Method for dynamically regulating and controlling laser mode based on thermo-optic effect

A thermo-optic effect and dynamic technology, applied in the direction of excitation methods/devices, lasers, laser components, etc., can solve the problems of difficult operation of optical integration, and achieve the effect of easy integration and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The gallium-doped zinc oxide microrods used in the present invention can be purchased commercially or obtained by self-synthesis. Wherein, the preparation method of gallium-doped zinc oxide microrods specifically includes the following steps:

[0038] S1. Weigh zinc oxide powder, graphite powder and gallium oxide powder according to the mass ratio of 1:1:0-0.5, mix them and grind them thoroughly, and use the ground mixture as a reaction source;

[0039] S2. Clean and dry the silicon wafer as the substrate, and cover the polished surface as the growth surface on the quartz boat equipped with the reaction source and not in contact with the reaction source;

[0040] S3. Put the quartz boat equipped with the reaction source and the silicon substrate into the quartz tube with openings at both ends, and place the whole in the high temperature zone of the tube furnace for reaction, and the reaction temperature is 1100-1200°C;

Embodiment 1

[0043] In this embodiment, the method for dynamically regulating the laser mode based on the thermo-optic effect includes the following steps:

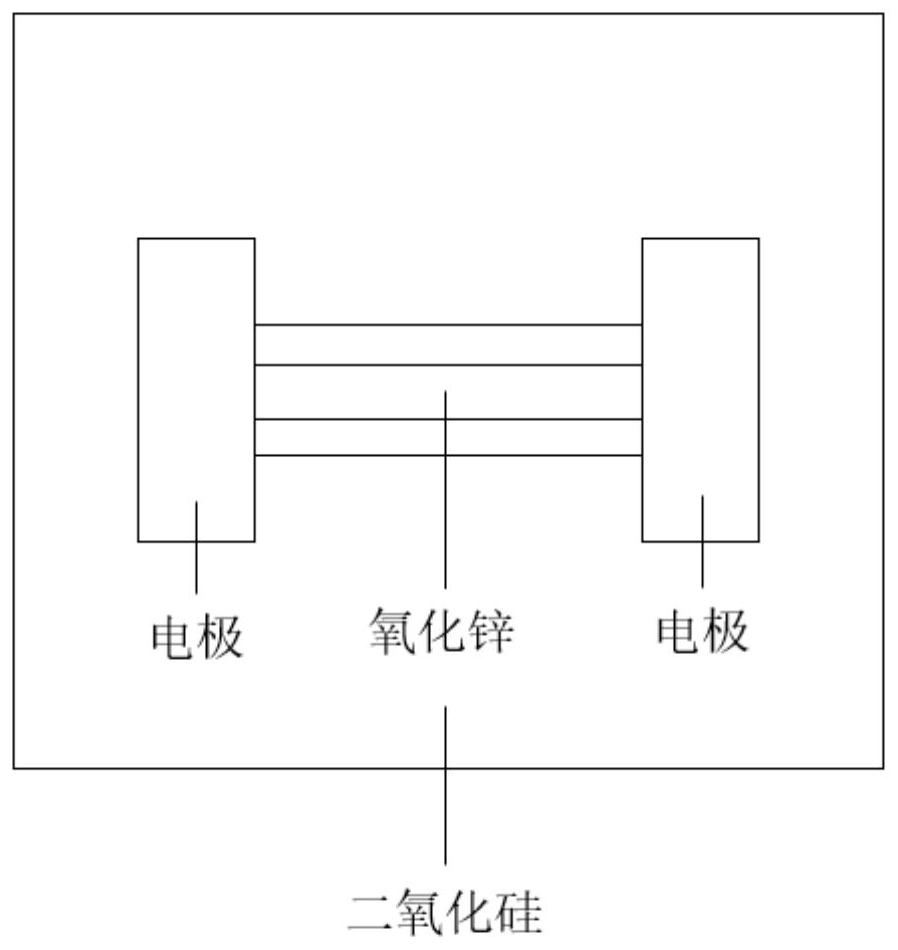

[0044] (1) Select a single microrod with a length of 0.5cm and a diameter of 10μm with a gallium-doped content of 0.2% zinc oxide and place it on an insulating silicon dioxide substrate with a length and width of 1cm×1cm; the two ends of the microrod are pressed with indium particles As an electrode, the electrode spacing is 500 μm;

