Method for controlling specific resistance of gallium-doped Czochralski silicon in crystal growth process

A crystal growth and resistivity technology, applied in the field of solar cell materials, can solve problems such as the inability to prepare high-efficiency solar cells, and achieve the effects of easy large-scale application, increased utilization, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

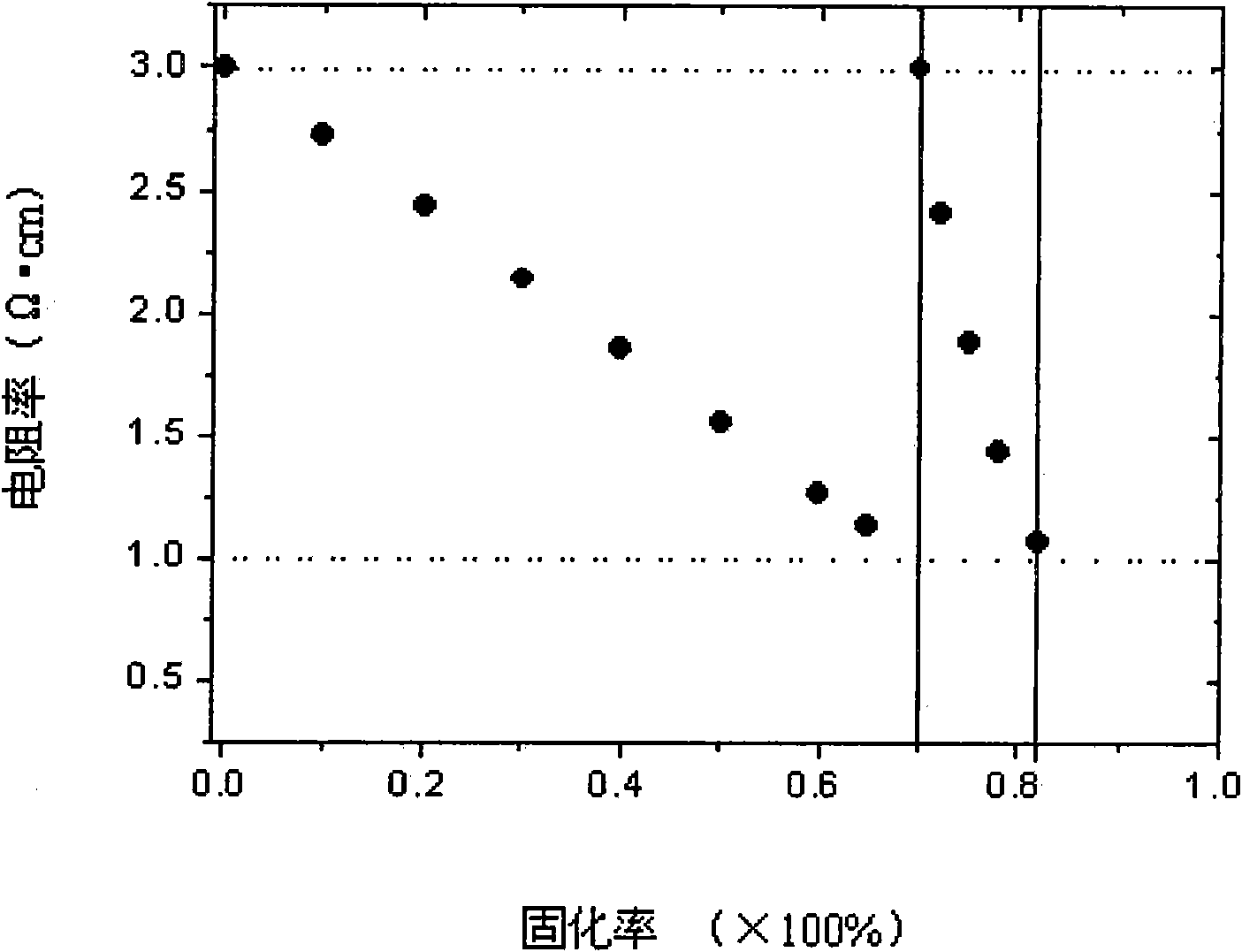

[0019] 50kg of polysilicon was put into a quartz crucible, and 1.365g of gallium was doped at the same time (making the target resistivity of the head of gallium-doped Czochralski silicon single crystal be 3Ω·cm). Under the protection of argon, polysilicon was melted at 1410°C, and gallium was melted into the polysilicon solution. The crystal growth parameters were adjusted as usual, and a Czochralski silicon single crystal with a diameter of 150 mm was grown at a growth rate of 1.2 mm / min. When the crystal growth length reached 80 cm, 2.25 mg of phosphorus was added to the remaining silicon solution through the dopant dopant device, and then the silicon single crystal growth continued, and it was finished when the solidification rate reached 82%. Samples were taken at different parts of the grown crystal, and then the axial distribution of the resistivity of the raw crystal was tested by the four-probe method, as shown in the attached figure 1 shown. It can be seen that the ...

