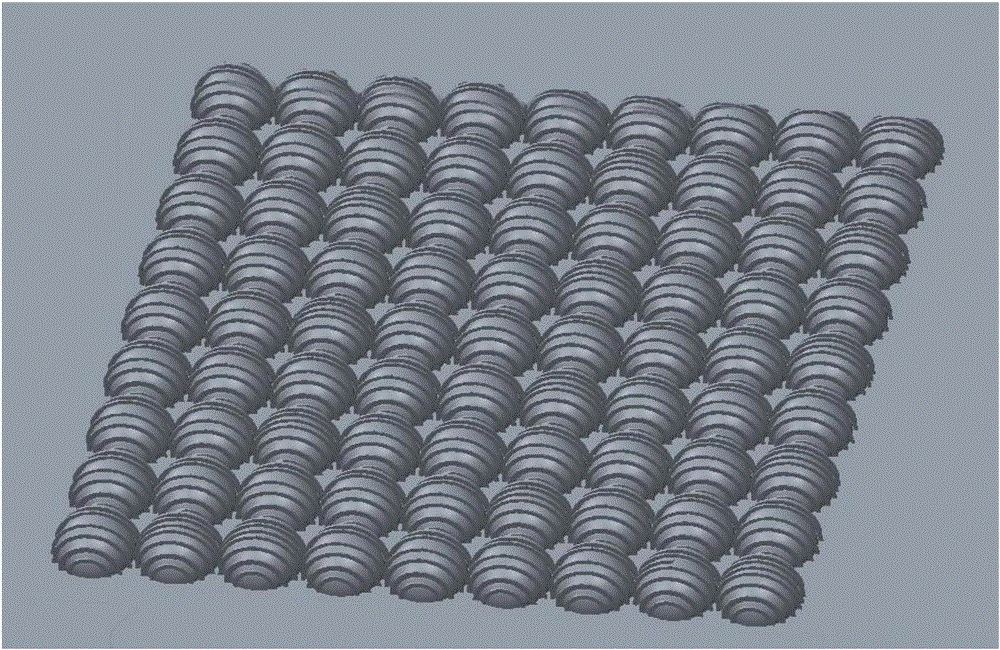

Semiconductor double-stage surface structure laser machining method based on electronic dynamic regulating and control

A technology of electronic dynamic control and dual-level surface structure, which is applied in the field of femtosecond laser applications, can solve the problems of short processing cycle, low repeatability, and high cost, and achieve the effects of short processing cycle, good repeatability, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

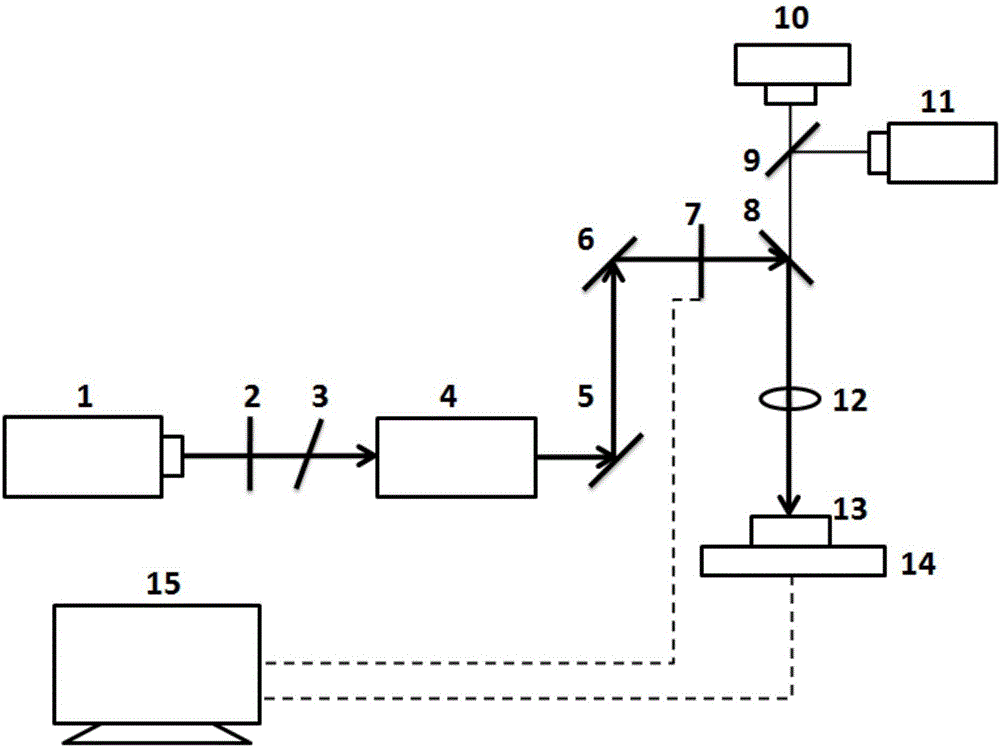

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0027] A method for electronically dynamic regulation and control of laser processing of semiconductor double-level surface structures, the specific steps are as follows:

[0028] Step 1. The femtosecond laser produces a femtosecond pulse laser with a center wavelength of 800nm, and uses a pulse time domain shaping device to shape the femtosecond pulse laser into a femtosecond laser double pulse sequence, and the sub-pulse energy ratio is 1:1;

[0029] Step 2. The femtosecond laser double pulse sequence obtained in step 1 is vertically incident on the surface of the sample, and focused by a plano-convex lens (f=100mm), and the focal point of the focused laser reaches the surface of the sample;

[0030] Step 3. Drop water into the Petri dish where the sample is placed, so that it is about 3mm below the sample;

[0031] Step 4. Find the focus again in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com