Preparation method of crystalline silicon solar cell passive film

A solar cell and passivation film technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of multiple impurities, dislocations and grain boundaries, low output power of polycrystalline silicon solar cells, and unsatisfactory passivation effect on the surface of silicon wafers, etc. problems, to achieve the effect of increasing output power and reducing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

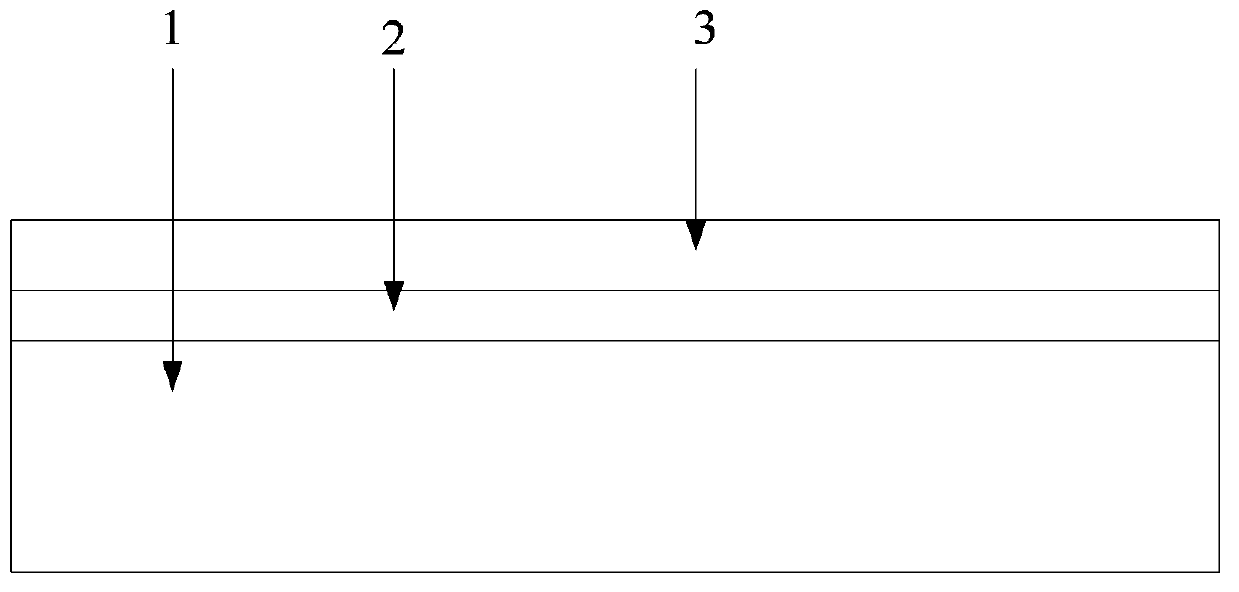

[0036] To this end, the invention discloses a method for preparing a passivation film for a crystalline silicon solar cell, comprising: pretreating a silicon wafer, forming an a-Si:H thin film on the surface of the silicon wafer, and forming an a-Si:H film on the surface of the a-Si: A SiNx:H film is formed on the surface of the H film and sintered.

[0037] As can be seen from the above scheme, the present application first forms a film layer on the surface of the silicon wafer mainly based on H, which plays a certain passivation effect on the surface of the silicon wafer, and then forms a SiNx:H thin film, and the H in the SiNx:H thin film It can play the role of secondary passivation on the surface of the silicon wafer, so that the passivation of the surface of the silicon wafer is more sufficient, and the defects such as impurities, dislocations and grain boundaries on the surface of the silicon wafer are reduced as much as possible. Compared with the existing anti-reflecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com