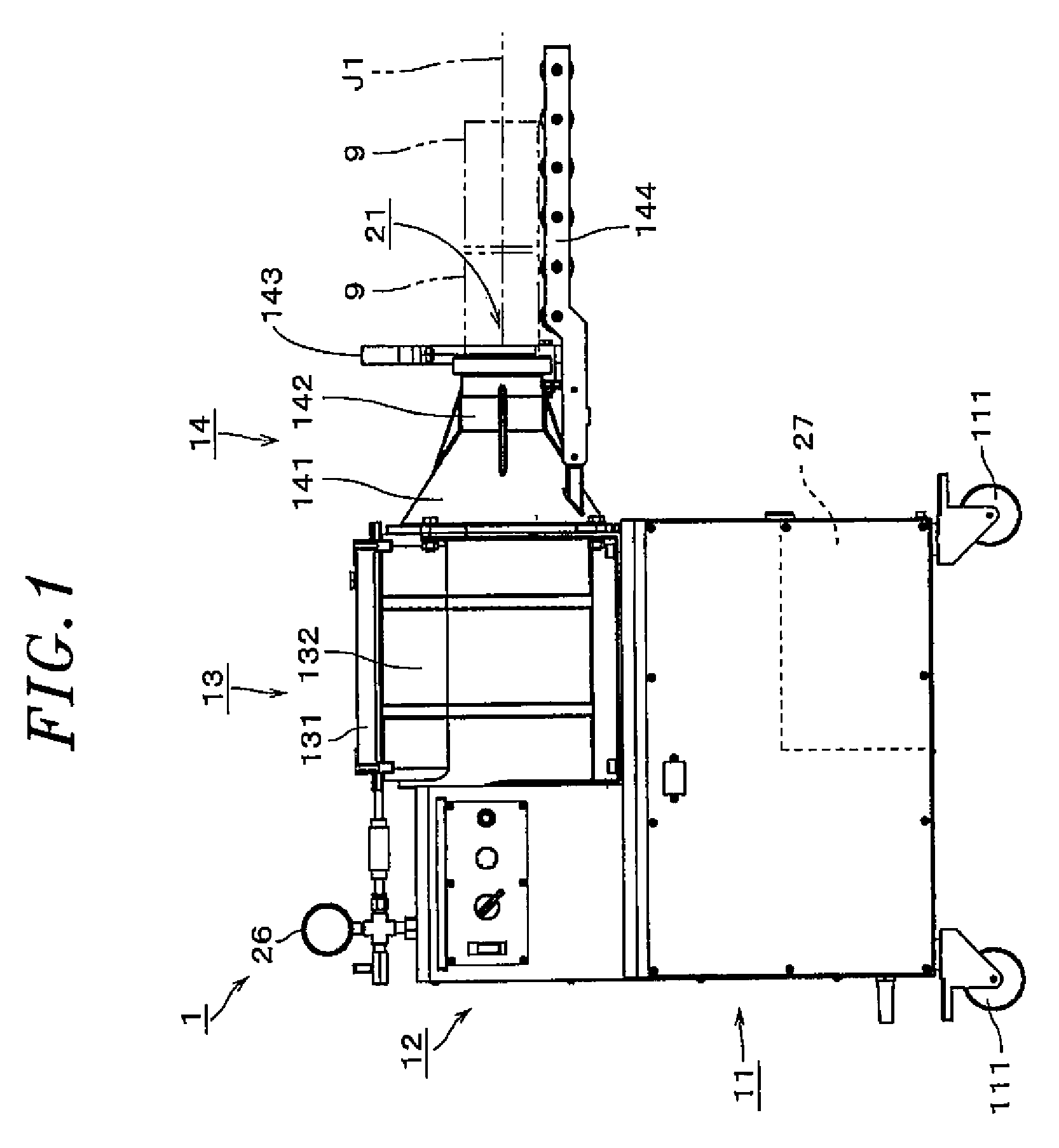

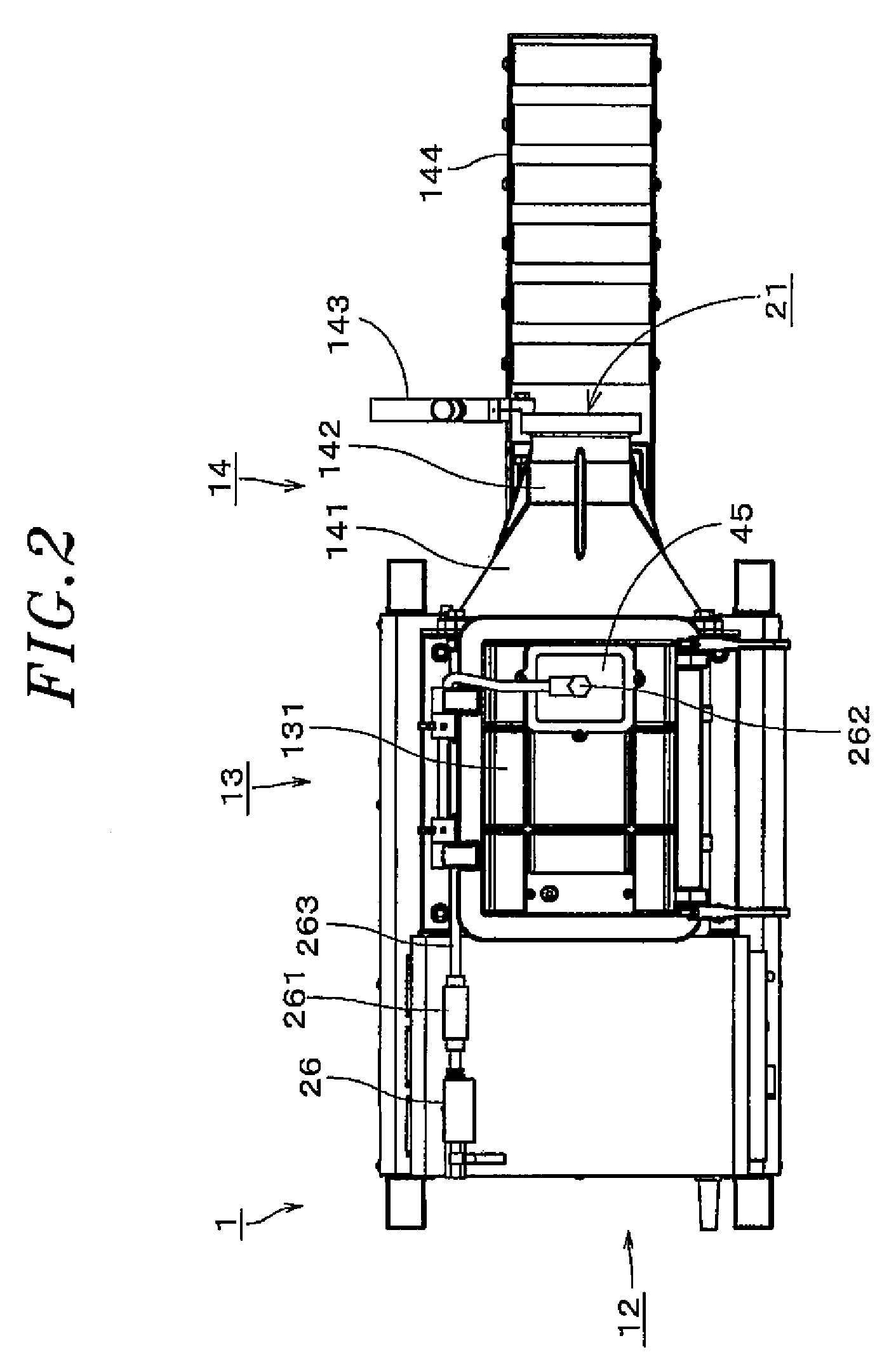

Kneading apparatus and method for kneading rubber-based composition using the same

InactiveUS7004616B2High viscosityImprove productivityRotary stirring mixersMixing/kneading with horizontally-mounted toolsHelical bladeEngineering

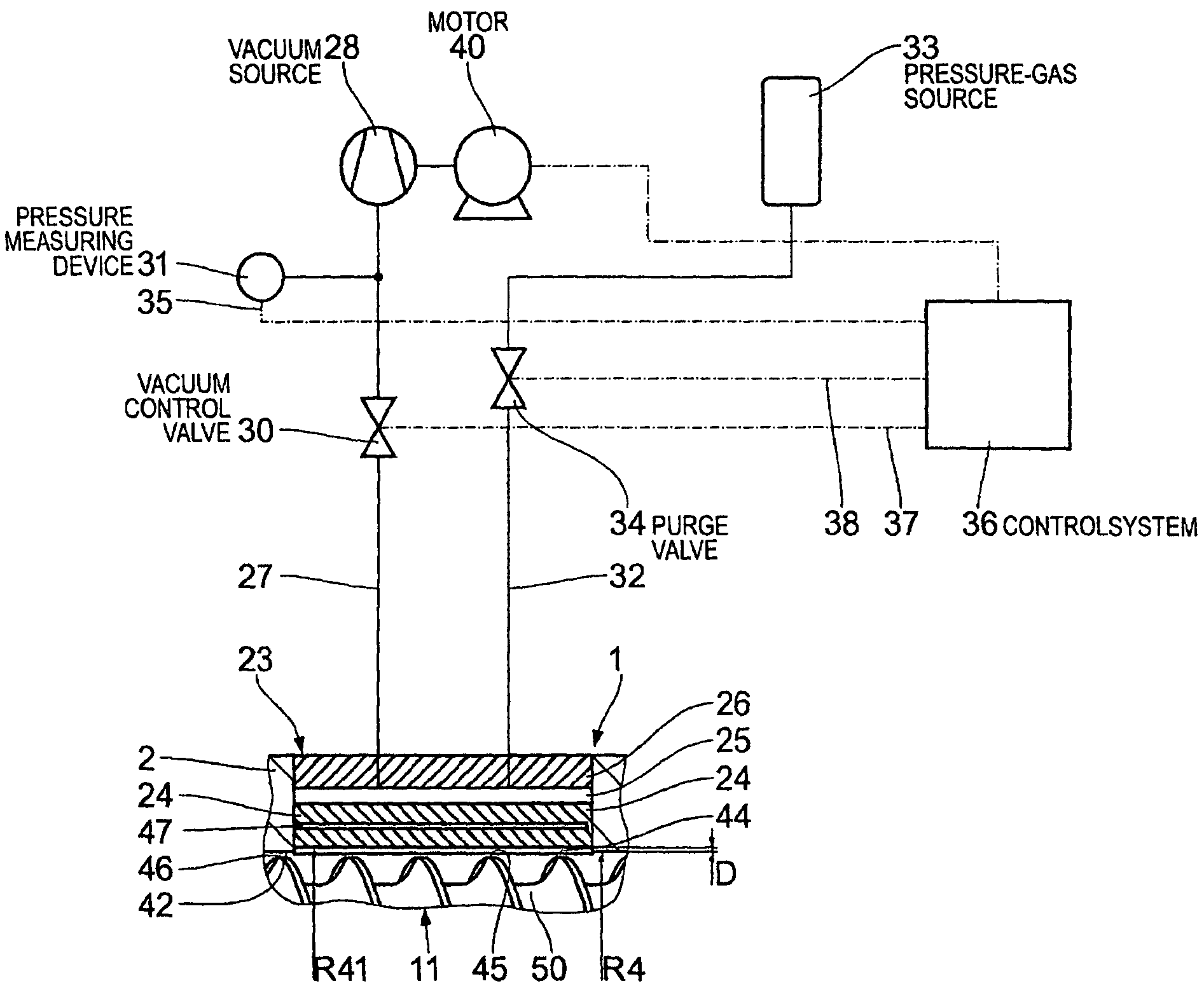

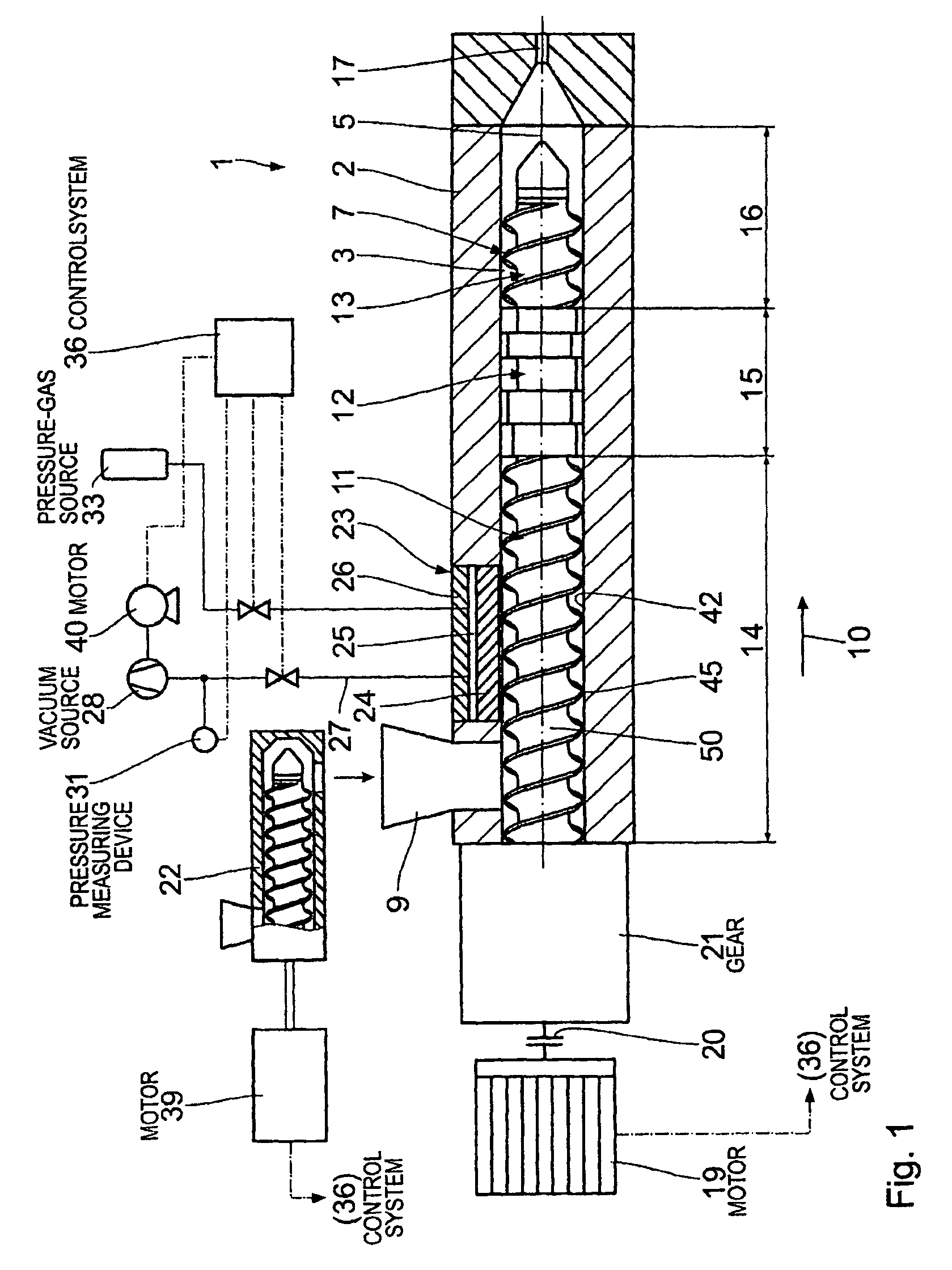

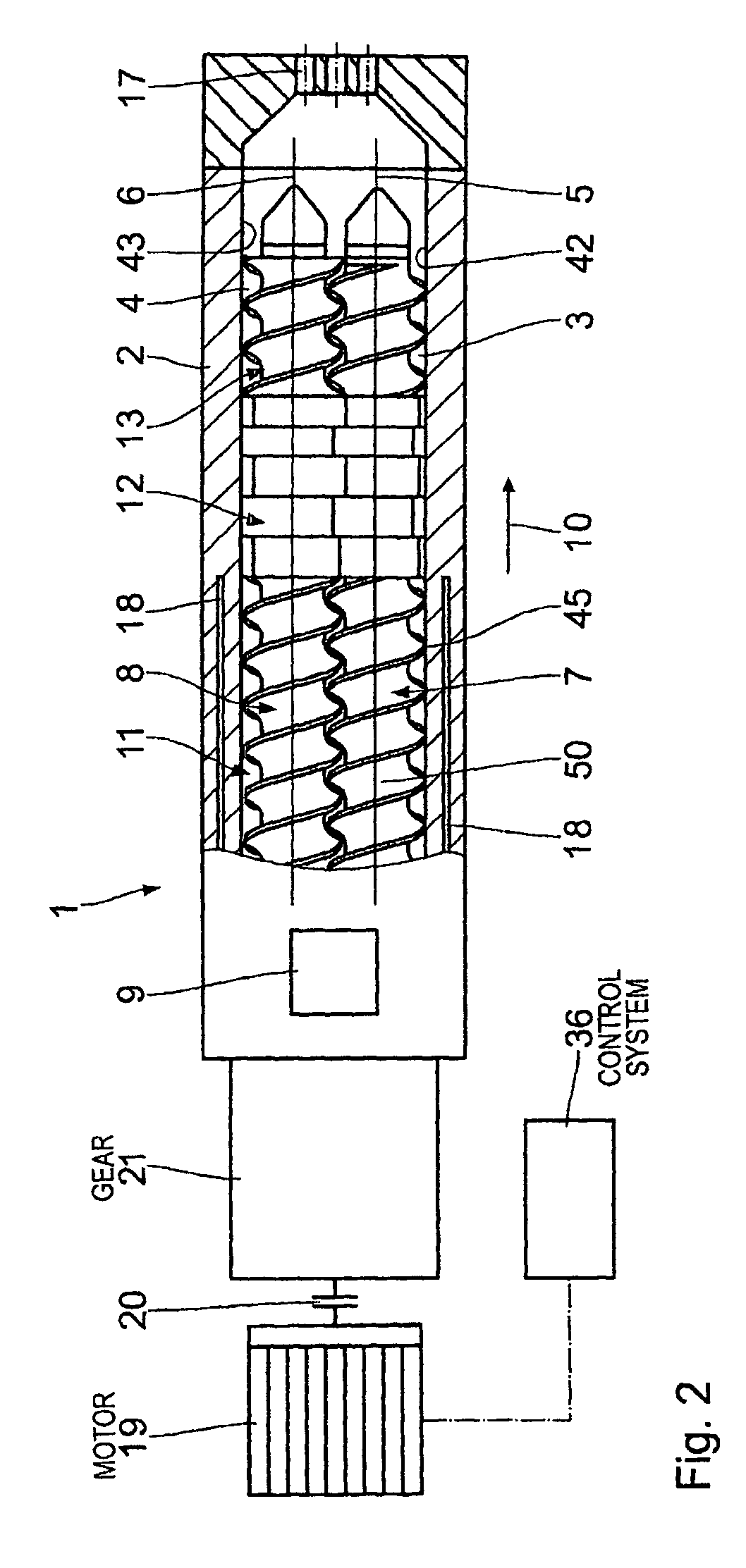

A kneading apparatus includes a barrel having a cylindrical chamber; a screw assembly rotating in the chamber so that a material to be kneaded is extruded in the axial direction by the rotation, the screw assembly including a screw section having helical blades and a kneading blade section in order to allow the material to flow into the clearance between the inner wall of the chamber and the kneading blade section, and to apply shearing forces to the material; a metering feeder for feeding the material at a substantially constant volumetric or gravimetric rate into the chamber; an injecting device for injecting a heat-removing medium into the chamber; and a discharging device for separating the heat-removing medium from the material and discharging the heat-removing medium from the chamber. A kneading method using the kneading apparatus is also disclosed.

