Printing ink concave plate printing machine capable of preventing coagulation and demisting and printing method

A gravure printing machine, gravure printing technology, applied in the direction of gravure rotary printing machine, printing machine, rotary printing machine, etc., can solve the problems of inability to print patterns, inability to achieve printing effect, inability to achieve, etc., to reduce processing costs , the effect of shortening processing time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

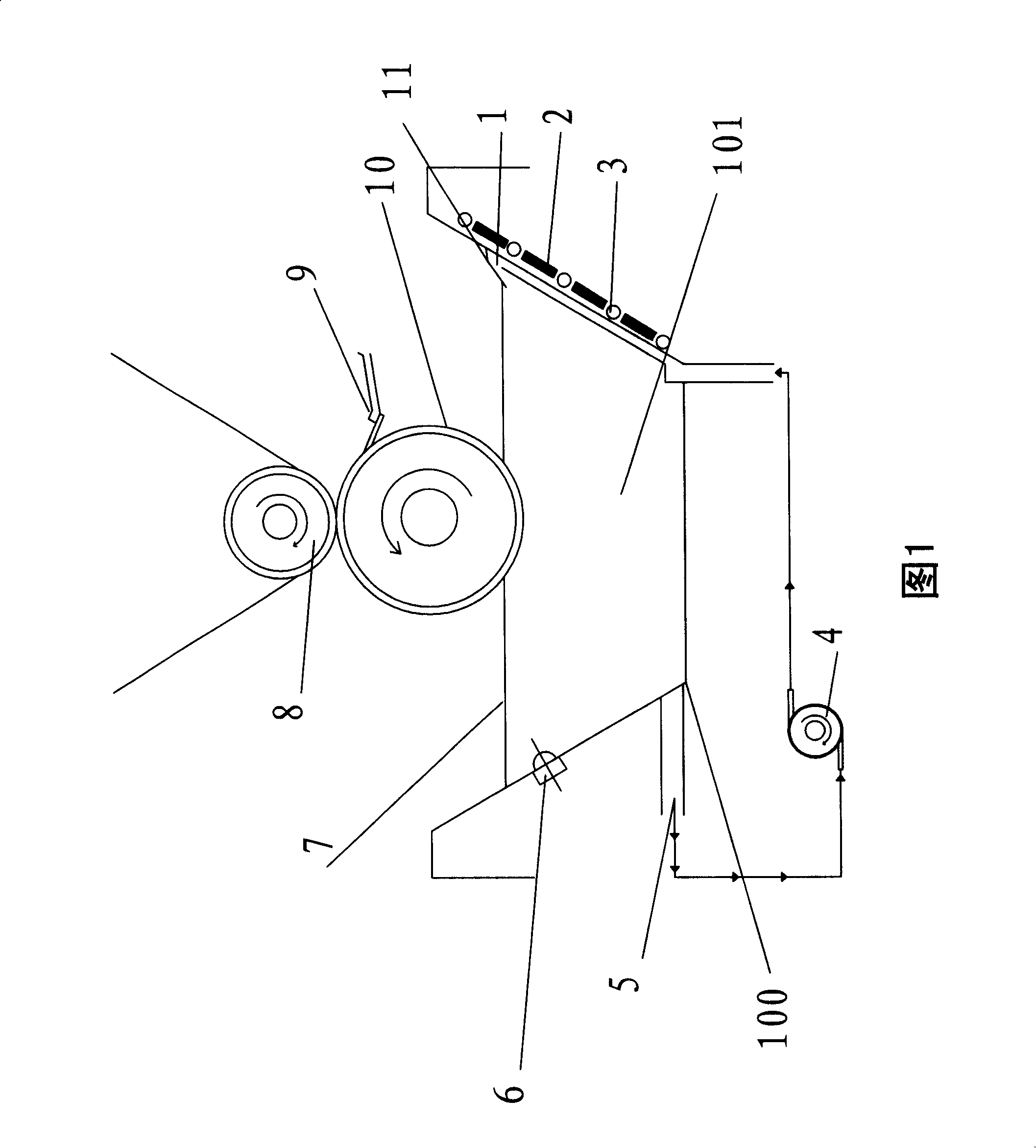

[0019] An ink gravure printing machine capable of anti-coagulation and defogging of the present invention can be improved on the basis of common gravure printing machines, and can also be newly designed and developed.

