Patents

Literature

67 results about "Reactive ion beam etching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

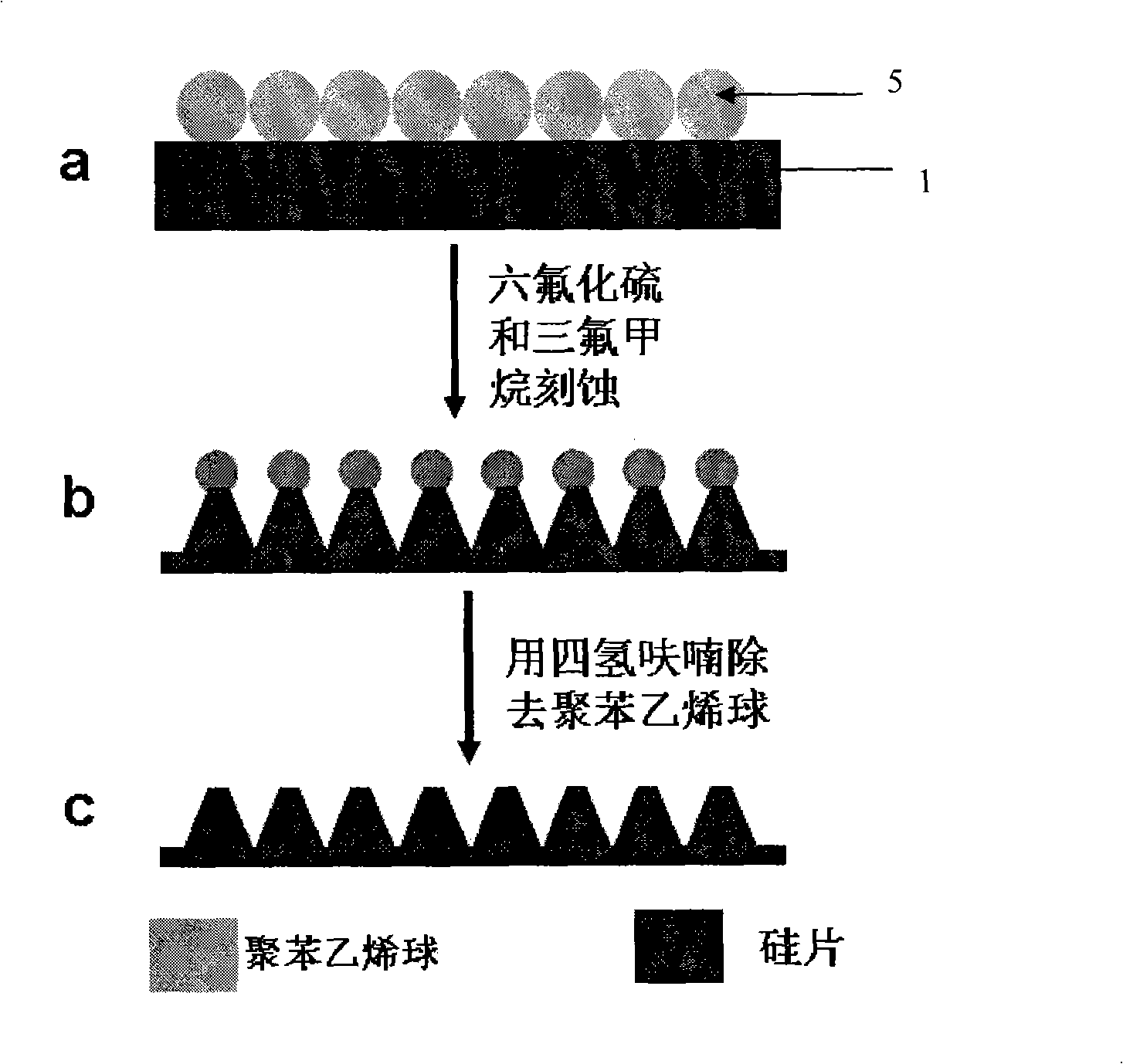

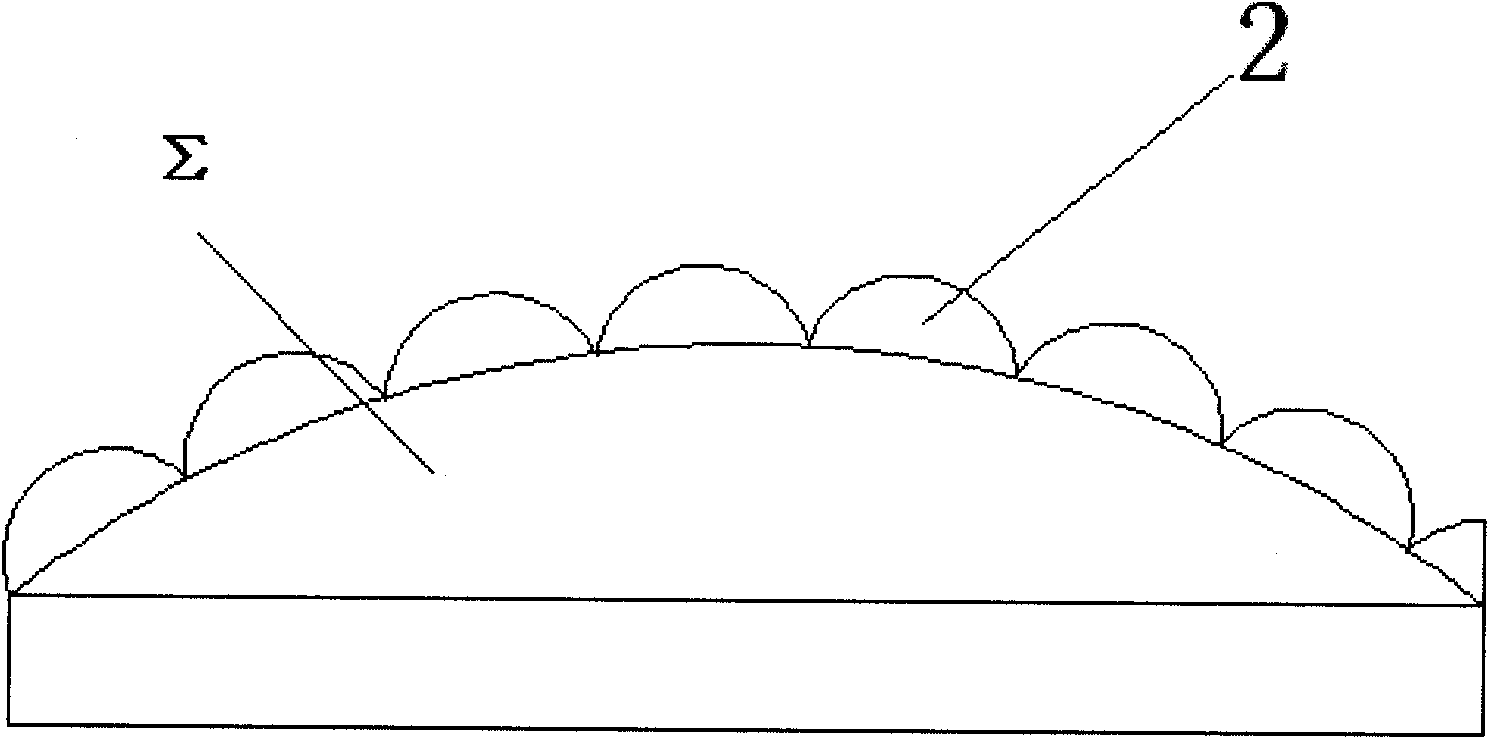

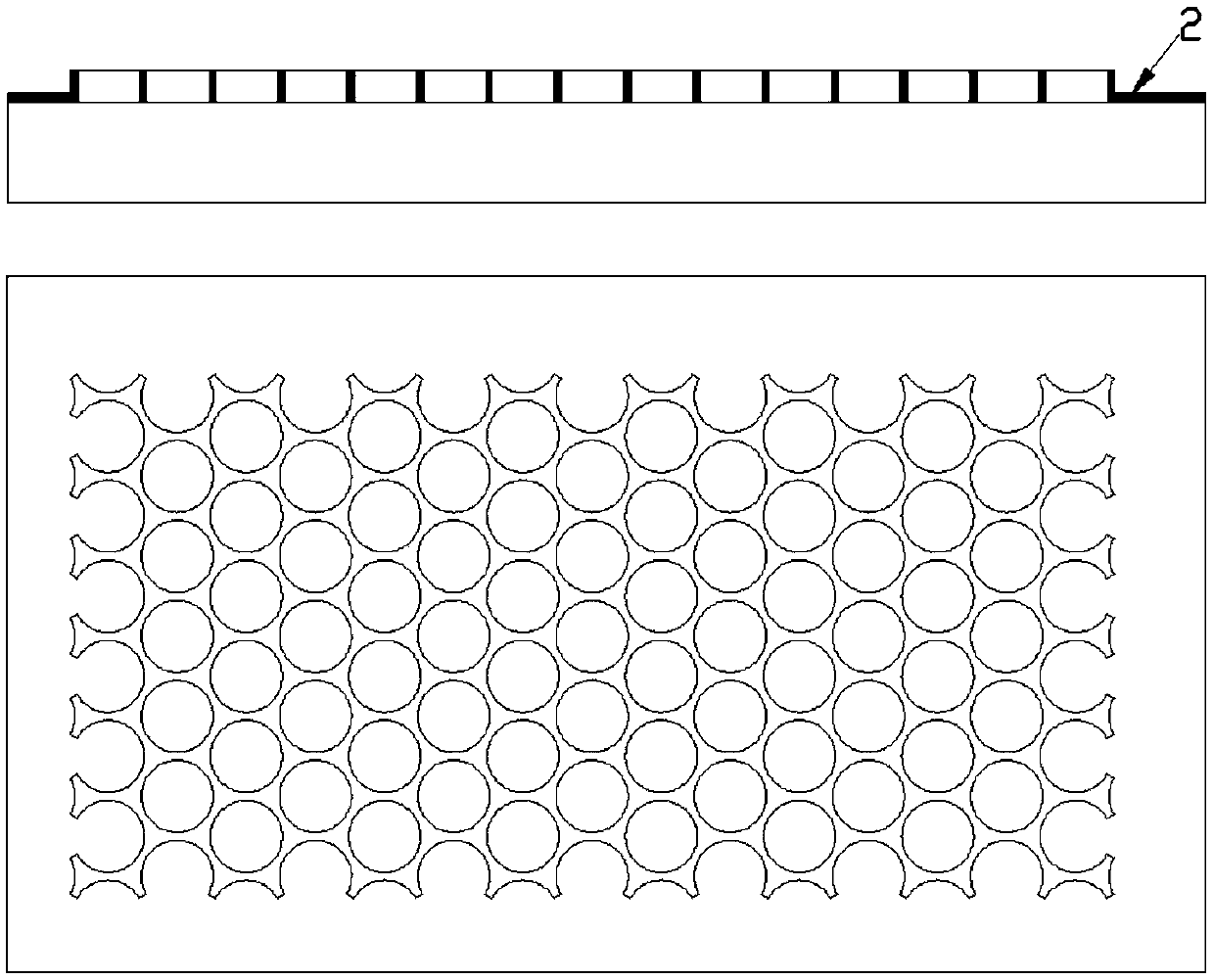

Method for constructing anti-reflection microstructure using single layer nanometer particle as etching blocking layer

InactiveCN101308219ASimple methodBase variableSemi-permeable membranesVolume/mass flow by thermal effectsSurface patternLight energy

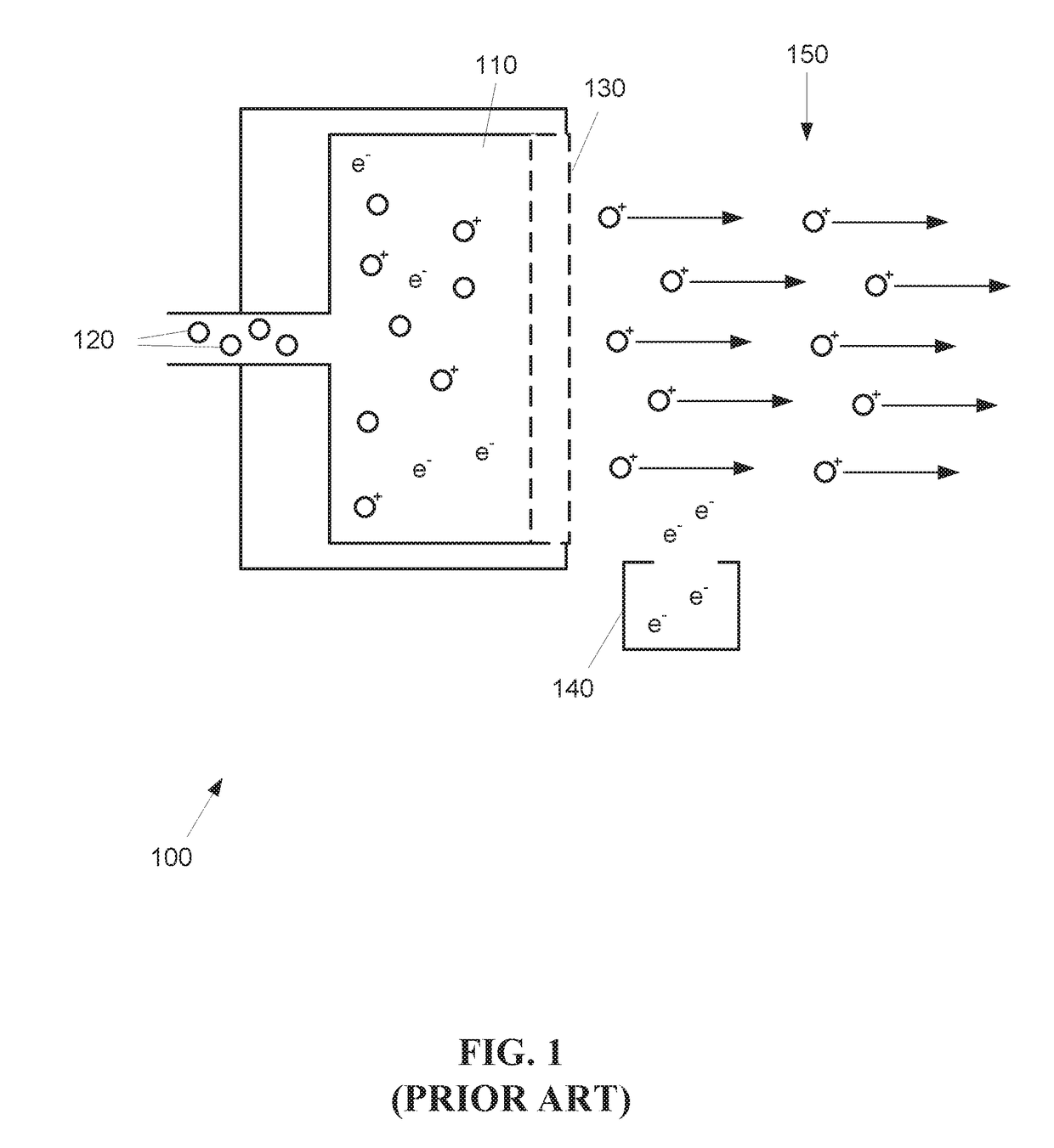

The invention belongs to the surface patterning microstructure construction technique, which relates to a method for constructing a microstructure with anti-reflection performance on a foundation base by combining the self-assembly technique with the reactive ion beam etching technique. The method is to take monolayer polymeric micro-spheres, silicon dioxide micro-spheres and nano-particles of metal or metal oxides as a barrier layer and implement the RIE etching to the foundation base, then an approximate cone-shaped microstructure is constructed on the foundation base, and the structure has extreme high anti-reflection performance, thereby effectively improving the light energy utilization rate, reducing the interference of veiling glare in an optical system, increasing the optical transmittance, and further improving the sensitivity and stability of the optical system, and the method can be used for constructing large-area anti-reflection structures. The method of the invention has advantages of simple operation, changeable foundation base, strong applicability, good repeatability, low cost, high efficiency, adjustable anti-reflective applied wavelength and conformity to industrialized standards, and can be used for making photoelectric devices such as solar batteries and white light sensors.