Owner:KOBE STEEL LTD

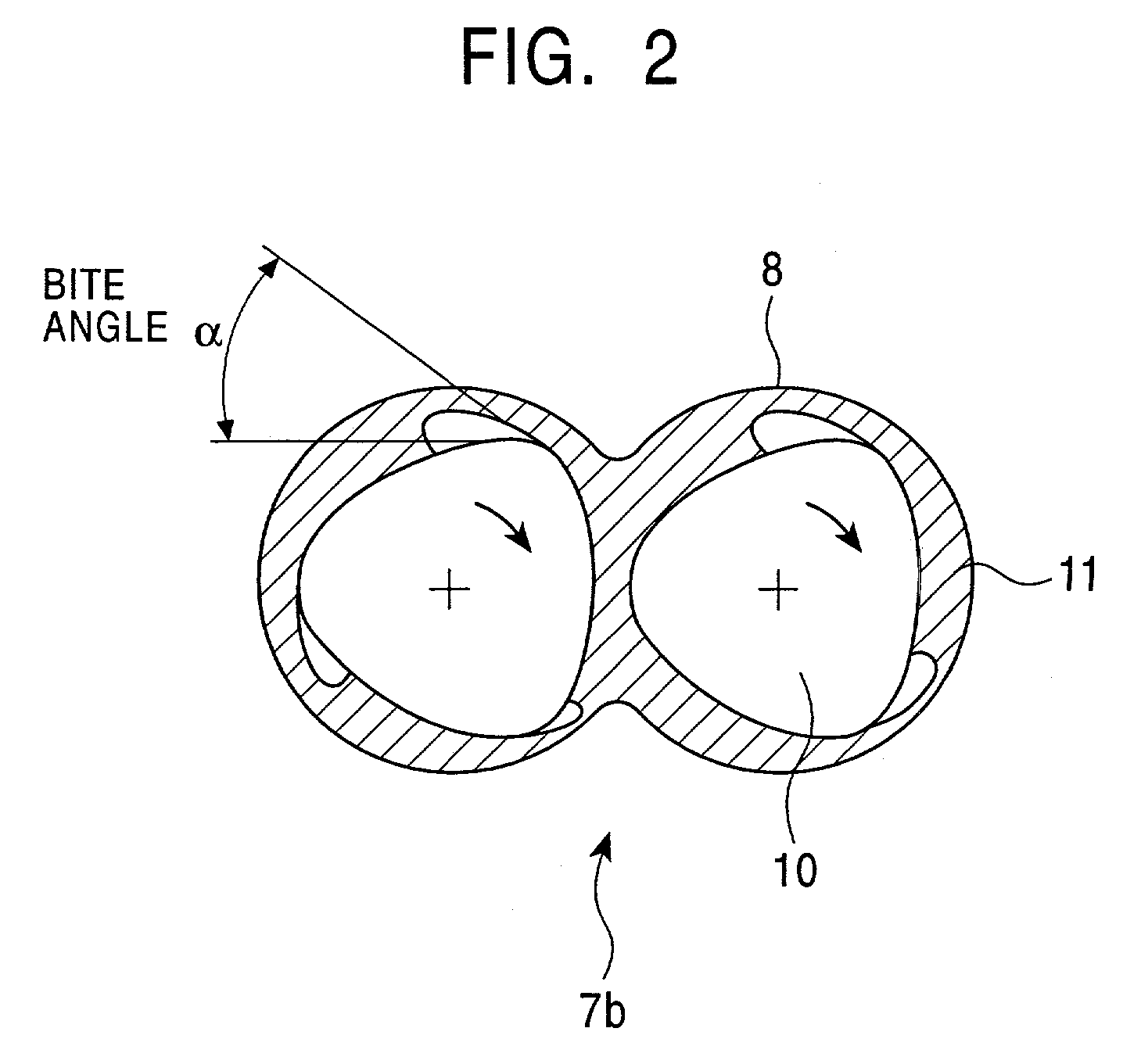

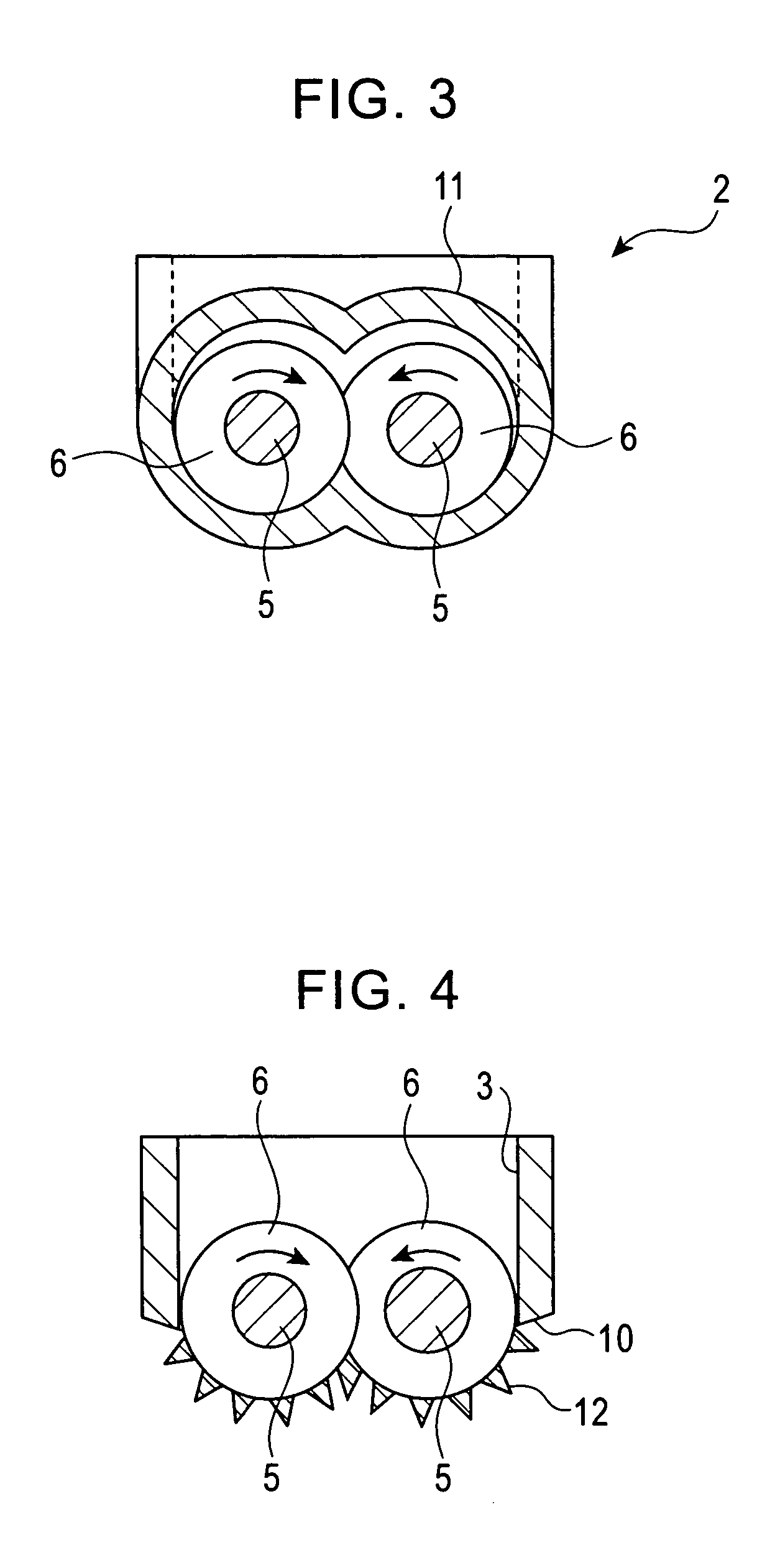

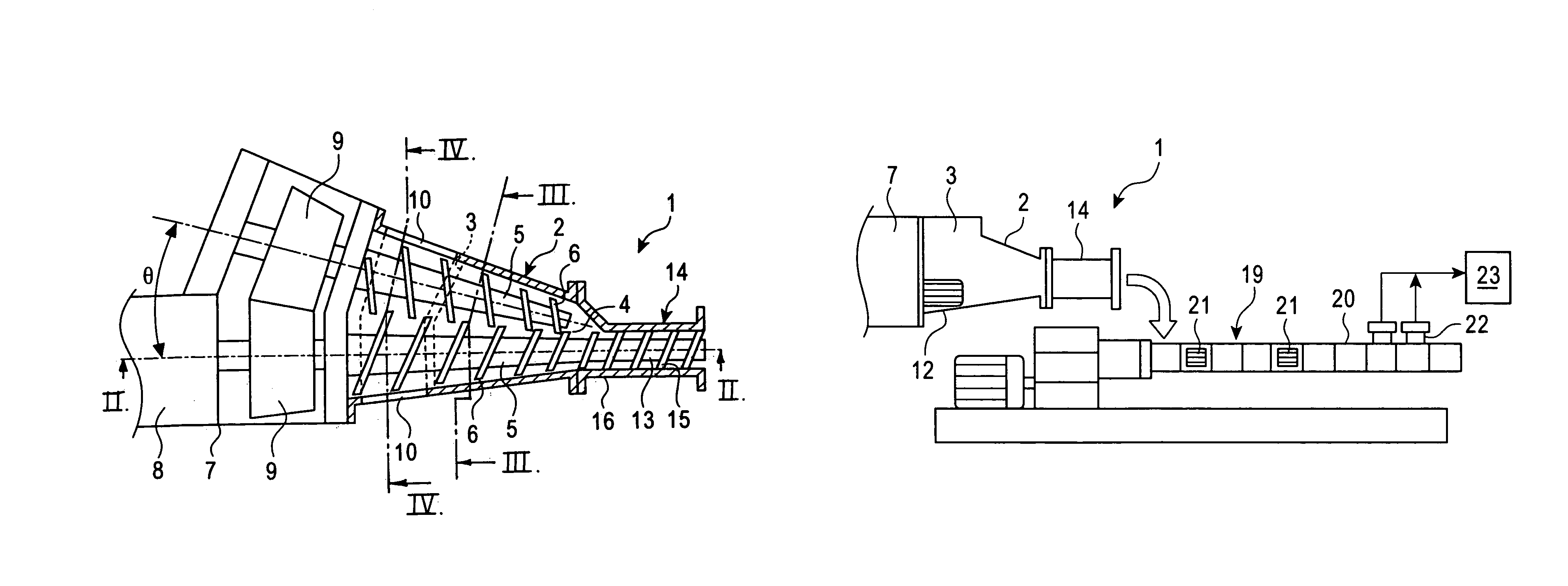

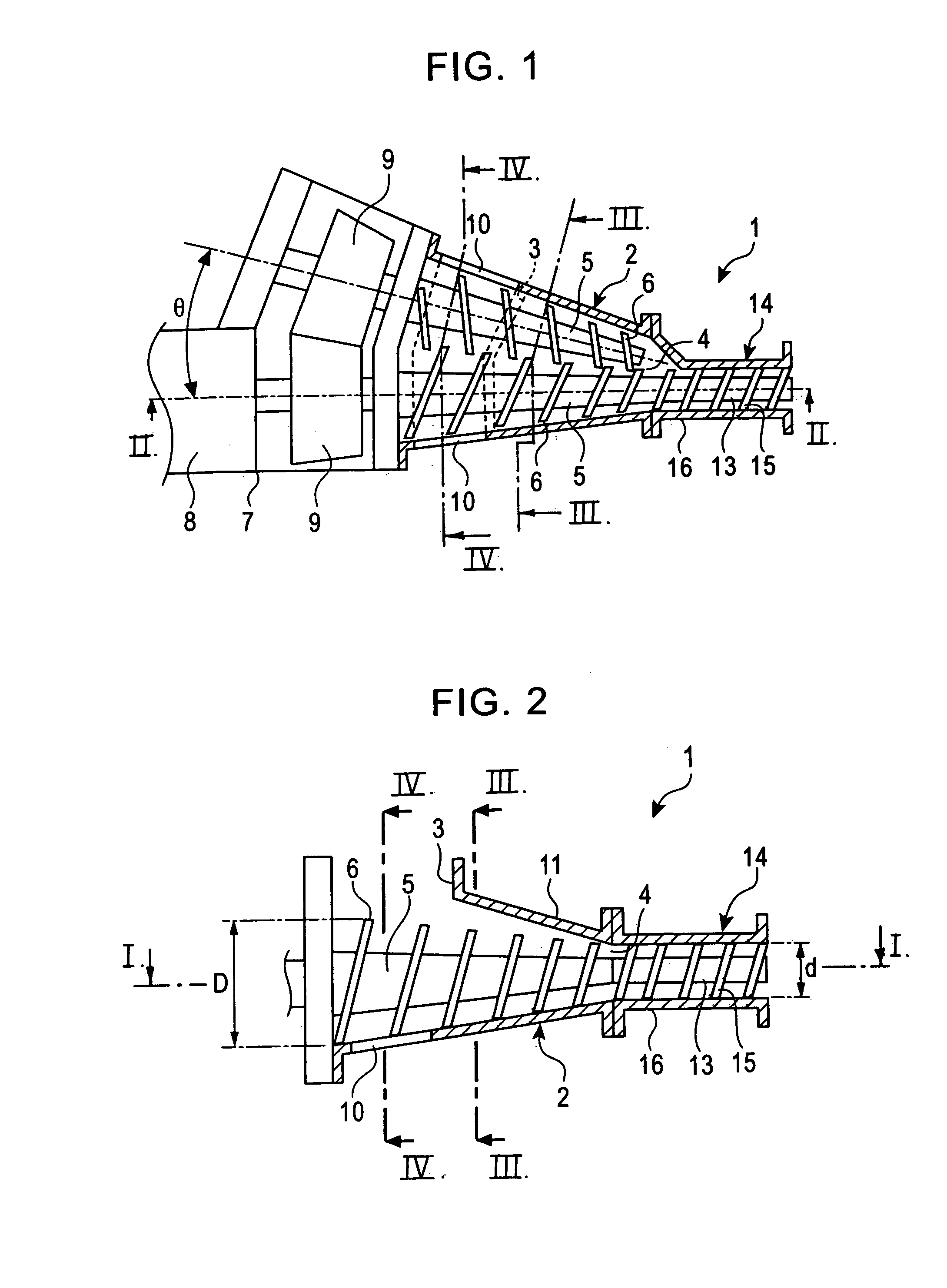

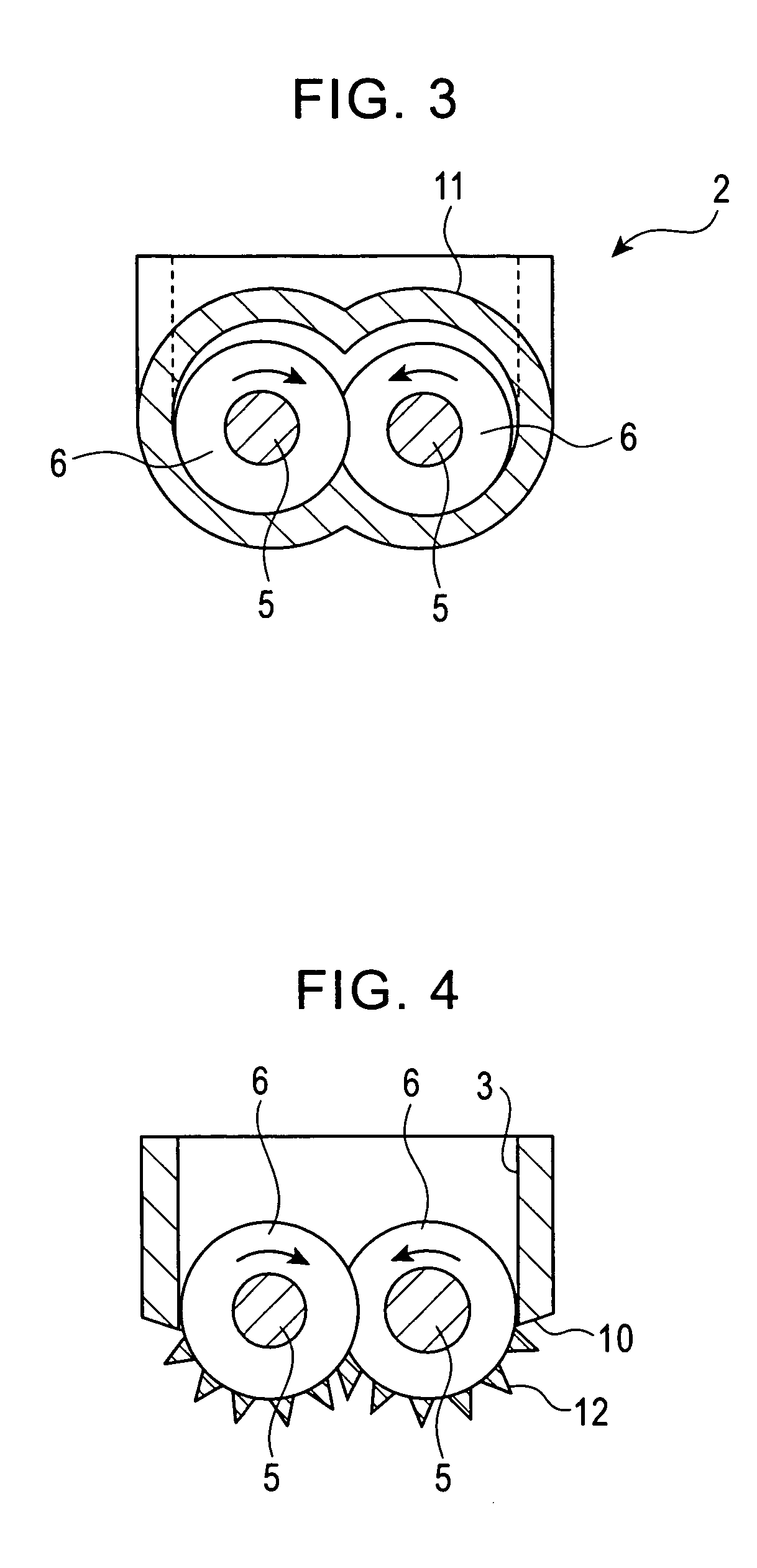

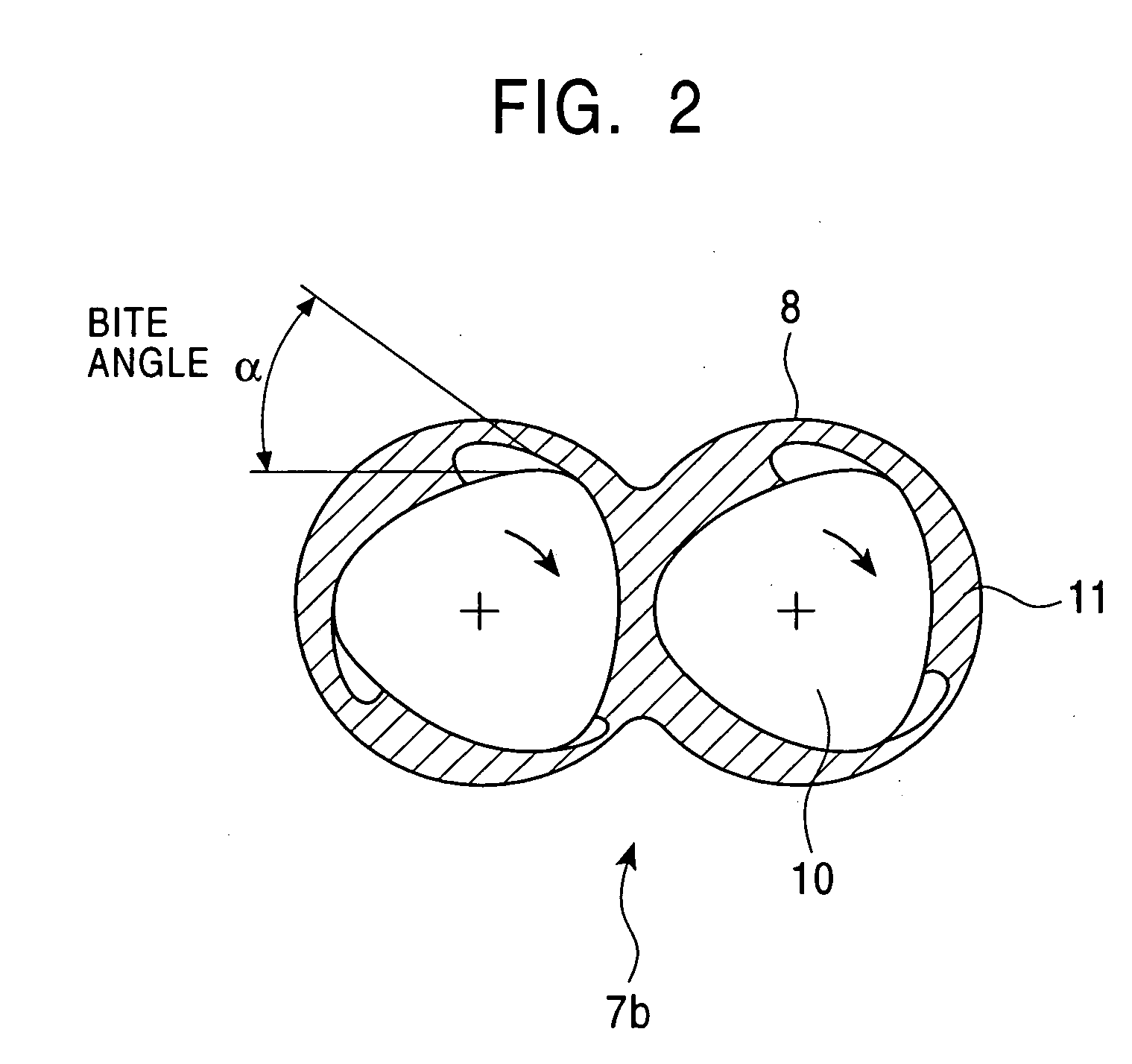

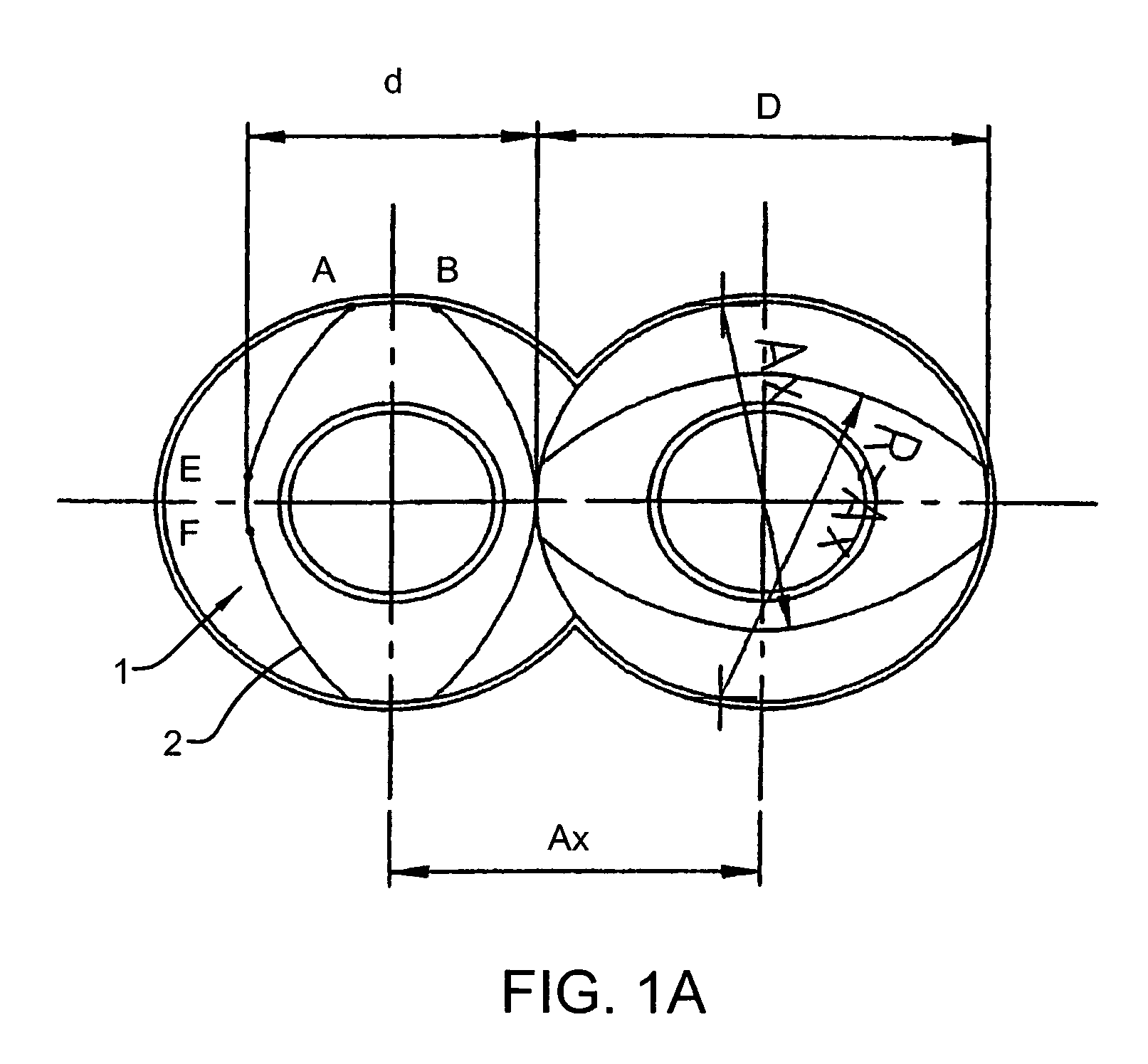

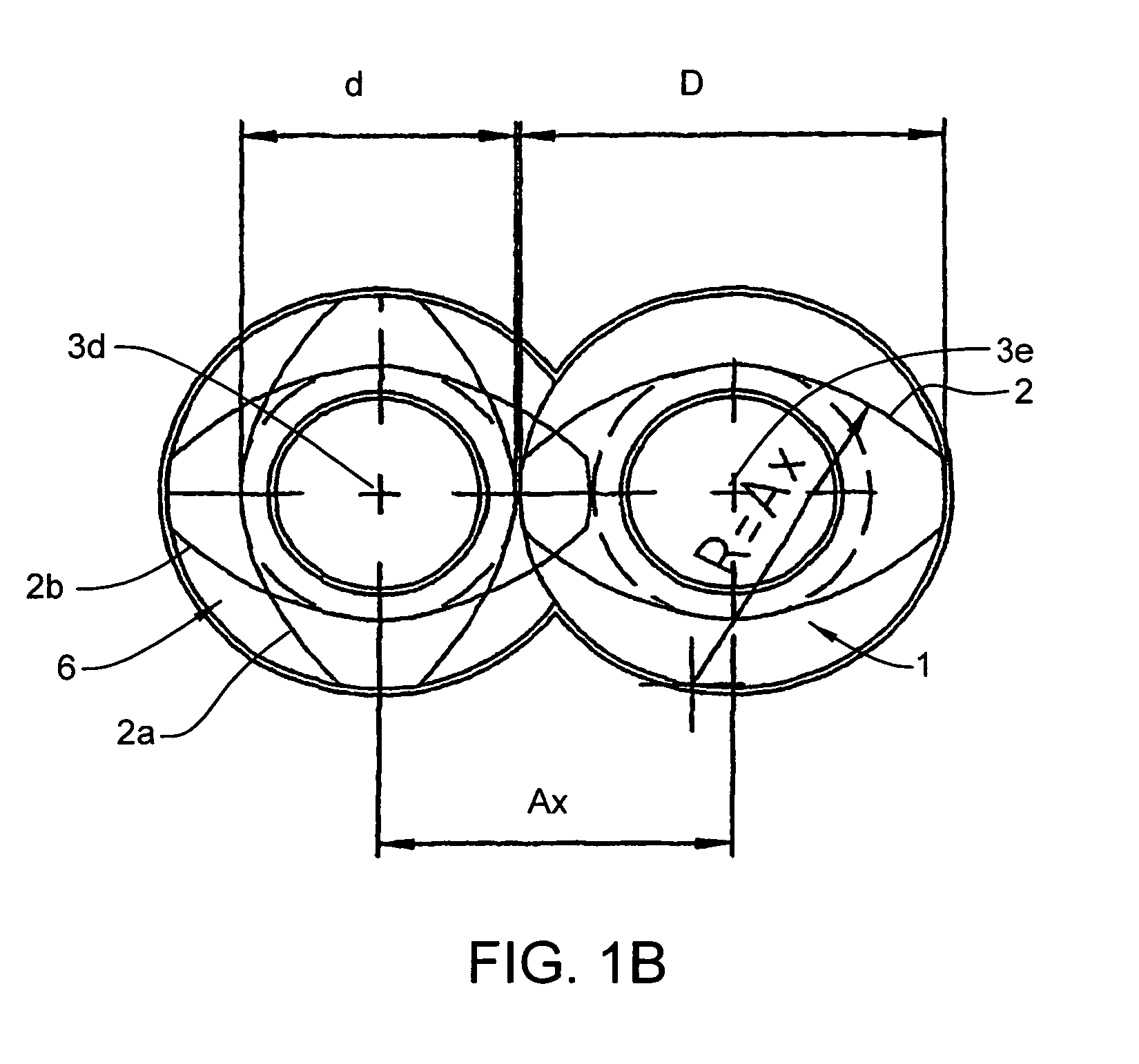

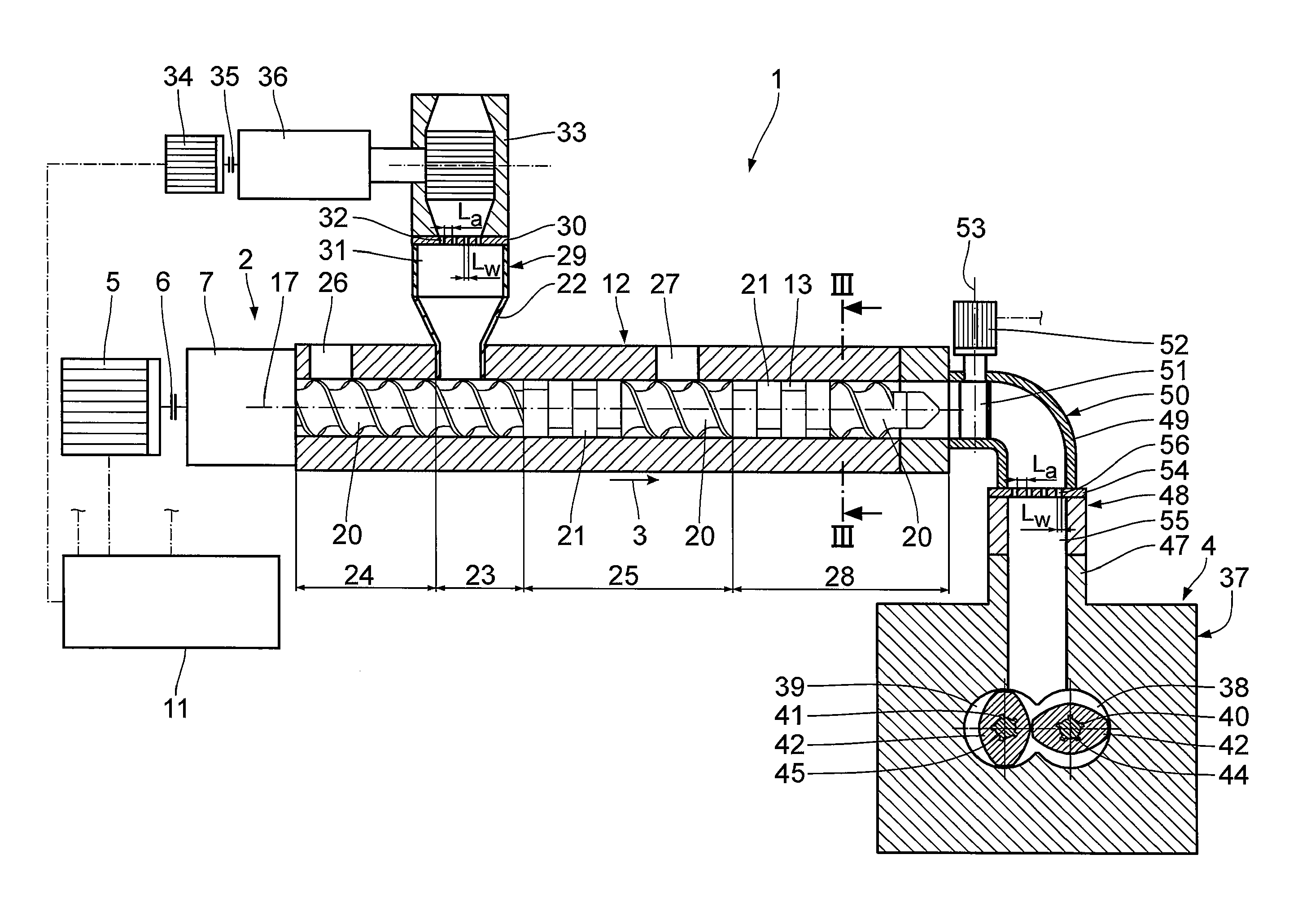

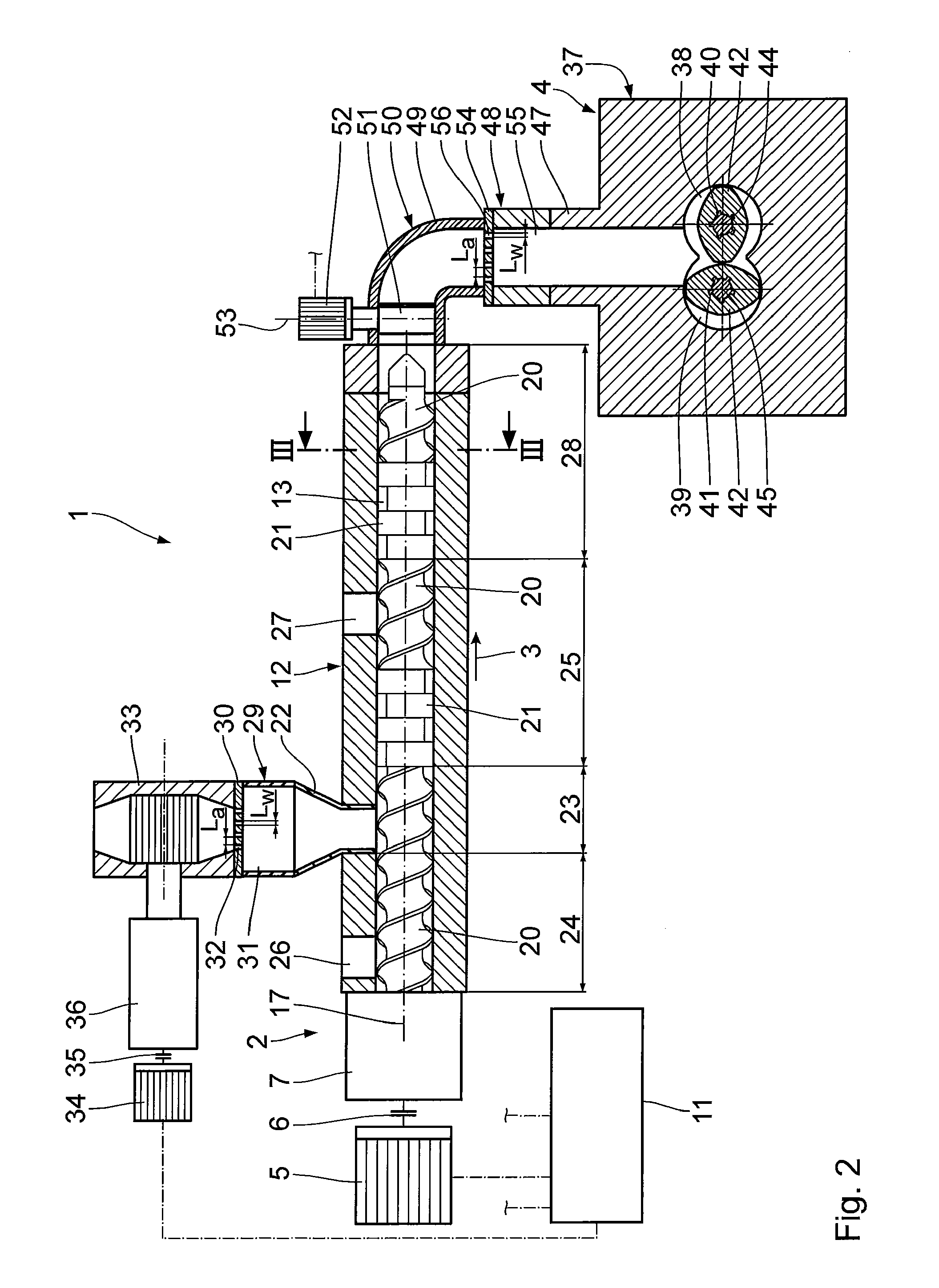

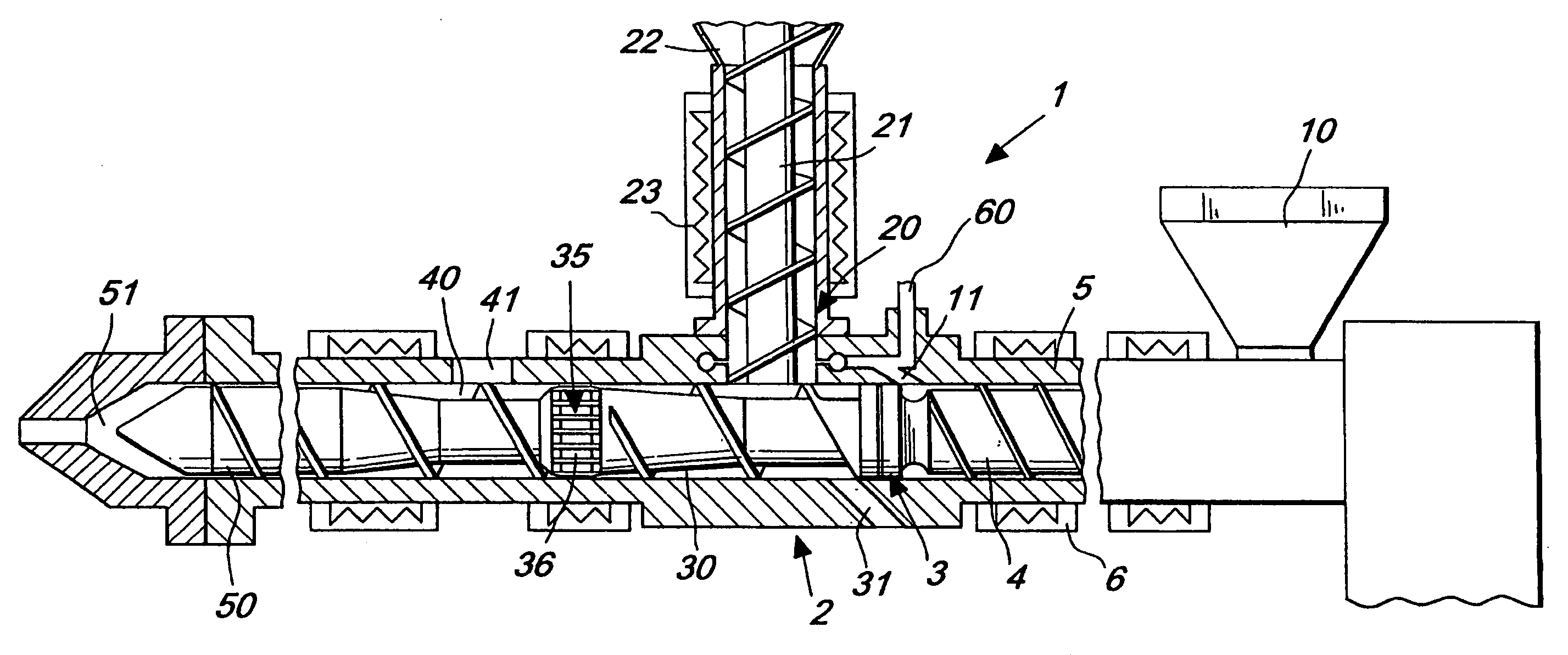

Conical twin-screw extruder and dehydrator

ActiveUS20050219943A1Increase in inner pressureImprove efficiencyDrying using combination processesDischarging apparatusEngineeringScrew thread

In a conical twin-screw extruder in which two rotor shafts having flights on the outer peripheral surfaces thereof and being adjacent to each other in the lateral direction are accommodated in a barrel having a raw material supply port on one side and a raw material discharge port on the other side, and the distance between the rotor shafts and the outside diameters of the flights thereof are gradually reduced from the supply port side to the discharge port side, characteristically, the barrel is provided with a water-removing port for removing water contained in a raw material supplied through the raw material supply port, out of the barrel. The extruder can be applied to raw materials various shapes, sizes, and properties.

Owner:KOBE STEEL LTD

Conical twin-screw extruder and dehydrator

ActiveUS7322738B2Efficient processEfficient compressionDrying using combination processesDischarging apparatusPolymer scienceEngineering

Owner:KOBE STEEL LTD

Kneading apparatus and method for kneading rubber-based composition using the same

InactiveUS20060034147A1Improve productivityHigh viscosityRotary stirring mixersMixing/kneading with horizontally-mounted toolsHelical bladeEngineering

A kneading apparatus includes a barrel having a cylindrical chamber; a screw assembly rotating in the chamber so that a material to be kneaded is extruded in the axial direction by the rotation, the screw assembly including a screw section having helical blades and a kneading blade section in order to allow the material to flow into the clearance between the inner wall of the chamber and the kneading blade section, and to apply shearing forces to the material; a metering feeder for feeding the material at a substantially constant volumetric or gravimetric rate into the chamber; an injecting device for injecting a heat-removing medium into the chamber; and a discharging device for separating the heat-removing medium from the material and discharging the heat-removing medium from the chamber. A kneading method using the kneading apparatus is also disclosed.

Owner:KOBE STEEL LTD

Extruder for continuously working and/or processing flowable materials

ActiveUS7284897B2Prevent exitImprove fill rateRotary stirring mixersFrozen sweetsEngineeringMechanical engineering

Owner:BLACH VERWALTUNGS GMBH

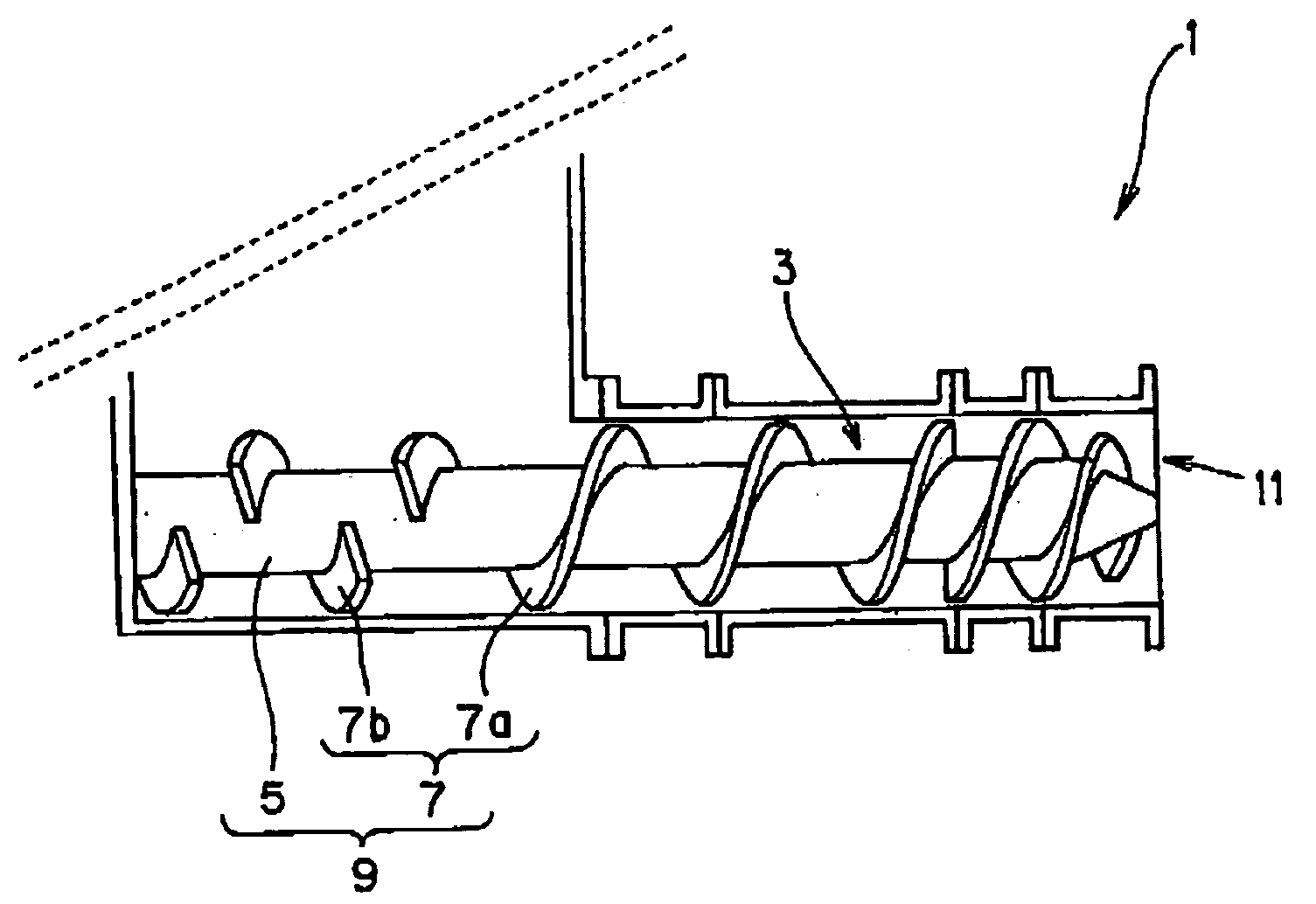

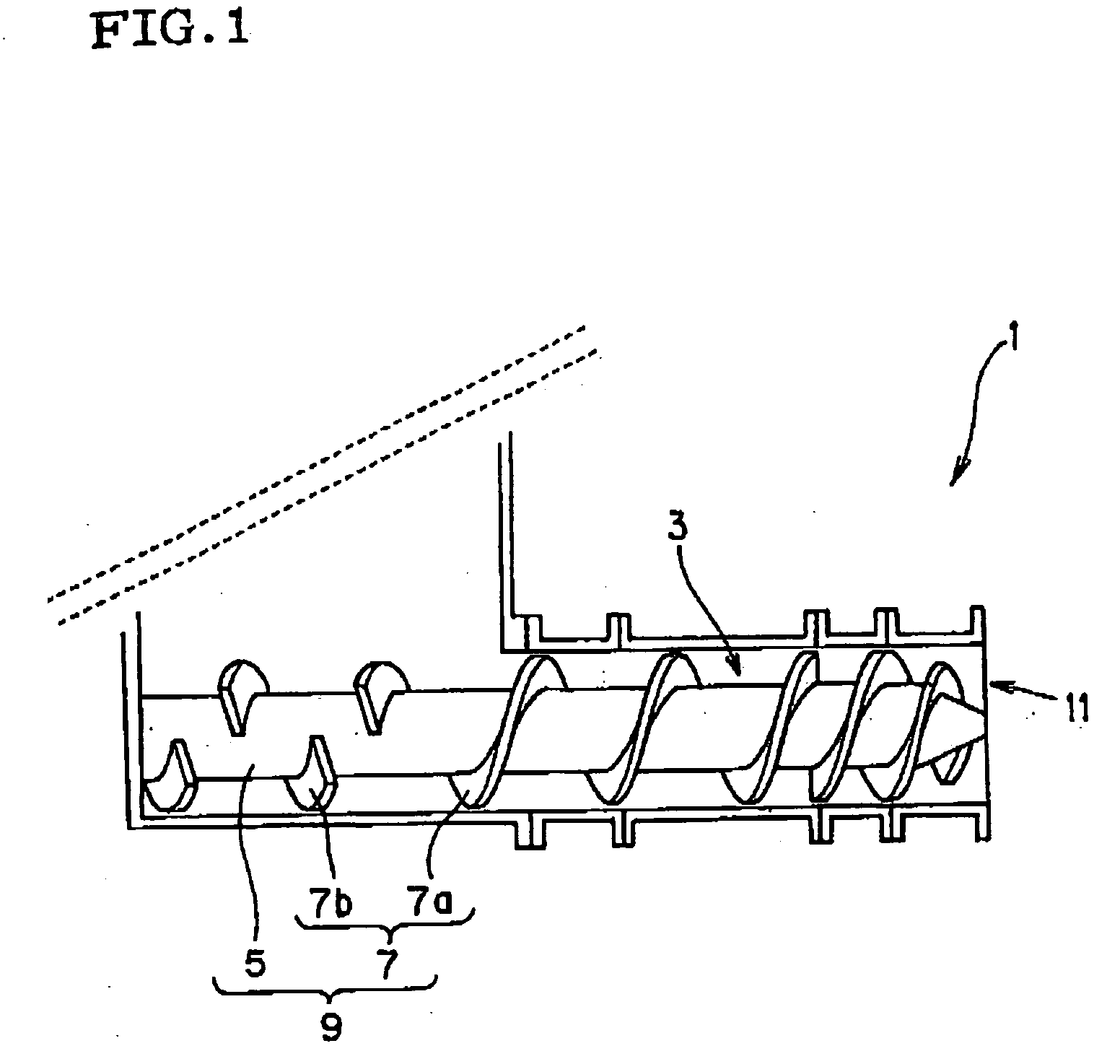

Screw for extruder, screw extruder, and kneading extruder using the screw extruder

InactiveUS20050073906A1Avoid problemsRotary stirring mixersMixing/kneading with horizontally-mounted toolsLeading edgeDrive shaft

A screw for an extruder includes a drive shaft and stirring blades arranged on the drive shaft, and blades among the stirring blades arranged at least part of the drive shaft adjacent to the leading edge of the drive shaft are interrupted blades, each of continuous surfaces of the interrupted blades being less than a full circle about the drive shaft. The screw is capable of effectively preventing problems that characteristics of a compressed material obtained are not unified in each part, resulting in uneven distribution, and discontinuous portions (screw marks) are formed inside the obtained compressed product.

