Material inflation method and device

A material and mixed material technology, applied in chemical instruments and methods, mixing/kneading with additional inflatable equipment, food science, etc., can solve the problem of inability to fully mix a large amount of gas with materials and gas, limited gas volume, etc. The material is not easy to gas mixing and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

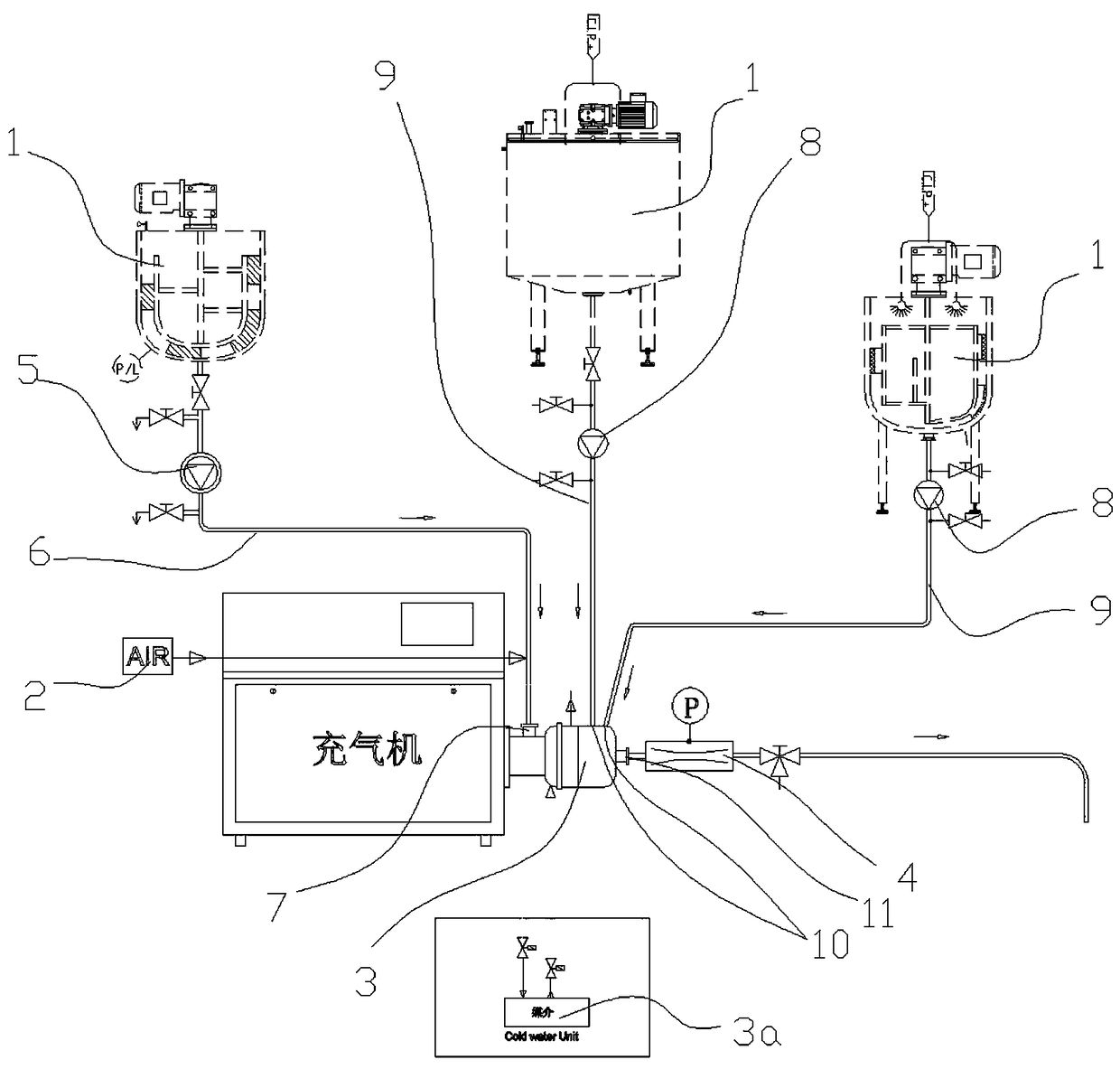

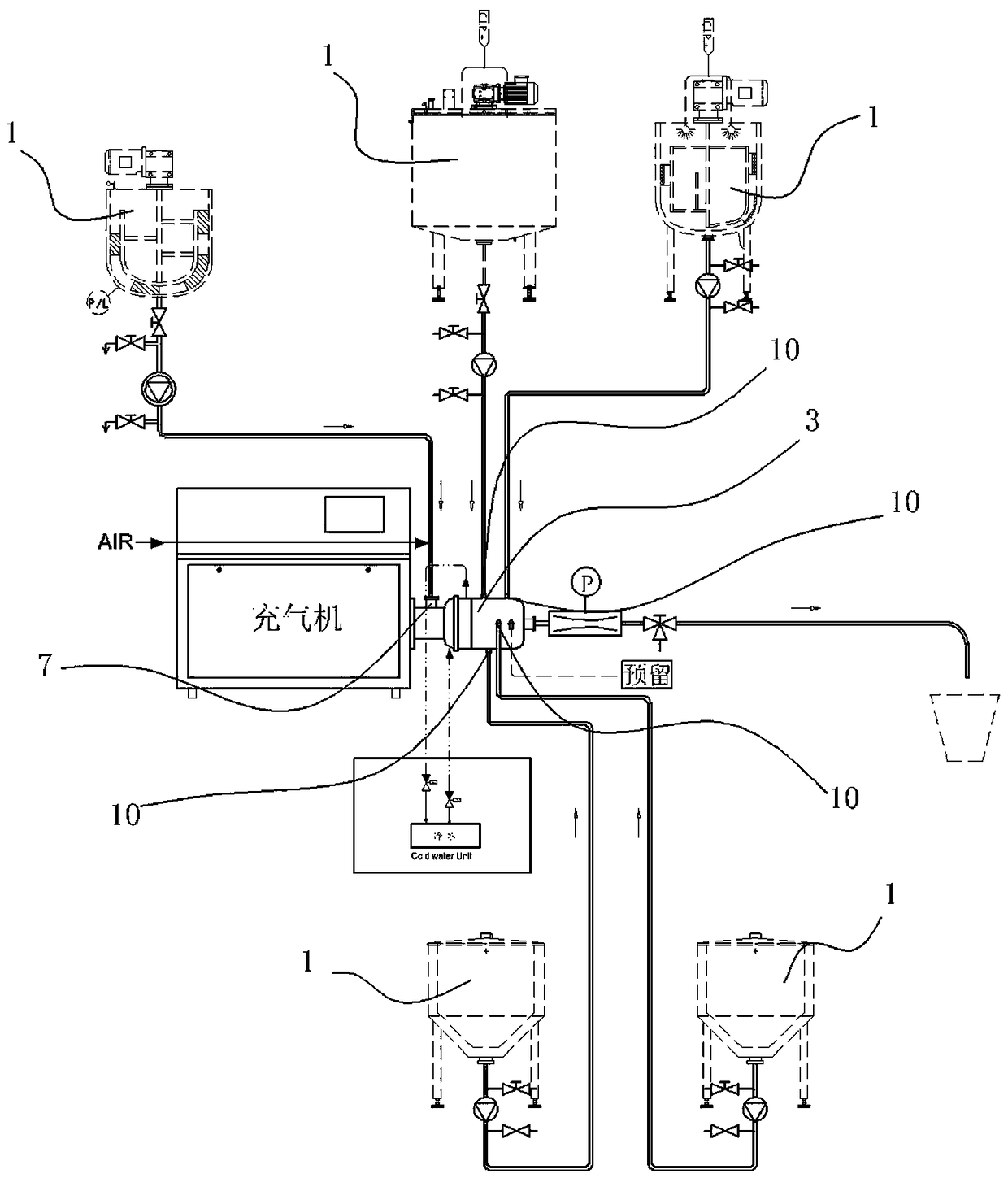

[0012] Such as figure 1 As shown, the material inflation device of the present invention is realized in this way, including more than two kinds of material storage tanks 1, a gas source 2, a liquid fluid and gas mixer 3 with a medium temperature regulating mechanism 3a, and a pressure regulator 4, which are particularly The advantage is that the material storage tank 1 for loading materials that are easily mixed with gas is connected to the liquid fluid and the front material inlet 7 of the gas mixer 3 through the first delivery pump 5 and the first delivery pipe 6, and the gas source 2 is introduced into the gas In the first conveying pipe 6, another material storage tank 1 is connected to the material inlet 10 of the rear section of the liquid fluid and gas mixer 3 through the second conveying pump 8 and the second conveying pipe 9, and the mixture of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com