Owner:JILIN UNIV

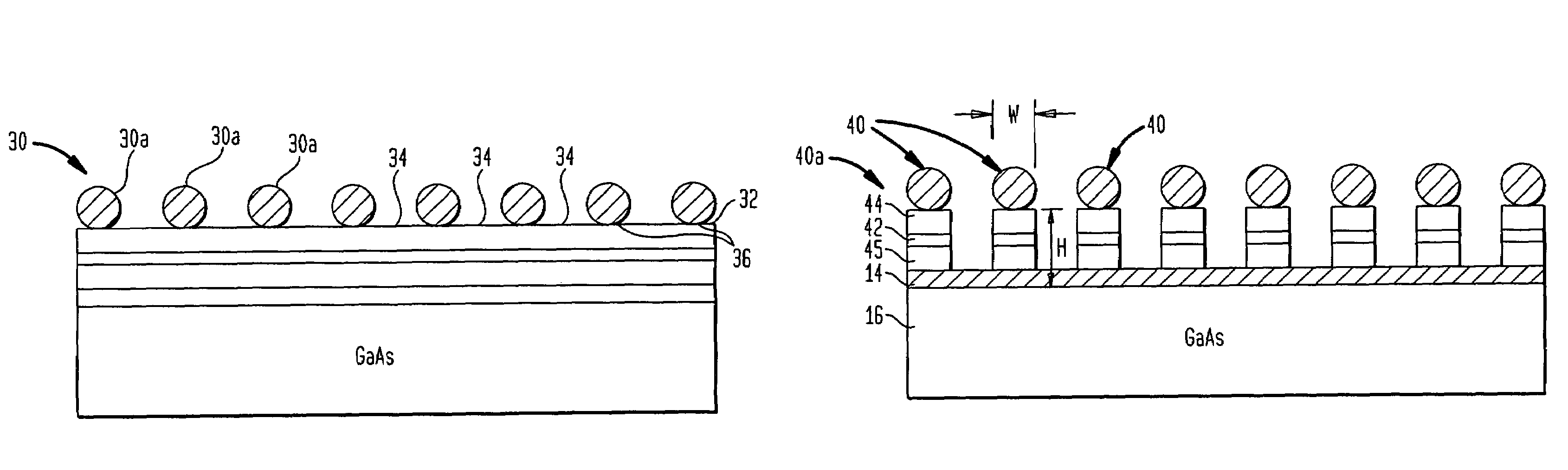

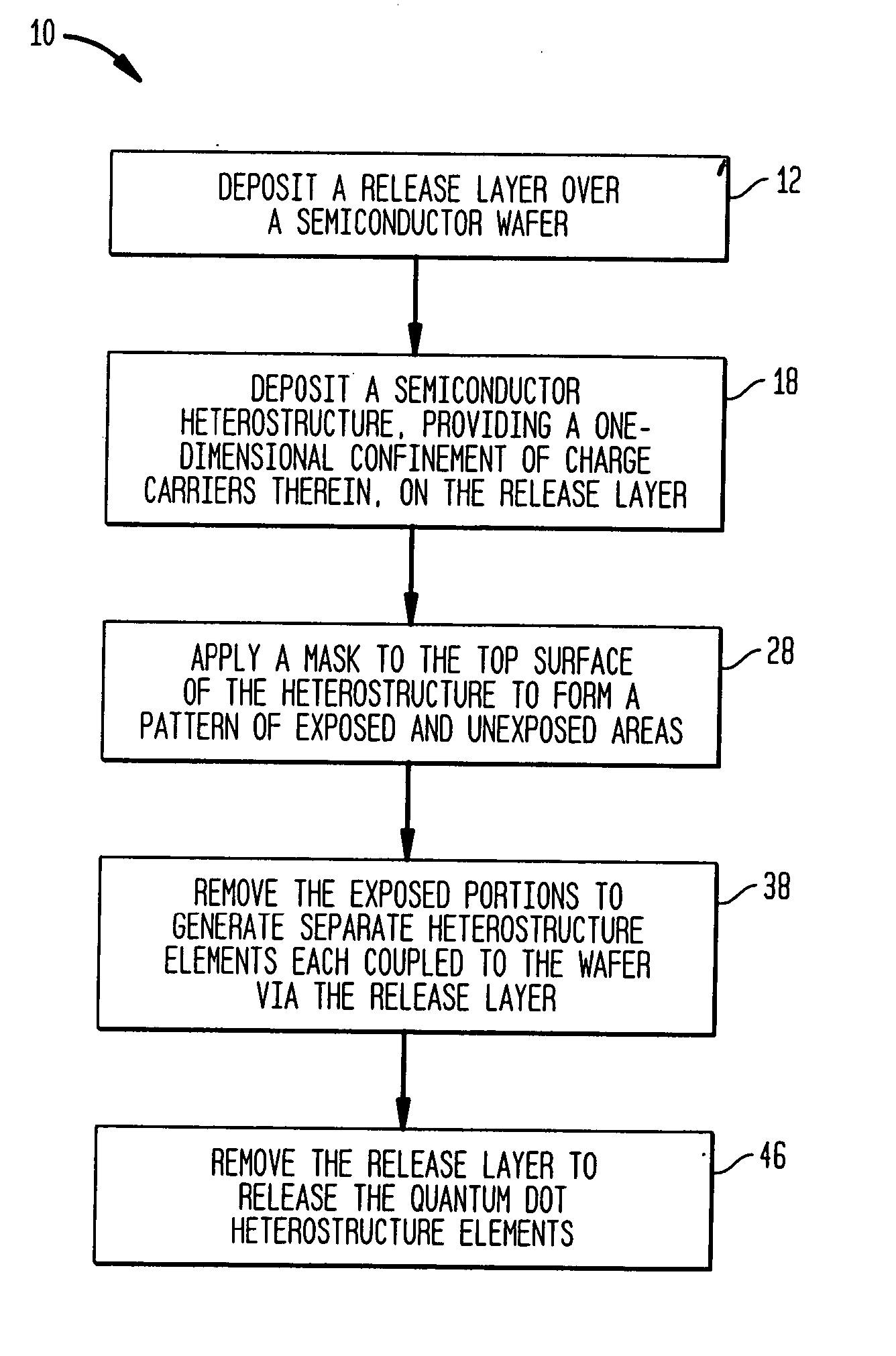

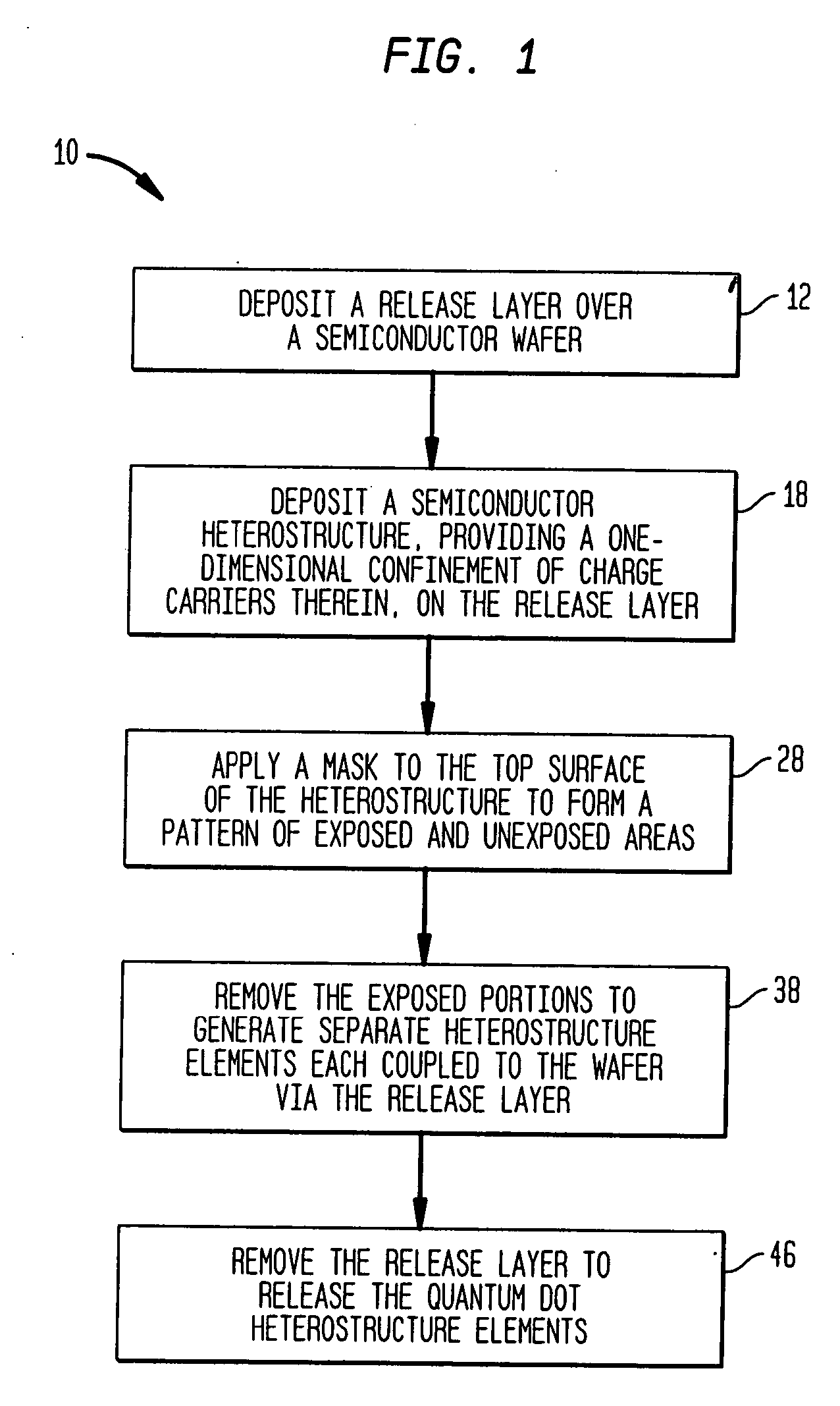

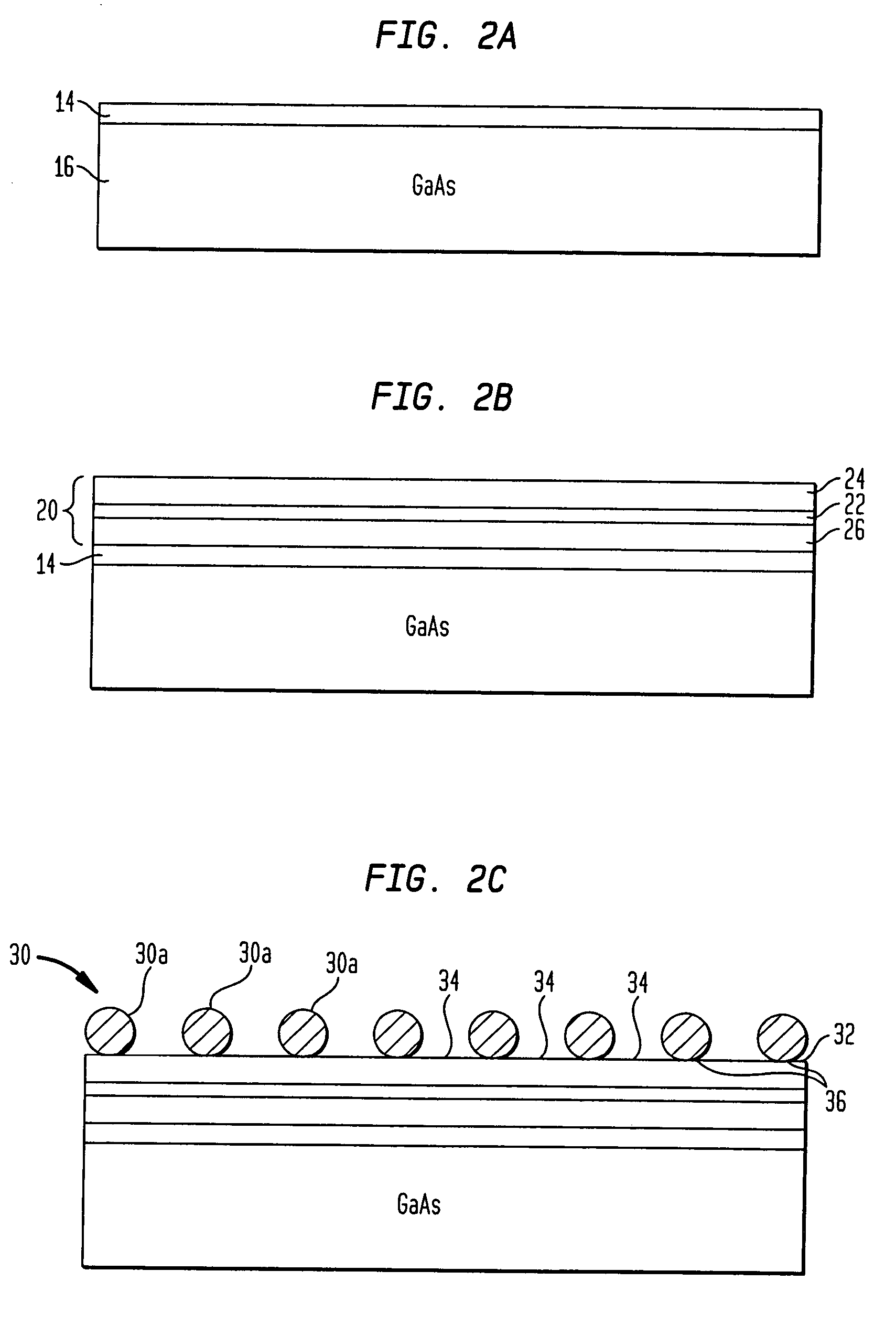

Precision synthesis of quantum dot nanostructures for fluorescent and optoelectronic devices