Owner:NGK INSULATORS LTD

Extruder having a set back gas-permeable wall portion

Owner:COPERION

Extruder

ActiveUS7419295B2Efficient devolatilization operationRotary stirring mixersMixing/kneading with horizontally-mounted toolsAir tightness

An extruder includes a barrel and a kneading screw extending through the barrel in a rotatable fashion. The kneading screw is provided with a devolatilization portion. The devolatilization portion includes a kneading flight that is twisted in a direction for transferring a material downstream. The kneading flight kneads the material while transferring the material downstream and separates a volatile component from the material. Impregnation sections, which allow the kneading chamber to be impregnated with the material, are respectively disposed adjacent to an upstream side and a downstream side of the devolatilization portion so that the air-tightness of the devolatilization portion of the extruder is maintained. Accordingly, an efficient devolatilization operation of the material is achieved.

Owner:KOBE STEEL LTD

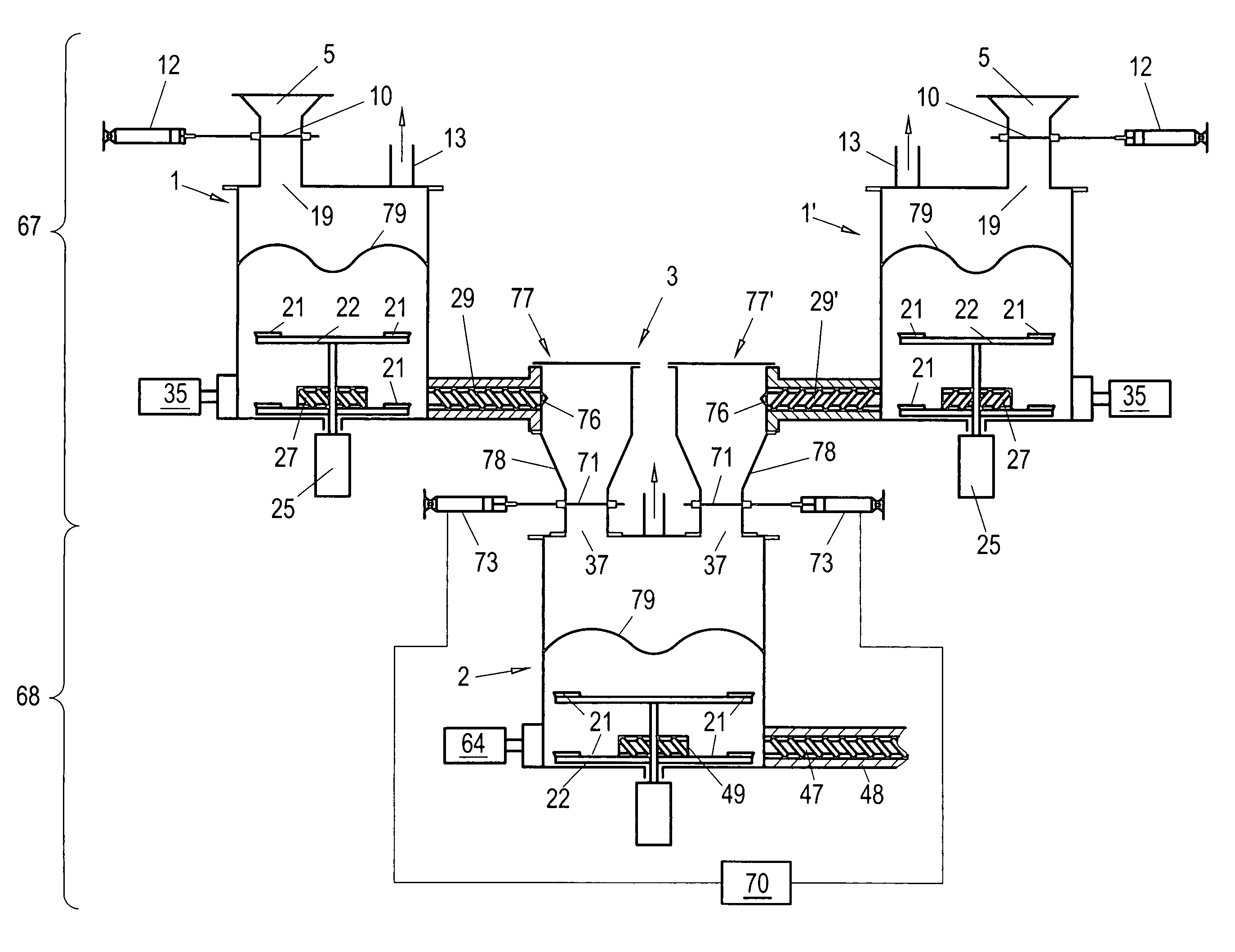

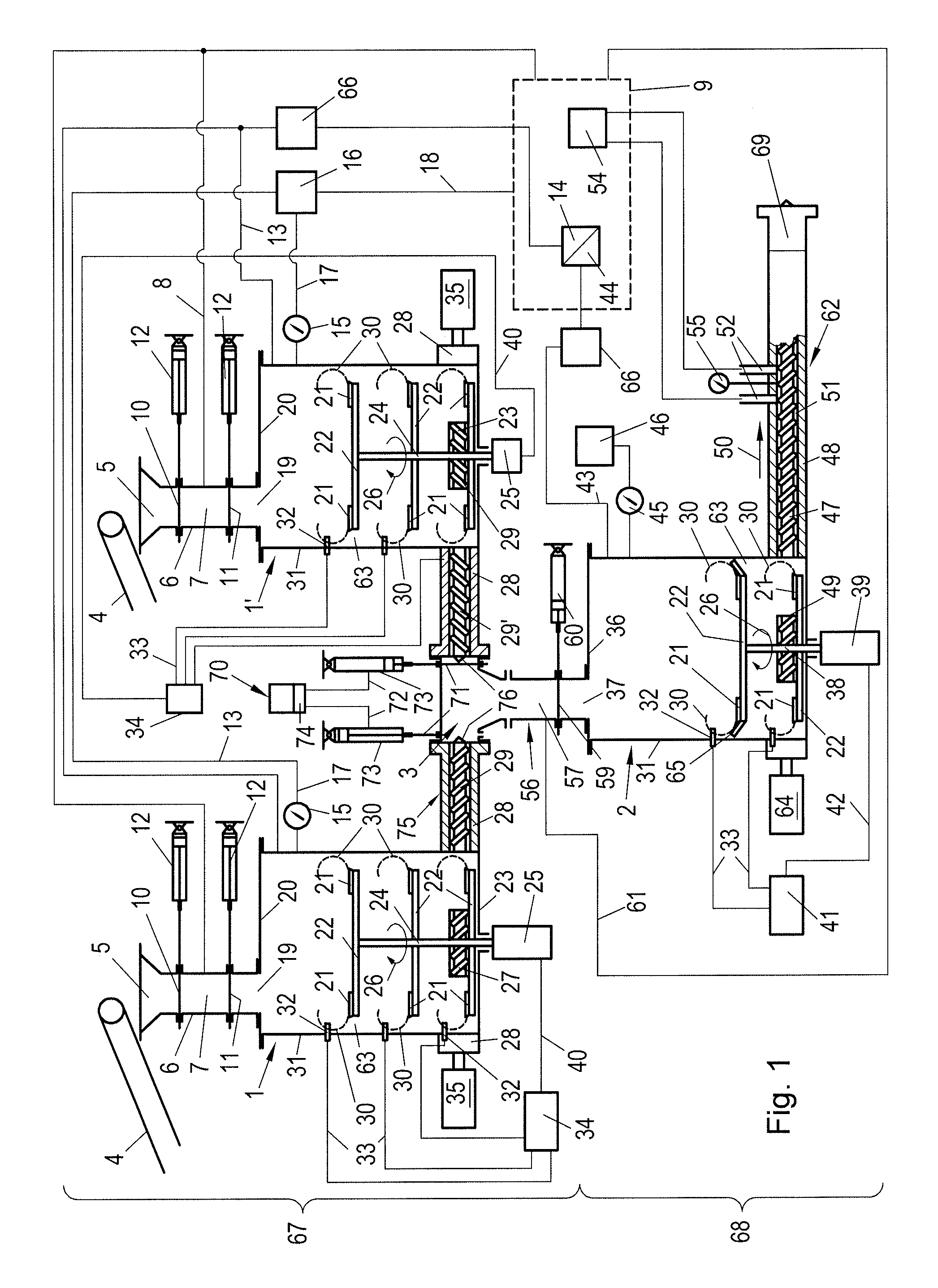

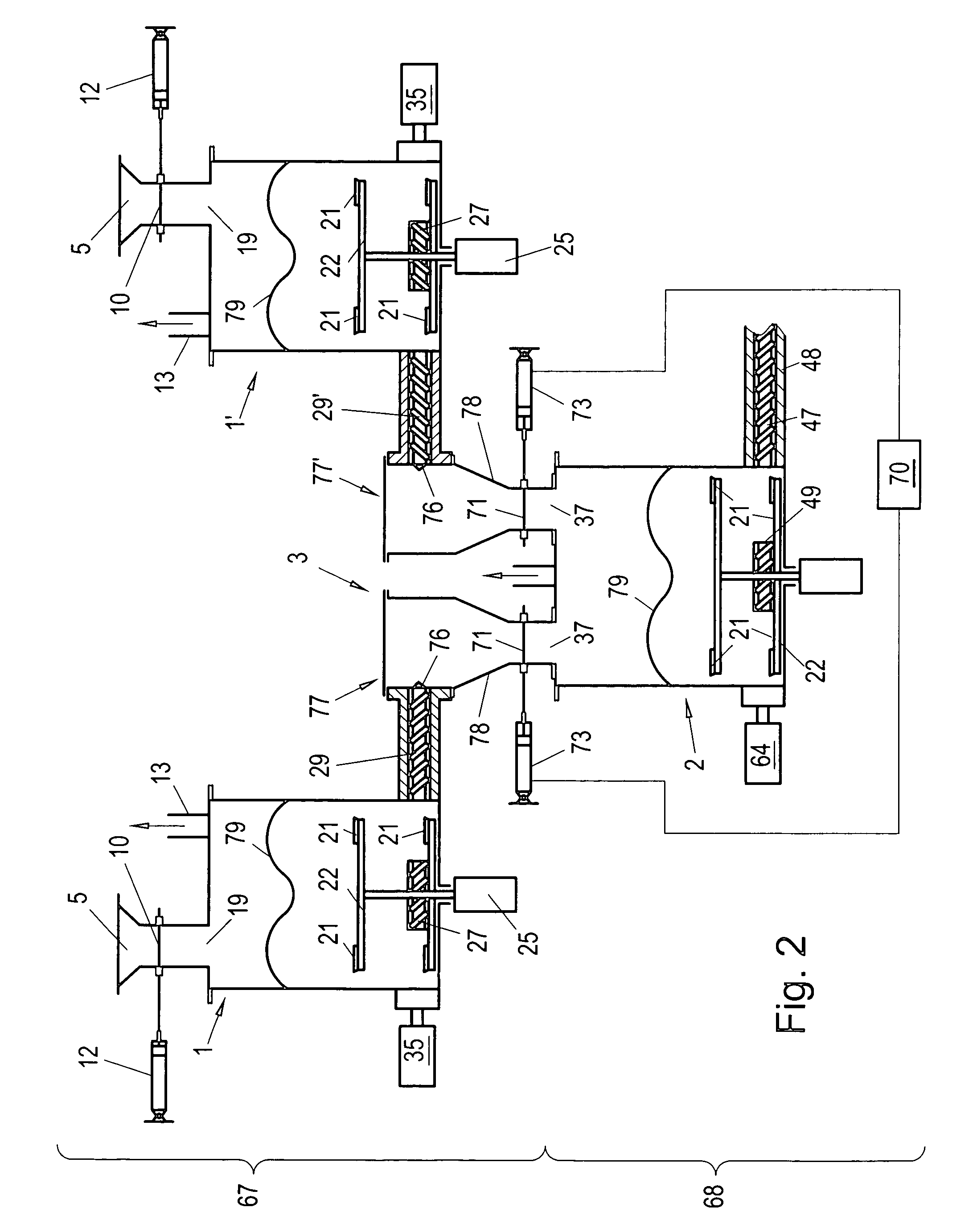

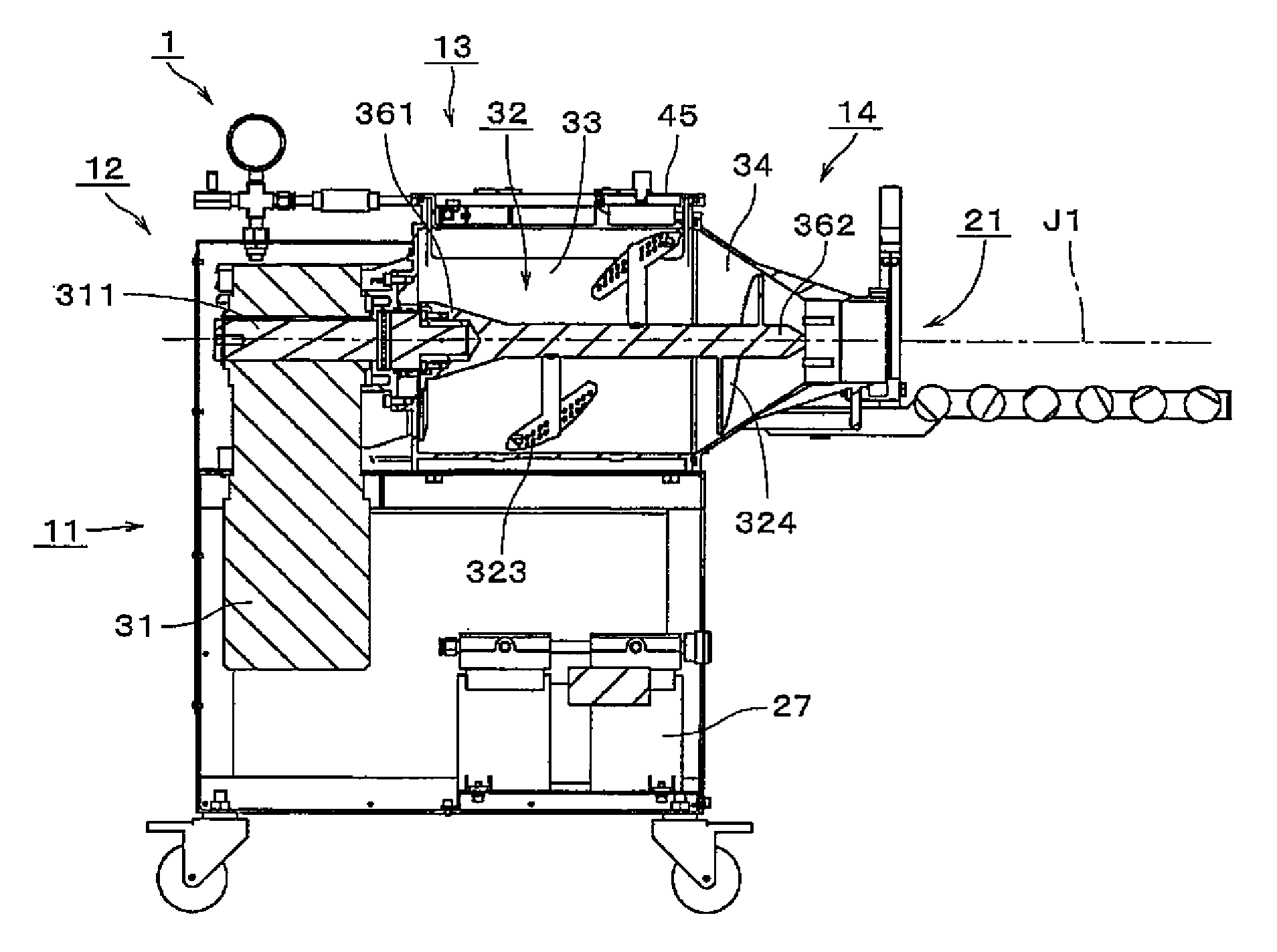

Device and method for the preparation of recyclable thermoplastic plastic material

ActiveUS8992067B2Excellent decontaminationRotary stirring mixersPlastic recyclingThermoplasticPlastic materials

An apparatus for the preparation of thermoplastic plastics material to be recycled has two treatment stages following one after the other. At least two receiving containers, which are capable of being evacuated and which are attached in parallel to a receiving container of the second stage, are present in the first stage. A device is present by which an alternating batch-wise charging of the receiving container of the second stage takes place from the receiving containers of the first stage. The said device controls discharge members of the receiving containers of the preceding stage, which leads into a channel. A shut-off member is provided for each receiving container of the preceding stage in the said channel. The alternating device controls the shut-off members.The method of preparing thermoplastic plastics material, to be recycled, utilizes an apparatus of this type.

Owner:EREMA ENG RECYCLING MASCH & ANLAGEN GMBH

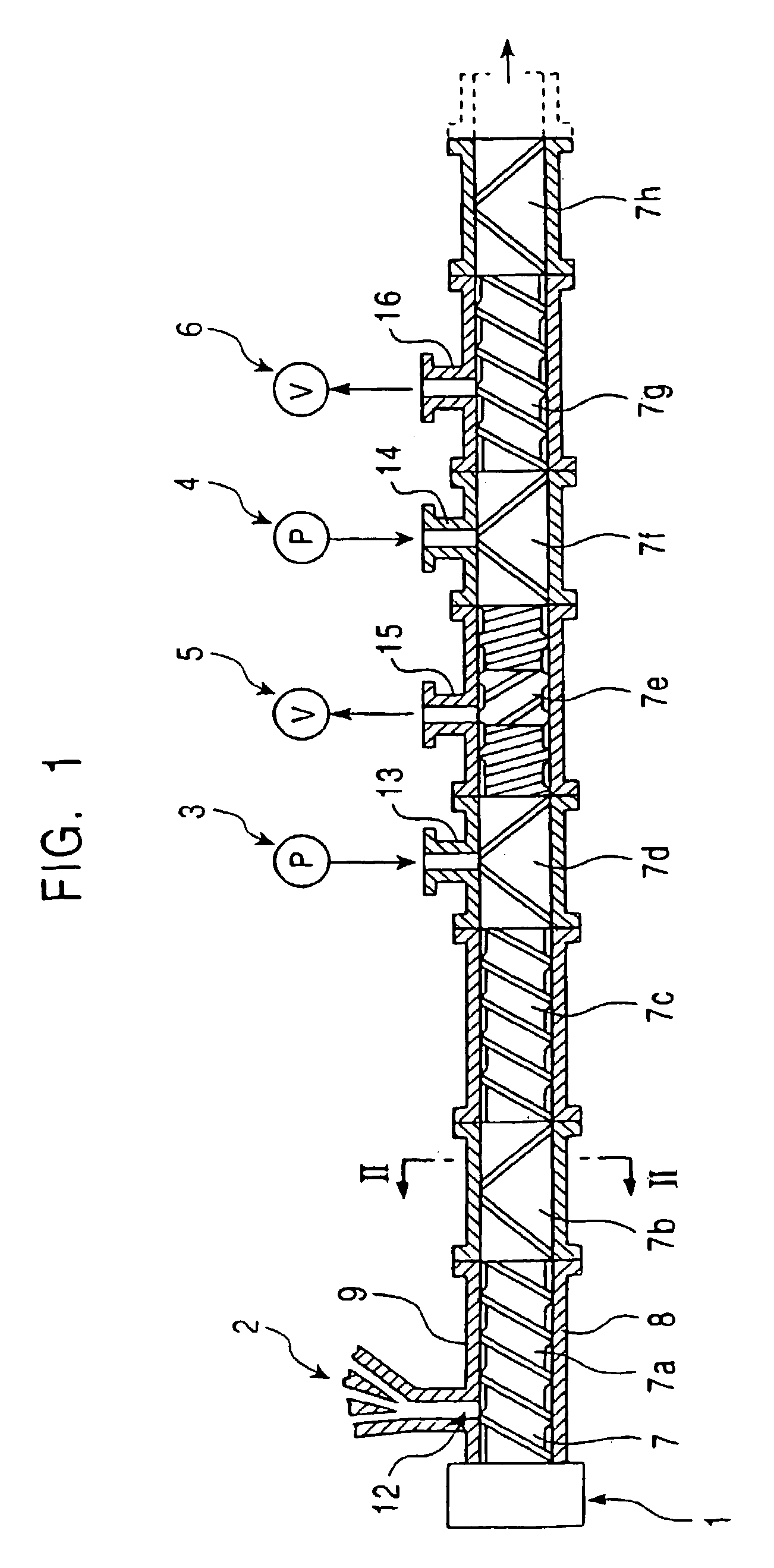

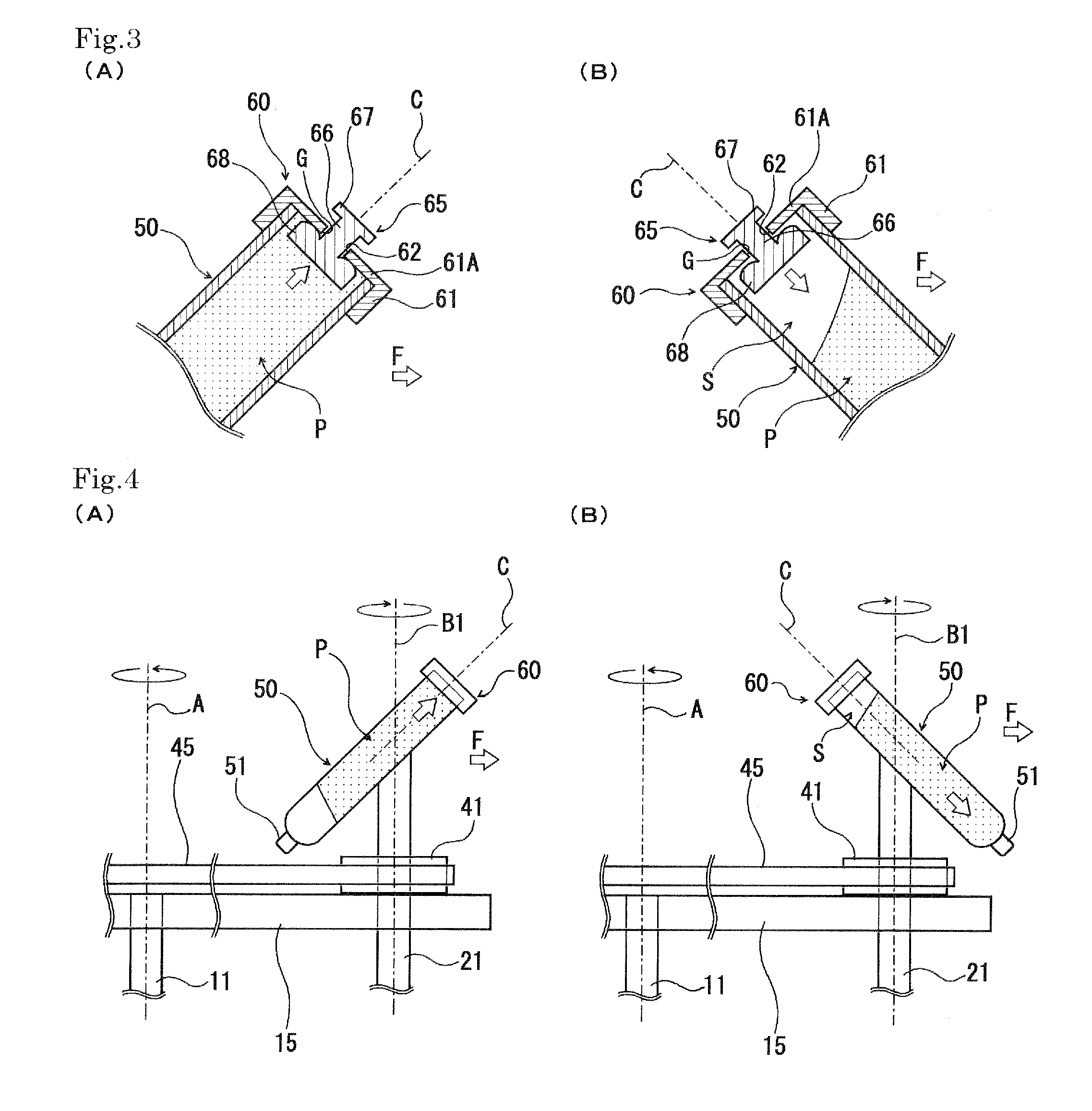

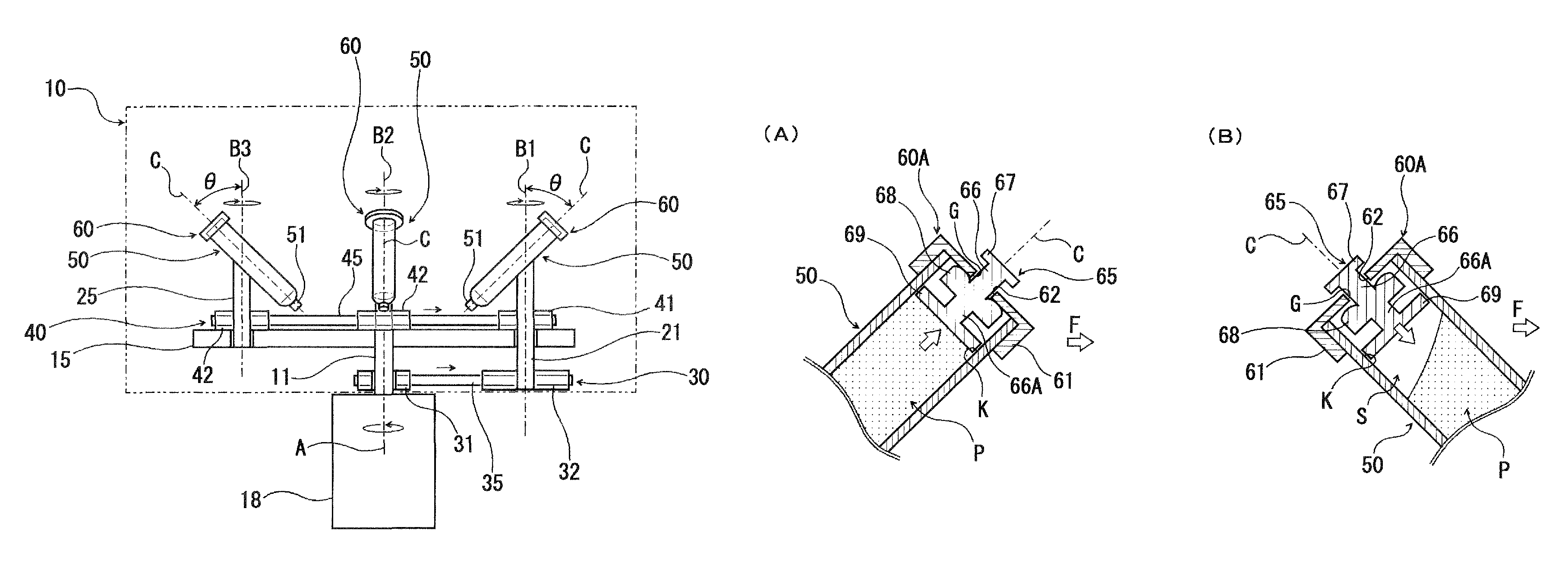

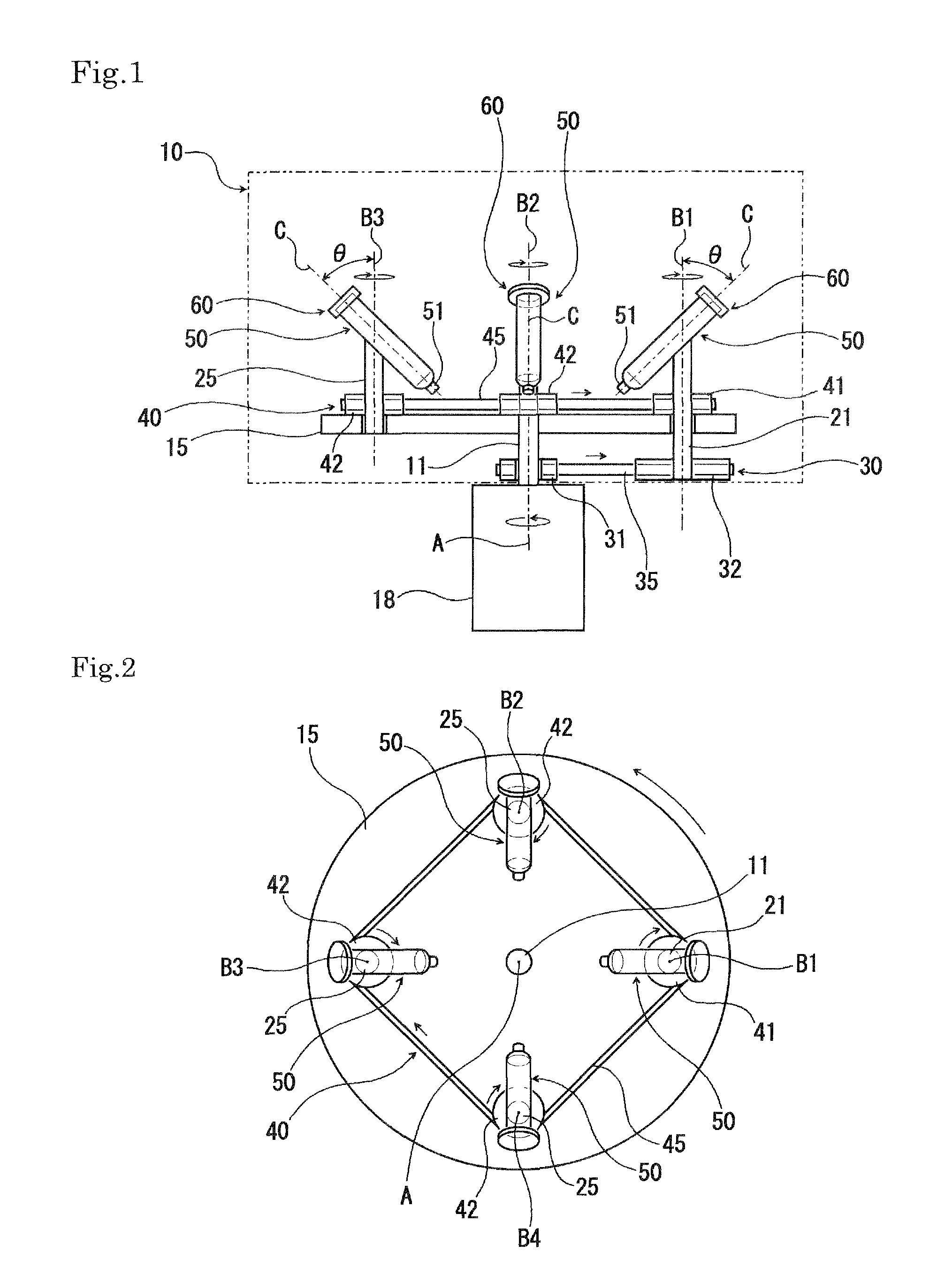

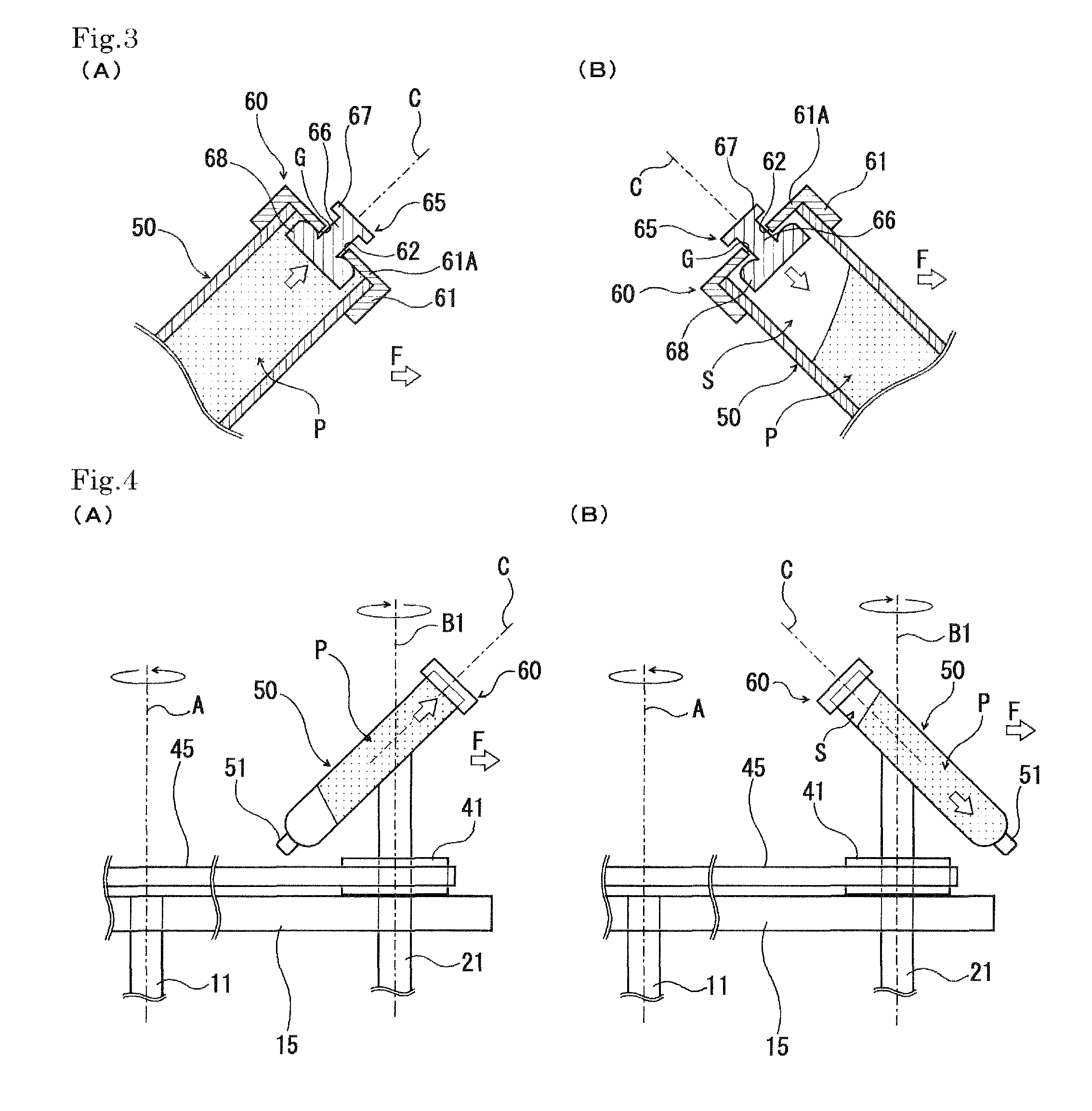

Vacuum kneading and deaerating device

ActiveUS20120106288A1Knead fullyImprove efficiencyRotating receptacle mixersShaking/oscillating/vibrating mixersRotational axisCentrifugal force

Disclosed is a vacuum kneading and deaerating device capable of conducting an uniform and sufficient kneading treatment and a sufficient deaerating treatment with a high efficiency for a paste material contained in a cylindrical paste container.This vacuum kneading and deaerating device is equipped with a rotating body for revolution, which is provided in a chamber held under a closed or pressure-reduced condition and rotated in a horizontal plane around a basic driving rotation axis, a container holding means which is provided in the chamber rotationably on an operating rotation axis parallel to the basic driving rotation axis in a revolution edge portion of the rotating body for revolution and detachably holds a paste container in a state that a central axis of the paste container obliquely intersects the operating rotation axis, and a driving mechanism for rotating the rotating body for revolution and the container holding means, wherein a deaeration valve for opening an internal space of the paste container to an internal space of the chamber by the action of centrifugal force attending on the revolution and rotation of the paste container, or a paste material-impermeable and gas-permeable membrane is provided in an opening portion of the paste container for placing the paste material.