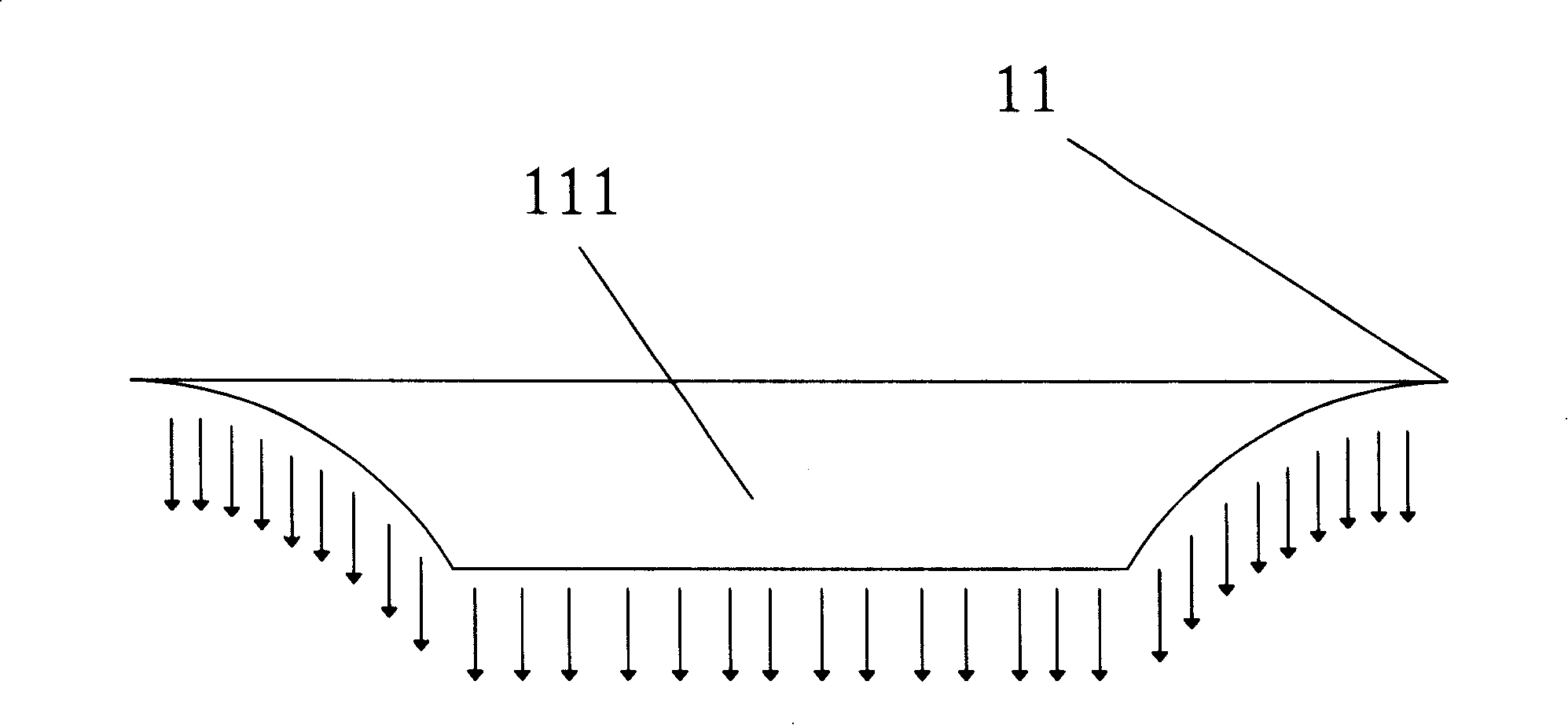

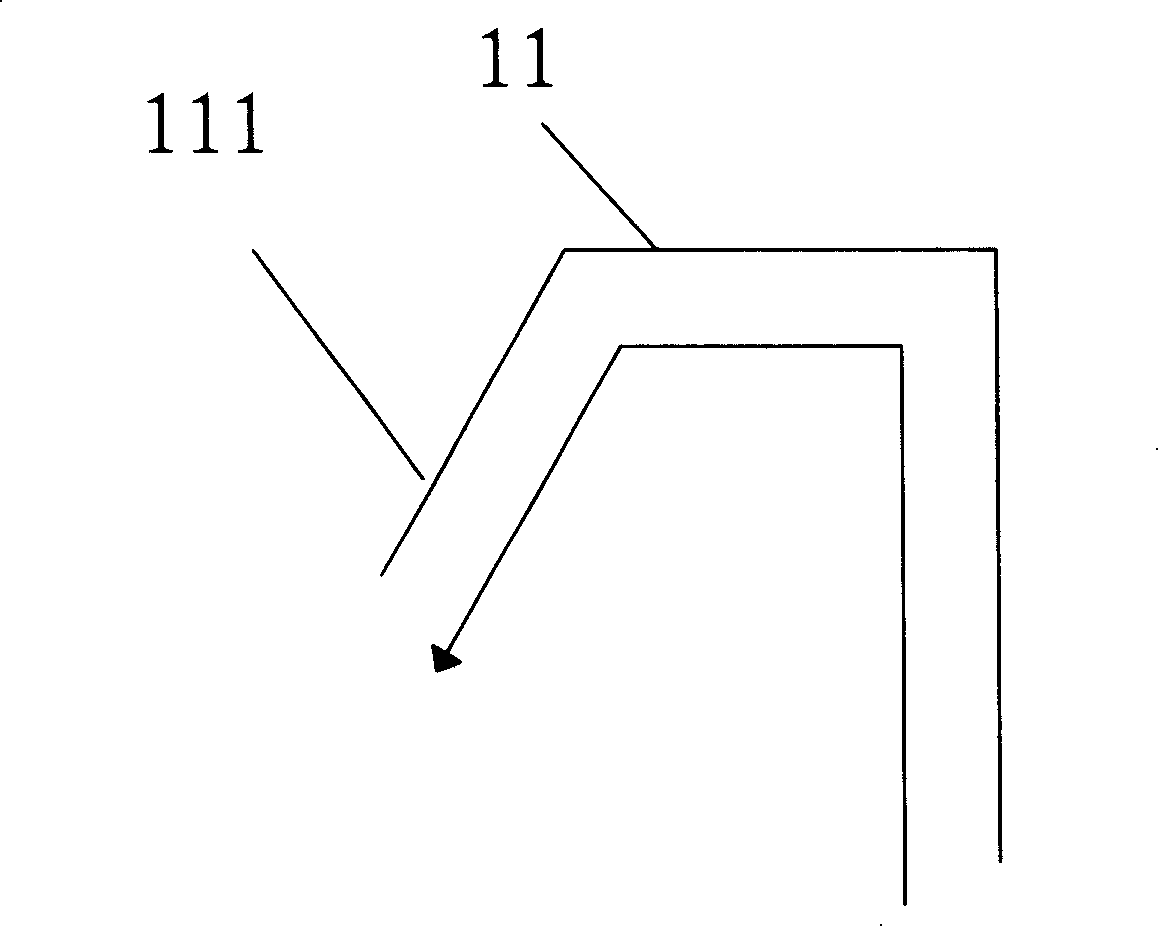

[0020] As shown in Figure 1, a kind of ink gravure printing machine capable of anti-condensation and defogging of the present invention includes an organic body 100 and a control device, and the said body 100 is provided with an ink for storing ink in the production process with an opening upward Storage chamber 101, wherein, the gravure printing machine also includes a gravure printing plate roller 10 and a stencil roller 8 with a groove consistent with the pattern shape on the outer periphery above the ink storage chamber, and the printing substrate is sheeted Tightly located in the middle of the gravure printing plate roll 10 and the stencil roll 8; the lowermost end of the gravure printing plate roll 8 extends into the ink upper surface of the ink storage ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com