InactiveUS7306963B2Good size uniformityNanoinformaticsSemiconductor/solid-state device manufacturingPhoton emissionFluorescence

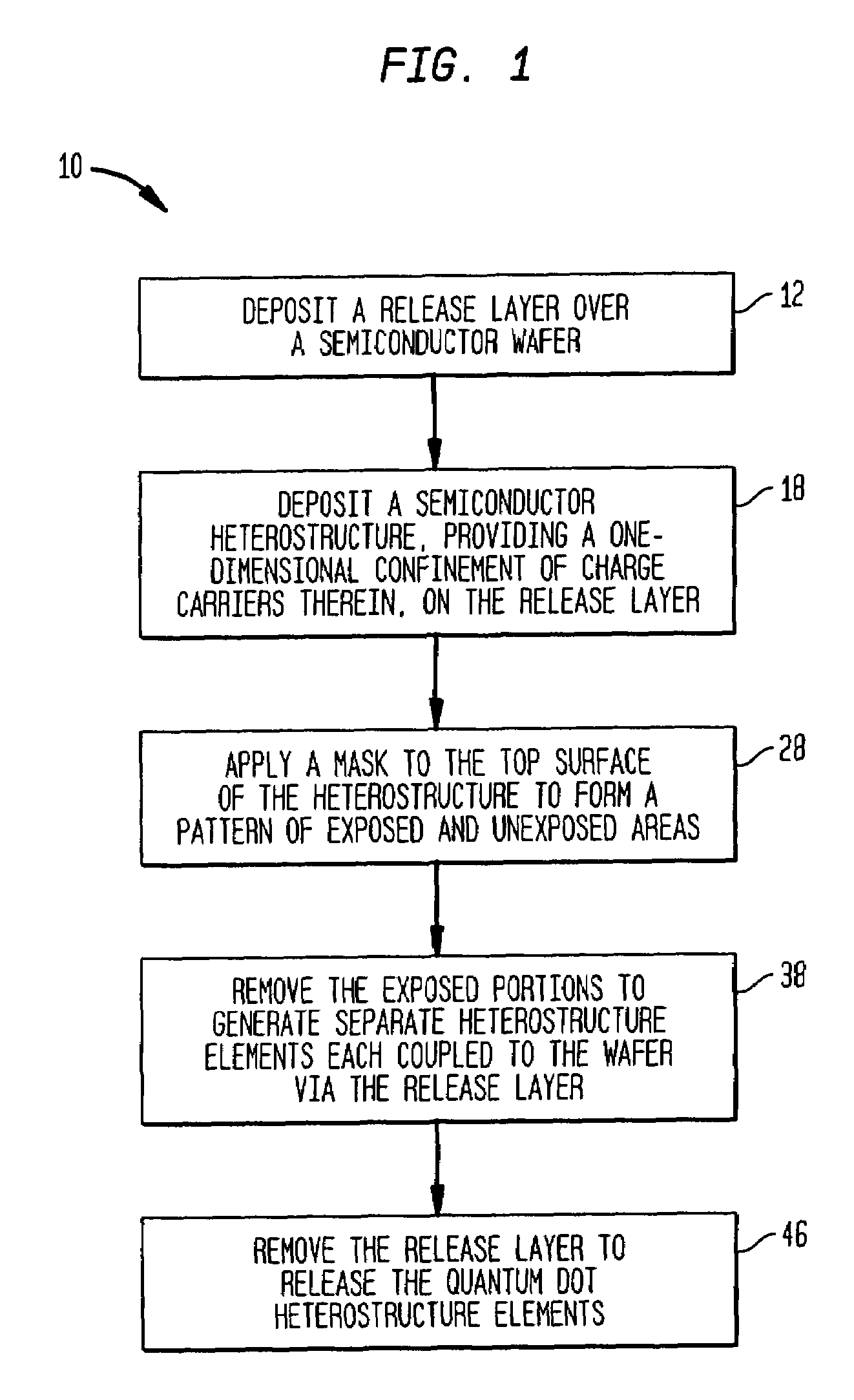

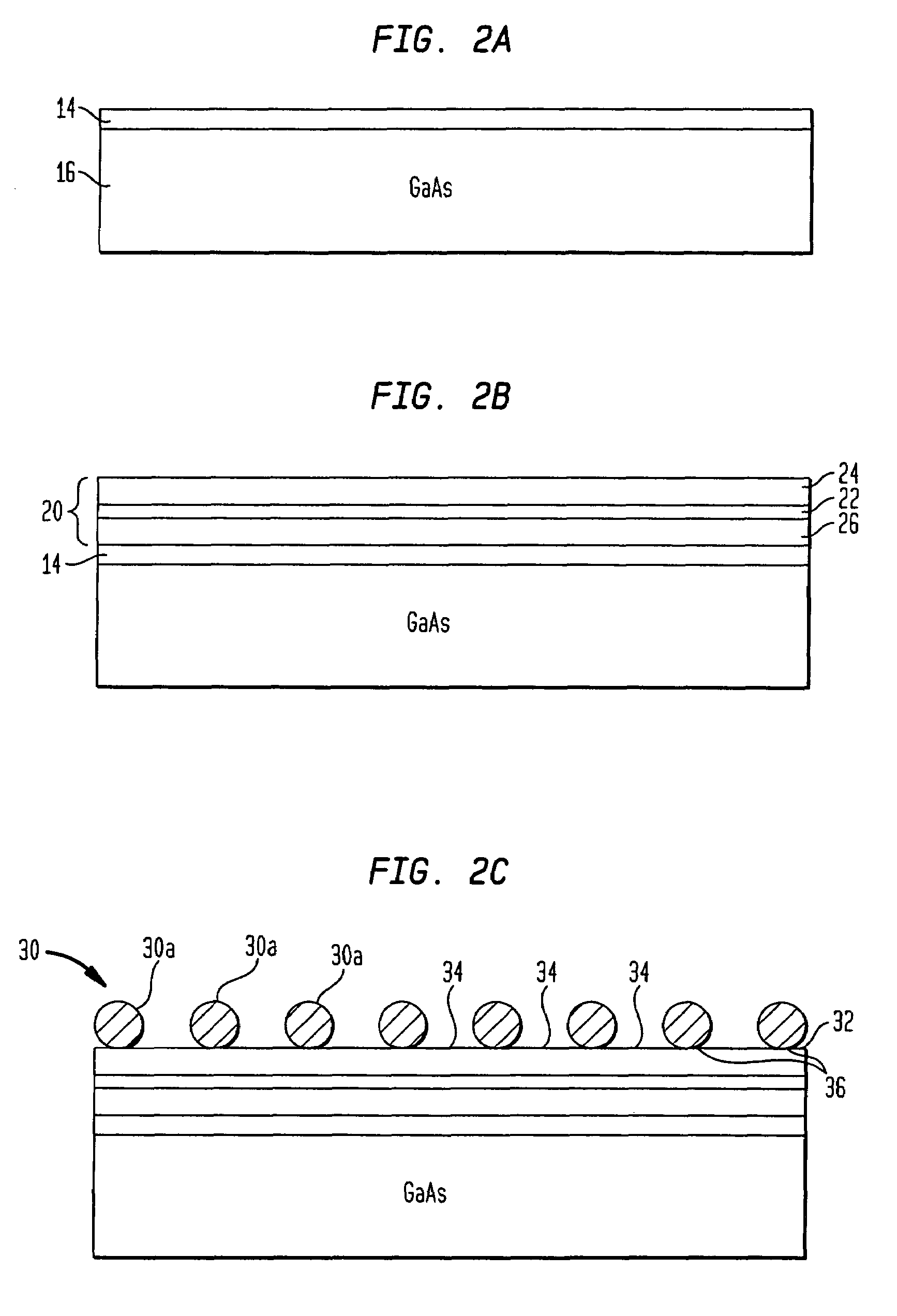

Methods are disclosed generally directed to design and synthesis of quantum dot nanoparticles having improved uniformity and size. In a preferred embodiment, a release layer is deposited on a semiconductor wafer. A heterostructure is grown on the release layer using epitaxial deposition techniques. The heterostructure has at least one layer of quantum dot material, and optionally, one or more layers of reflective Bragg reflectors. A mask is deposited over a top layer and reactive ion-beam etching applied to define a plurality of heterostructures. The release layer can be dissolved releasing the heterostructures from the wafer. Some exemplary applications of these methods include formation of fluorophore materials and high efficiency photon emitters, such as quantum dot VCSEL devices. Other applications include fabrication of other optoelectronic devices, such as photodetectors.