Owner:MARUKOMU

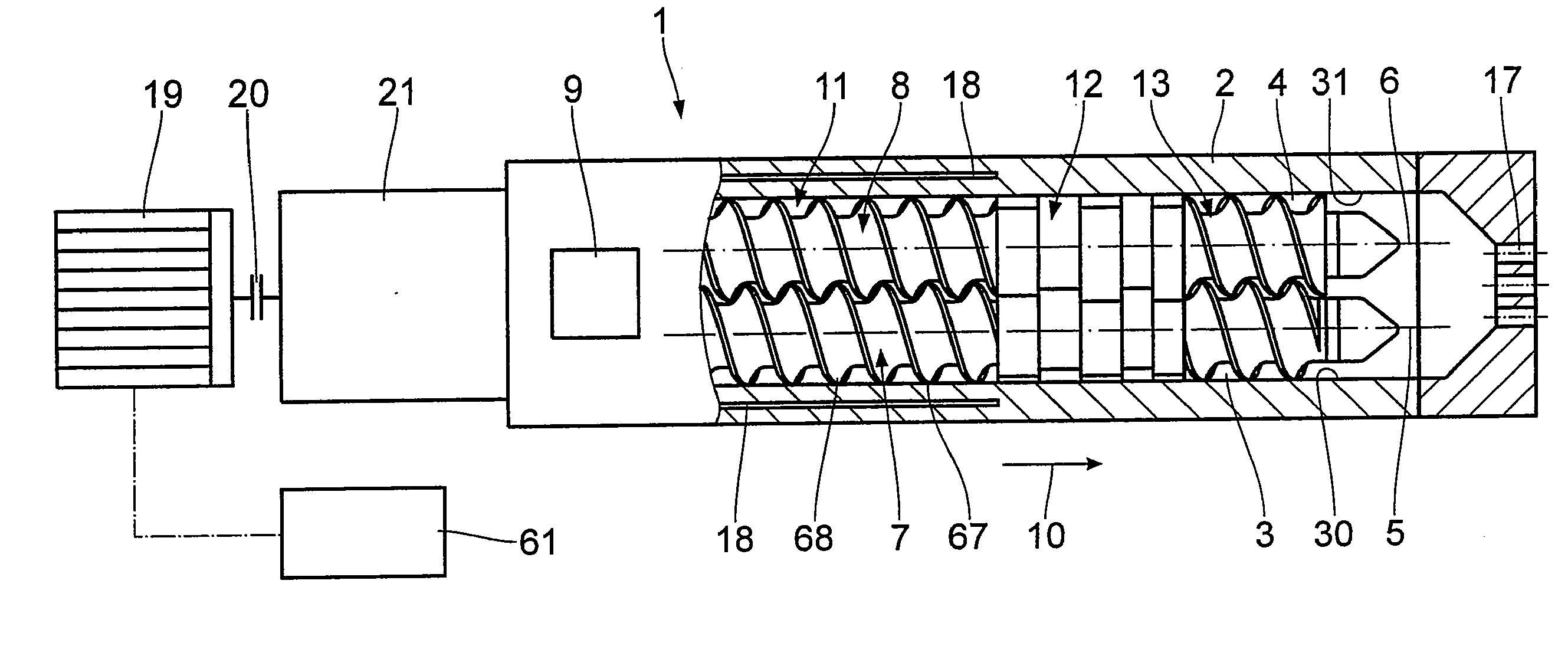

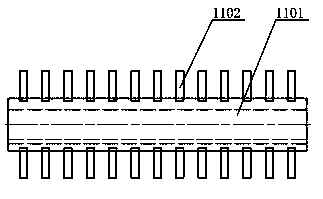

Planetary roller extruder with planet spindles and contact ring

ActiveUS20150043300A1Better degassingReduce in quantityTransportation and packagingRotary stirring mixersTrademarkEngineering

A planetary roller extruder with planetary spindles and stop ring. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:ENTEX RUST & MITSCHKE

Vacuum kneading and deaerating device

ActiveUS8534906B2Knead fullyImprove efficiencyRotating receptacle mixersShaking/oscillating/vibrating mixersCentrifugal force

A vacuum kneading and deaerating device has a rotatable body provided in a chamber held under a closed or pressure-reduced condition, and which is rotated in a horizontal plane around a basic driving rotation axis. A container holder is provided in the chamber rotationably on an operating rotation axis parallel to the basic driving rotation axis in a revolution edge portion of the rotatable body, and detachably holds a paste container such that a central axis of the paste container obliquely intersects the operating rotation axis. A driving mechanism rotates the rotating body and the container holder. A deaeration valve for opening an internal space of the paste container to an internal space of the chamber by the action of centrifugal force attending on the rotation of the paste container, or a paste material-impermeable and gas-permeable membrane, is provided in an opening portion of the paste container.

Owner:MARUKOMU

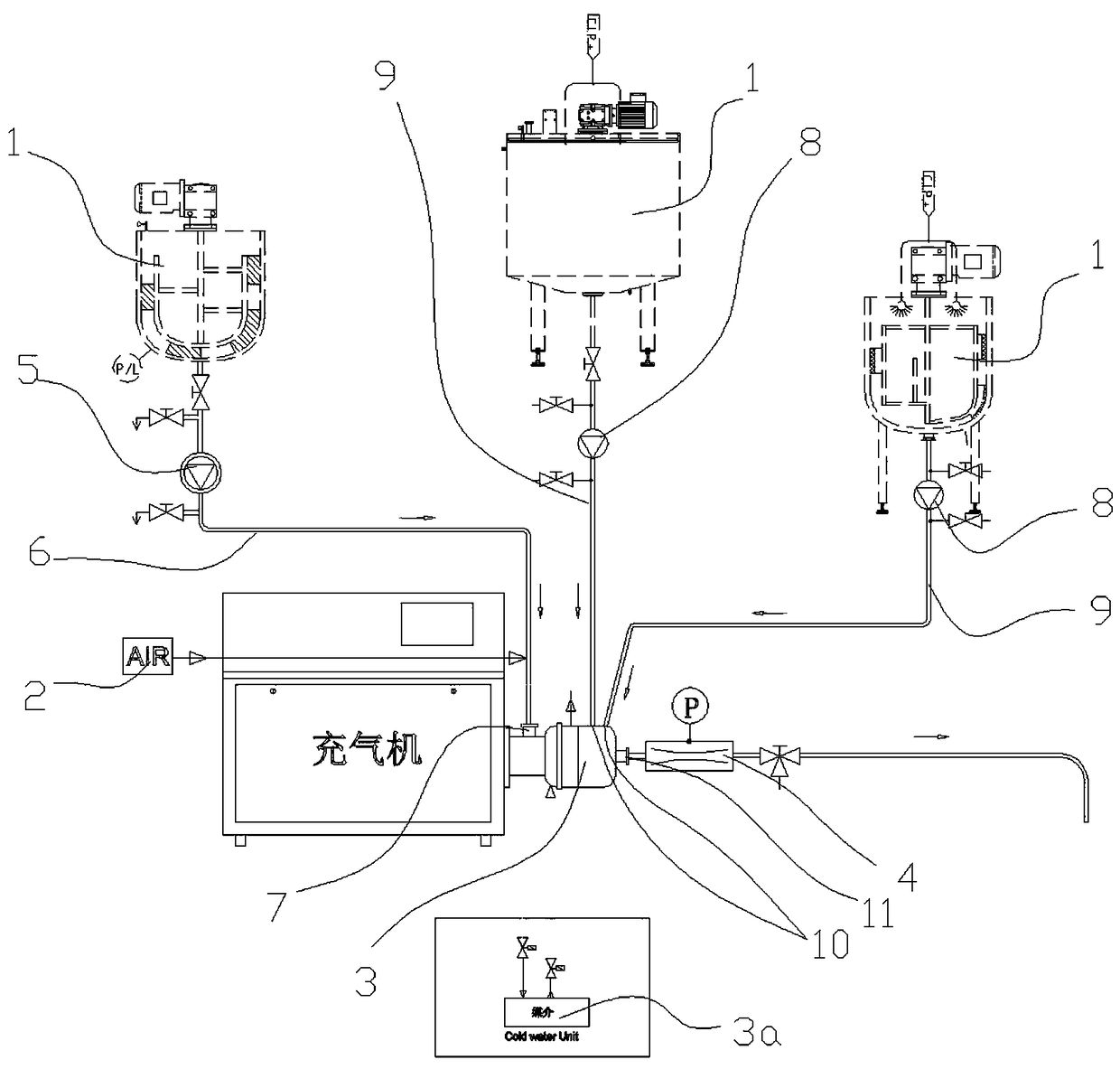

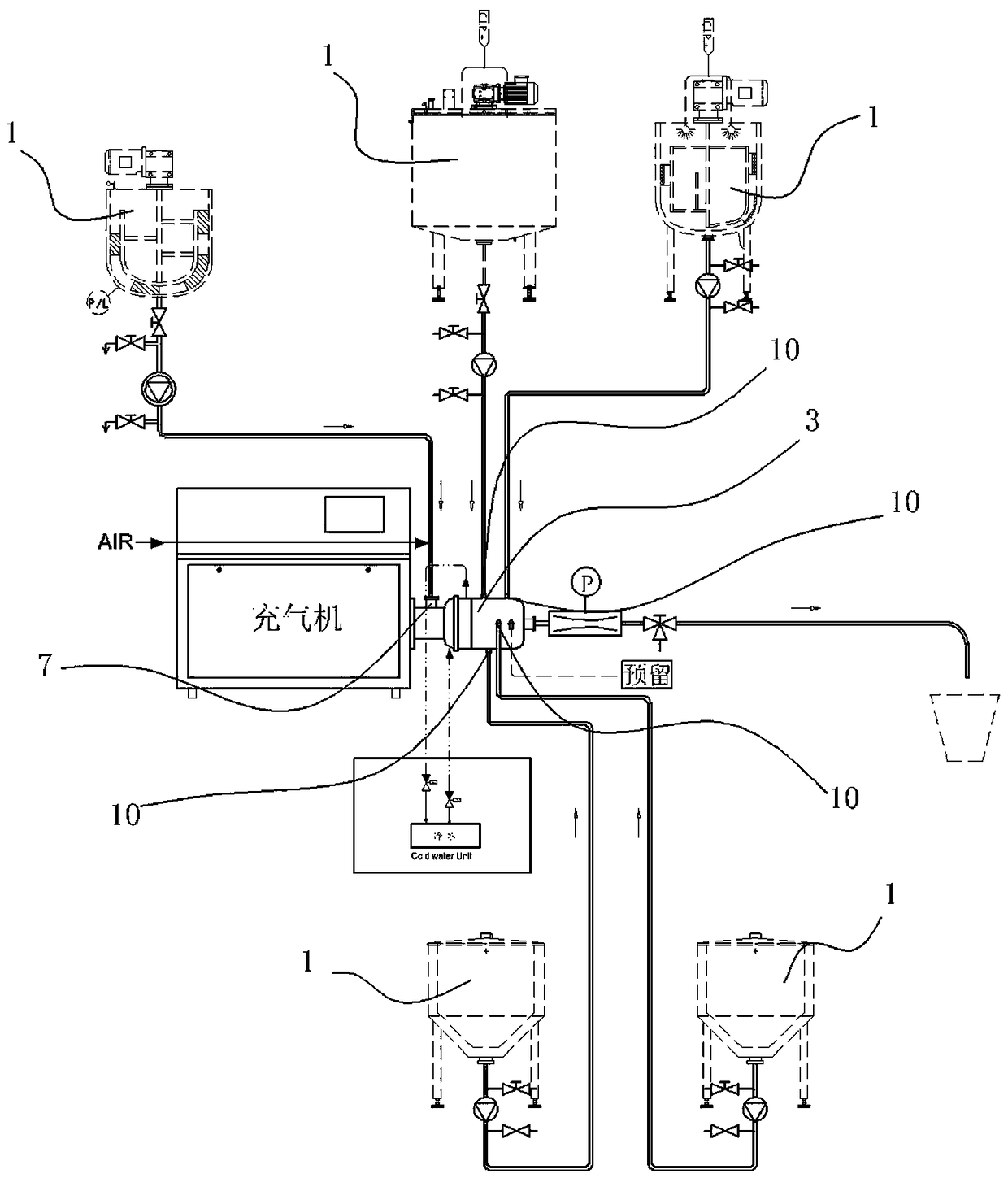

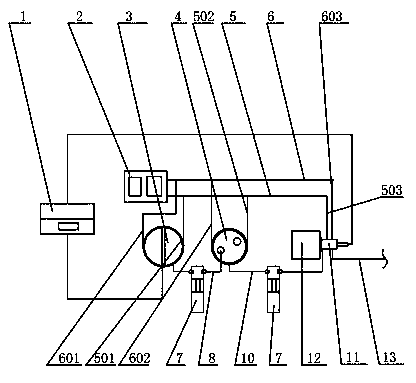

Material inflation method and device

PendingCN108079815AWell mixedEffectively mix inMixing/kneading structural elementsFlow mixersLiquid stateEngineering

The invention provides a material inflation method and device. The material inflation method is characterized by comprising the following steps: firstly, leading a material, which is easily mixed withgas, in a mixed material and injected gas into a liquid-state fluid and gas mixer; when the material and the gas are sufficiently mixed in the liquid-state fluid and gas mixer, conveying a mixture into a rear section of the liquid-state fluid and gas mixer; then injecting other materials in the mixed material into the rear section of the liquid-state fluid and gas mixer; after mixing, leading outfrom the liquid-state fluid and gas mixer; after regulating pressure through a pressure regulator, conveying the material to a user. Compared with the prior art, the material inflation method and device have the advantage that the mixed material can be sufficiently mixed with the gas only if certain material for forming the mixed material is easily mixed with the gas.

Owner:佛山市雅路斯工业设备有限公司

Screw machine having a vacuum housing insert

ActiveUS8360627B2Eliminate cloggingRule out the possibilityRotary stirring mixersFrozen sweetsEngineeringMechanical engineering

A screw machine for treating at least partially powdery bulk material has a housing with at least one housing bore and a screw arranged in the housing bore. A vacuum housing portion is provided, which is formed as a vacuum housing insert, which is releasably attached in the housing, in which a metal nonwoven is exchangeably held as a gas-permeable wall portion on a base body.

Owner:COPERION

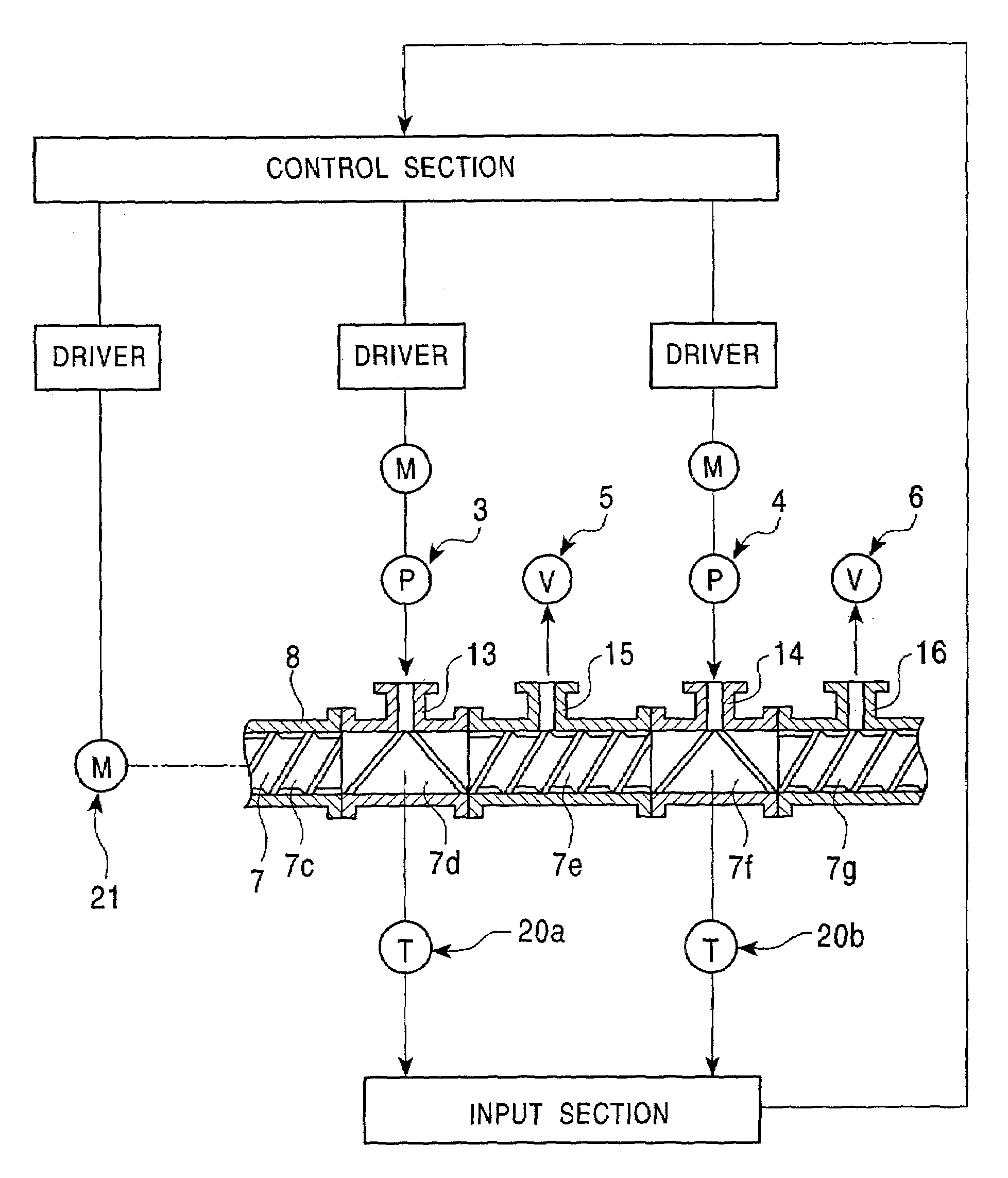

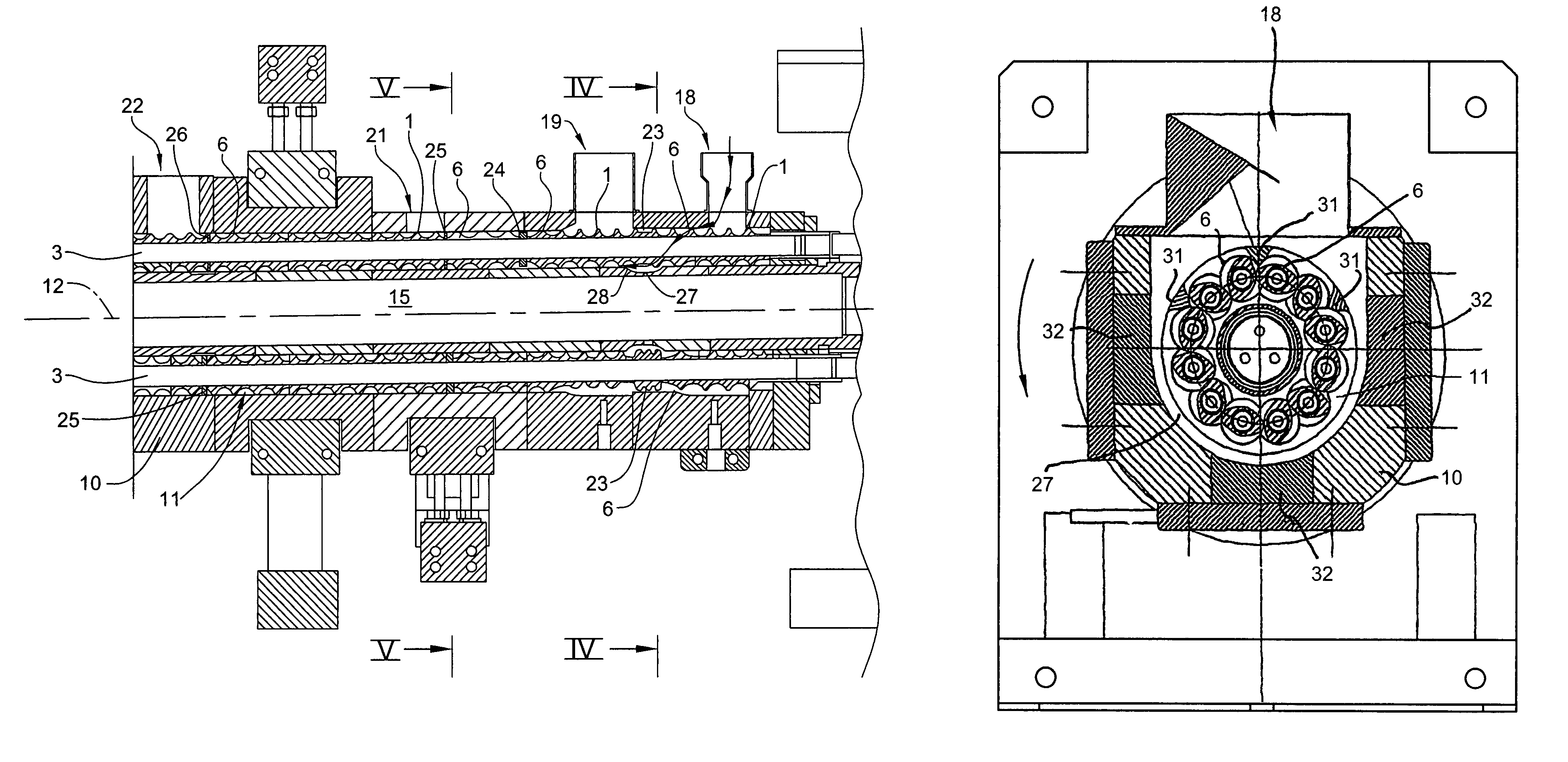

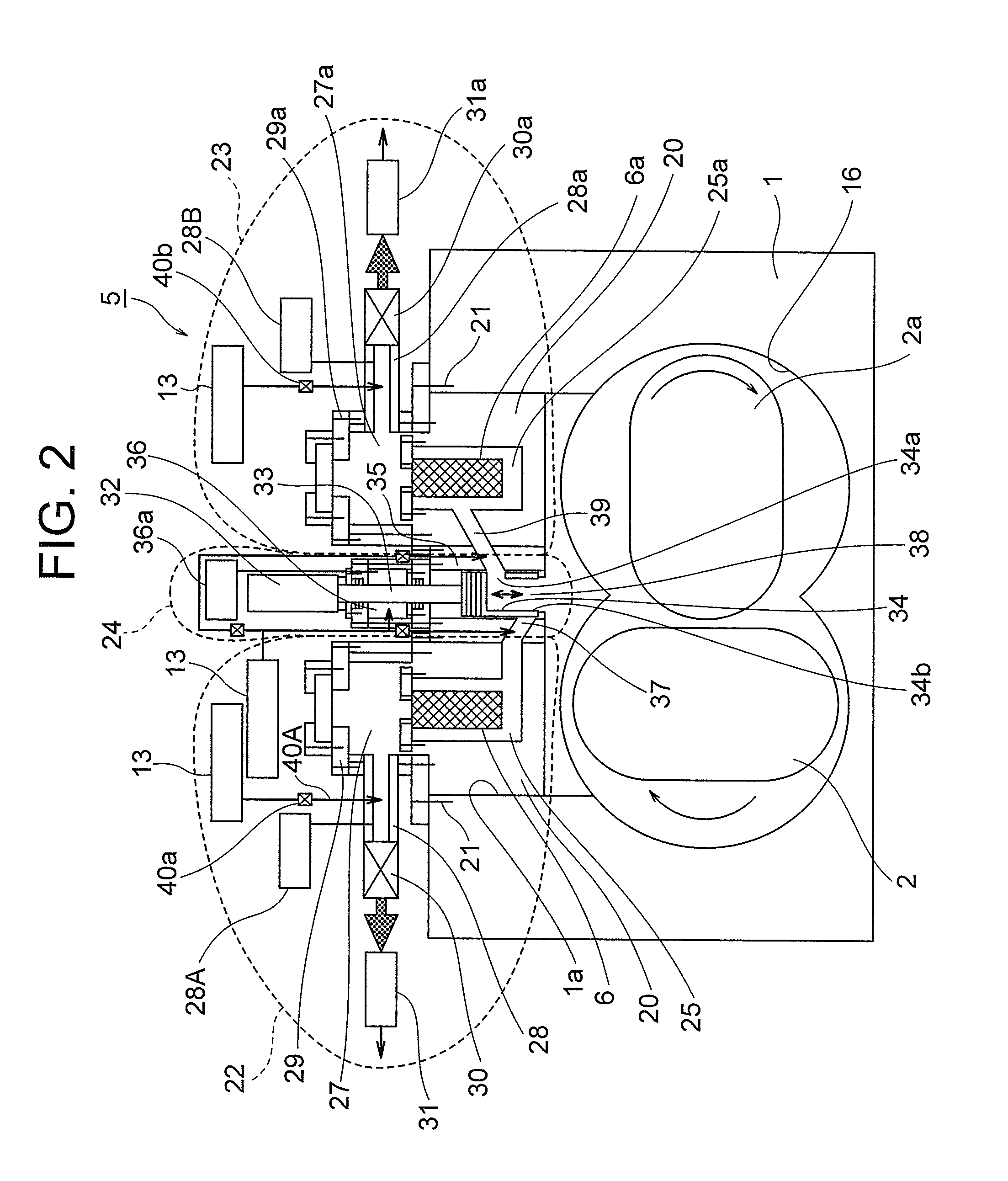

Continuous extrusion device based on twin screw extruder

InactiveUS20150314513A1Accurate acquisitionAccurate pressure detectionTransportation and packagingRotary stirring mixersEngineeringContinuous operation

The present invention performs, by using a pair of filters, continuous operation of a twin screw extruder even during replacement of a filter. The continuous extrusion device based on a twin screw extruder of the present invention has a pair of filters (6, 6a) provided in a degassing device (5), and a partition valve (24) having a valve (34) for setting the filters (6, 6a) and a screw hole (16) of a cylinder (1) to a communicating or non-communicating state, degassing being performed by using the second filter (6a) during replacement of the first filter (6), and the twin screw extruder being operated continuously even during replacement of the filters (6, 6a).

Owner:JAPAN STEEL WORKS LTD

Full-automatic cake beating machine

InactiveCN103385264ASimple structureWell mixedMixing/kneading with aerating apparatusMixing/kneading with vertically-mounted toolsWater sourcePulp and paper industry

The invention relates to a full-automatic cake beating machine. The full-automatic cake beating machine comprises a control cabinet, wherein the control cabinet is connected with a stirring power source and a beating head power source respectively, the output end of the stirring power source is connected with a stirrer, and the stirrer is positioned in a stirring cylinder; the output end of the beating head power source is connected with a spiked bat beating head which is connected with an air inlet pipeline; the stirring cylinder and the spiked bat beating head are respectively connected with a storing cylinder through a transmission pipeline and a rotor delivery pump, a cooling-water machine is also positioned on one side of the stirring cylinder, and the cooling-water machine is connected with an external water source through a water inlet pipe and a water returning pipe; the water inlet pipe is provided with multiple water inlet branches which are connected with the stirring cylinder, the storing cylinder and the spiked bat beating head, and the water returning pipe is provided with multiple water returning branches which are connected with the stirring cylinder, the storing cylinder and the spiked bat beating head. The full-automatic cake beating machine provided by the invention has the advantages that the structure is simple, the operation is convenient, the beating temperature is effectively guaranteed due to the arrangement of the cooling-water machine, the beating efficiency of a cake is improved, and the production cost is saved for enterprises.

Owner:新麦机械(中国)股份有限公司

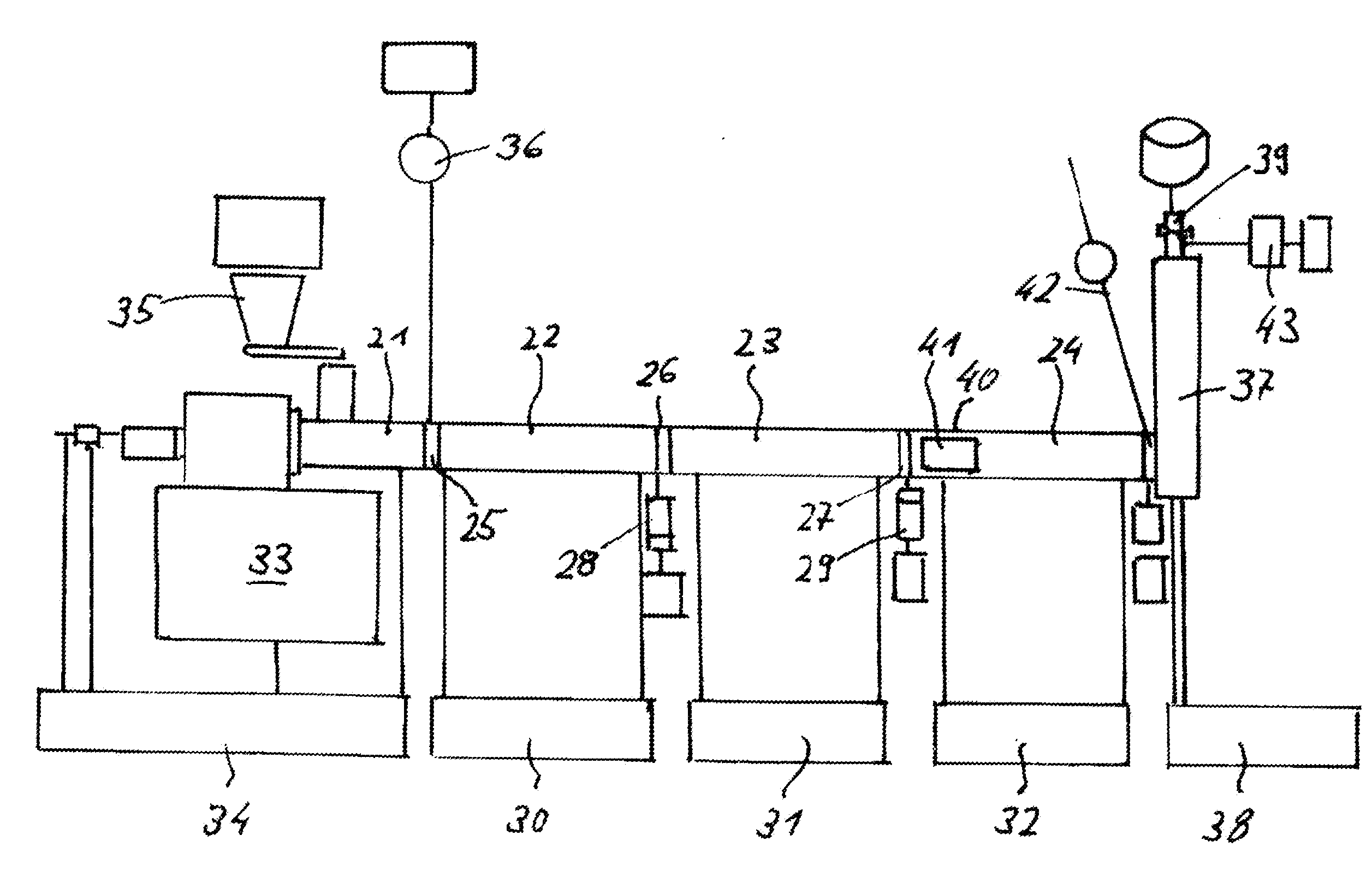

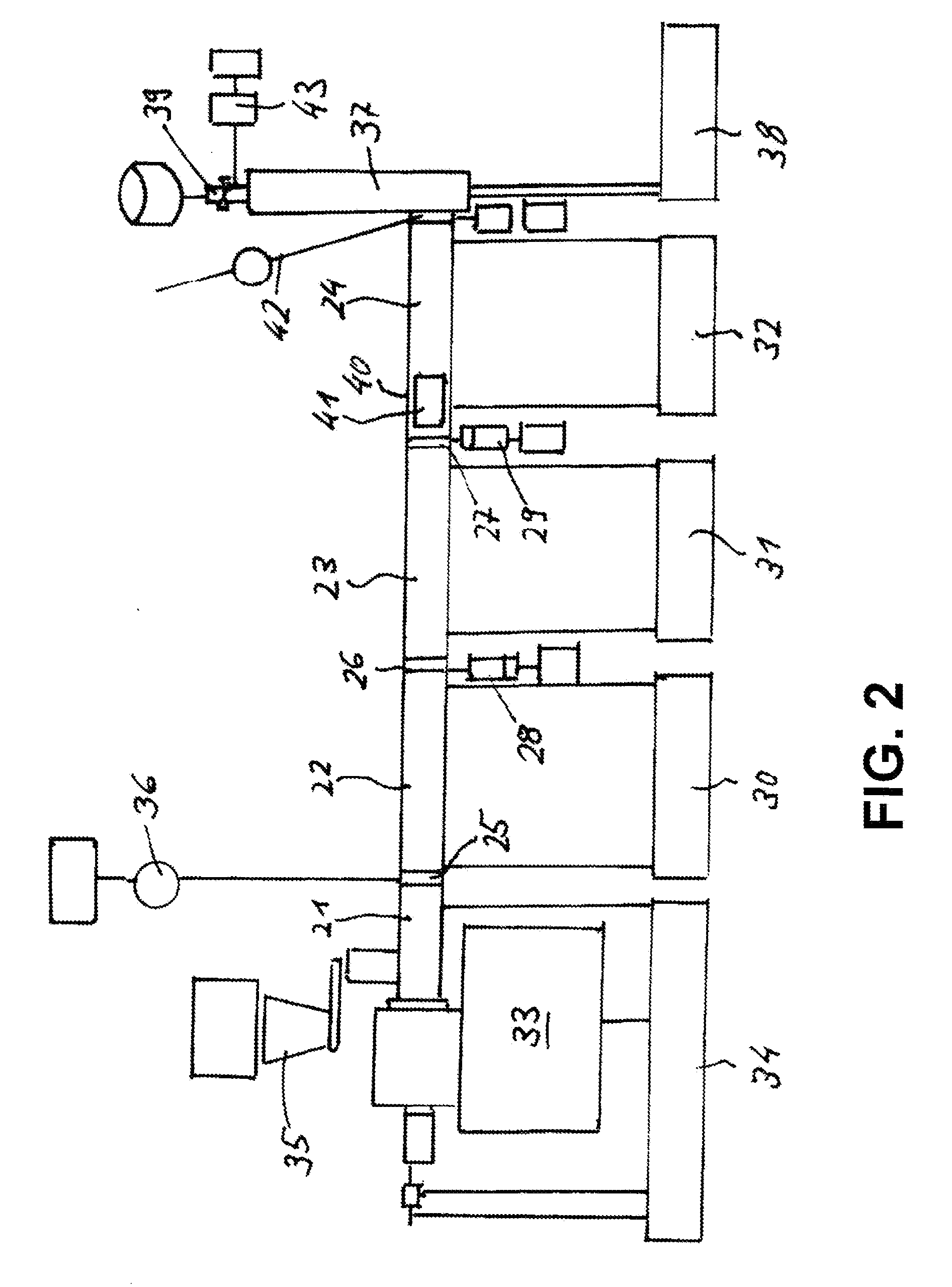

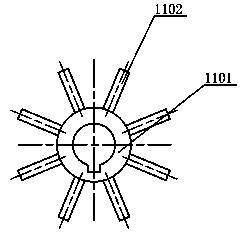

Device and method for dough production

ActiveUS7332190B2Reduced space requirementsLow specific energy inputShaking/oscillating/vibrating mixersDough treatmentAdditive ingredientEngineering

A device for the production of dough from ingredients intended for human consumption as well as from a liquid, water in particular, having a mixing chamber designed to receive and accommodate the ingredients as well as a dough produced from the former wherein conveying means for transporting the ingredients into the mixing chamber are mounted in the mixing unit. Kneading means is provided and includes a nozzle unit for the injection of the liquid into the mixing chamber and the ingredients. The nozzle unit is designed for the injection of the liquid under high pressure to intermixture the ingredients in a mass of dough-like consistency for the production of dough.