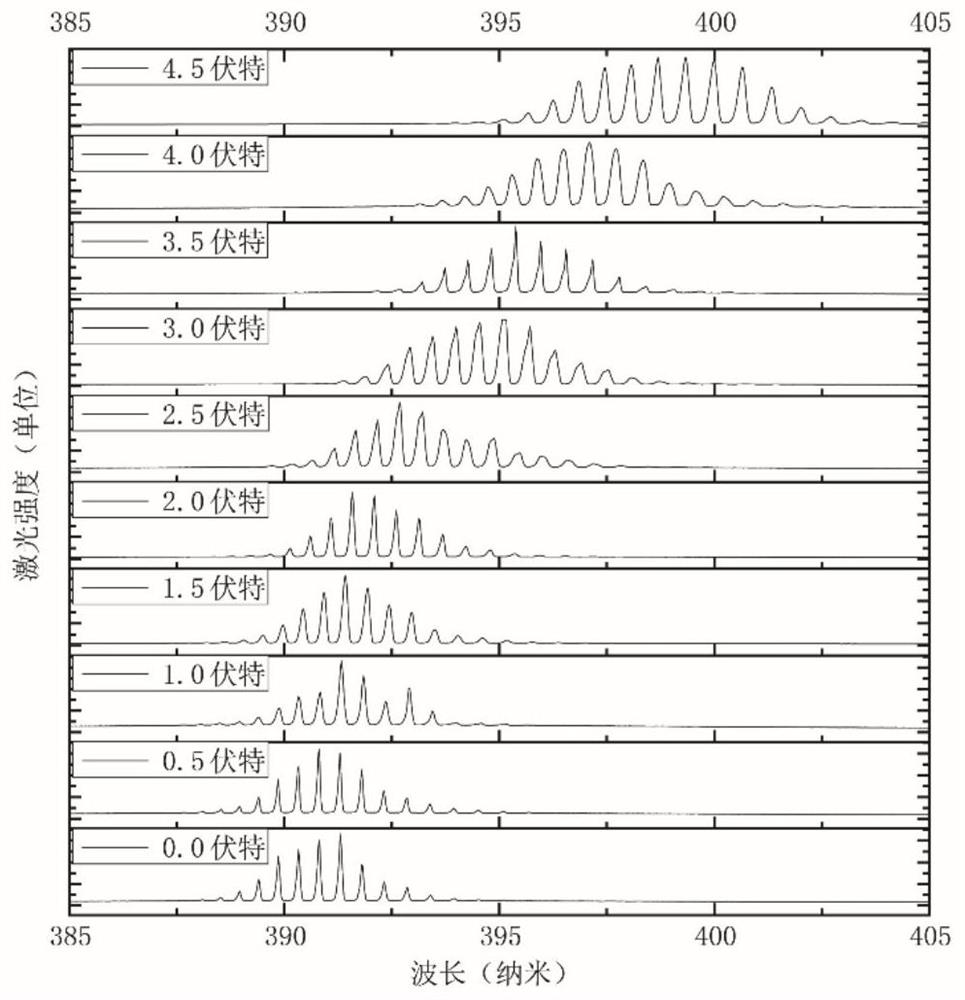

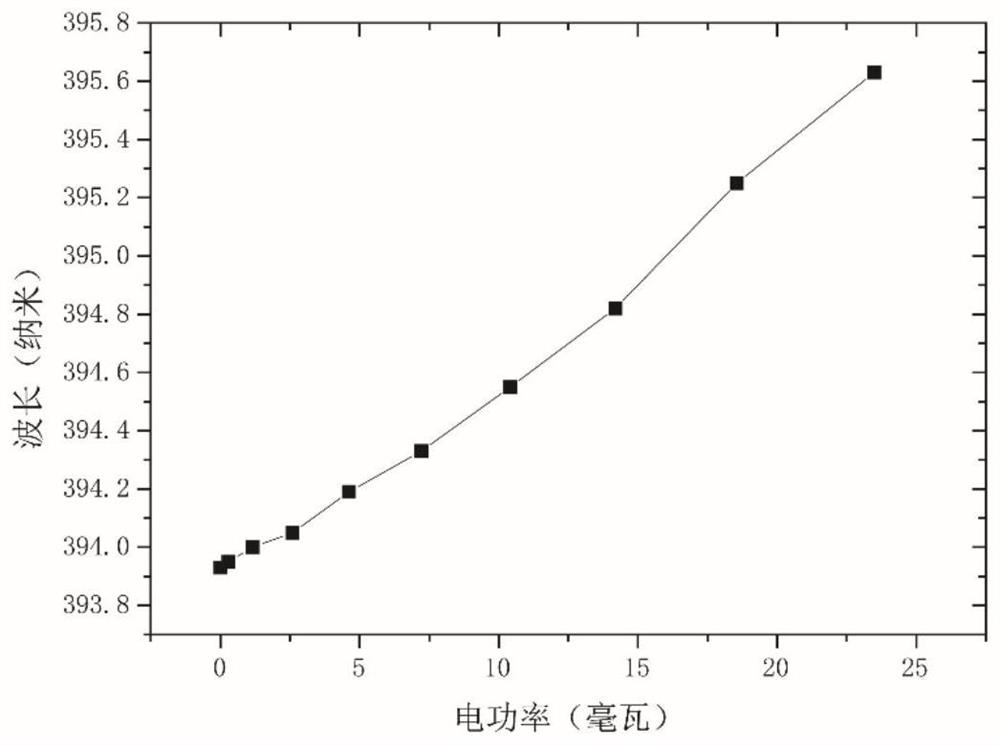

[0045] (2) Place the prepared device on a three-dimensional translation stage with a precision of 1 μm and a progress of 5 cm, adjust the translation stage, and pass through an optical microscope with an objective lens of 10 magnification and an eyepiece of 10 magnification. The excitation wavelength is 325 nm, and the repetition frequency is 1000 Hz. , the pump light with a pulse width of 100 fs is focused on gallium-doped zinc oxide microrods for optical excitation, and the optical signal of zinc oxide...

Embodiment 2

[0050] In this embodiment, the method for dynamically regulating the laser mode based on the thermo-optic effect includes the following steps:

[0051](1) Select a single microrod with a length of 0.8cm and a diameter of 5μm and a zinc oxide doped content of 0.2% with gallium, and place it on an insulating silicon dioxide substrate with a length and width of 1cm×1cm; press the two ends of the microrod with indium particles As an electrode, the electrode spacing is 600 μm;

[0052] (2) Place the prepared device on a three-dimensional translation stage with a precision of 2 μm and a process of 3 cm, adjust the translation stage, and pass through an optical microscope with an objective lens of 10 magnification and an eyepiece of 10 magnification, and the excitation wavelength is 355 nm, and the repetition frequency is 2000 Hz , the pump light with a pulse width of 100 fs is focused on gallium-doped zinc oxide microrods for optical excitation, and the optical signal of zinc oxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com