Multi-coating core-spun yarn and preparing machine thereof

A technology of core-spun yarn and preparation machine, applied in the field of core-spun yarn, which can solve problems such as low production efficiency, high cost, and poor practicability, and achieve the effects of ensuring product quality, reducing processing costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

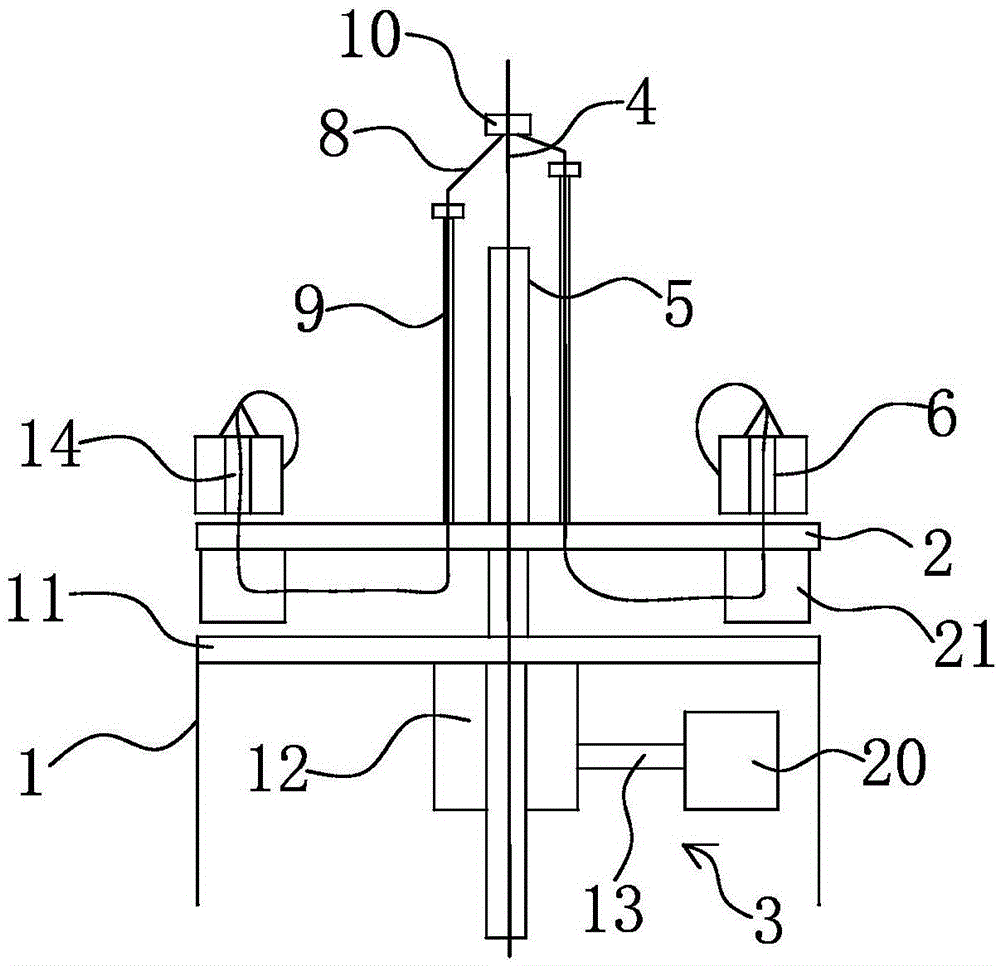

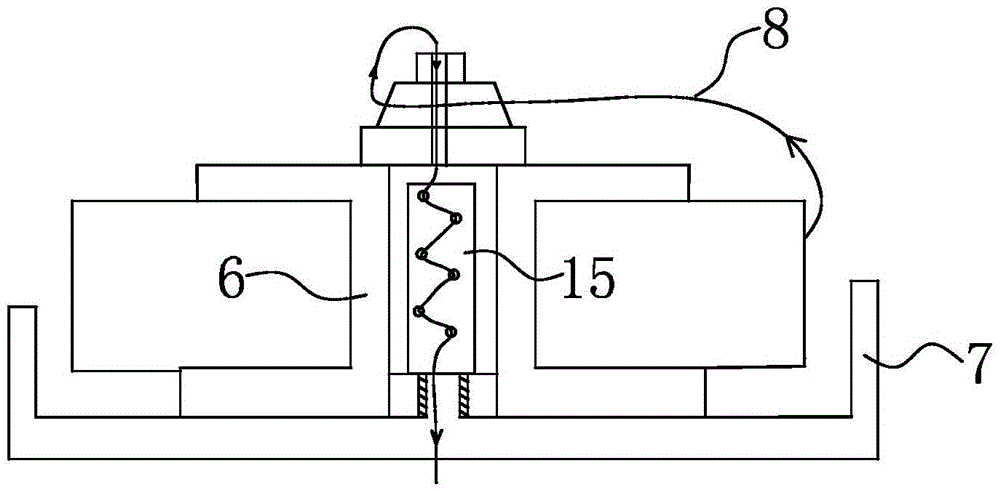

[0026] Such as Figure 2-4 As shown, the multi-coated core-spun yarn preparation machine includes a frame 1, on which a turntable 2 is rotatably connected, and the turntable 2 is connected with a driving mechanism 3, and a center yarn 4 is fixed on the turntable 2 from bottom to top. The central bobbin 5 passed through, the rotary table 2 is provided with at least one spindle 7 for placing the bobbin 6 on the periphery of the central bobbin 5, and the rotary table 2 is also fixed with a number of wrapped yarns for release from the bobbin 6 The thread passing needle tube 9 through which the thread 8 passes from bottom to top, the thread passing needle tube 9 is arranged in one-to-one correspondence with the spindle 7 and is located between the spindle 7 and the central bobbin 5, and the thread passing needle tube 9 moves clockwise or counterclockwise in the circumferential direction The height increases or decreases sequentially so that the wrapping points of each wrapping yarn...