Owner:SPIRE

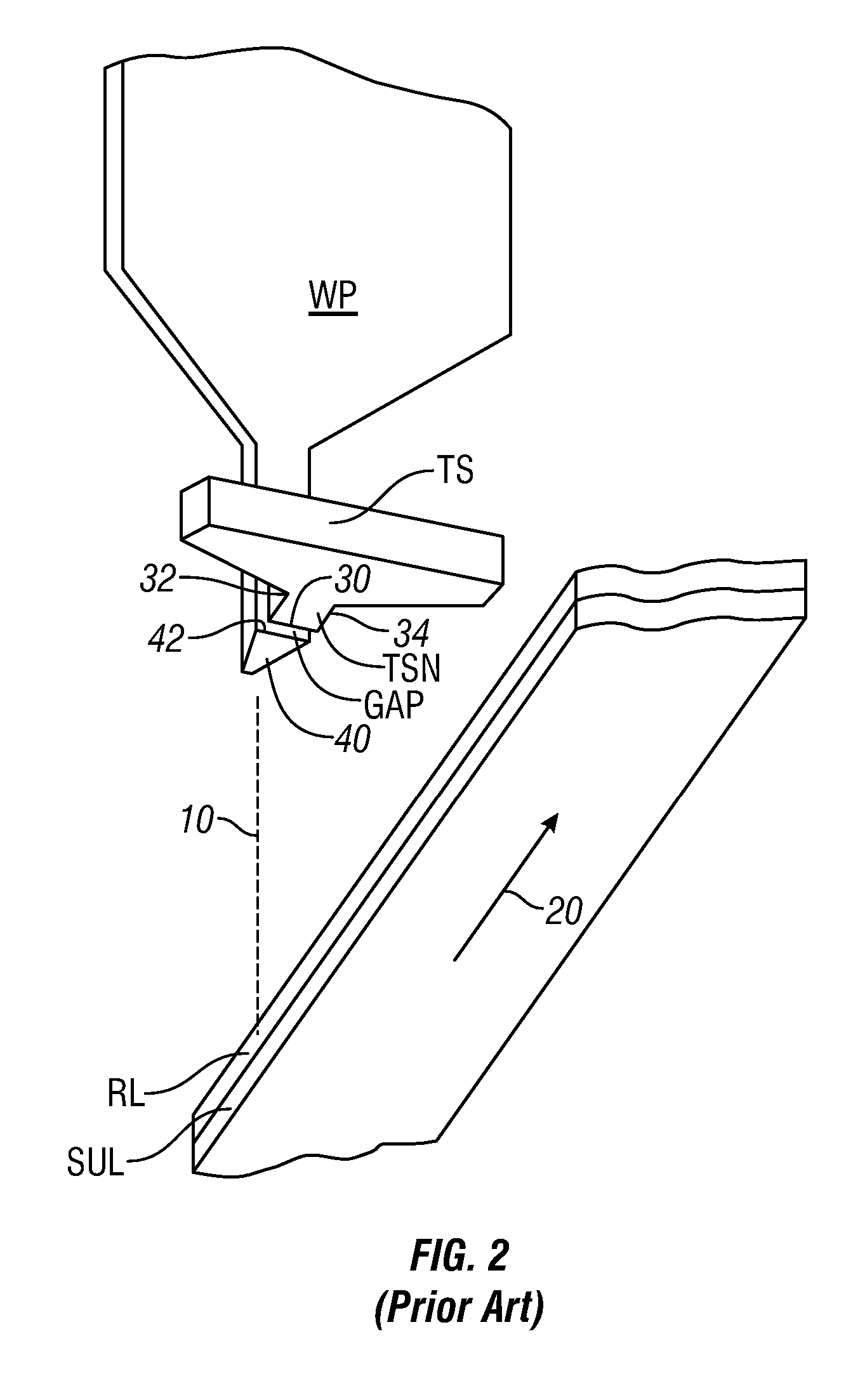

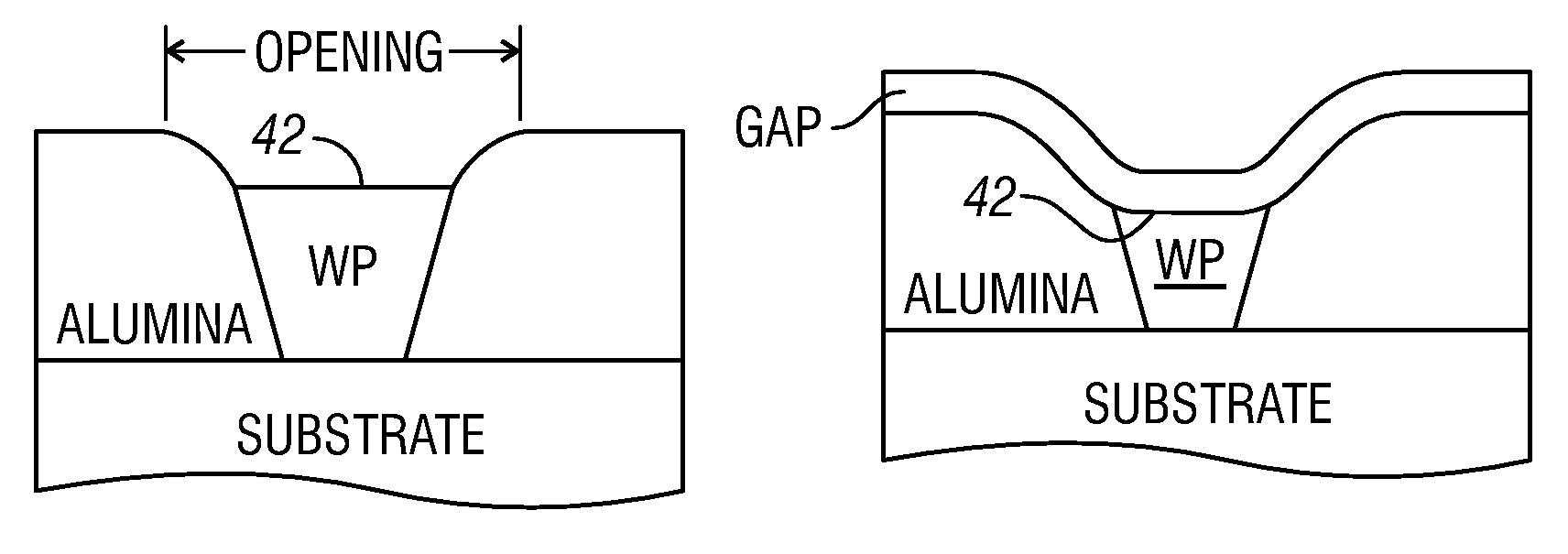

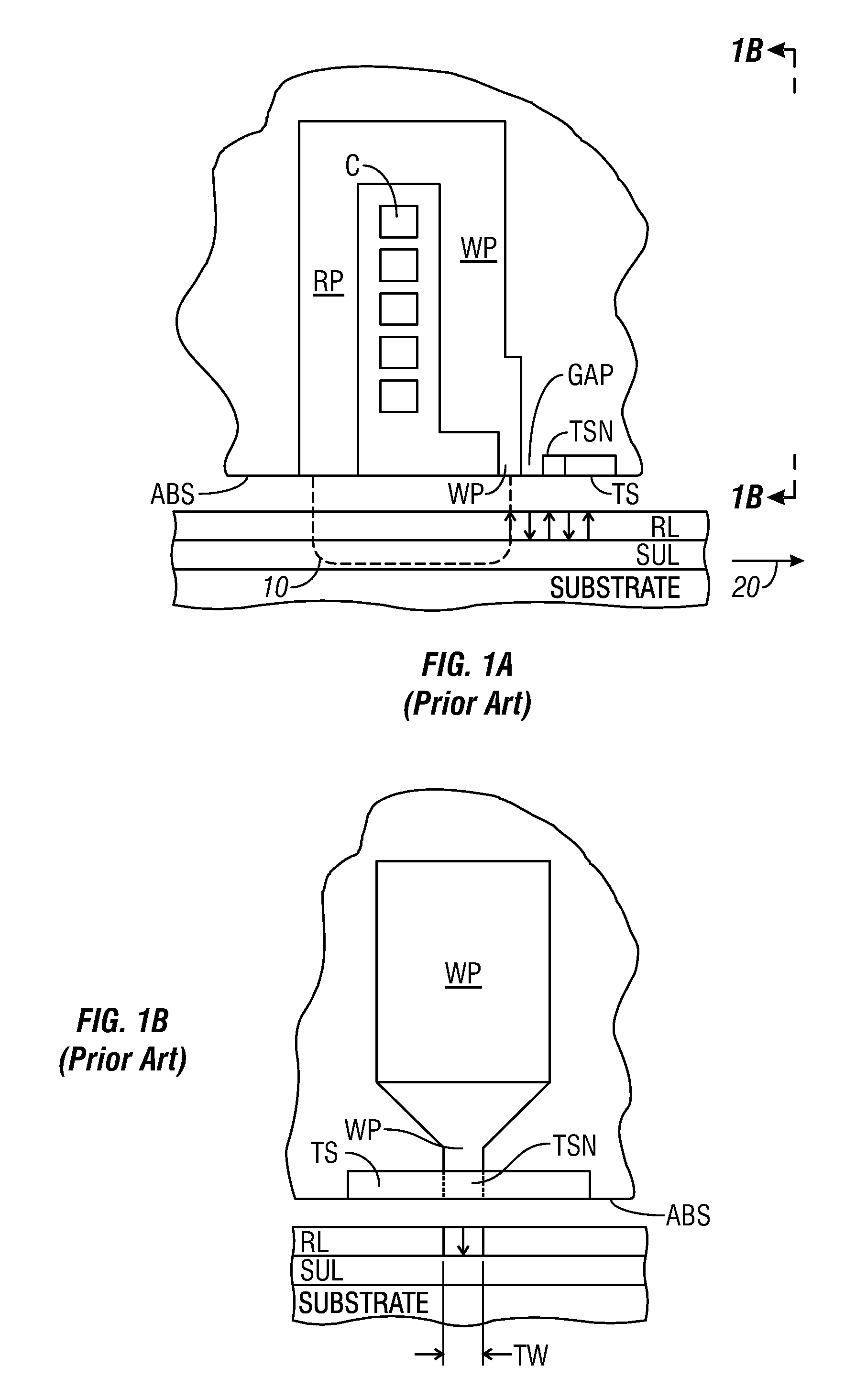