Owner:NOLL BERNHARD

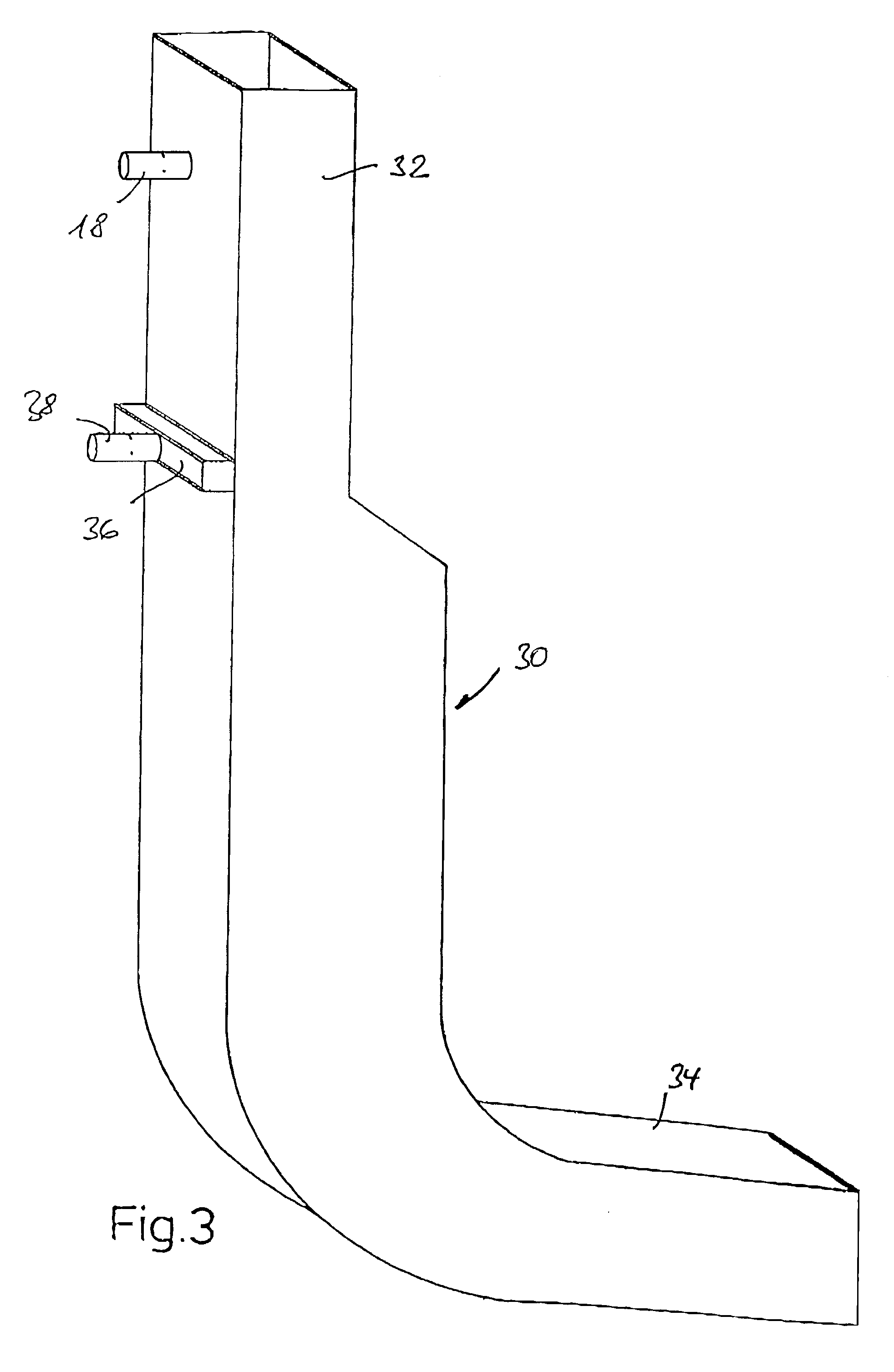

Method and processing installation for devolatilizing polymer melts

InactiveUS8388216B2Improve performanceImprove throughputRotary stirring mixersFrozen sweetsEngineeringPolymer melt

Owner:COPERION

Mixing and pulverizing device, melting method for mixing, and method of molding cellulose material impregnated with binder

InactiveUS7896638B2Small loadProblem costTransportation and packagingRotary stirring mixersCelluloseMoisture

A crushing and mixing device includes a mixing vessel in which a plurality of blades installed on a rotary shaft which is rotated by a motor as a driving source and freely rotatably supported, to mix and crush materials. A spiral vane is equipped to supply the materials which are introduced to a rotary shaft corresponding to an inlet from materials, to the mixing vessel; at least two blades are installed on the rotary shaft at an inclined angle; an outlet disposed at a side of a wall of the mixing vessel; the materials are mixed and crushed in the mixing vessel, and an entrained moisture therein is dewatered by the heat generated by actions of shearing, friction and compression; and a molten binder is impregnated in the dehydrated materials.

Owner:M & F TECH

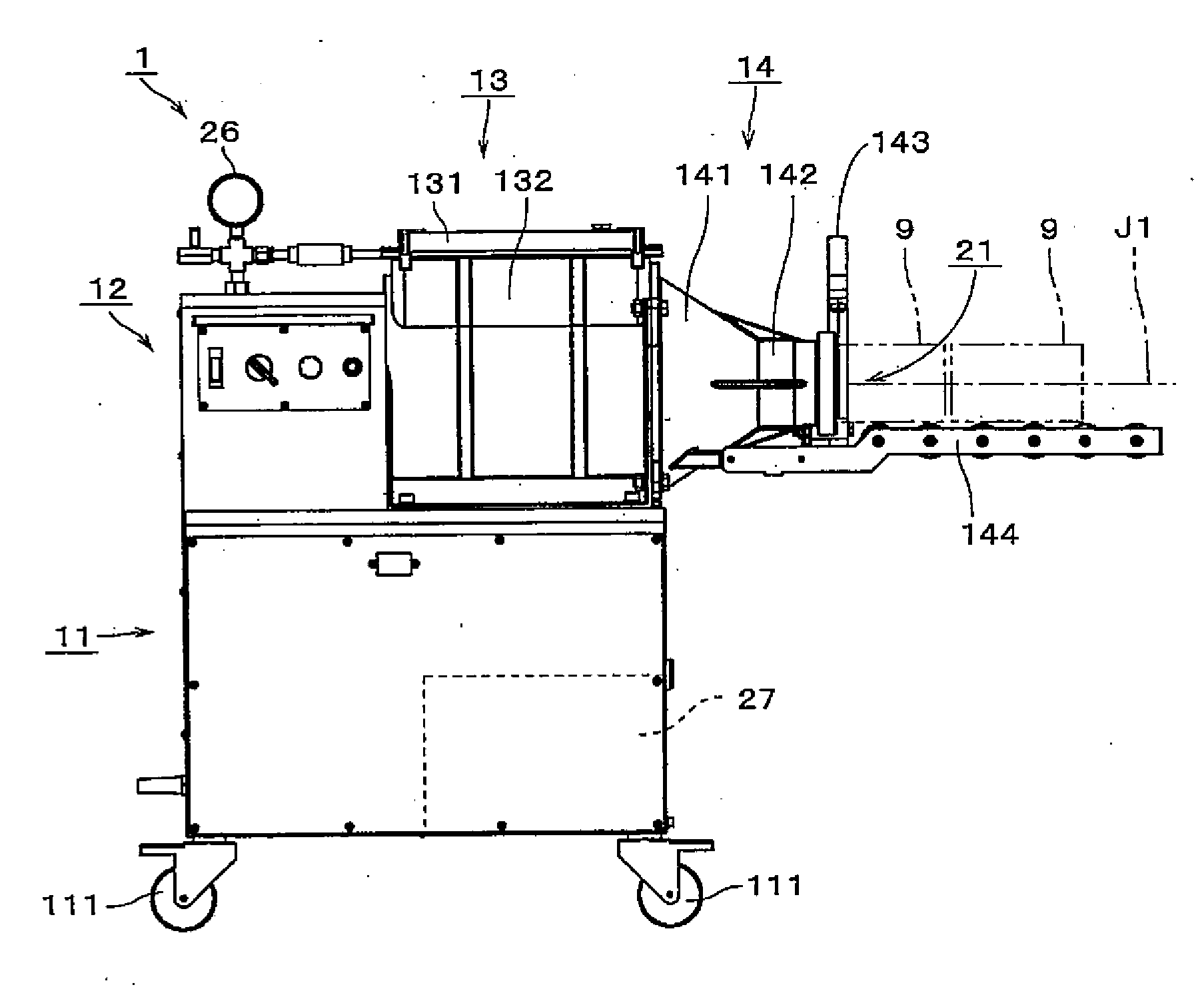

Clay mixing apparatus

ActiveUS20120250447A1Avoid distortionEfficient removalDischarging apparatusRotary stirring mixersEngineeringMechanical engineering

A clay mixing apparatus includes a mixing chamber, a rotor arranged within the mixing chamber, a drive unit arranged to rotate the rotor, an ejecting unit, a pressure reducing unit; and an exhaust flow path. The rotor includes a shaft rotated by the drive unit, an extruding member and a mixing member. The mixing member includes a plurality of arms and a plurality of blades arranged at tip ends of the arms. The exhaust opening is opposed, in a radial direction about the center axis, to a portion of the mixing member lying near the extruding member and / or a portion of the extruding member lying near the mixing member.

Owner:NIDEC SHIMPO CORP

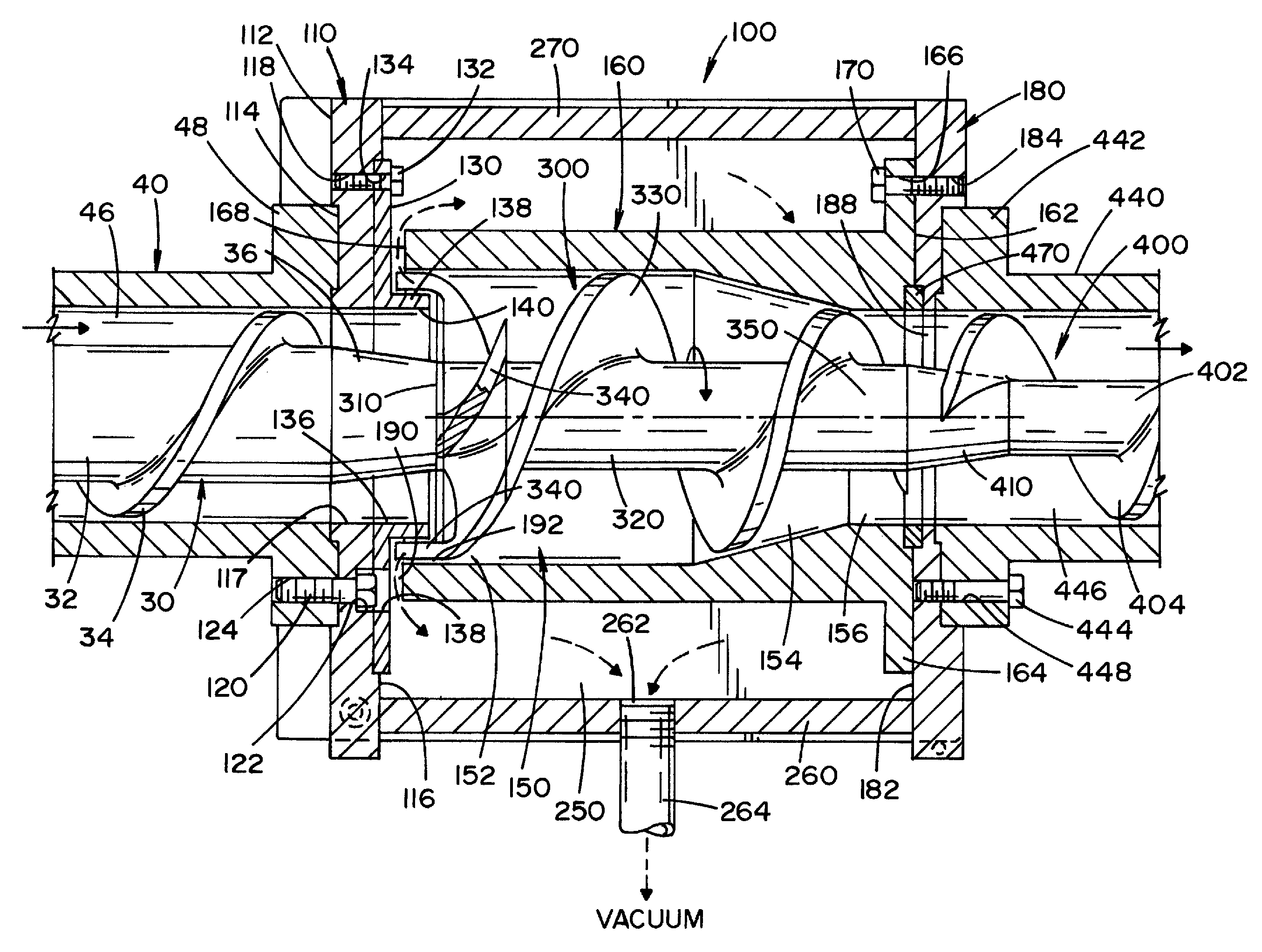

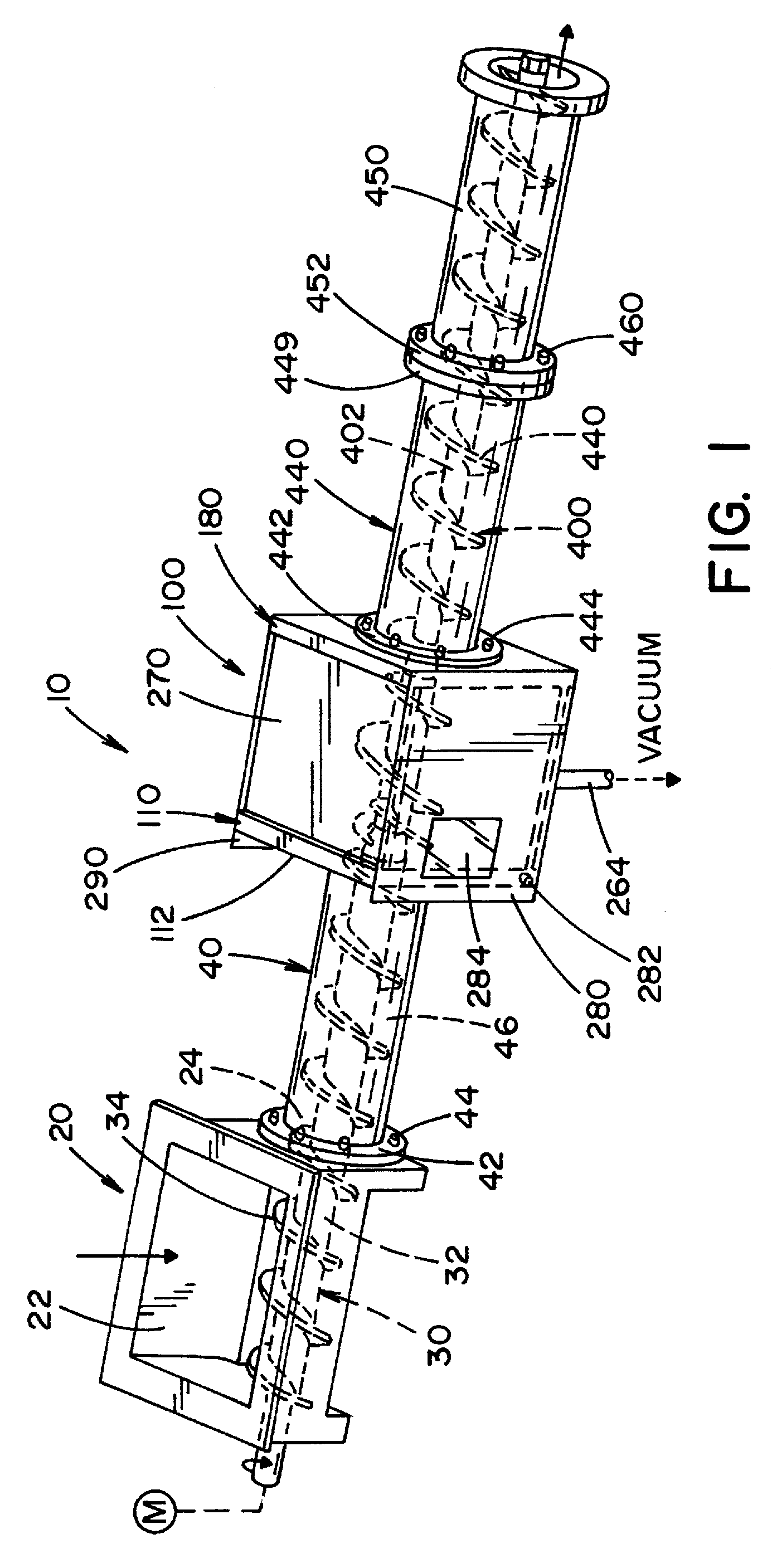

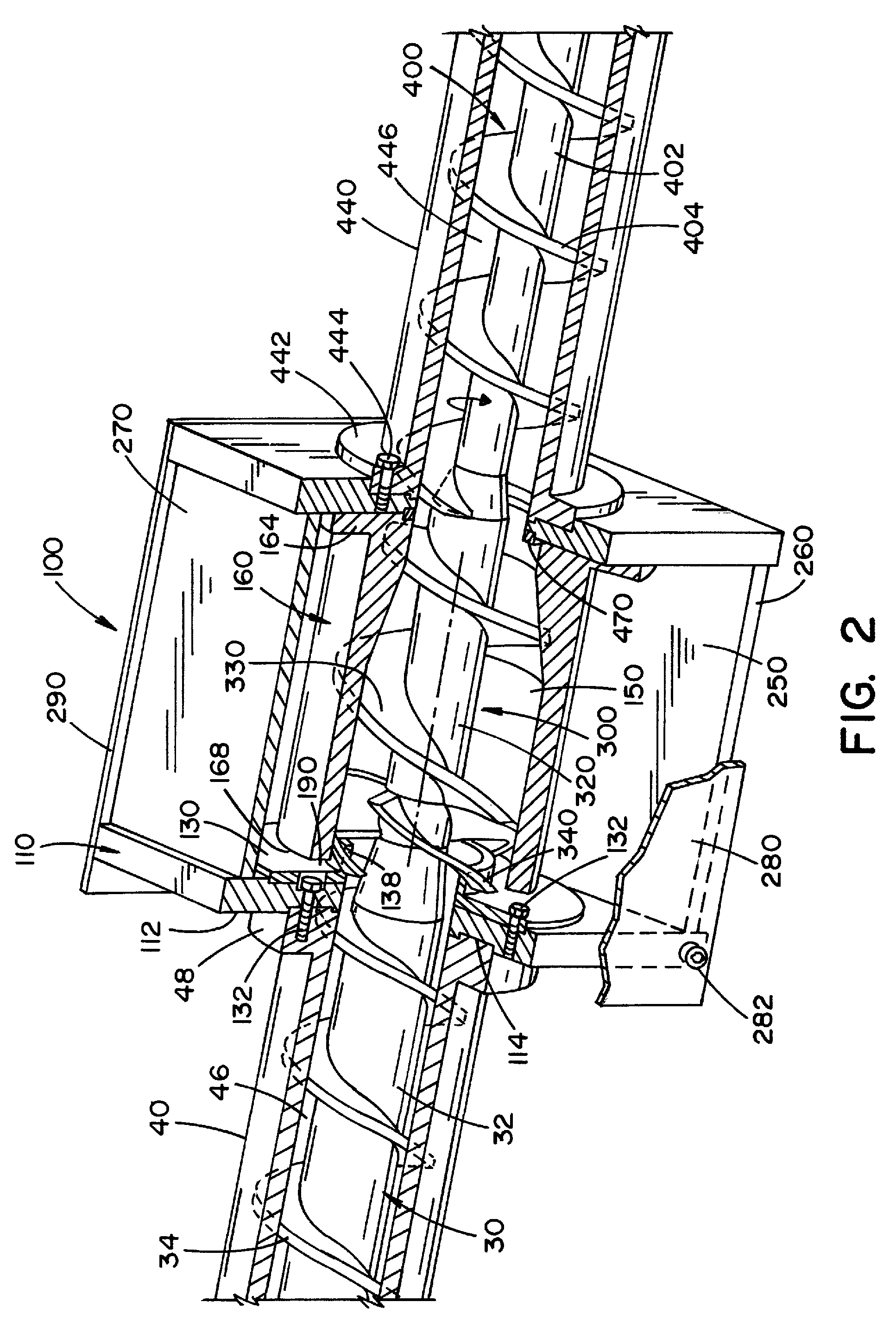

Apparatus for de-airing material in an extruder that includes a vent block

ActiveUS8992068B2Reducing root portionIncrease pitchRotary stirring mixersFrozen sweetsMechanical engineering

An extruder for feeding material and for removing gas from the fed material. The extruder includes a vent block positioned between a first and second auger. The vent block including a vent cavity having a feed end and an exit end, an inner feed ring that partially extends into said vent cavity at the feed end of the vent cavity, and a screw element rotatably positioned in the vent cavity. A front portion of the outer ring is longitudinally aligned with or overlapping the front end of the inner feed ring. The outer ring forms at least one gap or opening at or adjacent the feed end of the vent cavity to enable a vacuum to be pulled on the vent cavity as material is moved though the vent cavity from the feed end to the exit end by the screw element.

