Full-automatic cake beating machine

A whisker, fully automatic technology, applied in the direction of mixing/kneading with additional inflatable equipment, mixing/kneading with vertical installation tools, etc., can solve the problems of enterprise cost increase, early operation personnel, etc., and achieve saving production The effect of cost, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, illustrate the specific embodiment of the present invention.

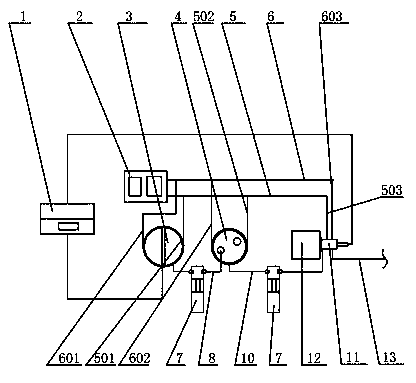

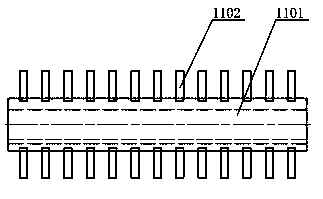

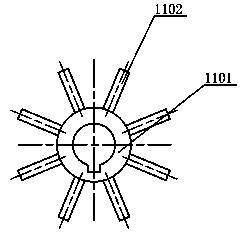

[0019] Such as figure 1 Shown, the present invention comprises control cabinet 1, and control cabinet 1 is respectively connected stirring power source and hair head power source 12, and stirring power source is a stirring motor, and hair head power source 12 is a hair motor. Connect the stirrer at the output end of the stirring power source, and place the stirrer in the mixing tank 3; The input of gas when the tooth stick hair head is working; the mixing tank 3 and the mace hair head 11 are respectively connected to the storage tank 4 through the transmission pipeline 10, the rotor delivery pump 7; The machine is connected to the external water source through the water inlet pipe 5 and the water return pipe 6, such as figure 1 As shown, on the water inlet pipe 5, a first water inlet branch 501 is formed to connect with the mixing tank 3, a second water inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com