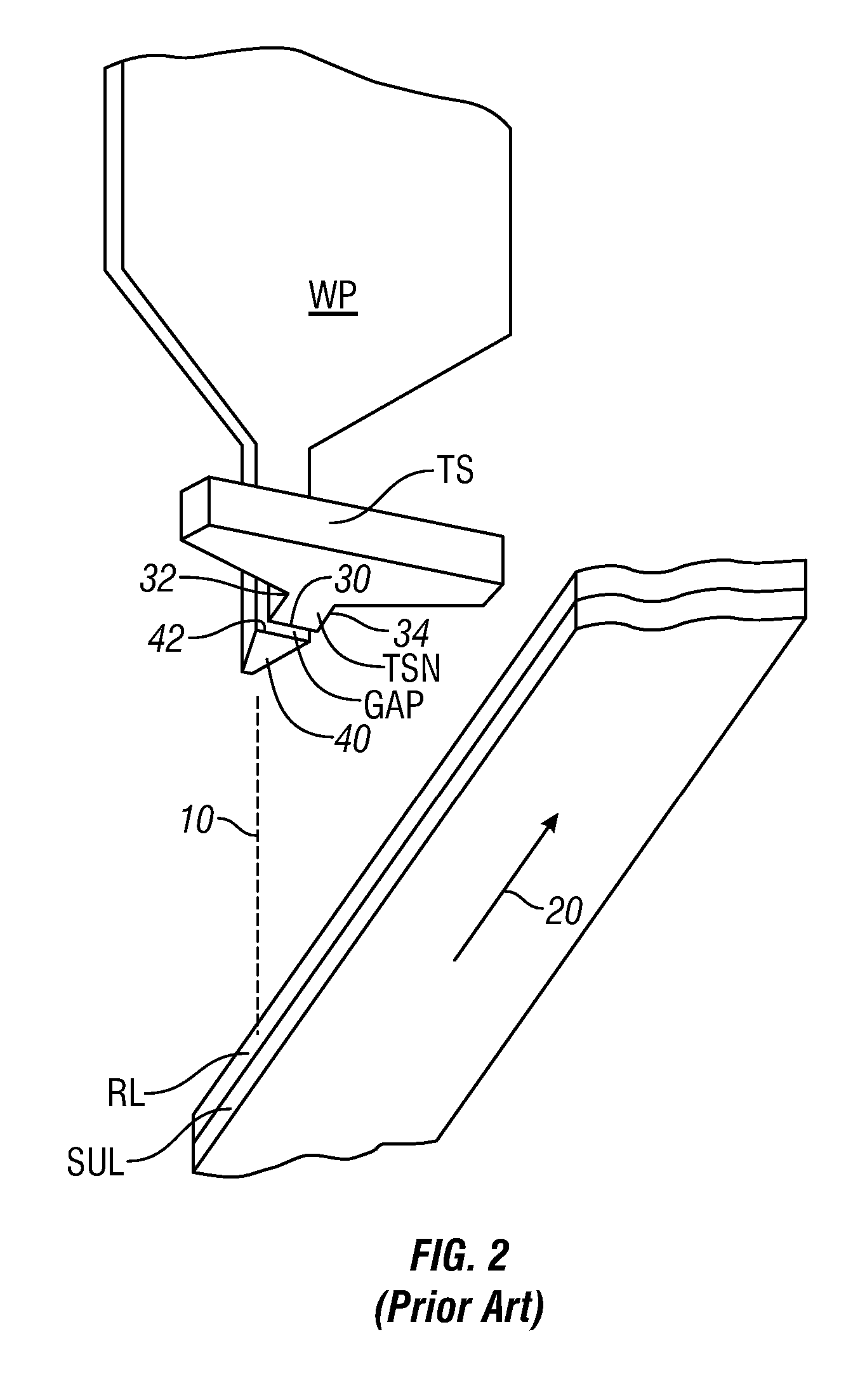

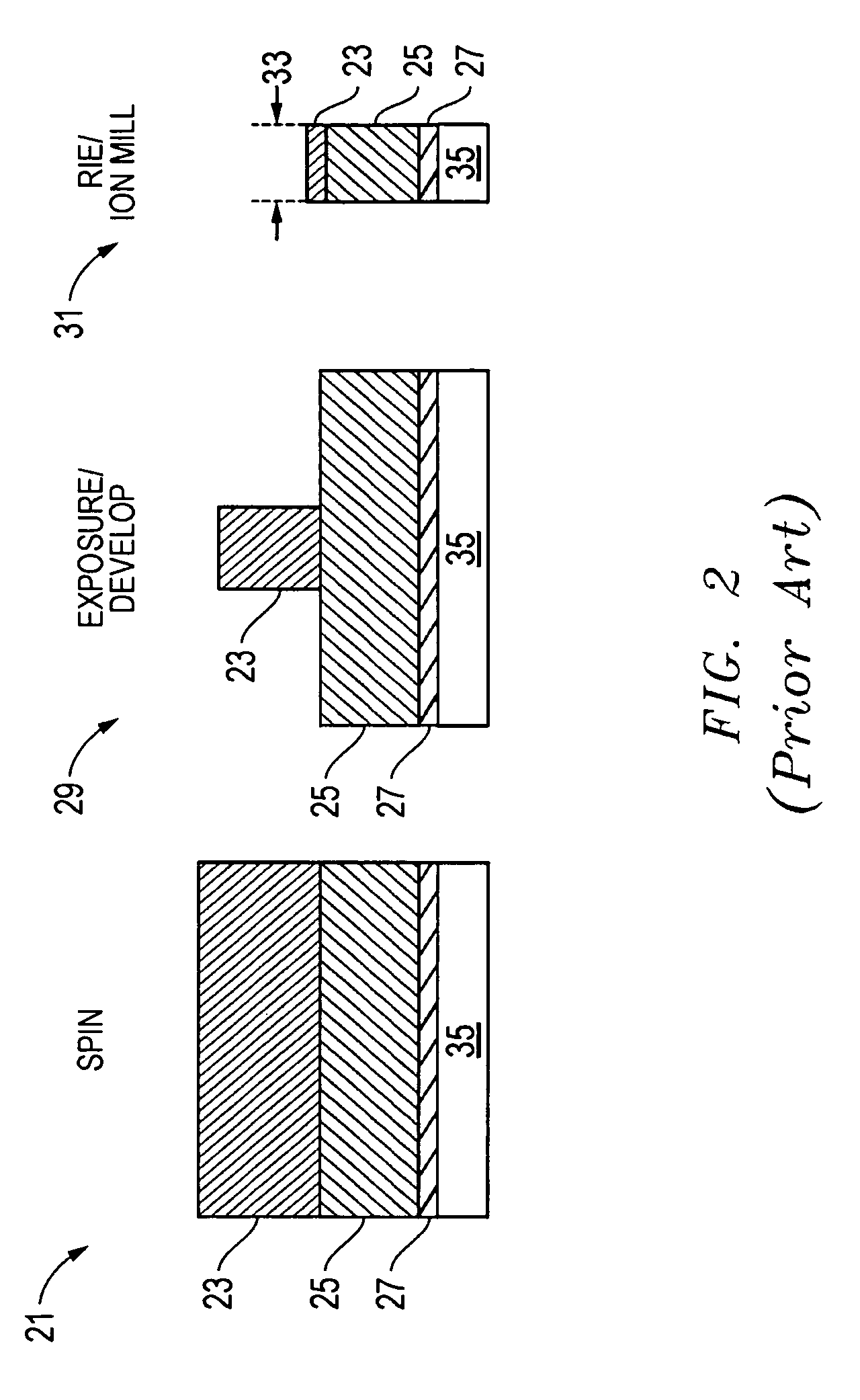

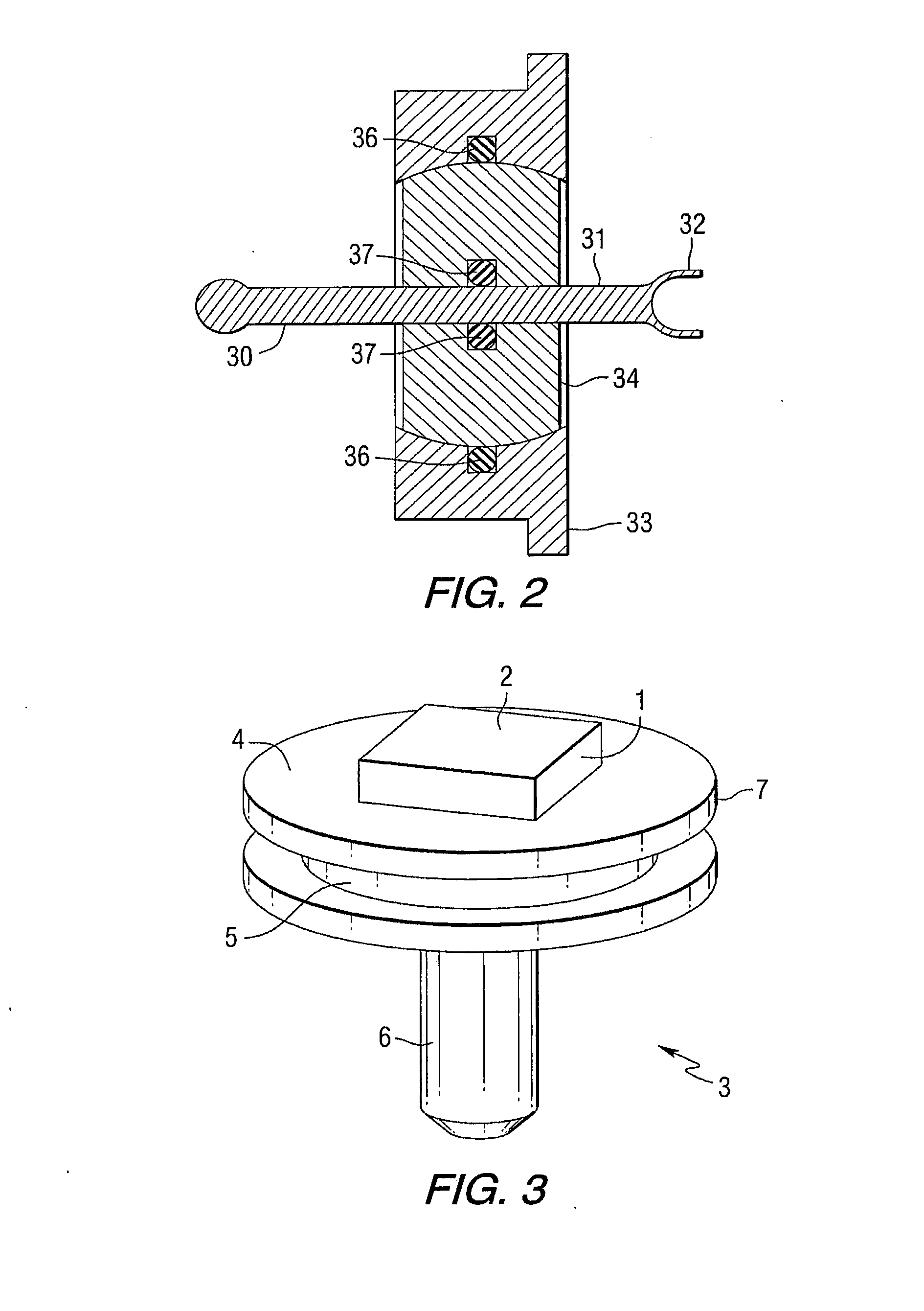

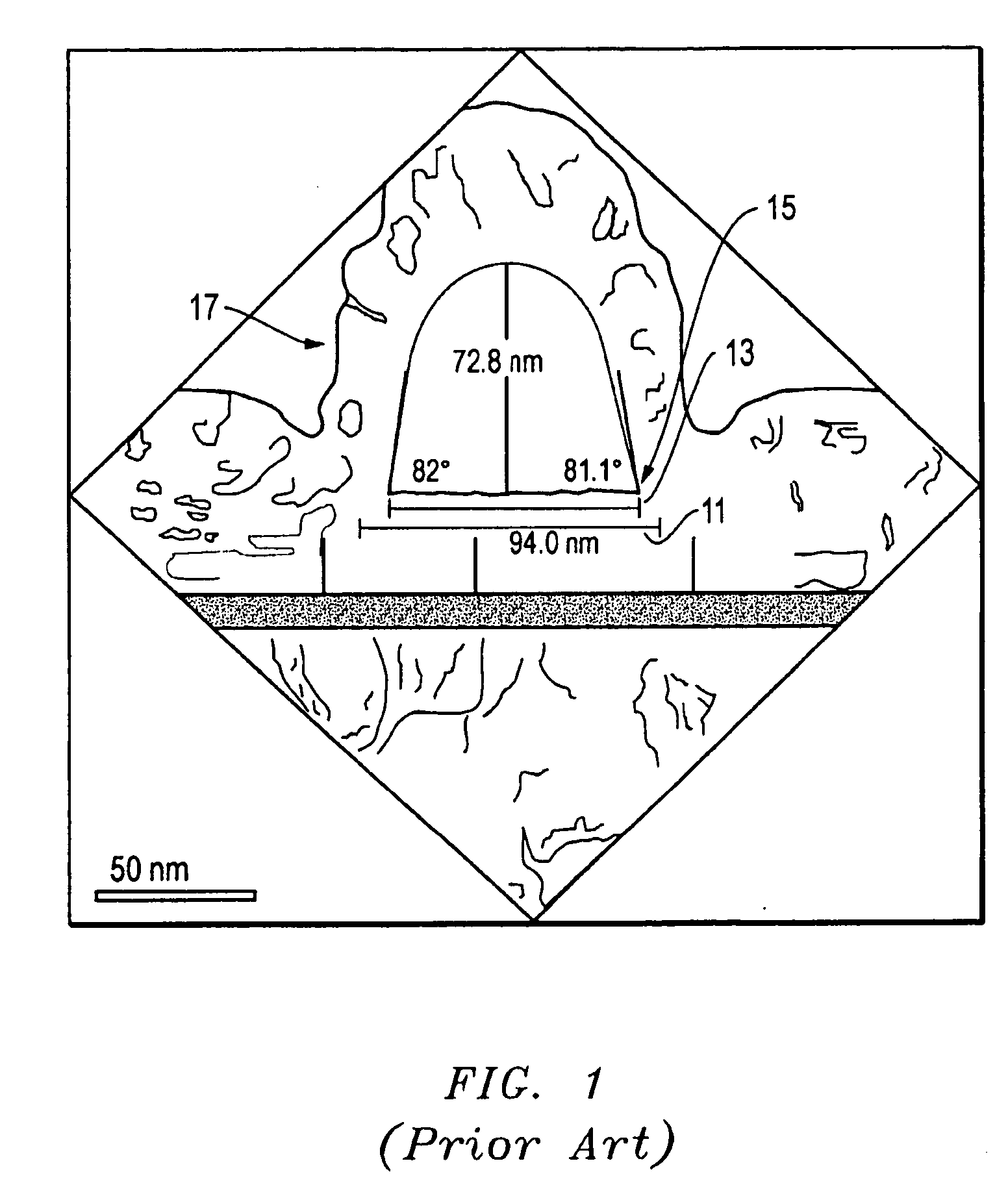

