Growth method of gallium-doped czochralski silicon, gallium-doped monocrystalline silicon and application

A growth method and technology of single crystal silicon, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of wide distribution range of resistivity of gallium-doped single crystal silicon, lower battery ratio, unfavorable industrial application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a method for growing gallium-doped Czochralski single crystal silicon, which specifically includes the following steps:

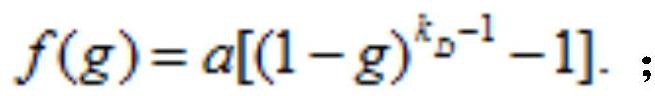

[0051] 580 kg of high-purity polysilicon raw material was charged into a crucible, and 48 g of high-purity gallium metal was added. The crucible is loaded into a crystal growth furnace, heated and melted to form a silicon melt, and gallium-doped Czochralski single crystal growth is carried out according to the Chester Czochralski single crystal method. Complete the necking and shouldering, enter the equal-diameter growth stage, set the diameter to 228mm, and the crystal grows stably at a rate of 2mm / min, then the crystal growth rate v is 81.7cm 3 / min. The gaseous donor dopant is configured, and the high-purity phosphine gas is diluted 100 times with high-purity argon gas, that is, the concentration is 1% by volume. Set the initial doping rate V D (1) is 2.4×10 -6 mol / min, converted into an effective donor gas flow rate o...

Embodiment 2

[0054] This embodiment provides a method for growing gallium-doped Czochralski single crystal silicon. The same parameters as in embodiment 1 are used to grow gallium-doped single crystal silicon crystals. The main difference lies in the adjustment of the use of gaseous donor dopants, as follows:

[0055] Set the doping rate V D (1)=2.0×10 -6 mol / min, the converted effective flow rate is 4.4mL / min. Use a program to control the flow, so that the flow changes uniformly with time. Set the time function q(t)=t / 300min, t(min), and feed the gaseous donor dopant according to the operating flow rate Q(t)=t / 300*4.4mL / min. When the crystal grows to a length of about 4.5 meters and the solidification ratio g is 0.75, stop feeding the donor gas, and then start to enter the finishing and follow-up procedures.

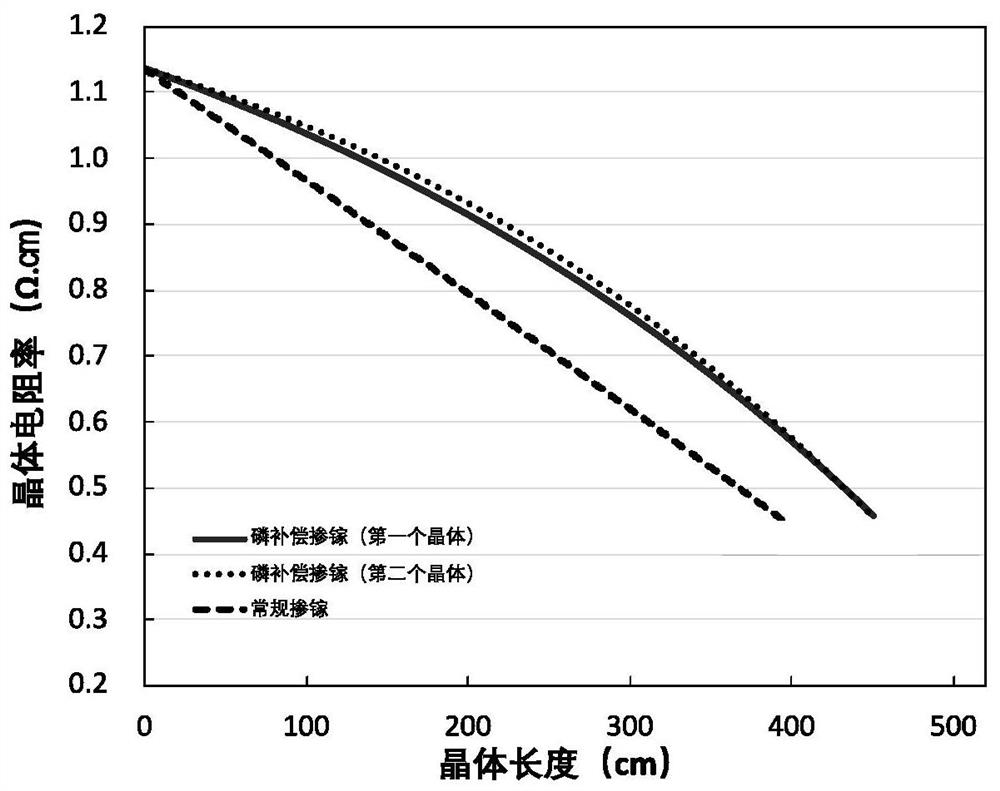

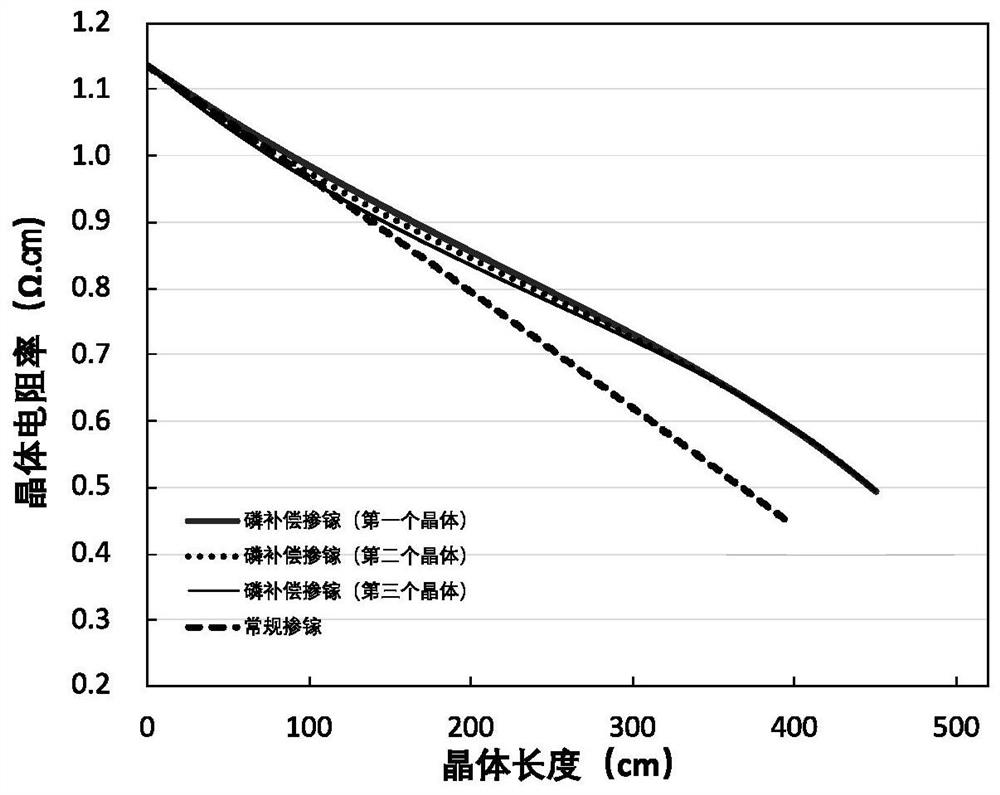

[0056] The test shows that the resistivity of the head is about 1.1Ω.㎝, and that of the tail is about 0.5Ω.㎝. Refill the high-purity polysilicon raw material according to the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com