Controllable degrading magnesium-based metal material

A magnesium-based metal and amino technology, which is applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems of unreachable and prolonged degradation time of magnesium-based metal materials, and achieve low preparation temperature and high production efficiency. The process is easy to control, avoiding the effects of pyrolysis and excessive thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0031] Preparation of SiO2-enriched nano-bioactive glass particles

[0032] Disperse 10 g of ethyl orthosilicate, 0.85 g of triethyl phosphate, 0.8 g of calcium bicarbonate, 8.0 g of nitric acid tetrahydrate, and 0.8 g of citric acid in absolute ethanol in a round-bottomed flask, stir at room temperature for 3 hours, and place in Seal and age at 60°C for 24 hours, take it out and transfer it to a dry pot to dry at 37°C for 24 hours, then put it in a muffle furnace for calcination at 600°C for 2 hours, take it out and use a ball mill to grind it to 40-100nm to obtain 5.8g of nano-bioactive glass.

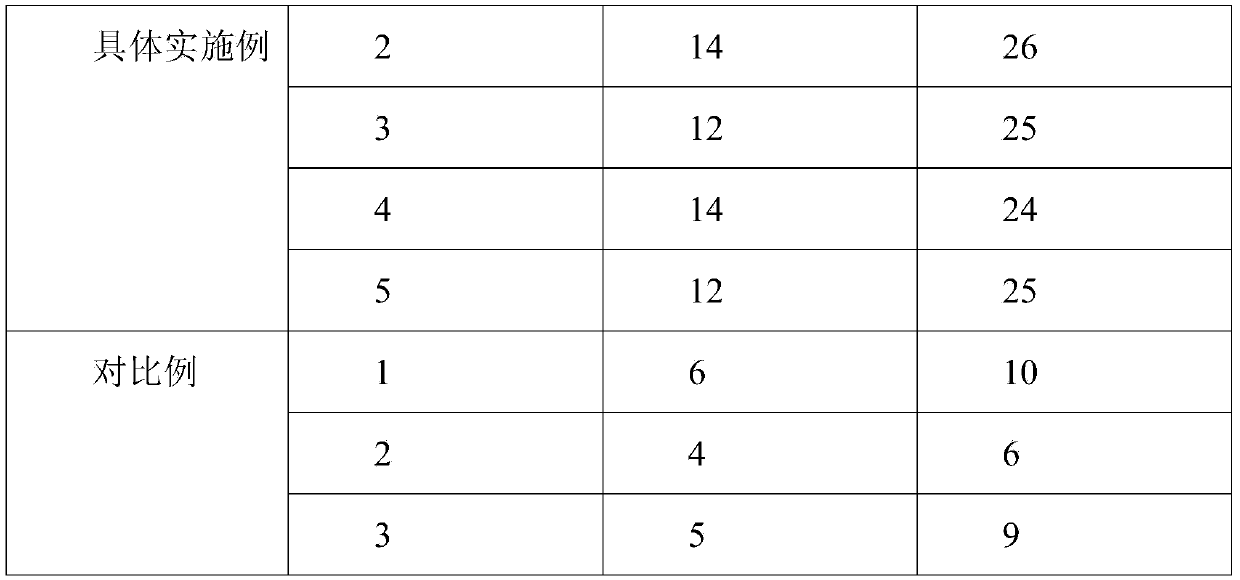

specific Embodiment 2

[0033] Nano-bioactive glass particles grafted with tannic acid.

[0034] Get 5 g of nano-biological glass particles obtained in Example 1, dry them, put them into a round bottom flask, disperse them in anhydrous toluene solution, add 37% tannic acid ring-opening polymerization of material quality under nitrogen protection, and react for 35 hours. The reaction product is washed several times with an organic solvent to obtain the grafted tannic acid nano-biologically active glass particles.

[0035] Then the composition of grafted tannic acid nano bioactive glass particles and arginine and lysine (wherein, the composition of arginine and lysine is 15% of the material quality) is dissolved and mixed evenly with dichloromethane A magnesium-based metal material is prepared.

specific Embodiment 3

[0036] Nano-bioactive glass particles grafted with tannic acid.

[0037] Prepare 5 g of nano-biological glass particles according to the method in Example 1, dry them in a round bottom flask, disperse them in anhydrous toluene solution, add 35% tannic acid ring-opening polymerization of the material mass under nitrogen protection, and react for 40 h , the reaction product is washed several times with an organic solvent to obtain the grafted tannic acid nano-biologically active glass particles.

[0038] Then, the nanometer bioactive glass particles of grafted tannic acid and arginine (wherein the arginine is 10% of the mass of the material) are dissolved and mixed with dichloromethane to prepare the magnesium-based metal material evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com