Owner:THE BONNOT

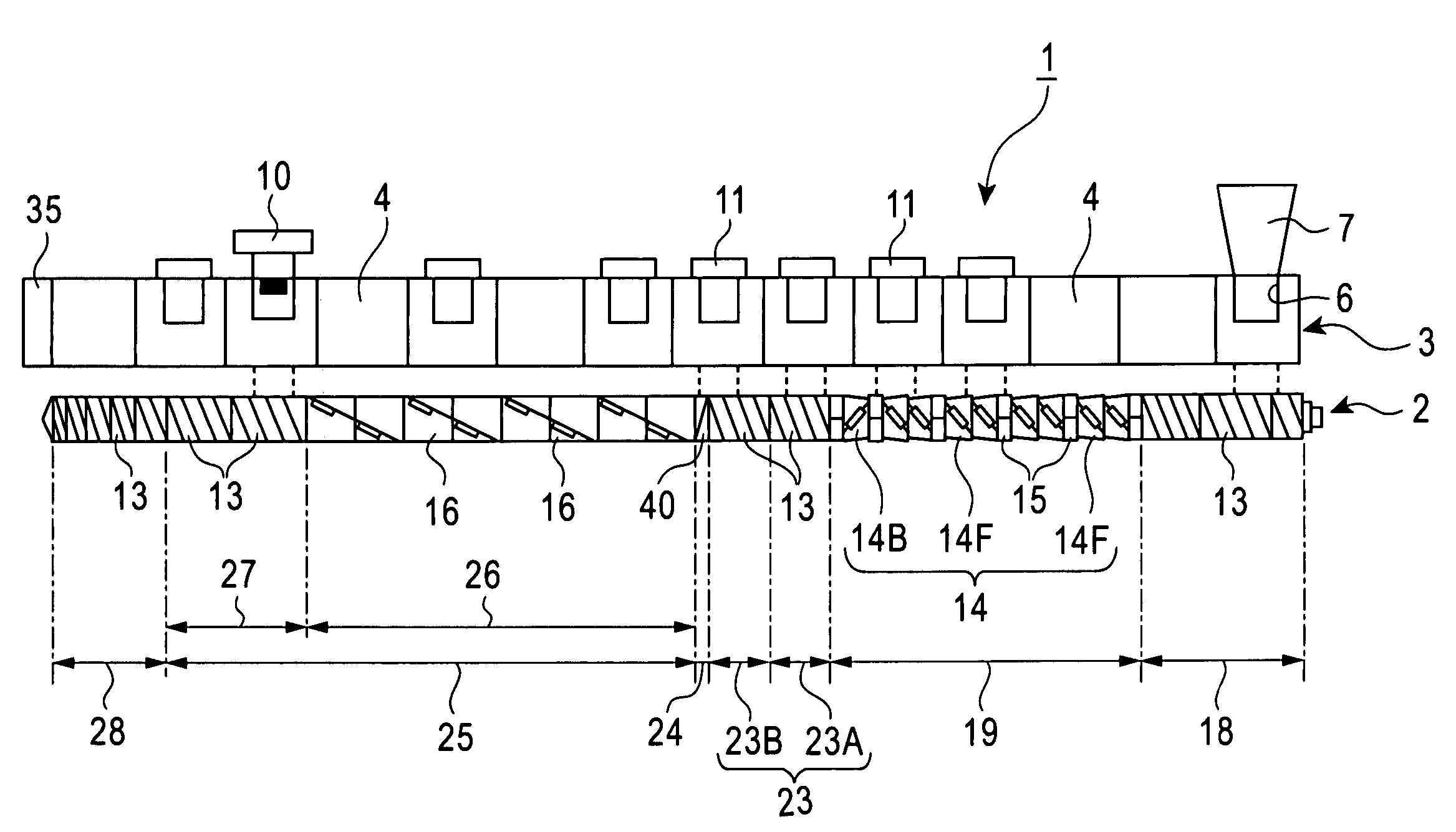

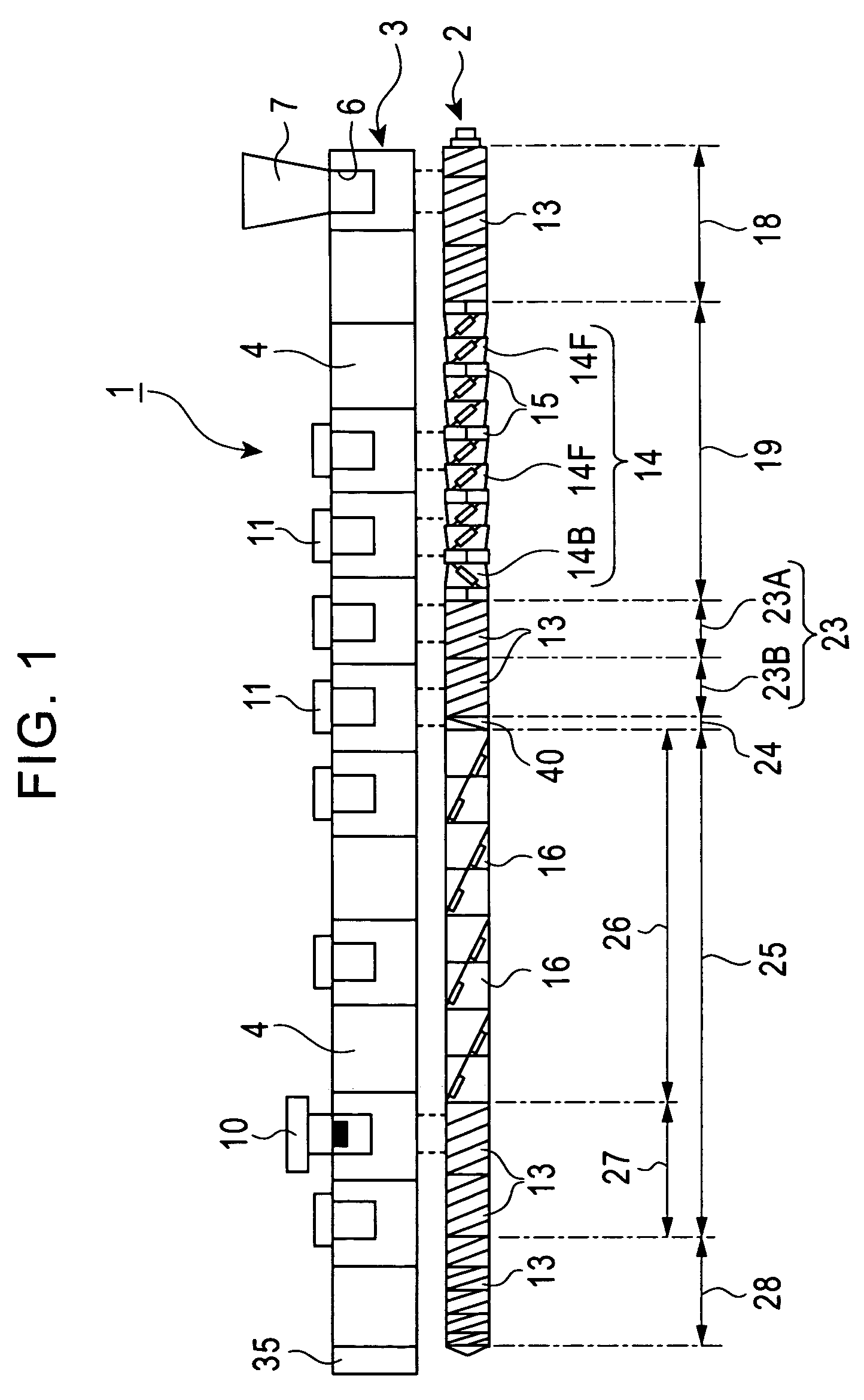

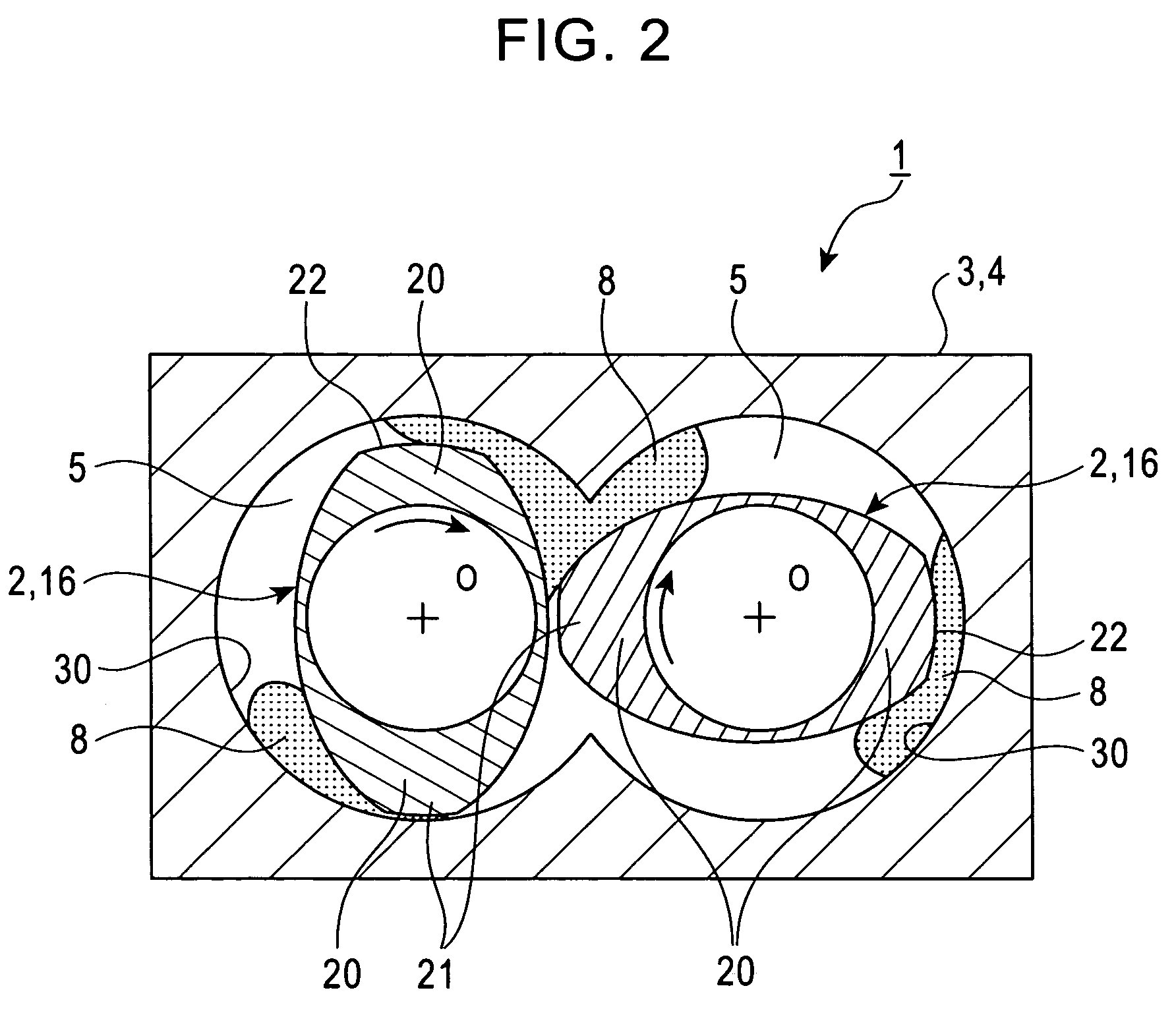

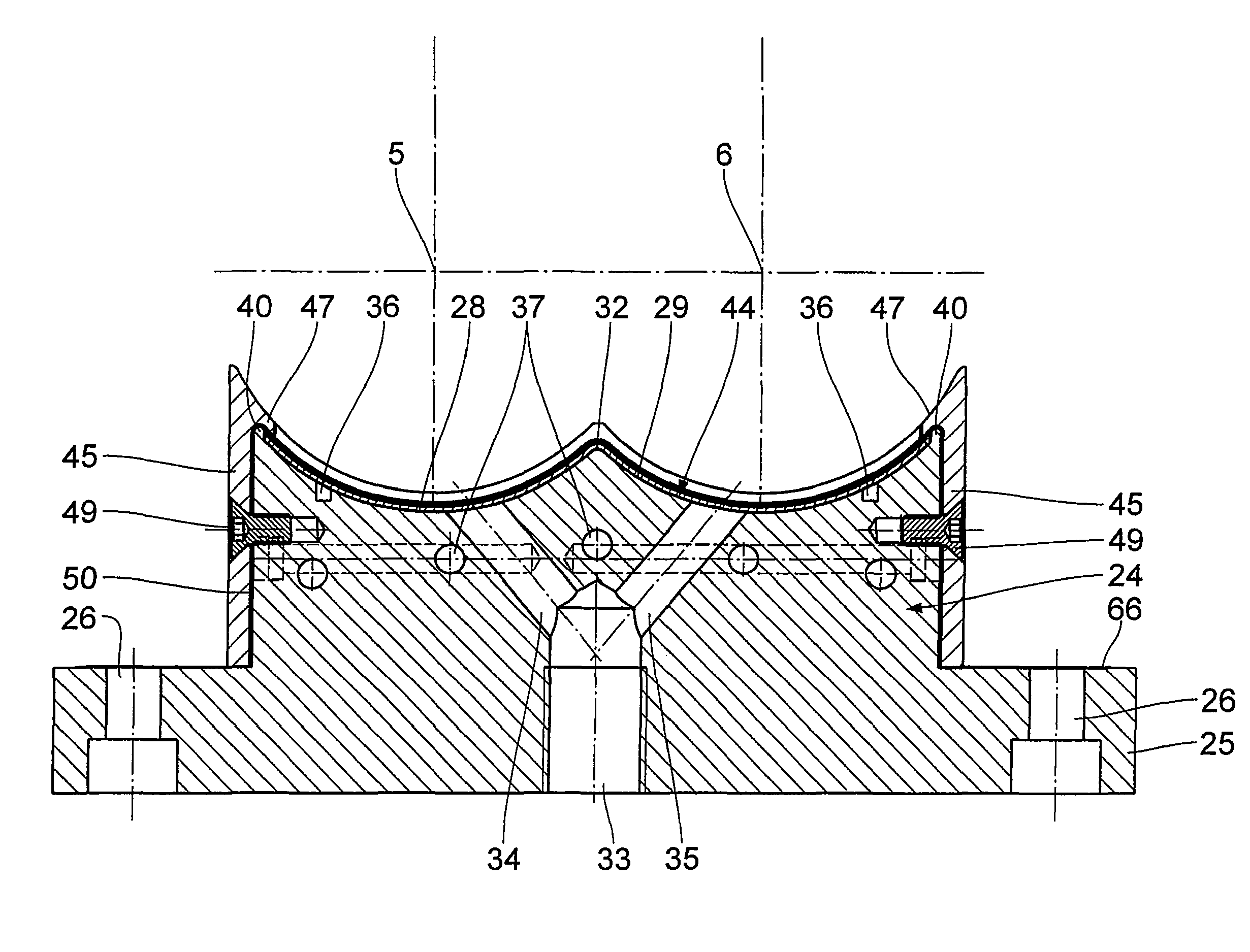

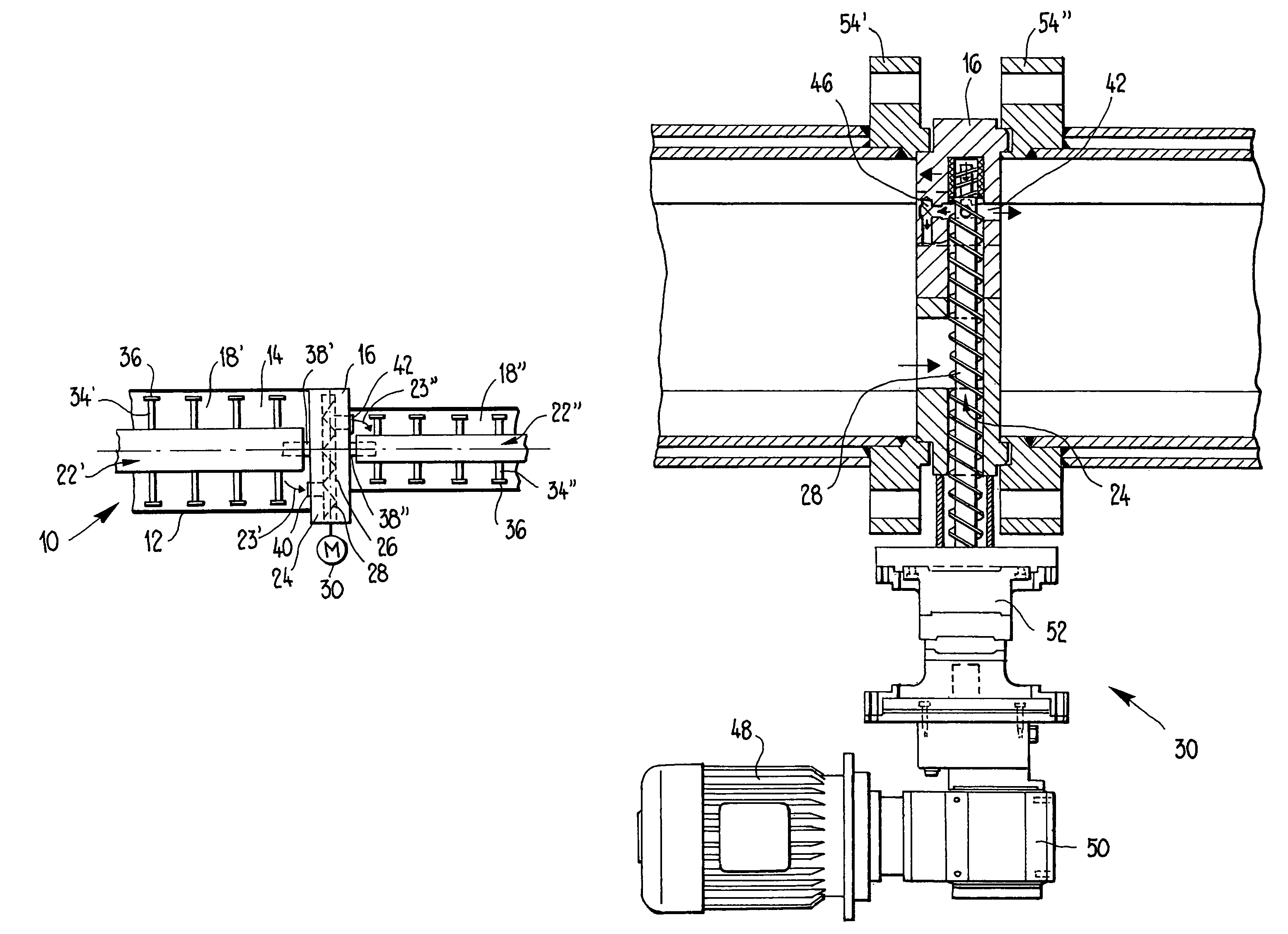

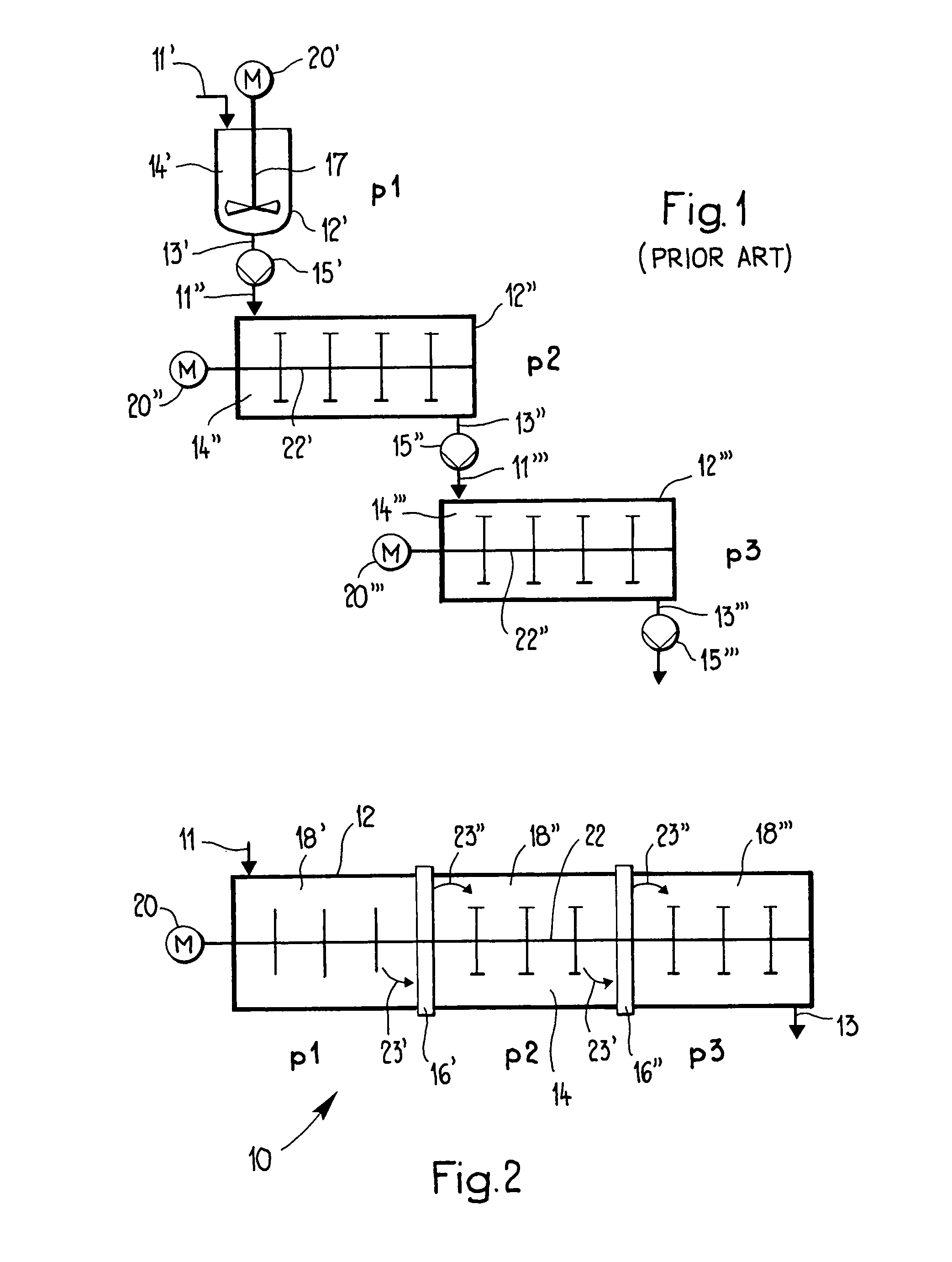

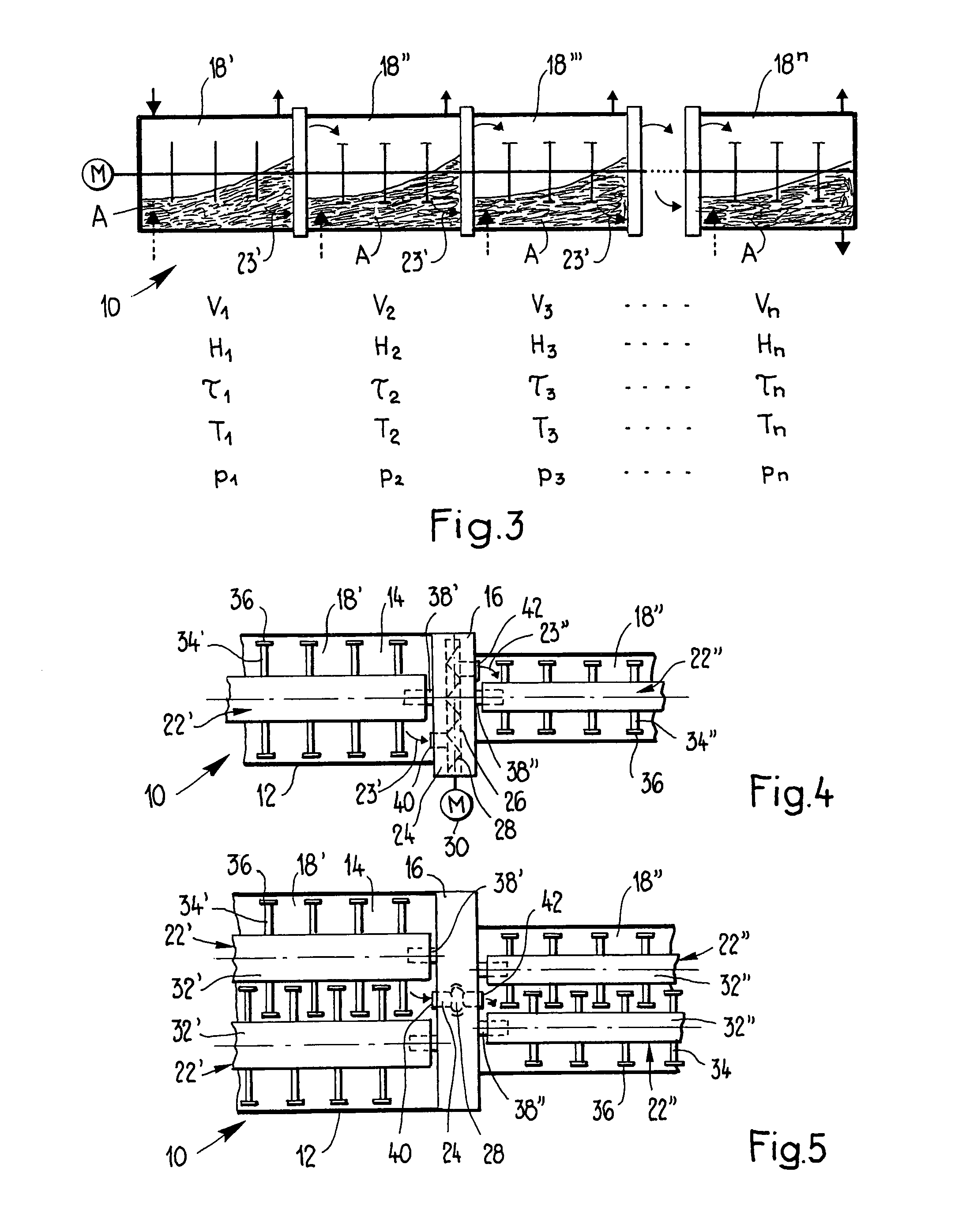

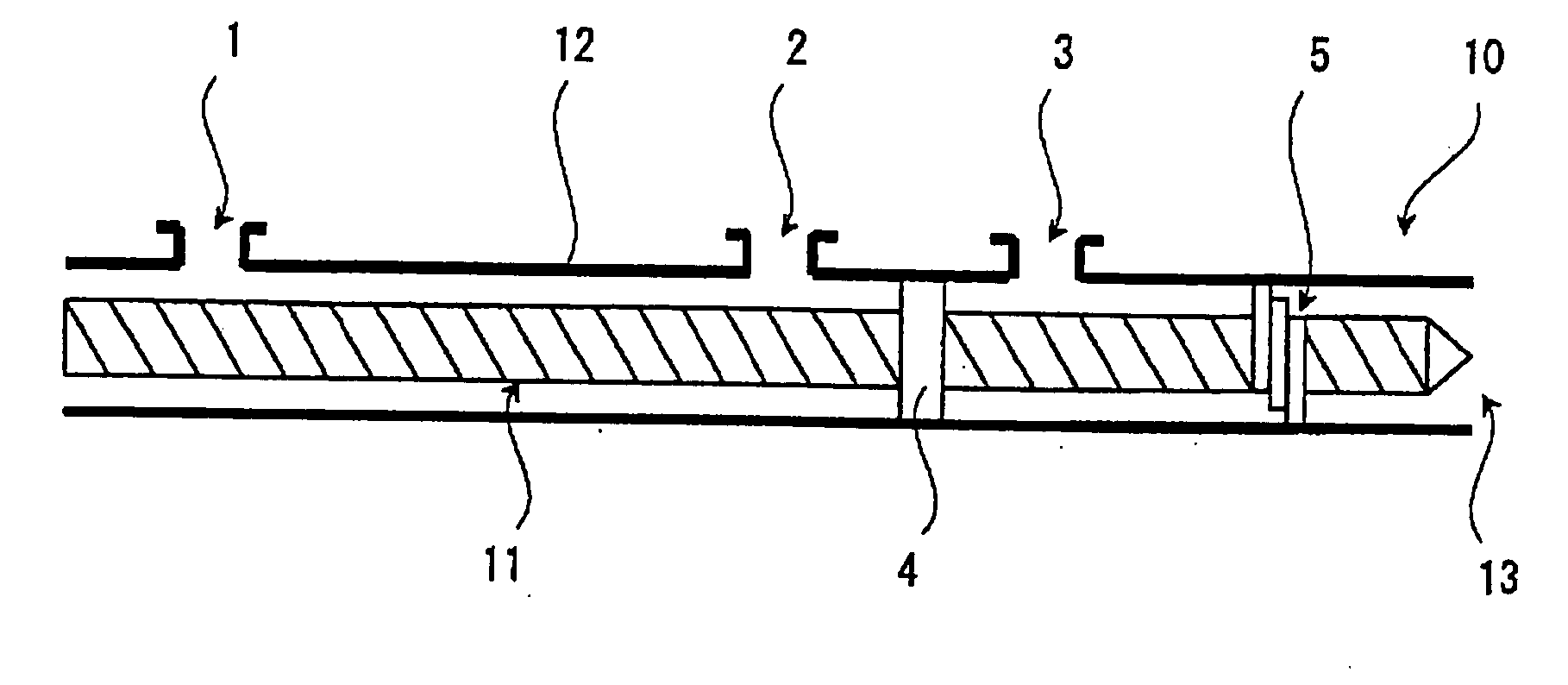

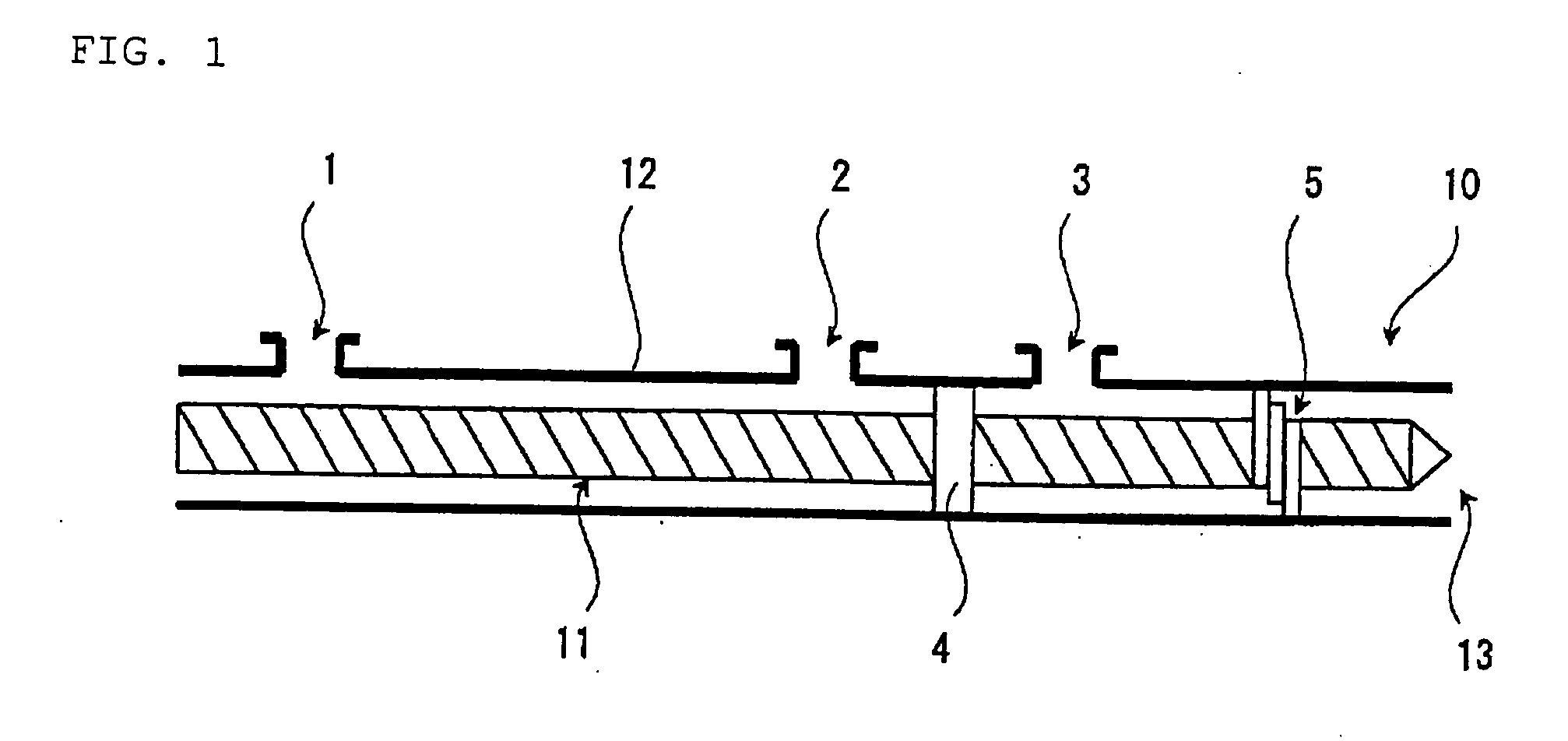

Large-volume reactor having a plurality of process spaces

ActiveUS7083319B2Reduce traffic lossIncrease in sizeRotary stirring mixersTransportation and packagingInterior spaceEngineering

A large-volume reactor (10) for treating a free-flowing material, having a housing (12) which surrounds an interior space (14), a material feed (11) at one end of the housing (12) and a material discharge (13) at the other end of the housing (12). A rotor shaft (22), which is driven in rotation about its axis and conveys the material in the direction from the material feed (11) to the material discharge (13), is arranged in the interior space (14). A partition wall (16) in the interior space (14) defines two separate process spaces (18′, 18″) from one another, and the partition wall (16) includes a build-up system (24) having a build-up system passage (26) which leads from an inlet opening (40) which opens out into the first process space (18′), to an outlet opening (42) which opens out into the second process space (18″). The build-up system passage (26) is configured to pass the material from the first process space (18′) into the second process space (18″) and so that the flowing material forms a barrier which effectively prevents gas from passing through the passage.

Owner:BUSS SMS GMBH VERFAHRENSTECHN

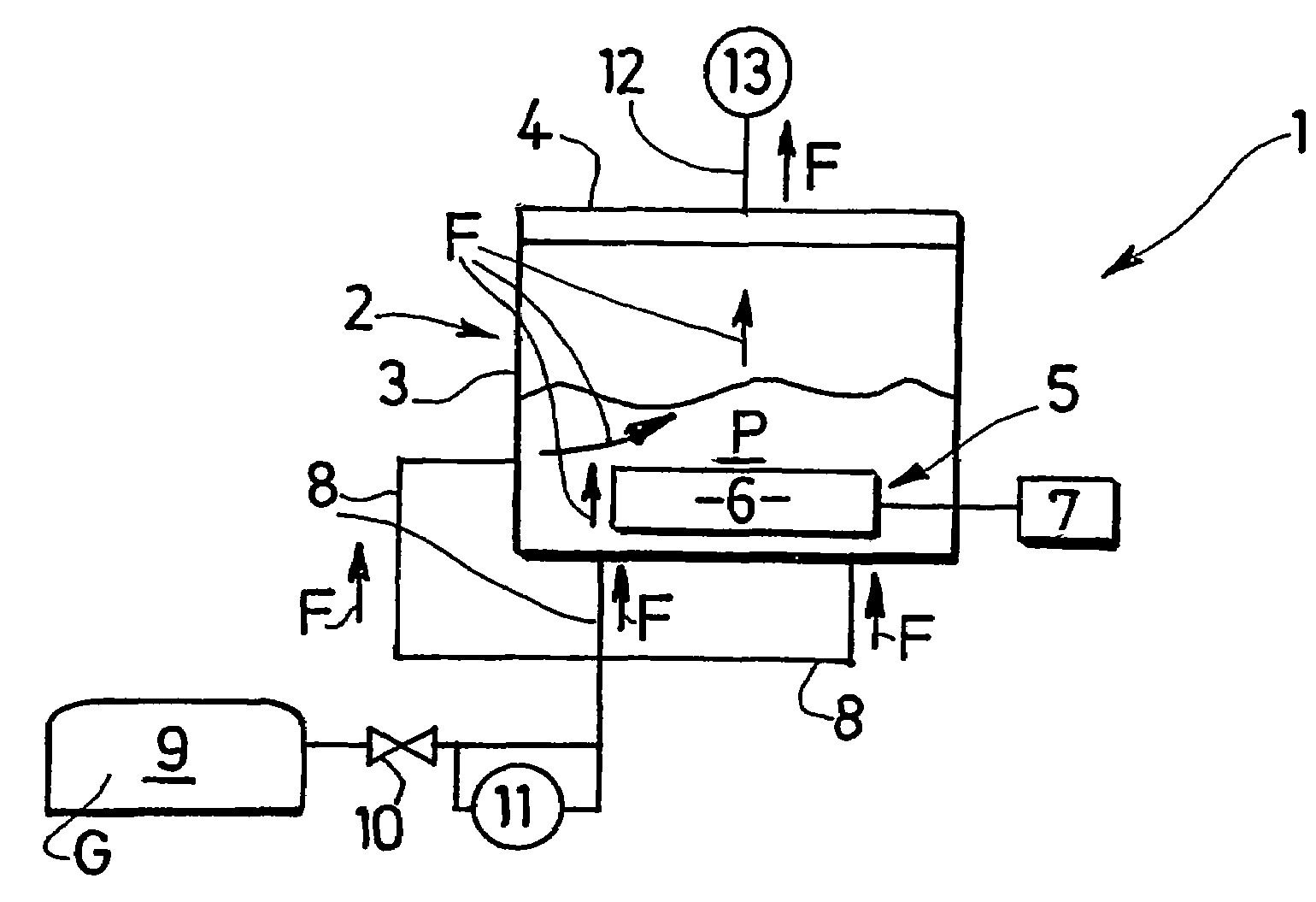

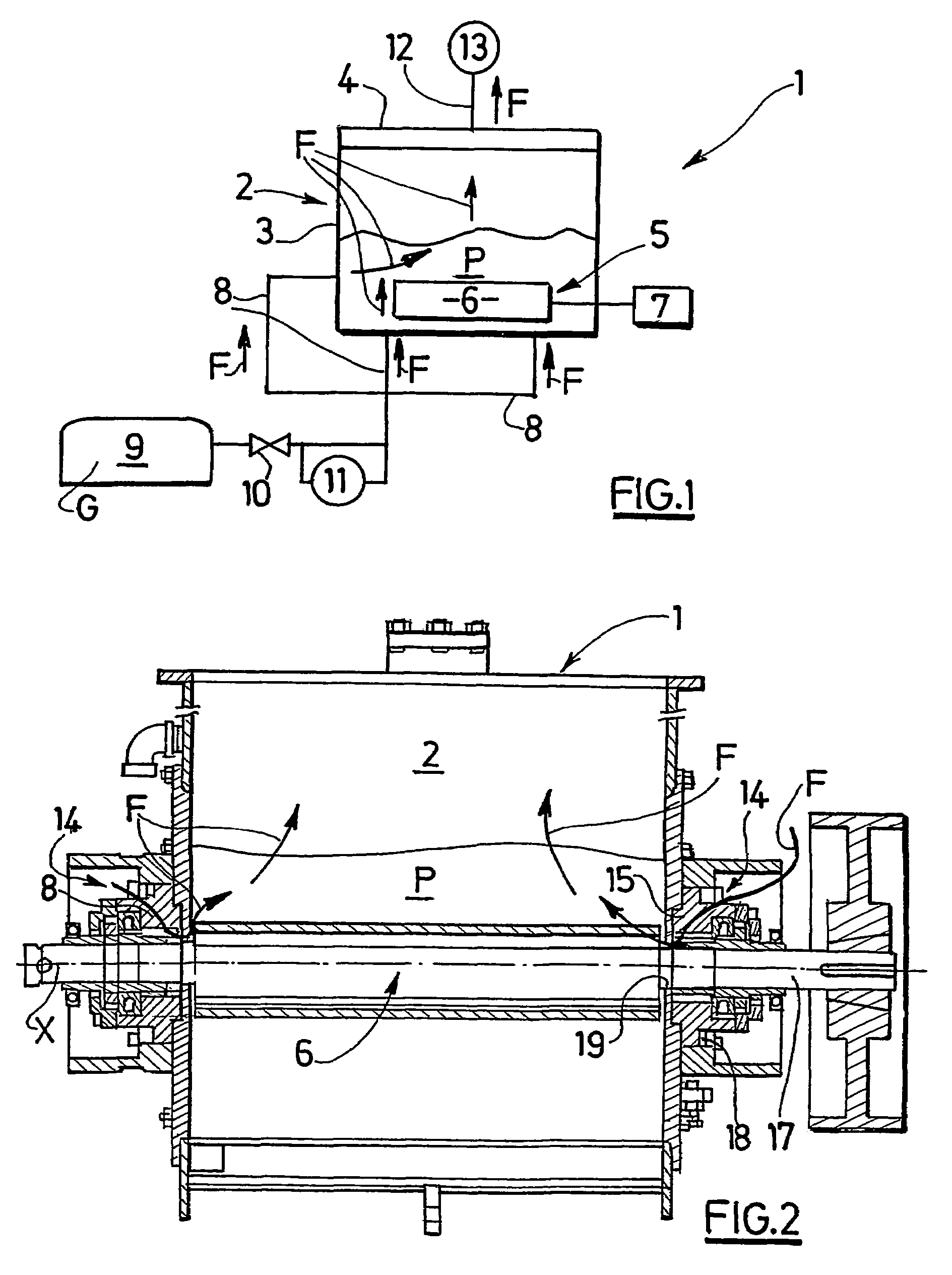

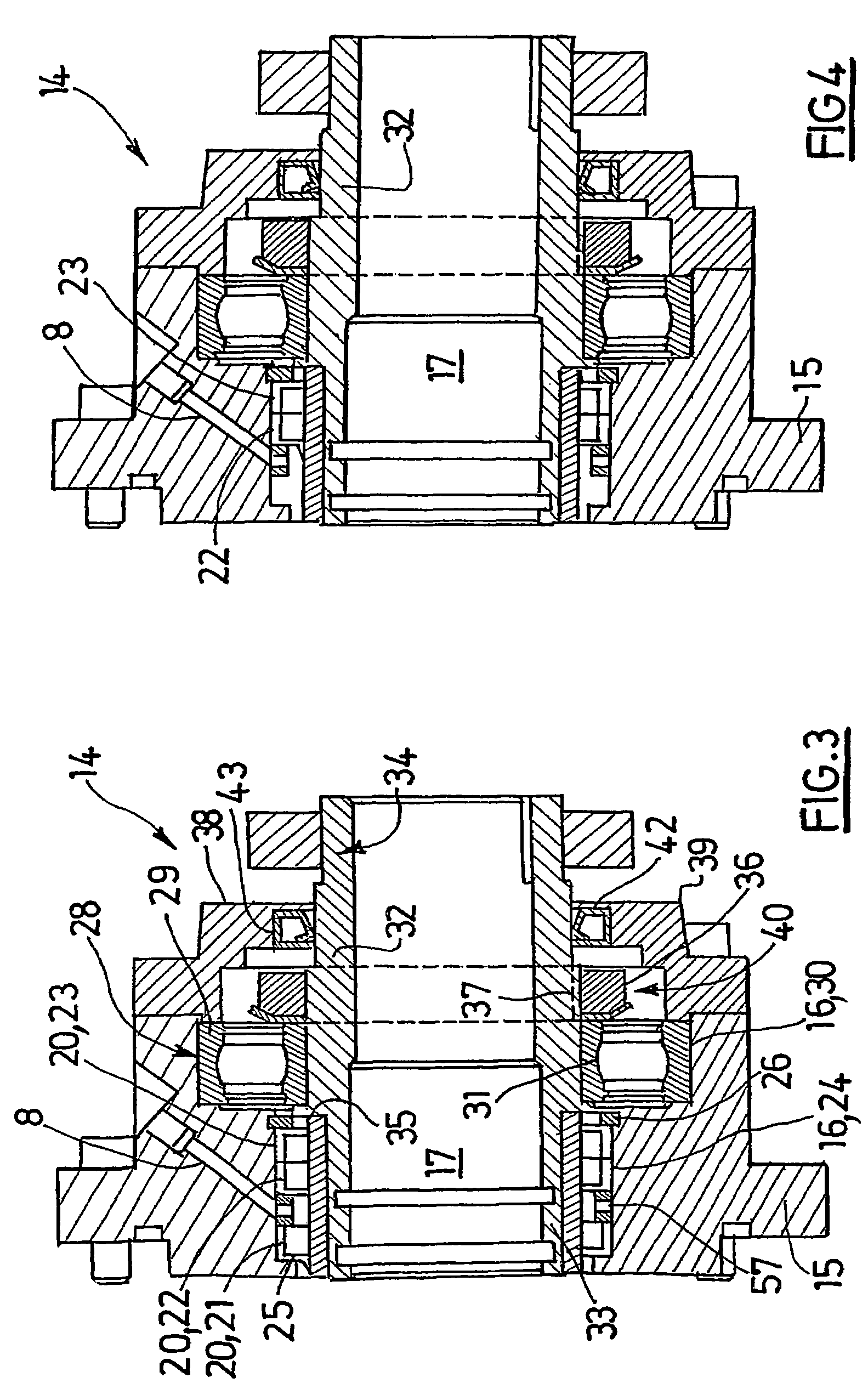

Vacuum kneading method with the introduction of oxygen and the device used to carry out said method

InactiveUS7514112B2Easy accessReduced dimensionDough treatmentTransportation and packagingEngineeringProduct gas

The invention relates to a method of kneading dough in order to produce bread or similar products. According to the invention, the dough ingredients are introduced into a chamber and all of said ingredients are subsequently kneaded. The inventive method is characterised in that it comprises: a vacuum phase during which a vacuum is applied in the chamber; and one or more phases involving the introduction of gas, during which a gas containing oxygen is introduced into the chamber. The aforementioned vacuum phase continues more or less throughout the entire kneading phase, with at least one part of each introduction phase taking place simultaneously with the kneading phase. The invention also relates to a device that is used to carry out said method.

Owner:VMI INC

Method for producing composite materials such as thermoplastic resins with mineral and/or vegetable fillers

InactiveUS20090238028A1Eliminate the problemPrevent degradationRotary stirring mixersMixer accessoriesMaterials scienceExtrusion

A method for producing composite materials, such as thermoplastic resins with mineral and / or vegetable fillers, consisting in feeding a mineral and / or vegetable filler, preheating the filler, feeding a melted thermoplastic resin onto the filler, introducing the mixture of the filler and the thermoplastic resin in an extruder, subjecting the mixture to high compression, producing a high partial vacuum, and compressing the mixture in an extrusion head, out of which the material to be subjected to subsequent treatments flows.

