Fluoro-carbon preservative weather-resistant coating and preparation method thereof

A technology of weather-resistant coatings and fluorocarbons, applied in anti-corrosion coatings, polyester coatings, coatings, etc., can solve the problems of inelasticity, difficulty in construction, unstable performance, etc., and achieve good anti-corrosion performance, easy construction, and good protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

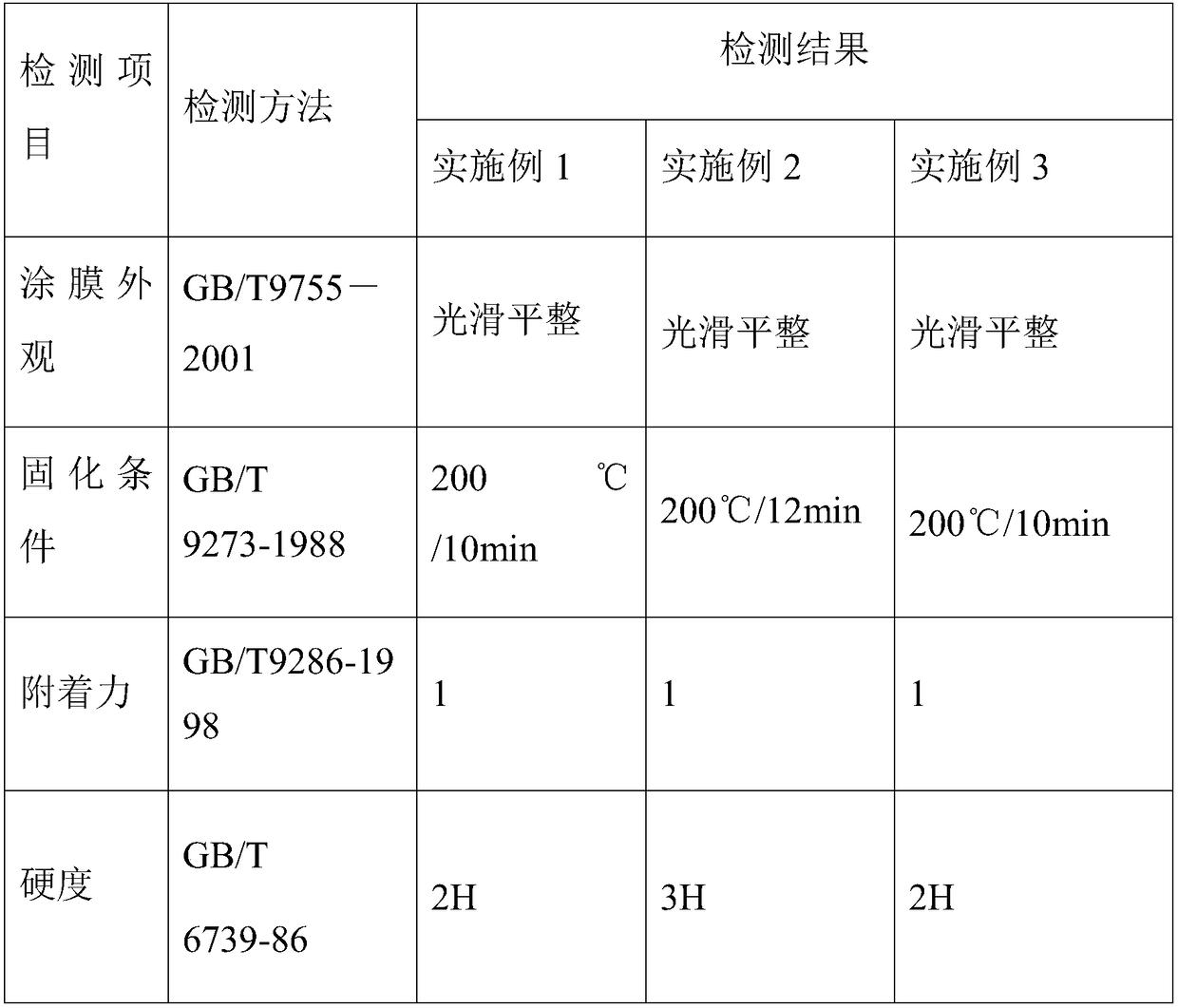

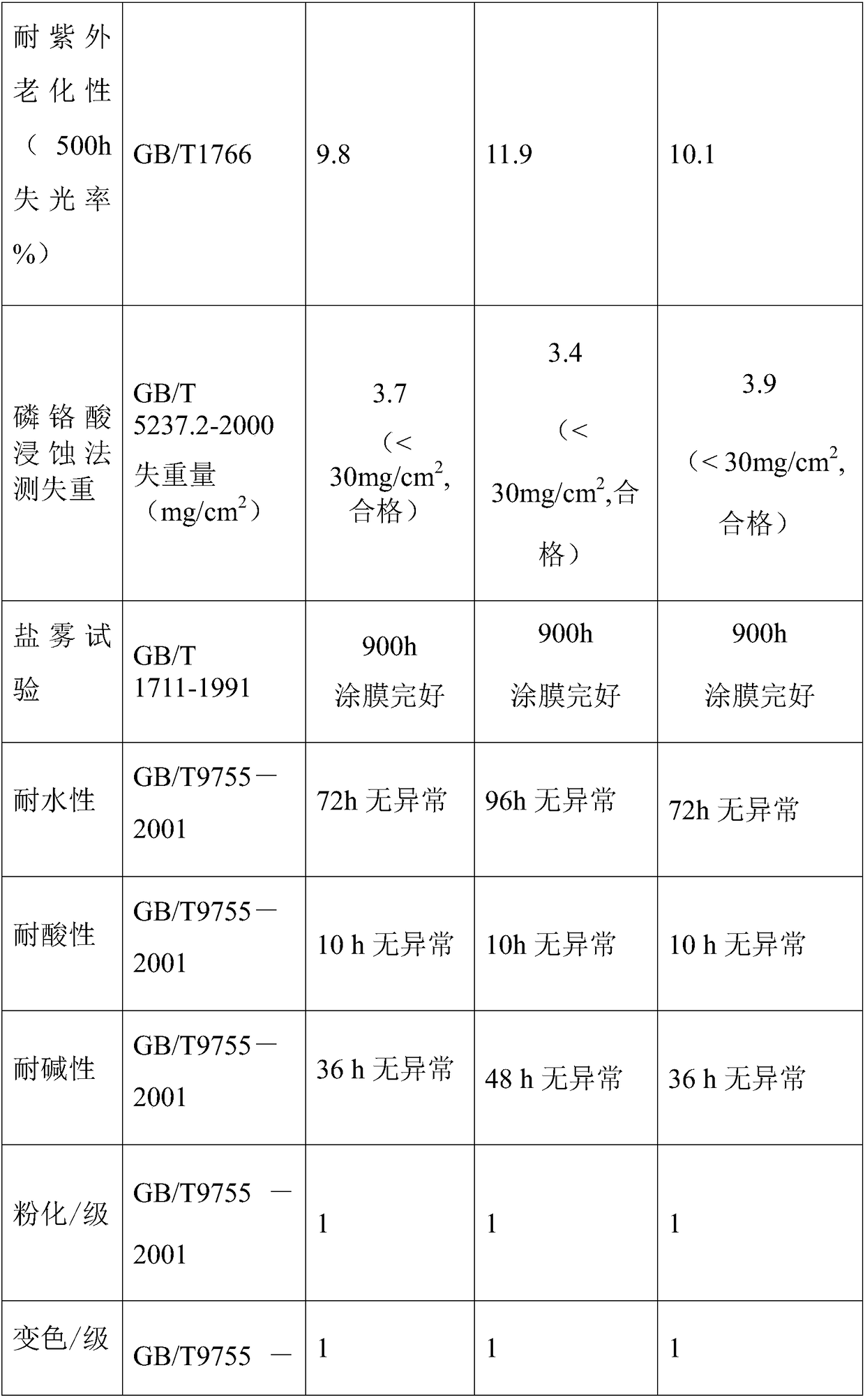

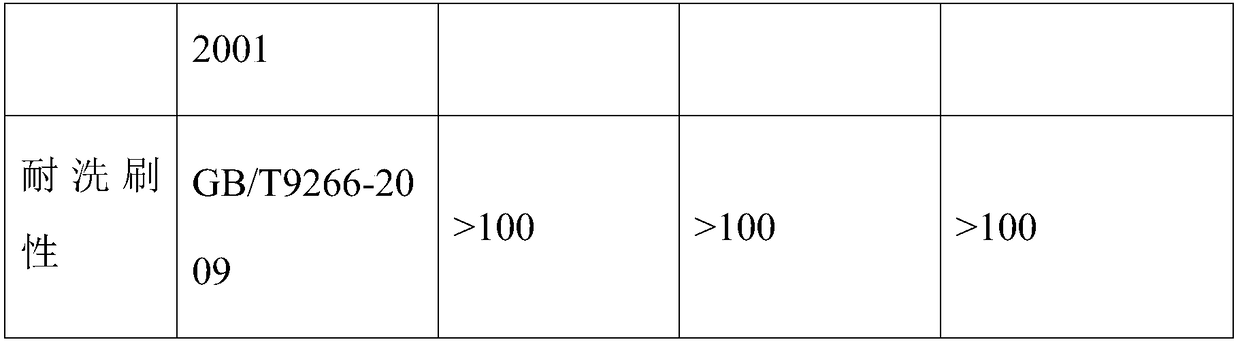

Examples

Embodiment 1

[0024] Weigh each component (parts by weight) according to the following formula: 15 parts of PVDF fluorocarbon emulsion, 12 parts of fluorine-modified acrylic emulsion, 5 parts of polyhydroxystyrene emulsion, 5 parts of alkyd resin emulsion, and 10 parts of modified graphene oxide solution. 1.5 parts of curing agent, 25 parts of pigments and fillers, 8 parts of additives, 10 parts of organic solvents (6 parts of xylene, 4 parts of N-methylpyrrolidone), 2 parts of 95% ethanol, and 5 parts of deionized water.

