Growth method of gallium-doped Czochralski single crystal silicon, gallium-doped single crystal silicon and its application

A growth method and monocrystalline silicon technology, which is applied in the growth of gallium-doped Czochralski monocrystalline silicon, gallium-doped monocrystalline silicon and its applications, can solve the problem of wide distribution range of resistivity of gallium-doped monocrystalline silicon, high cost of use, and battery problems. problems such as reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a method for growing gallium-doped Czochralski single crystal silicon, which specifically includes the following steps:

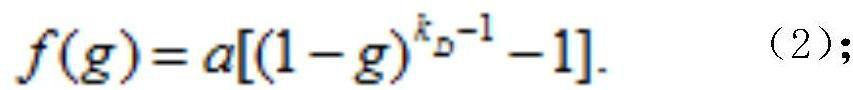

[0051] 580 kg of high-purity polysilicon raw material was charged into a crucible, and 48 g of high-purity gallium metal was added. The crucible is loaded into a crystal growth furnace, heated and melted to form a silicon melt, and gallium-doped Czochralski single crystal growth is carried out according to the Chester Czochralski single crystal method. Complete the necking and shouldering, enter the equal-diameter growth stage, set the diameter to 228mm, and the crystal grows stably at a rate of 2mm / min, then the crystal growth rate v is 81.7cm 3 / min. The gaseous donor dopant is configured, and the high-purity phosphine gas is diluted 100 times with high-purity argon gas, that is, the concentration is 1% by volume. Set the initial doping rate V D (1) is 2.4×10 -6 mol / min, converted into an effective donor gas flow rate o...

Embodiment 2

[0054] This embodiment provides a method for growing gallium-doped Czochralski single crystal silicon. The same parameters as in embodiment 1 are used to grow gallium-doped single crystal silicon crystals. The main difference lies in the adjustment of the use of gaseous donor dopants, as follows:

[0055] Set the doping rate V D (1)=2.0×10 -6 mol / min, the converted effective flow rate is 4.4mL / min. Use a program to control the flow, so that the flow changes uniformly with time. Set the time function q(t)=t / 300min, t(min), and feed the gaseous donor dopant according to the operating flow rate Q(t)=t / 300*4.4mL / min. When the crystal grows to a length of about 4.5 meters and the solidification ratio g is 0.75, stop feeding the donor gas, and then start to enter the finishing and follow-up procedures.