Owner:MECCANICHE MODERNE

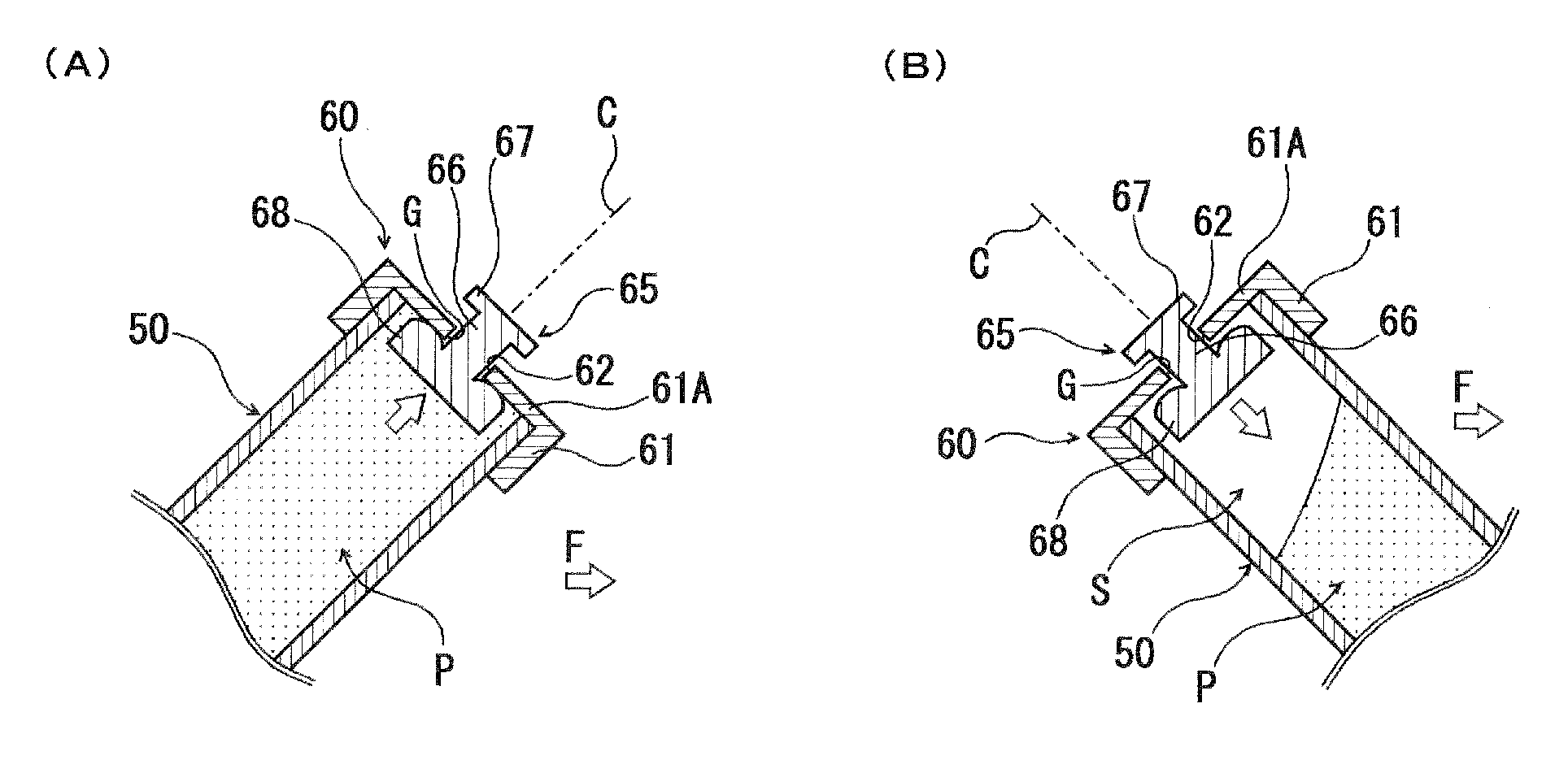

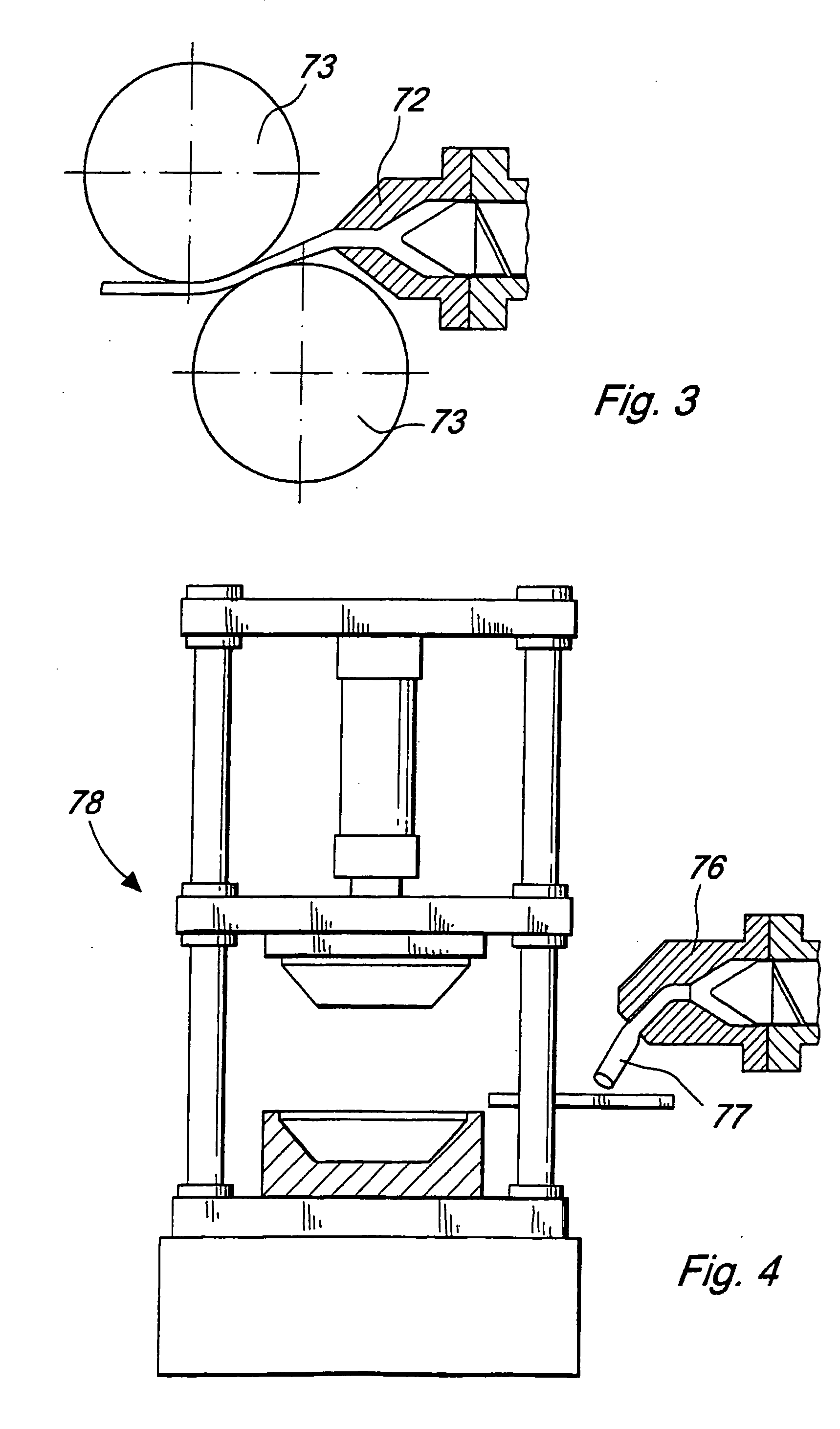

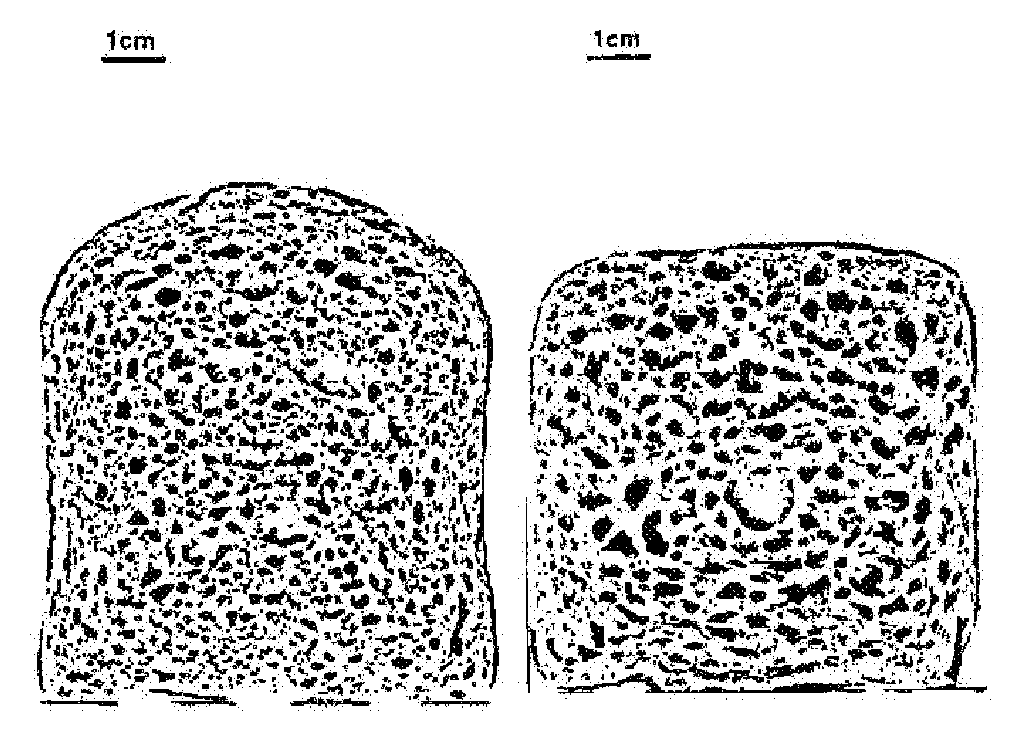

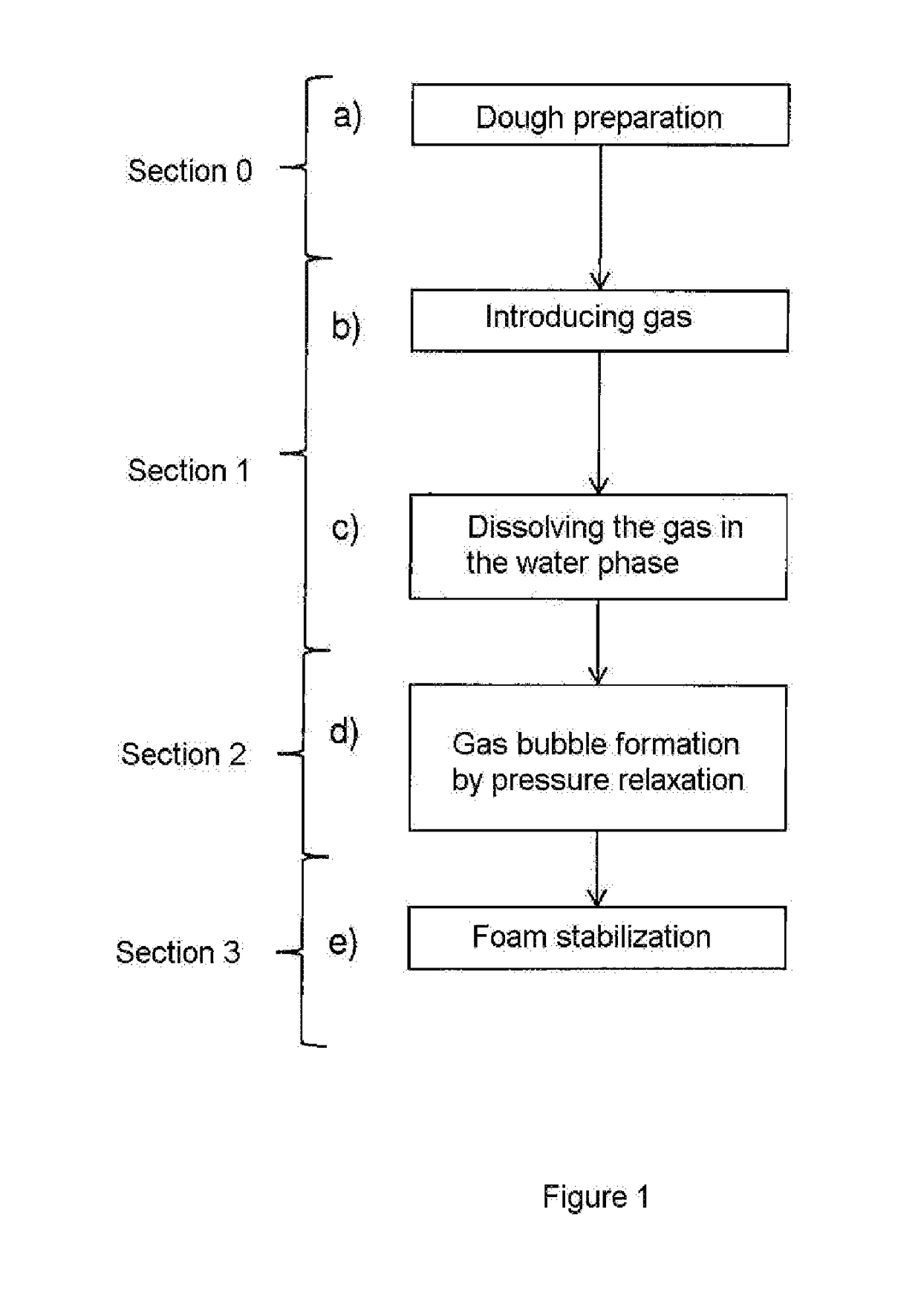

Foamed, dough-based food and apparatus and method for production thereof and use of the apparatus

ActiveUS20180317501A1Degradation for retention propertyLittle wearMixing/kneading with horizontally-mounted toolsPre-baking dough treatmentMethods of productionGas bubble

A dough-based food product, an apparatus and method for production of the dough-based food product. A food product matrix to be foamed includes a proportion by weight of a starch-containing raw material and a proportion by weight of water. Gas that has been dissolved or is to be dissolved is introduced into the food product matrix to be foamed. The gas is dissolved under pressure in the food product matrix to be foamed. Gas bubbles are formed by expansion and increasing the volume with a resulting reduction in density of the dough as a result of bubble growth for formation of a foamed food product matrix of the food product to be produced. The foam is then stabilized. Gas is introduced into and dissolved in the aqueous component of the food product matrix to be foamed in a subcritical state below the critical point and at a pressure of 10 bar≤p<critical pressure of the gas.

Owner:ETH ZZURICH +1

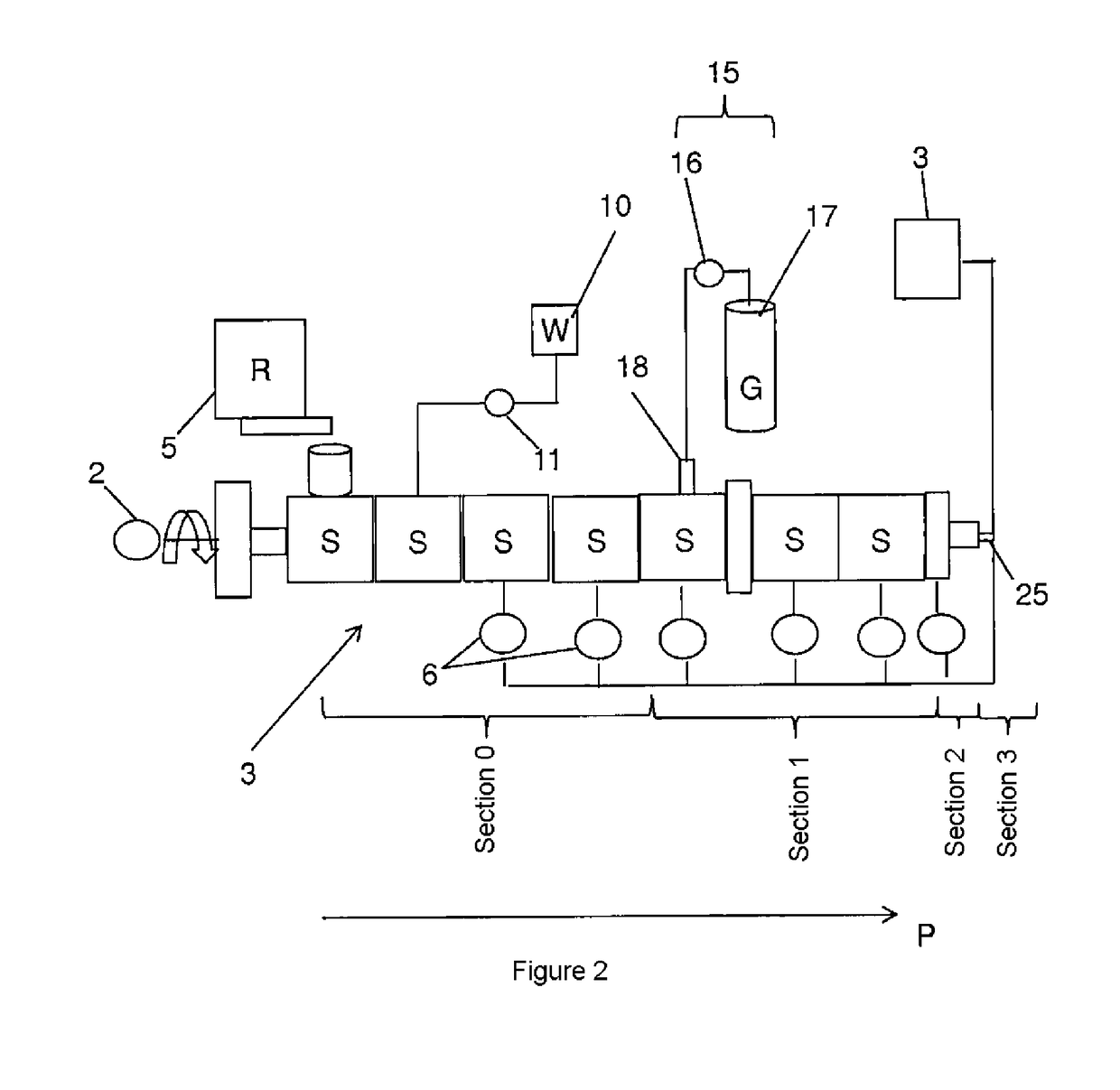

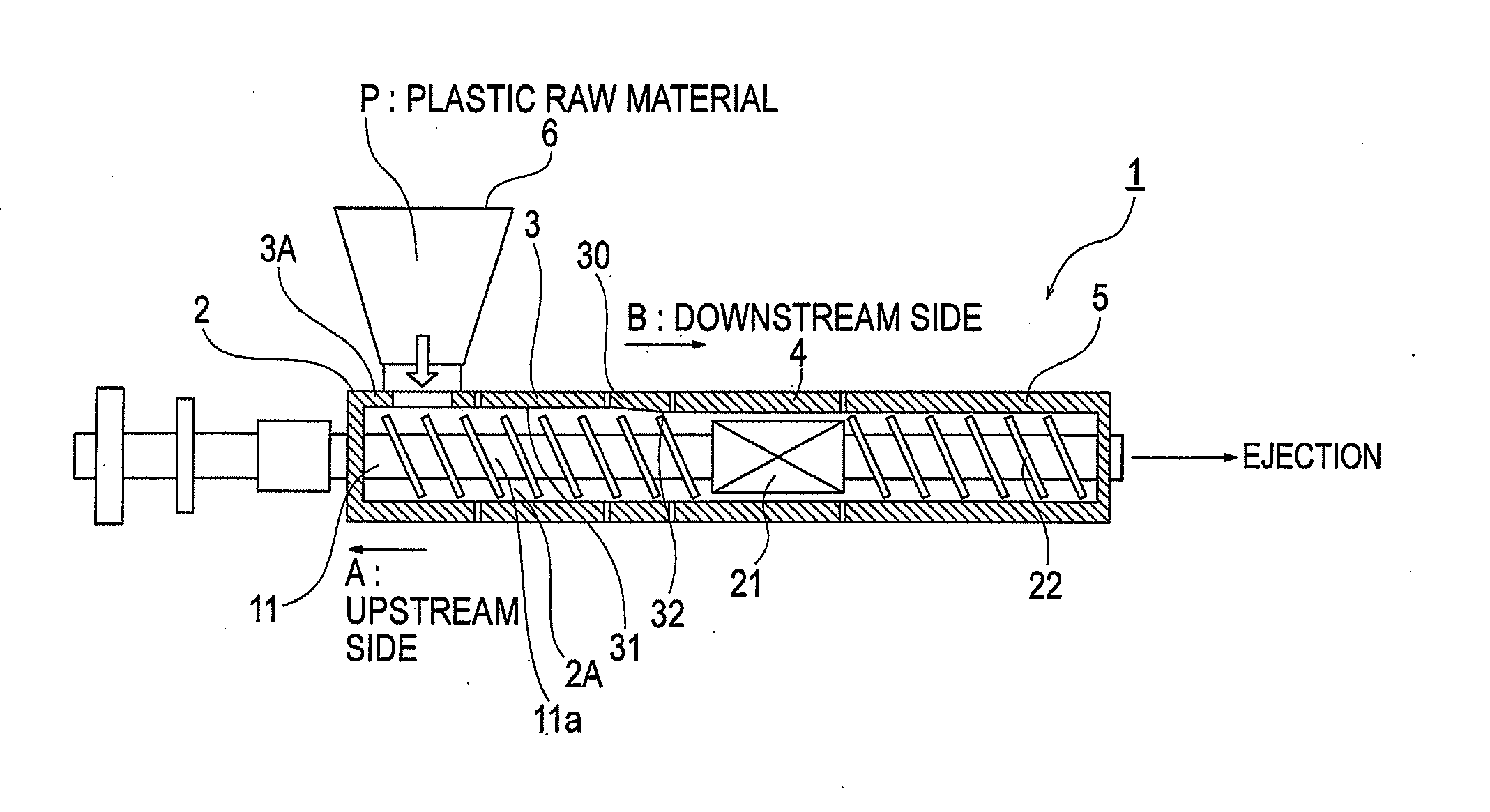

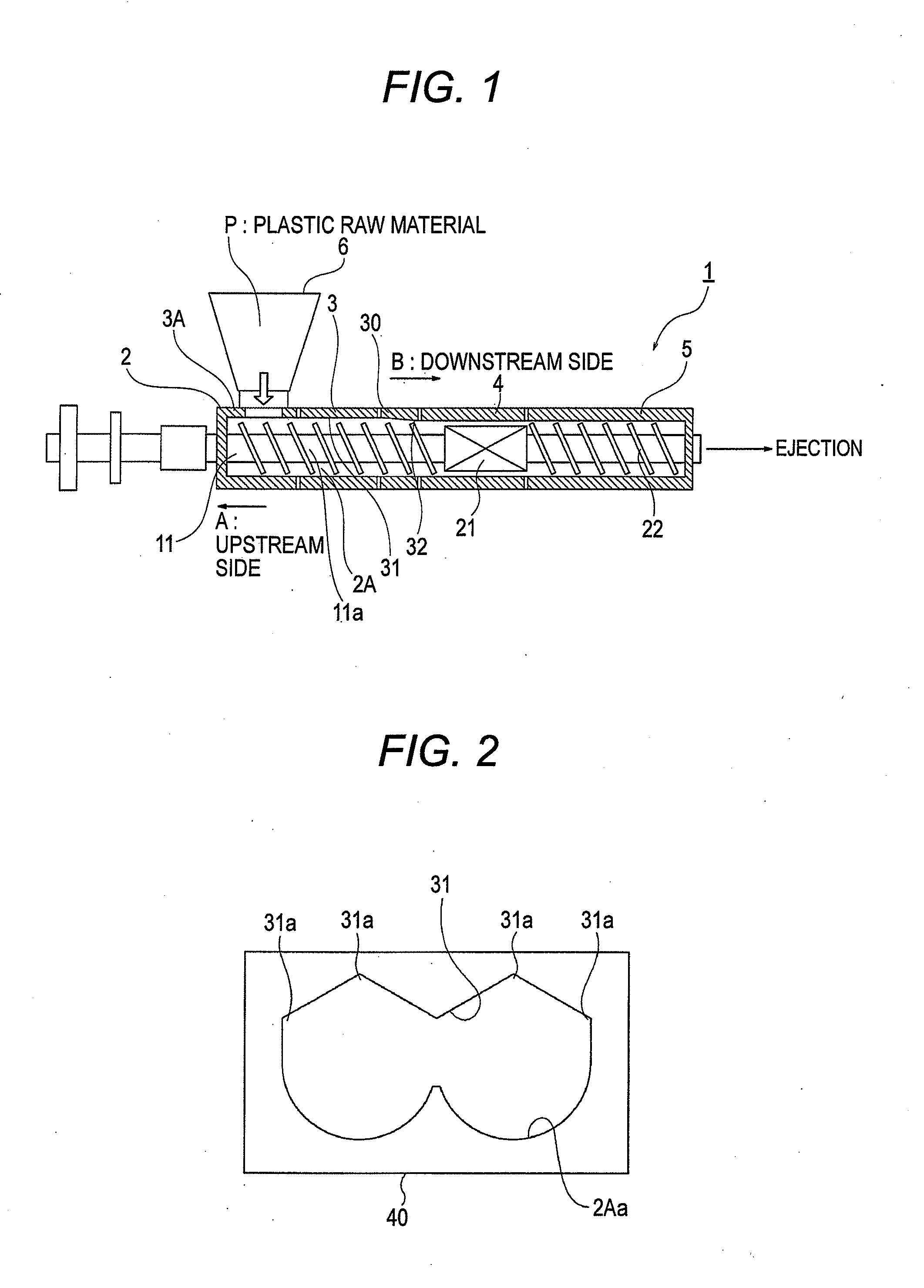

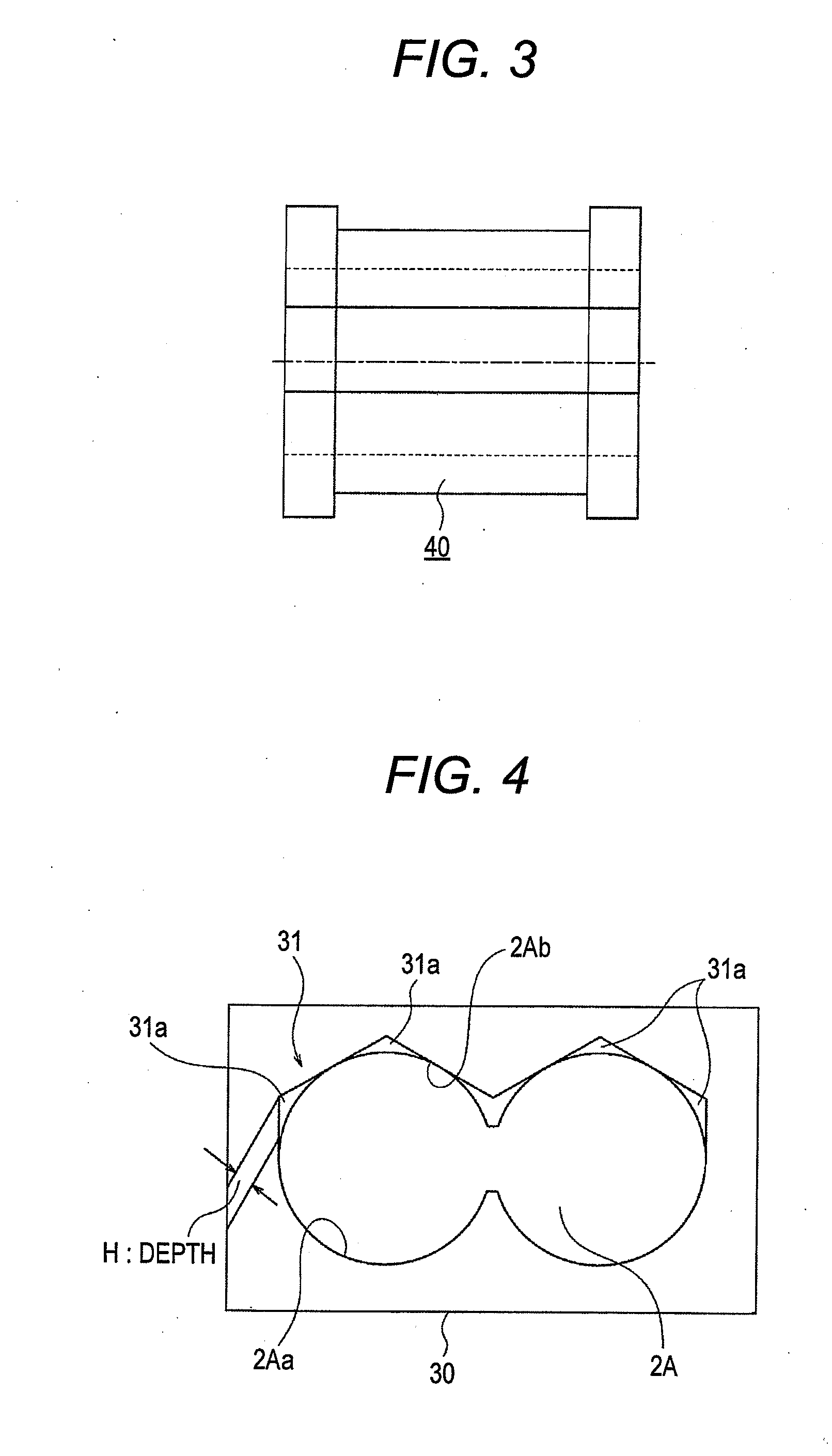

Apparatus and method for plastic extrusion

ActiveUS20120081989A1FrictionalImprove abilitiesRotary stirring mixersMixing/kneading with aerating apparatusFrictional coefficientEngineering

An object of the invention is to improve capacity of process and not require a vent portion by an upper polygonal groove and a transition portion provided to a transport cylinder.A plastic extrusion method and apparatus according to the invention is a method and a configuration, in which an upper polygonal groove and a transition portion are integrally or separately provided to a transport cylinder so as to increase a frictional coefficient of an inner wall of the cylinder, to increase transport efficiency of a plastic raw material by a screw, and to allow at least gas, etc., pass toward a hopper side without using a vent portion.