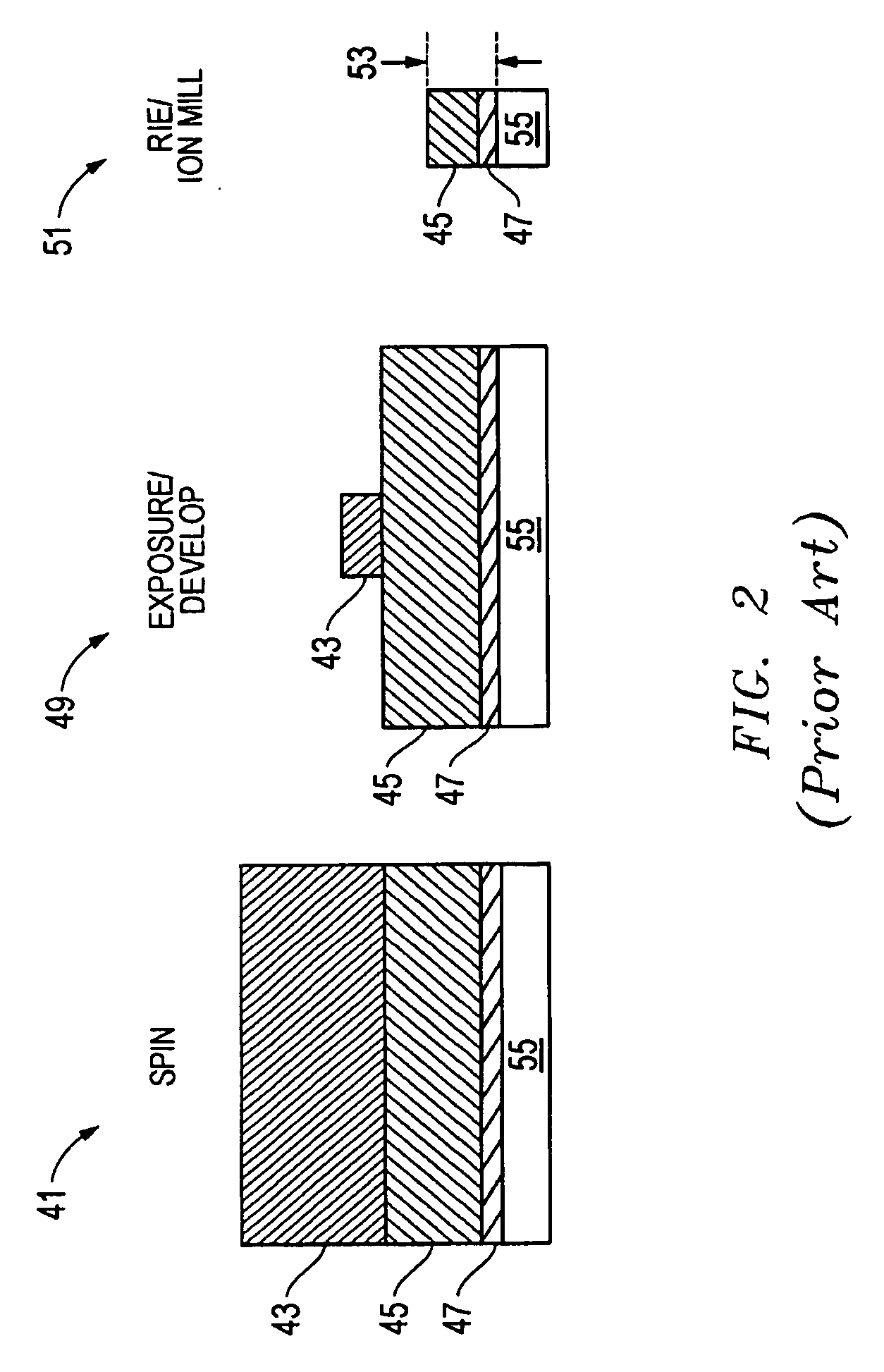

Perpendicular magnetic recording write head with notched trailing shield and method for making