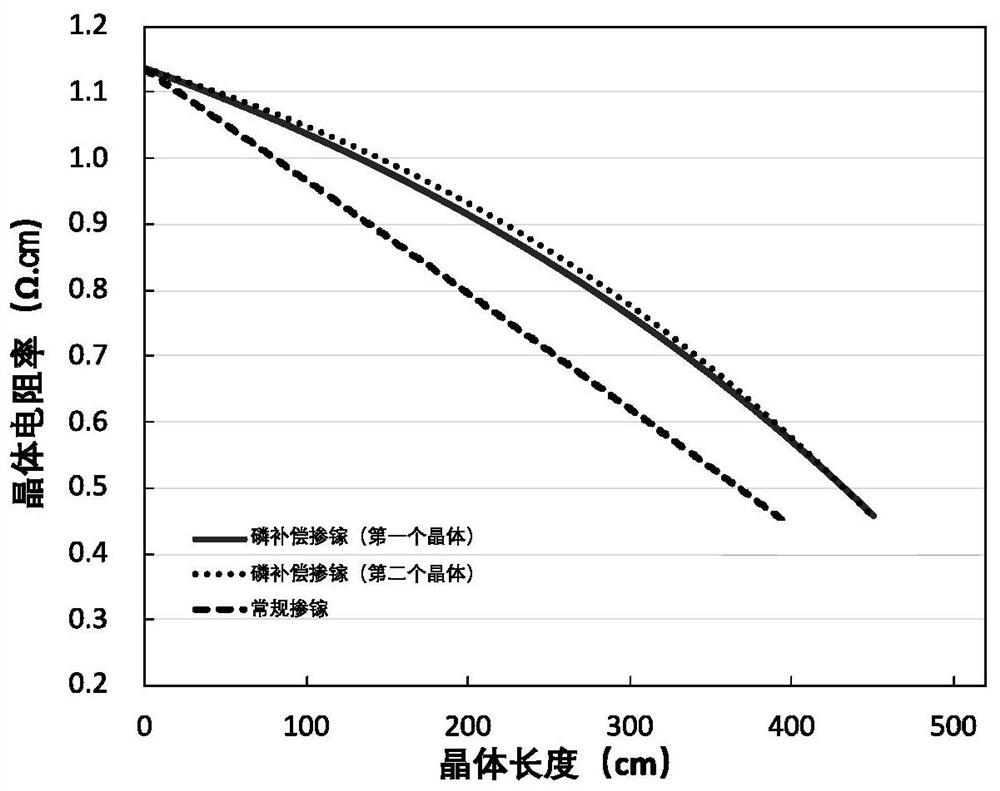

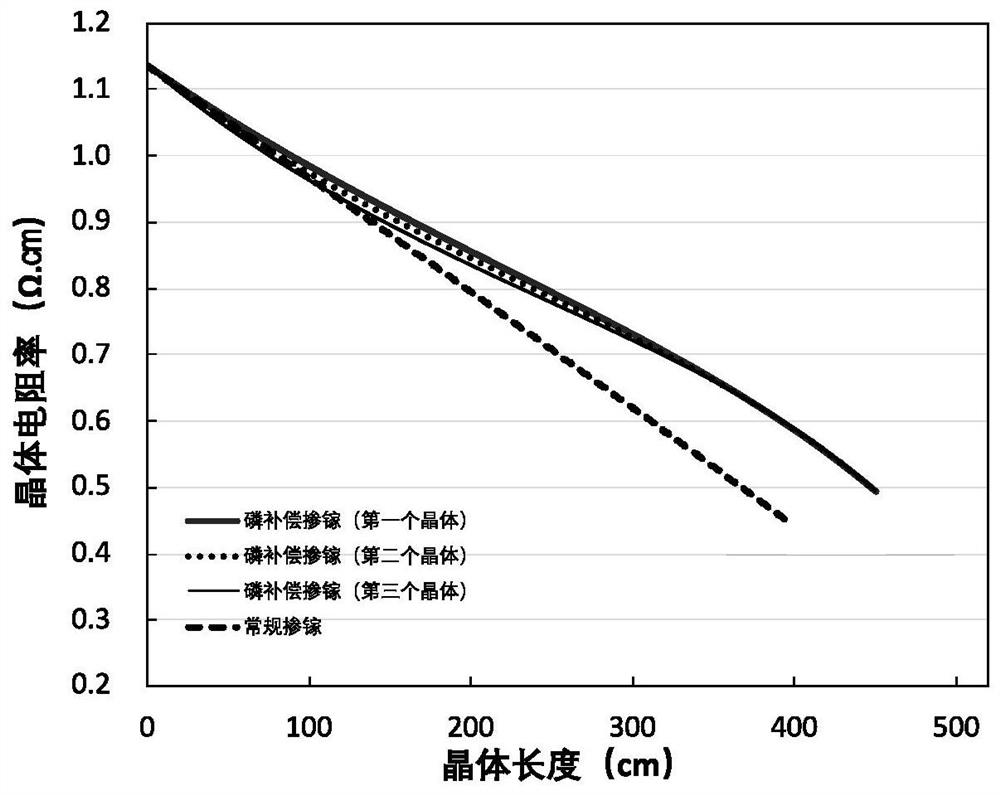

[0056] The test shows that the resistivity of the head is about 1.1Ω.㎝, and that of the tail is about 0.5Ω.㎝. Refill the high-purity polysilicon raw material according to the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com