Owner:JAPAN STEEL WORKS LTD

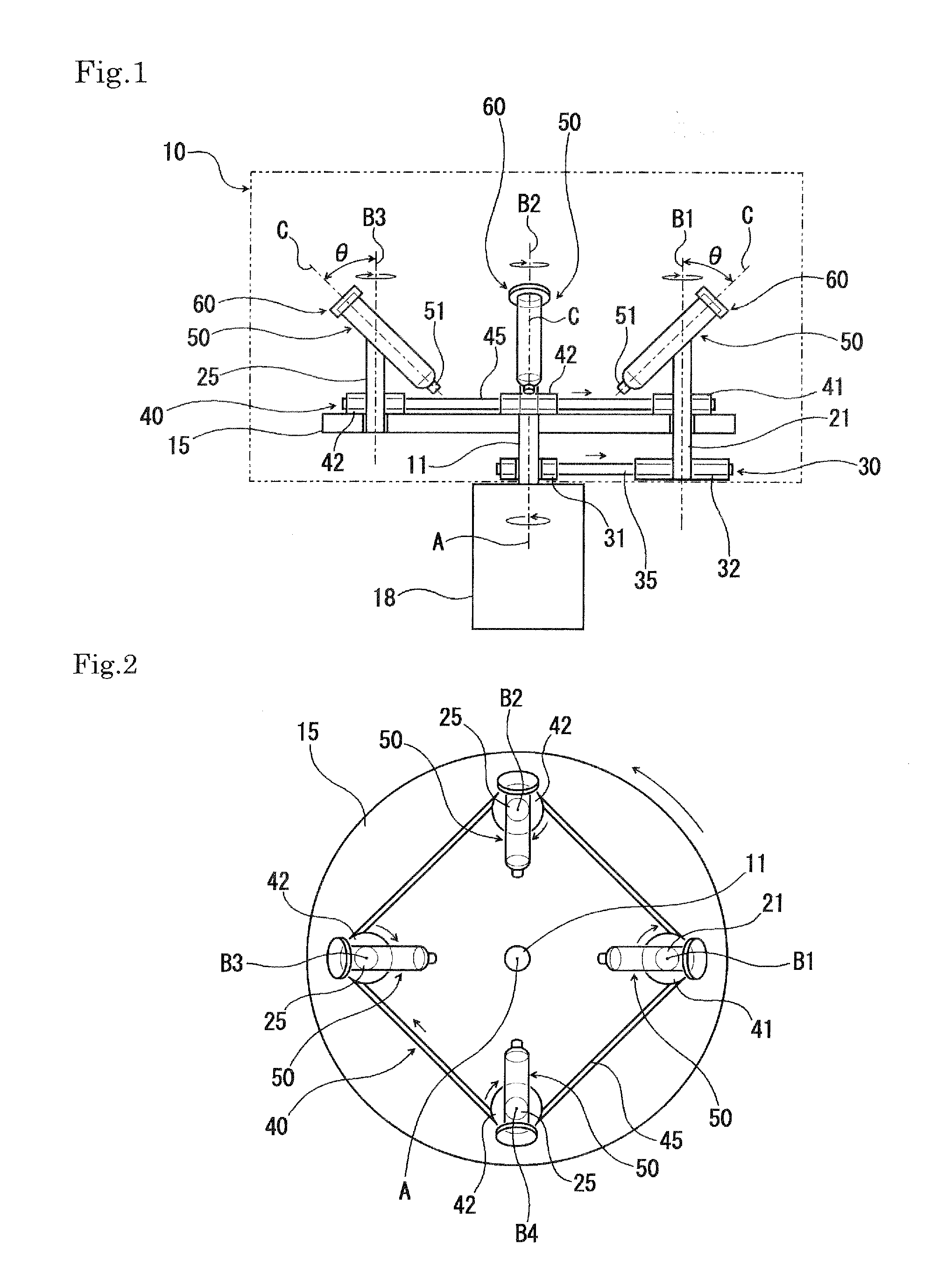

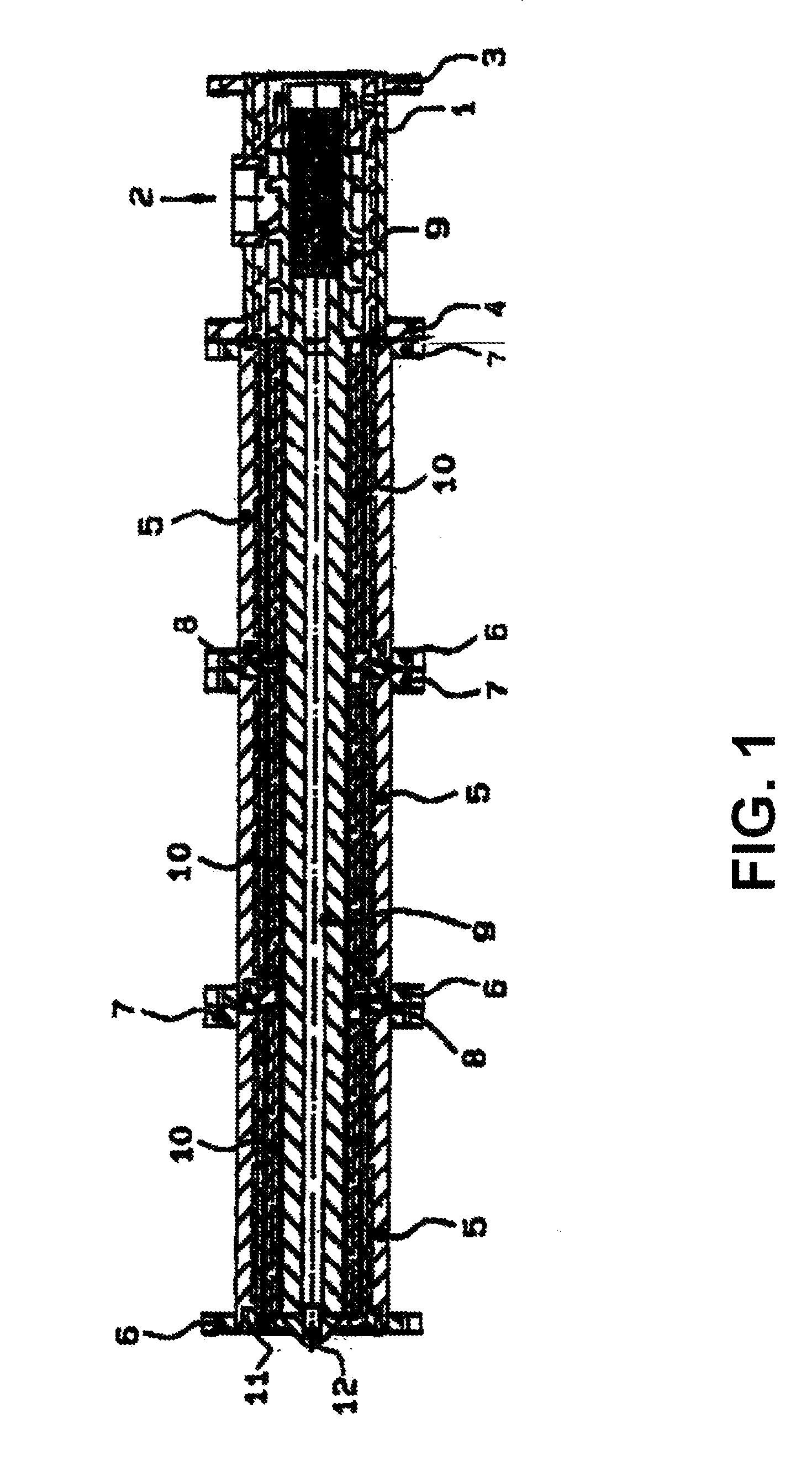

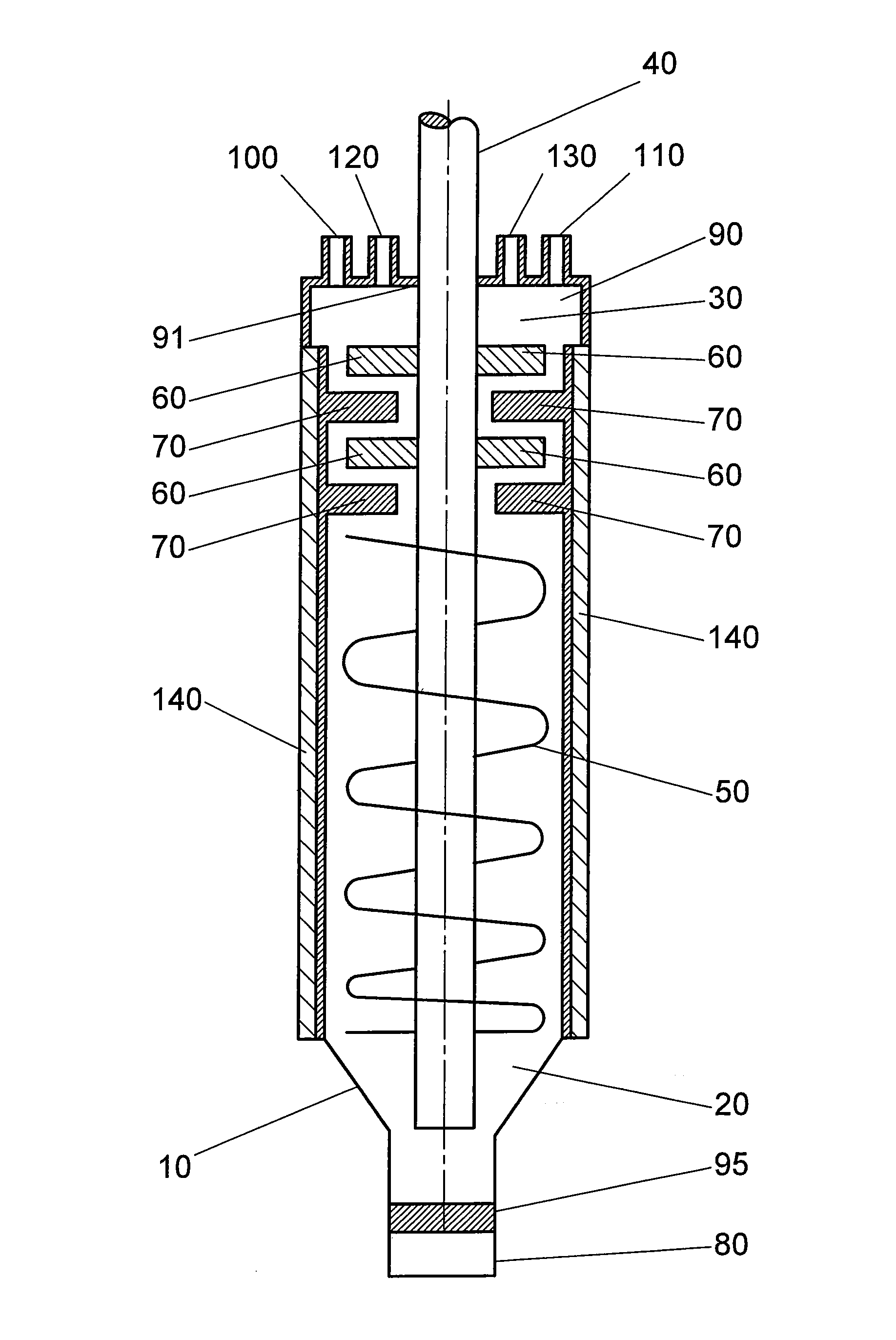

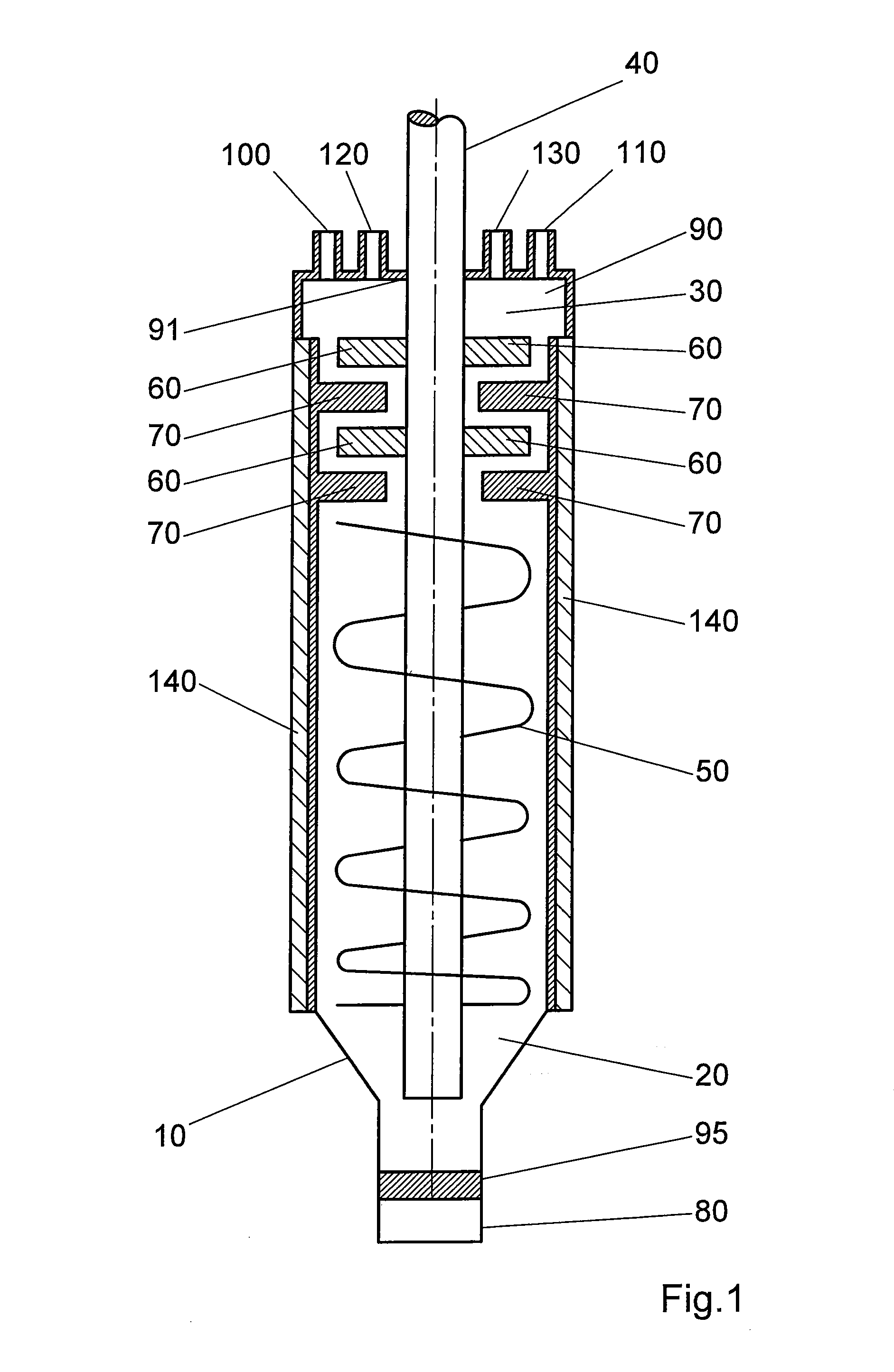

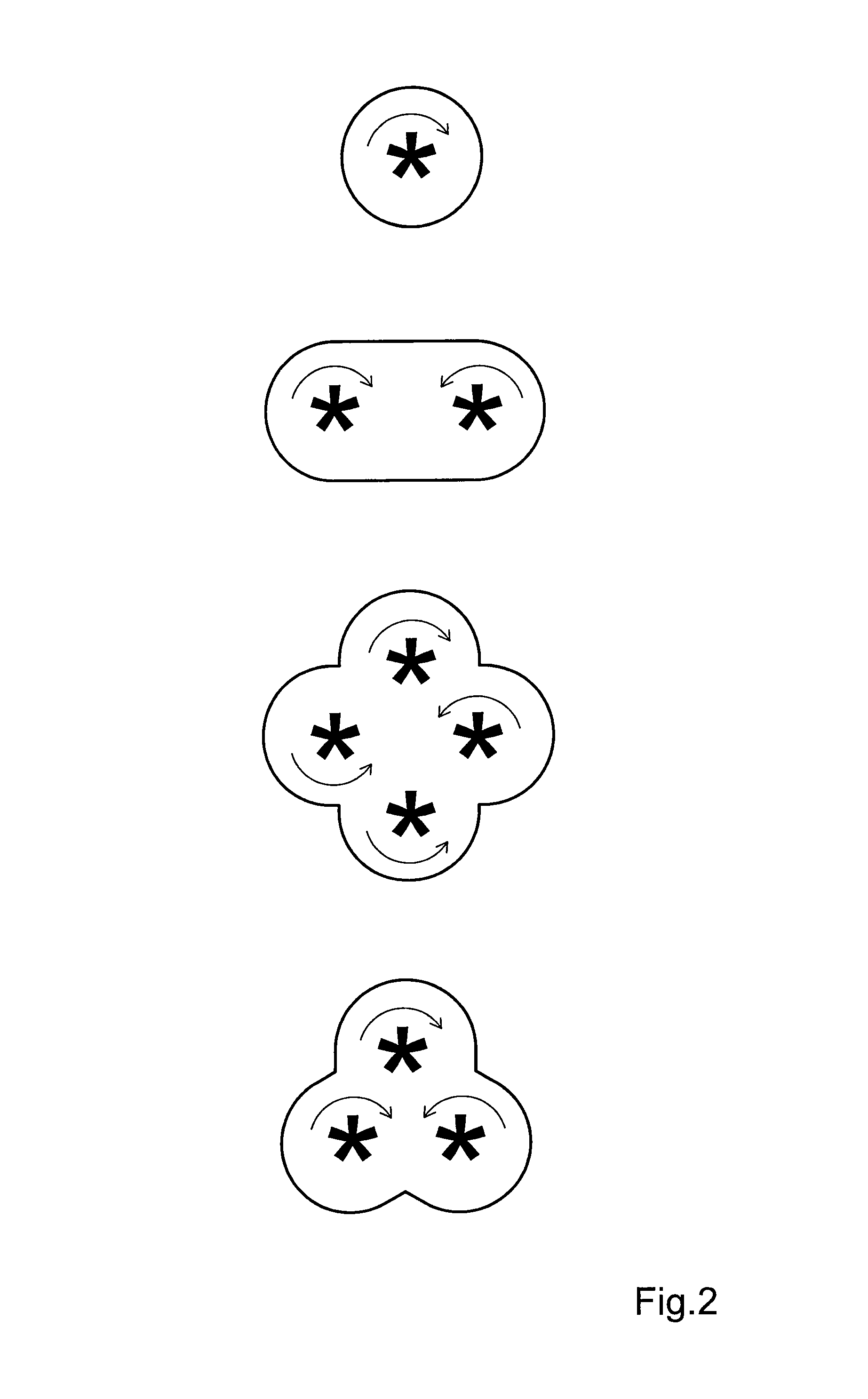

PMMA bone paste mixing apparatus and method

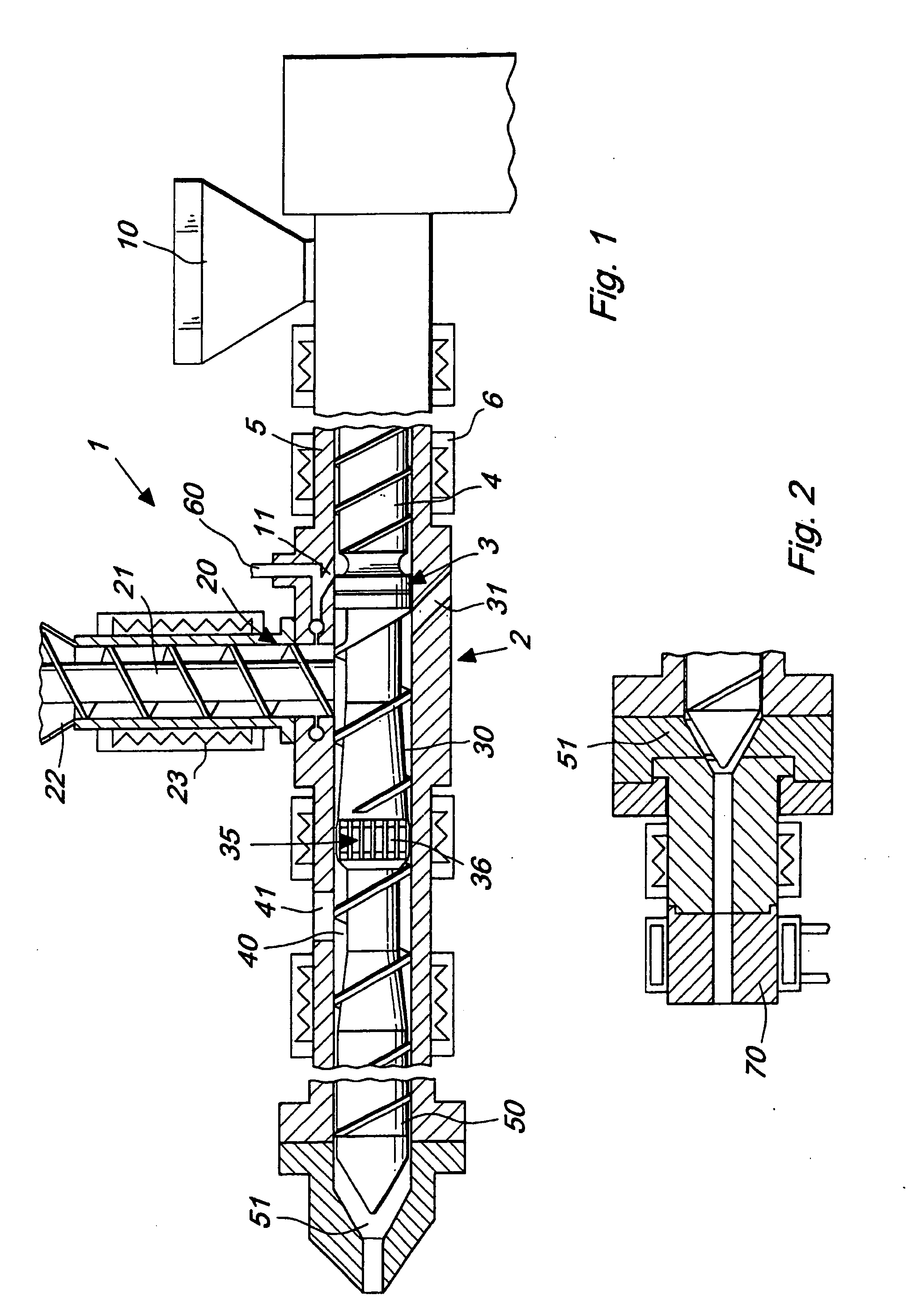

A device is provided with which it is possible to produce poly(methyl methacrylate) bone-cement paste, which is degassed to the greatest extent possible, while avoiding large-volume mixing containers and large cement volumes contained therein. The device includes a tubular hollow body (10) having a first opening (30) on the input side and a second opening (20) on the output side, at least one rotatably-mounted shaft (40) arranged in the axial direction in the tubular hollow body (10), thread turns (50) arranged axially along the outer side of the shaft (40), wherein the shaft (40) has at least one section with thread turns (50) whose pitch decreases in the direction of the second opening (20), at least one stirring blade (60) arranged on the shaft (40), and rigid mixing elements (70) arranged on the inner side of the tubular hollow body (10).

Owner:HERAEUS MEDICAL

Clay mixing apparatus

ActiveUS9016927B2Efficient removalSuppression of distortionDischarging apparatusRotary stirring mixersEngineeringMechanical engineering

Owner:NIDEC SHIMPO CORP

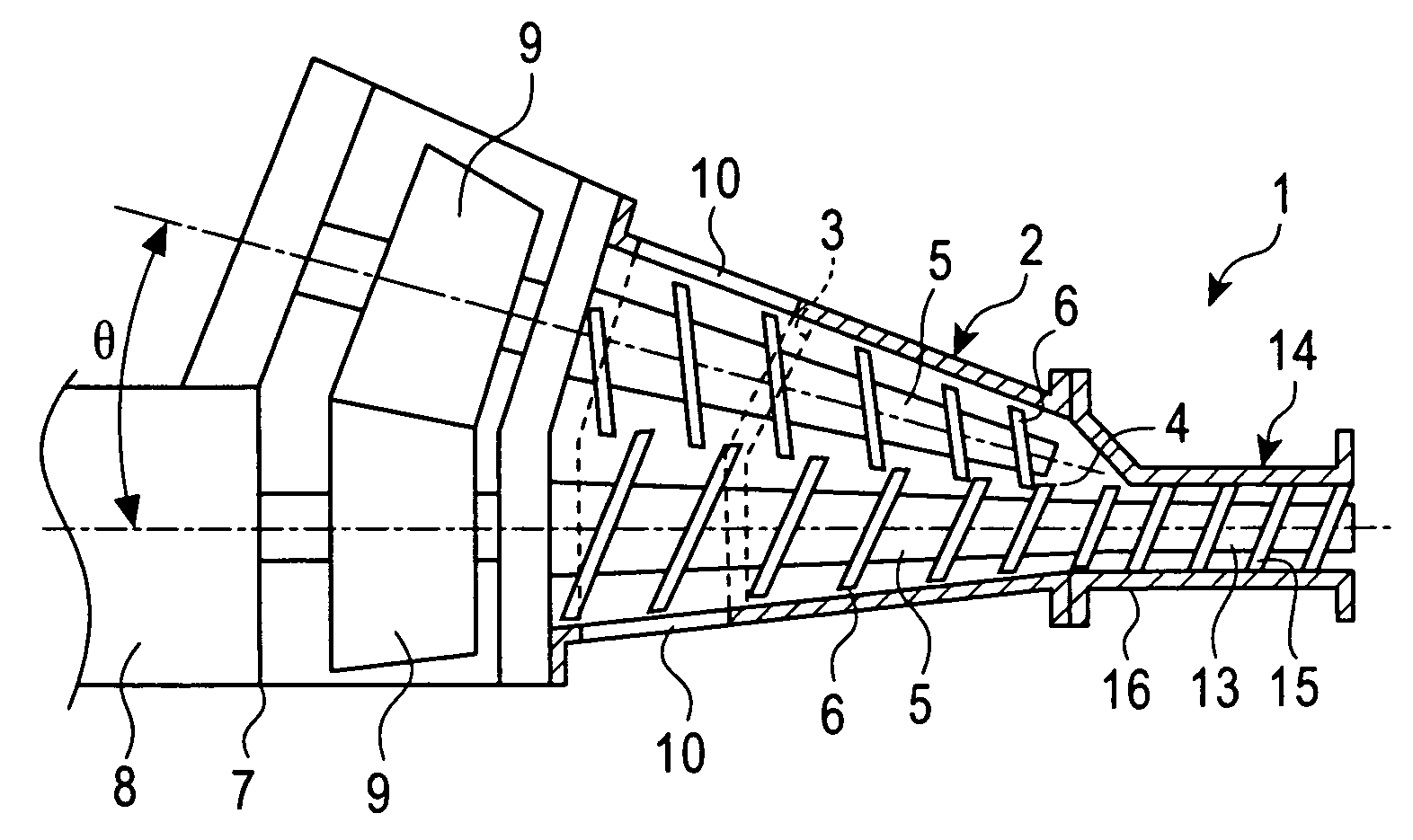

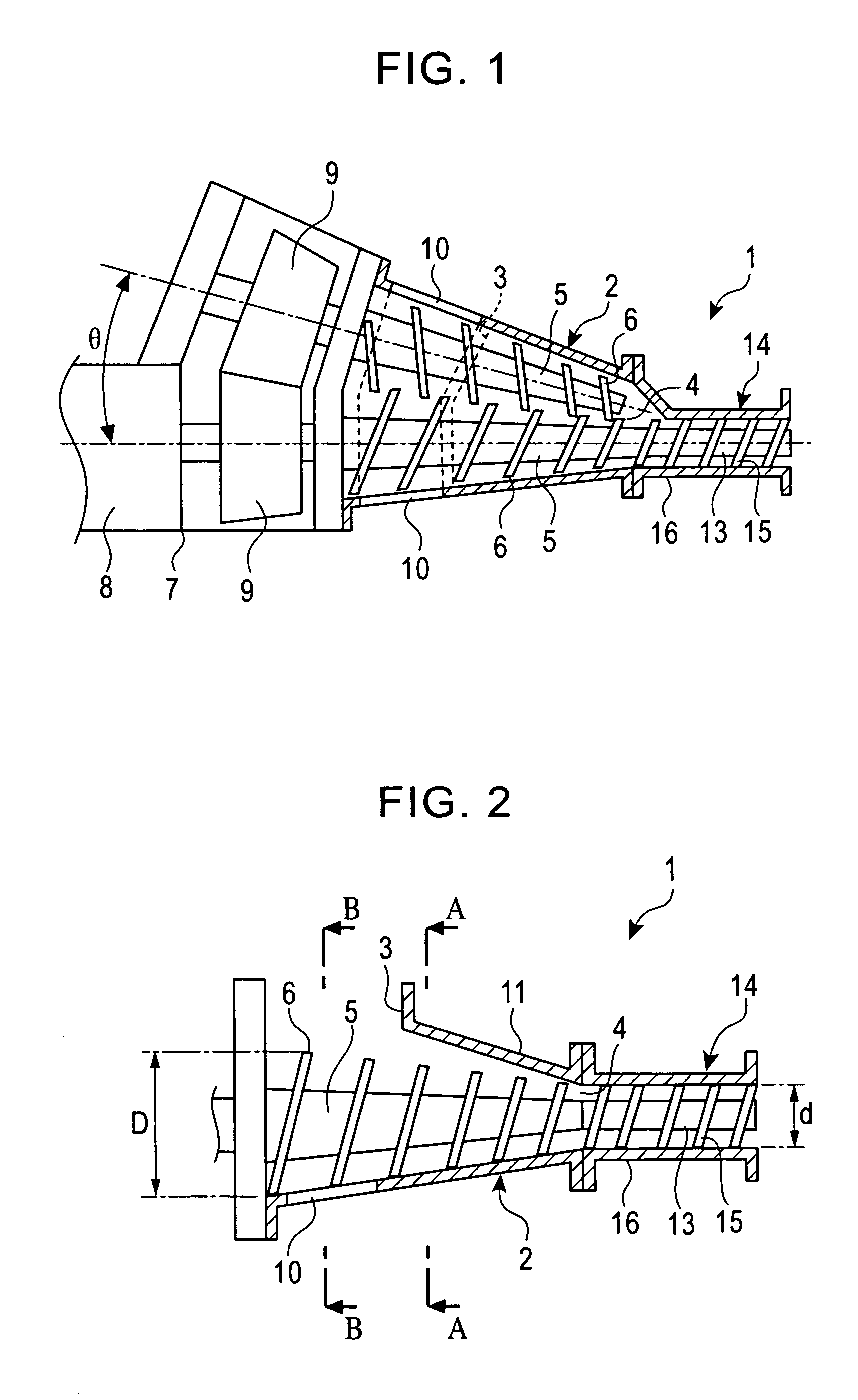

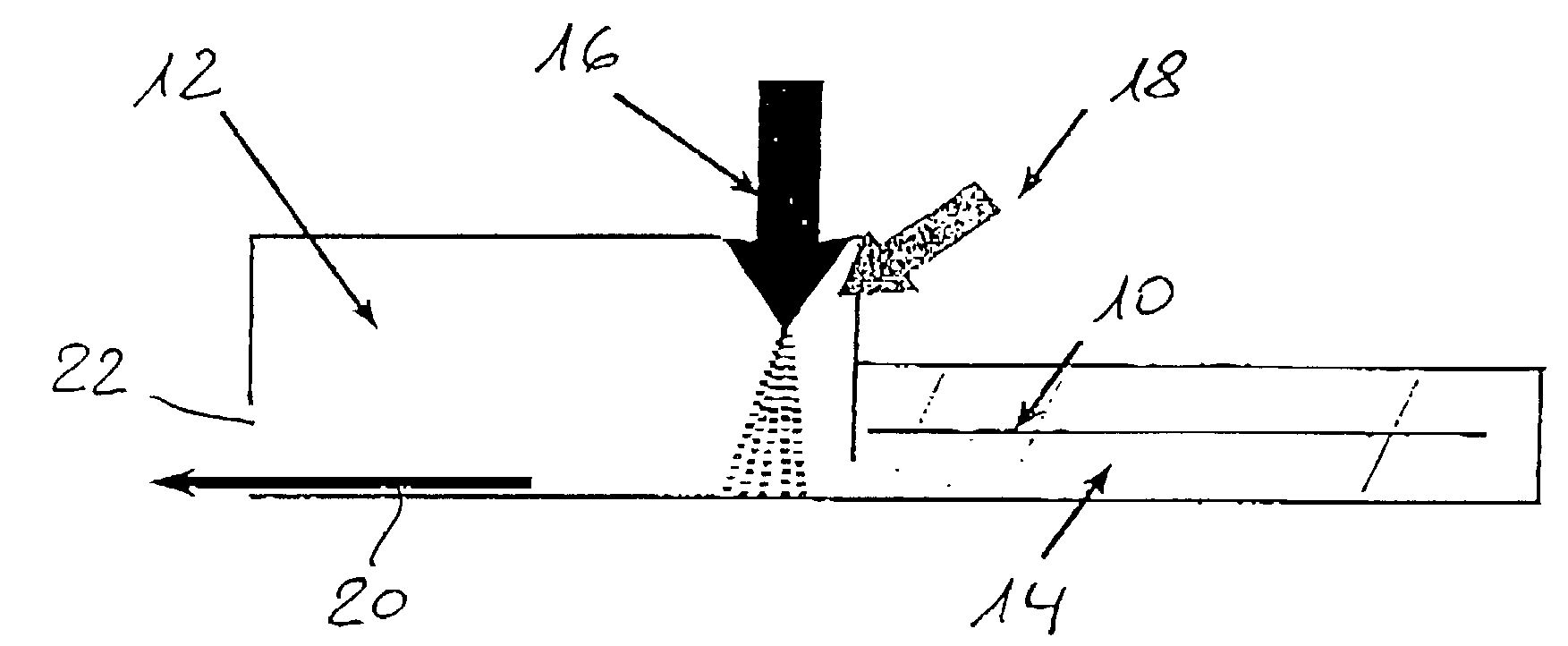

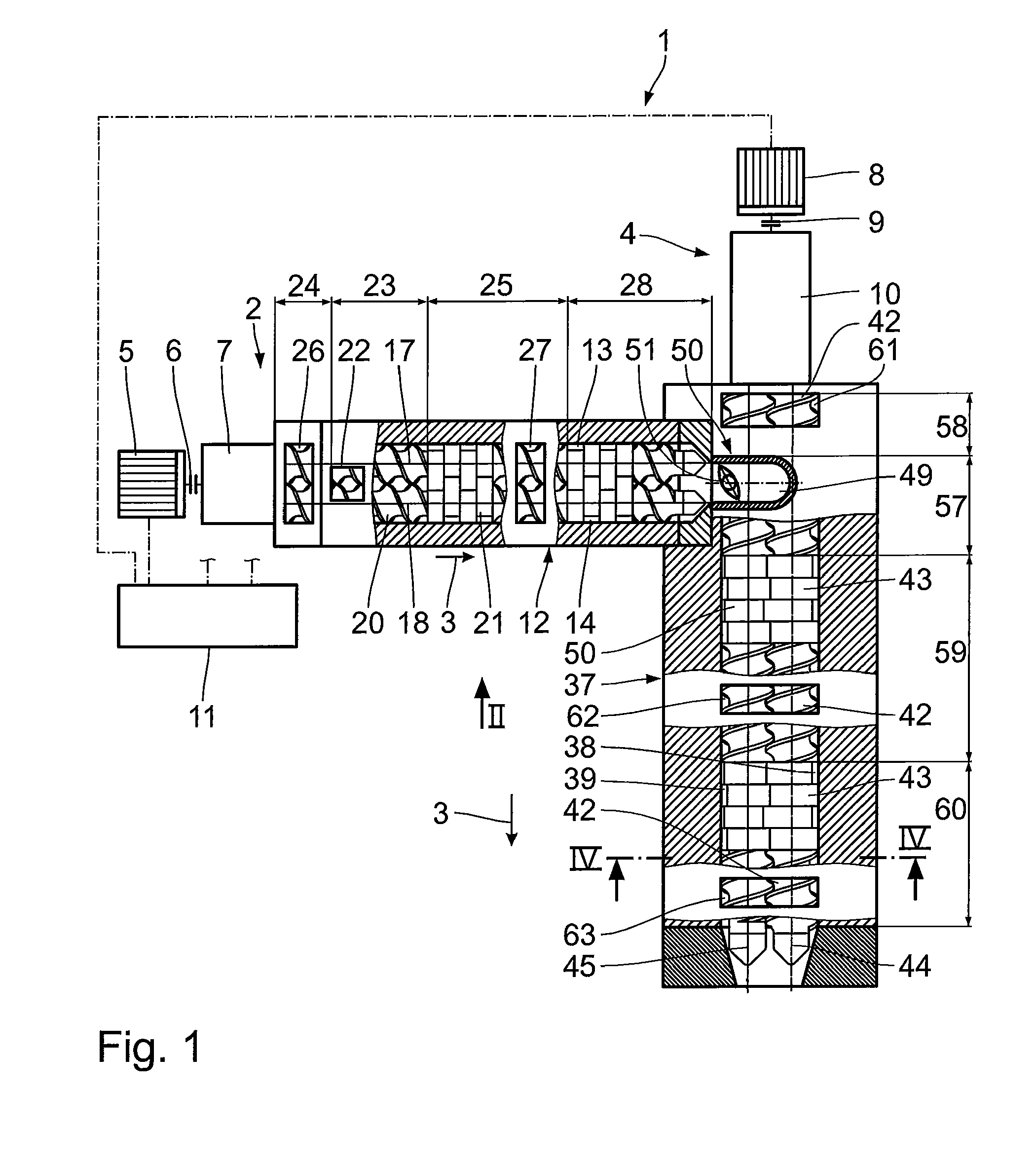

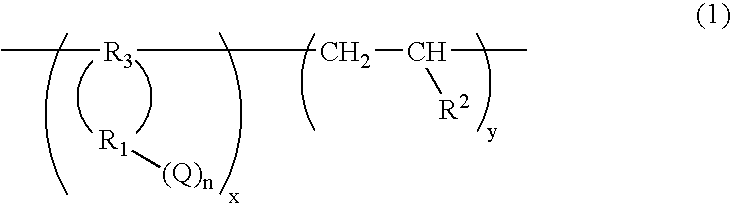

Process for Producing Cycloolefin Resin Composition

ActiveUS20070299199A1Reduce volatilityLess deteriorationRotary stirring mixersMixing/kneading with horizontally-mounted toolsPolymer scienceTwin screw extruder

A process for producing a cycloolefin resin composition comprising a cycloolefin resin and an additive by using a twin-screw extruder is provided, in which loss of the additive caused by volatilization through a vent during kneading is reduced and kneading of resin material with the additive can be sufficiently carried out. When the cycloolefin resin and the additive are kneaded by using a vented twin-screw extruder (10) to produce the cycloolefin resin composition containing the additive, an additive introduction opening (3) is disposed downstream of a vent (2) located nearest to a discharge opening (13) of the twin-screw extruder, and the additive is charged through the additive introduction opening located at a distance from the discharge opening of the twin-screw extruder in the range between longer than 10D and not longer than 30D.

Owner:MITSUI CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com