Embodiment 2

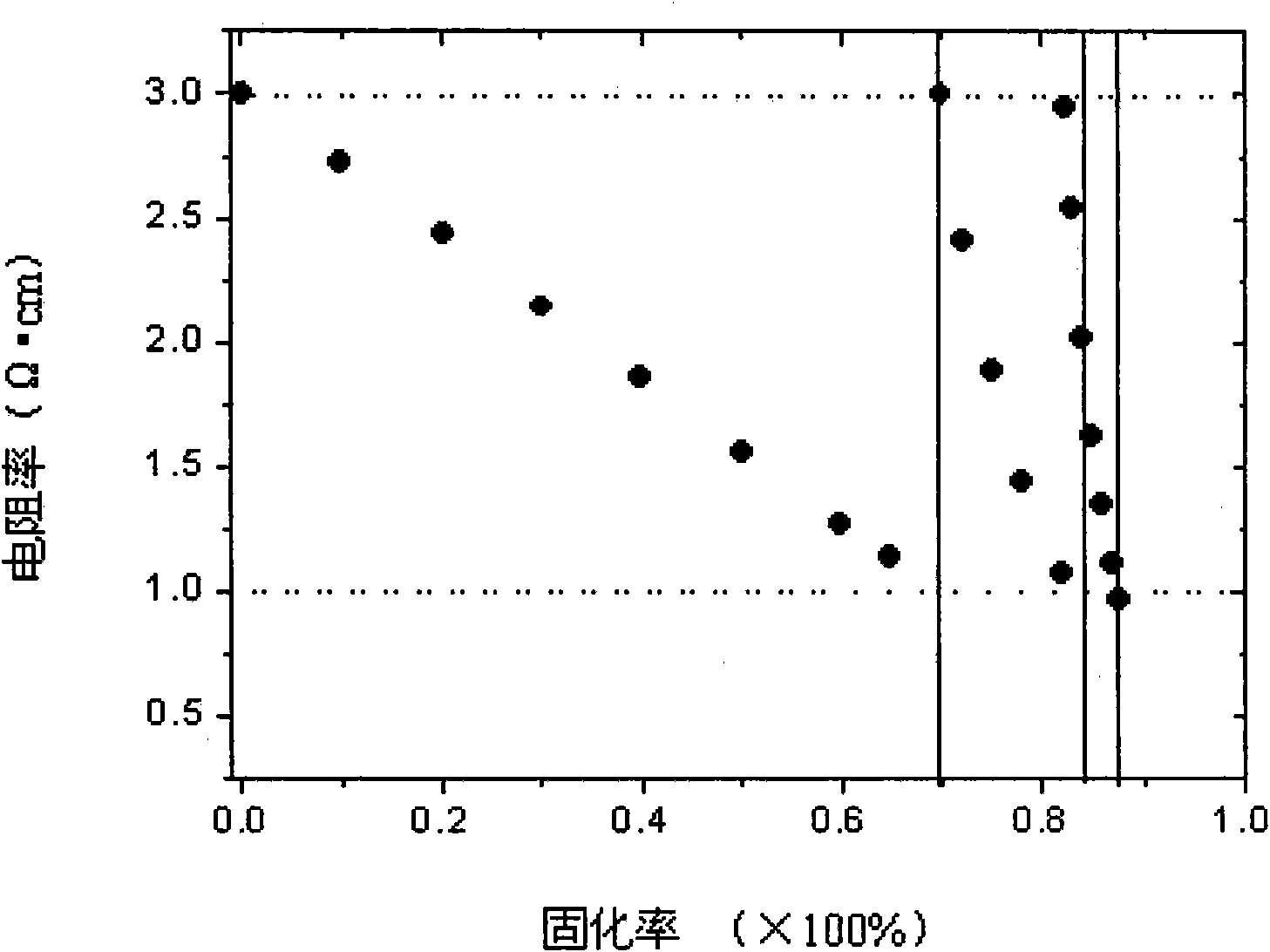

[0021] 50kg of polysilicon was put into a quartz crucible, and 1.365g of gallium was doped at the same time (making the target resistivity of the head of gallium-doped Czochralski silicon single crystal be 3Ω·cm). Under the protection of argon, polysilicon was melted at 1410°C, and gallium was melted into the polysilicon solution. The crystal growth parameters were adjusted as usual, and a Czochralski silicon single crystal with a diameter of 150 mm was grown at a growth rate of 1.2 mm / min. When the crystal growth length reached 80 cm, 2.25 mg of phosphorus was added into the crucible through the dopant dopant device, dissolved into the remaining silicon melt, and then continued to grow silicon single crystal. When the crystal length reached 94 cm, 1.35 mg of phosphorus was added to the crucible through the dopant dopant device, and dissolved into the remaining silicon melt. Finish when the curing rate reaches 88%. Samples were taken at different parts of the grown crystal, a...

