Board flatness detection device

A detection device and flatness technology, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of decorative paint cracks, affecting the decorative function of wooden boards, falling, etc., achieving low manufacturing cost, simple structure, and increased firmness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

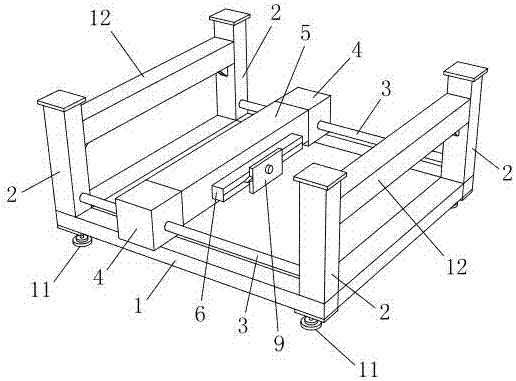

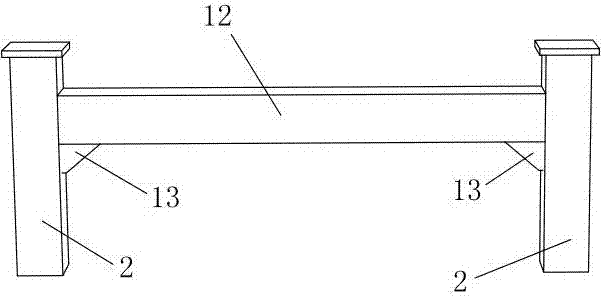

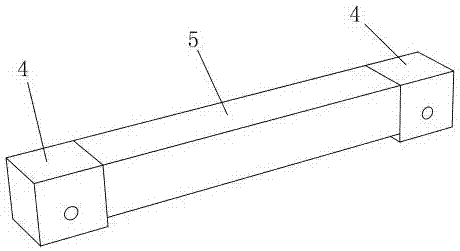

[0019] Such as Figure 1 to Figure 4 As shown, it is a plank flatness detection device of the present invention, including a base 1, the bottom of the base 1 is provided with legs 11, and the legs 11 are screwed to the four corners of the base 1 respectively, by setting the legs 11 of the same height, the The base 1 is adjusted to a horizontal position, and the support feet 11 are made of rubber material, which has a certain friction force, and the support feet 11 can be attached to the ground to prevent the base 1 from moving. The base 1 is provided with a support rod 2, and a connecting rod 12 is arranged between two adjacent support rods 2 along the width direction of the base 1. The connection effect improves the stability of the whole device. A reinforcing plate 13 is welded between the supporting rod 2 and the connecting rod 12. The reinforcing plate 13 generally adopts a triangular shape to increase the connection between the supporting rod 2 and the connecting rod 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com