[0025] Prepare fluorocarbon anti-corrosion and weather-resistant coatings as follows:

[0026] (1) Preparation of modified graphene oxide solution: add graphene oxide into deionized water, shake well, prepare 0.5 mg / mL graphene oxide aqueous solution, and ultrasonically disperse the 0.5 mg / mL graphene oxide aqueous solution 45min; Dissolve PEG with a molecular weight of 1000 in deionized water to prepare a 0.5mg / mL PEG aqueous solution; drop the PEG aqueous solution into...

Embodiment 2

[0032] This example is basically the same as Example 1, the difference being: 1. When preparing the modified graphene oxide solution, 0.5 mg / mLPEG (molecular weight is 1500) aqueous solution is dropped into the graphene oxide aqueous solution at a volume of 0.1:1 , to obtain a modified graphene oxide solution; 2. Weigh each component (parts by weight) according to the following formula: 55 parts of PVDF fluorocarbon emulsion, 10 parts of fluorine-modified acrylic emulsion, 10 parts of polyhydroxystyrene emulsion, alkyd resin emulsion 15 parts, 20 parts of modified graphene oxide solution, 3 parts of curing agent (Desmodur3390), pigment and filler (5 parts of isocyanate modified nano-silica, 5 parts of rutile titanium dioxide, 5 parts of barite powder, 10 parts of mica powder parts) 25 parts, additives 10 parts (wetting and dispersing agent sago-3550 1.5 parts / sago-3500 1.5 parts, anti-settling agent BYK-410 0.5 parts, leveling agent sago-3561 1 part, defoamer BYK-3455 1 part, ...

Embodiment 3

[0034] This example is basically the same as Example 1, except that when preparing a new type of fluorocarbon anti-corrosion and weather-resistant coating, the components (parts by weight) are weighed according to the following formula: 20 parts of PVDF fluorocarbon emulsion, fluorine-modified 8 parts of acrylic emulsion, 8 parts of polyhydroxystyrene emulsion, 8 parts of alkyd resin emulsion, 10 parts of modified graphene oxide solution, 1.5 parts of initiator, and 2 parts of curing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com