Embodiment 3

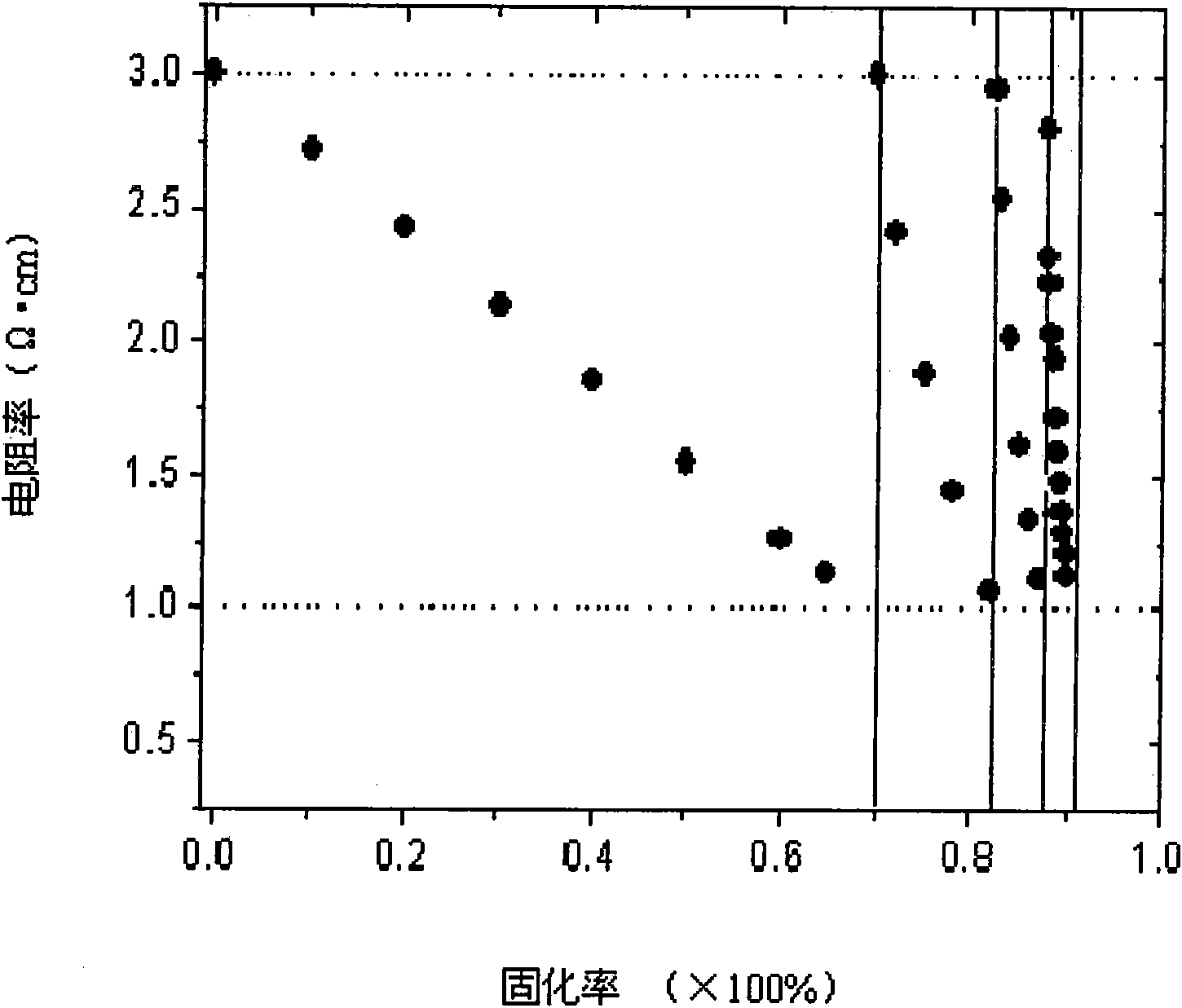

[0023] 50kg of polysilicon was put into a quartz crucible, and 1.365g of gallium was doped at the same time (making the target resistivity of the head of gallium-doped Czochralski silicon single crystal be 3Ω·cm). Under the protection of argon, polysilicon was melted at 1410°C, and gallium was melted into the polysilicon solution. The crystal growth parameters were adjusted as usual, and a Czochralski silicon single crystal with a diameter of 150 mm was grown at a growth rate of 1.2 mm / min. When the crystal growth length reached 80 cm, 2.25 mg of phosphorus was added into the crucible through the dopant dopant device, and dissolved into the remaining silicon melt to continue growing silicon single crystal. When the crystal length reaches 94cm, add 1.35mg of phosphorus into the crucible through the dopant dopant device, dissolve into the remaining silicon melt, and continue to grow silicon single crystal. When the crystal length reaches 94cm, add 1.35mg of phosphorus into the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com