Embodiment 2

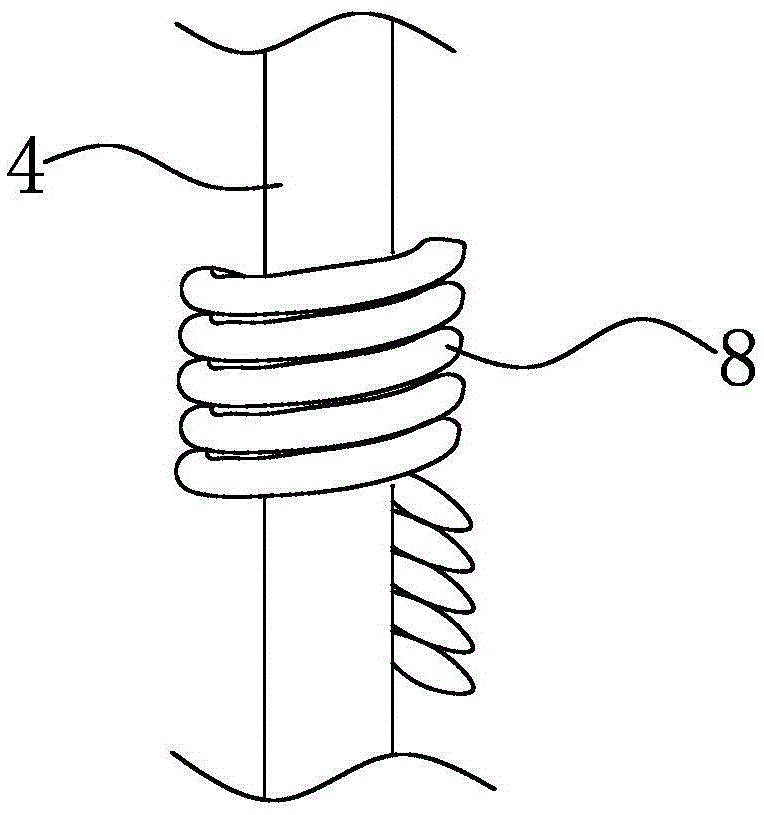

[0032] Such as figure 1 As shown, the multi-coated core-spun yarn produced by the multi-coated core-spun yarn preparation machine is characterized in that the multi-coated core-spun yarn includes a central yarn 4, and the outer periphery of the central yarn 4 is spirally wrapped with several wrapped yarns 8, each The helical wrapping directions of the covering yarns 8 are the same, and each covering yarn 8 is arranged side by side along the axial direction of the central yarn 4 in sequence. The thread-passing needle tubes 9 are arranged circumferentially and their heights increase or decrease sequentially, so that the wrapping points of each wrapped yarn 8 and the center yarn 4 are arranged in sequence along the axis of the center yarn, and multiple center yarns 4 are juxtaposed at the same time to form a "belt". Shape" to ensure that there will be no gaps between the center yarns 4, which is conducive to improving the production efficiency of the multi-coated core yarn and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com