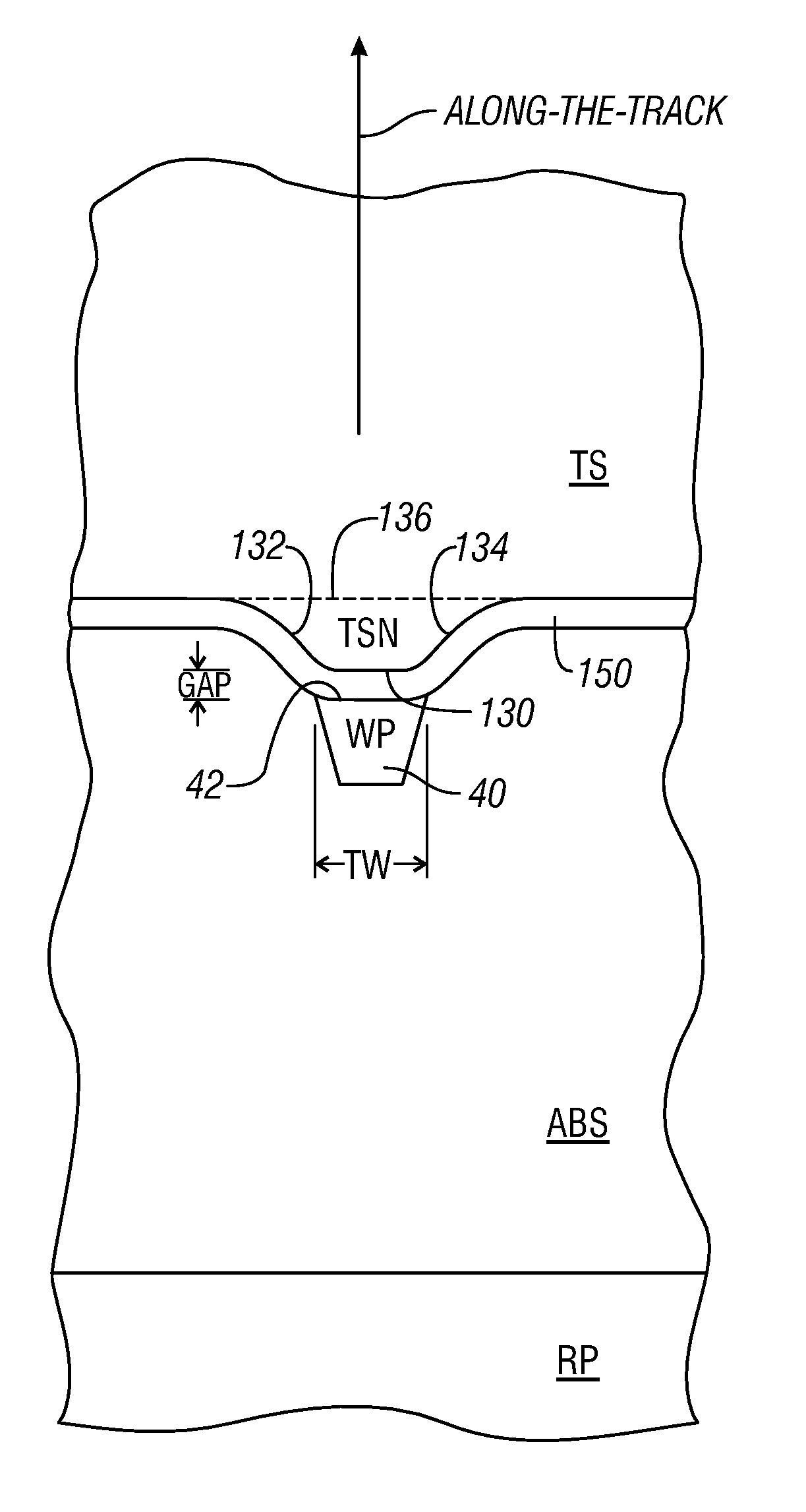

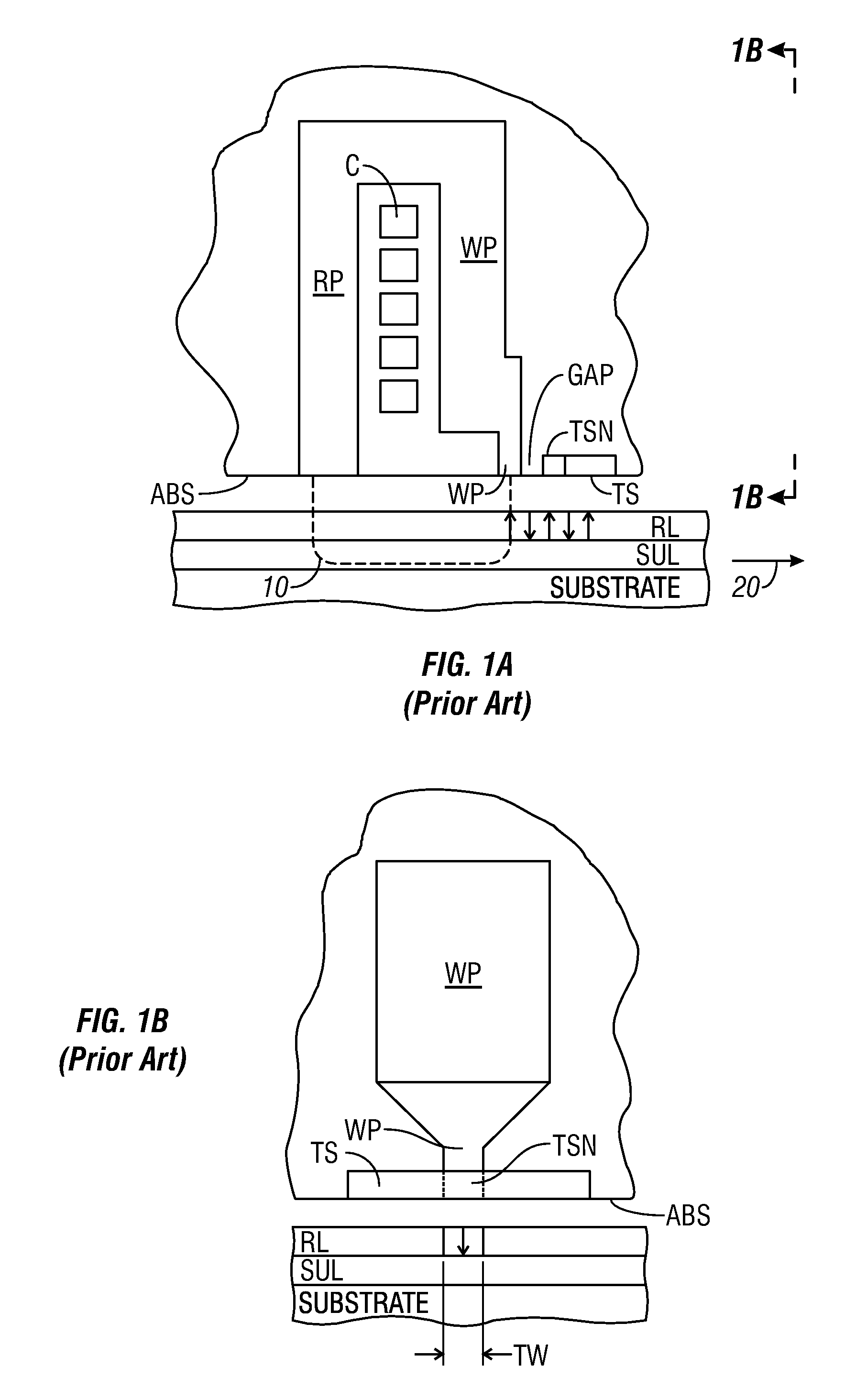

InactiveUS20070263324A1Reduce saturationReduced-thickness gapElectrical transducersDisposition/mounting of recording headsEngineeringTrailing edge

The invention is a perpendicular magnetic recording write head with a write pole, a trapezoidal-shaped trailing shield notch, and a metal gap layer between the write pole and notch. The write pole has a trailing edge that has a width substantially defining the track width and that faces the front edge of the notch but is spaced from it by the gap layer. The write head is fabricated by a process than includes reactive ion beam etching of a thin mask film above the write pole to remove the mask film and widen the opening at the edges of the write pole. The gap layer and notch are deposited into the widened opening above the write pole. The write pole has nonmagnetic filler material, such as alumina, surrounding it except at its trailing edge, where it is in contact with the gap layer, which is formed of a different material than the surrounding filler material.

Owner:WESTERN DIGITAL TECH INC

Precision synthesis of quantum dot nanostructures for fluorescent and optoelectronic devices

Methods are disclosed generally directed to design and synthesis of quantum dot nanoparticles having improved uniformity and size. In a preferred embodiment, a release layer is deposited on a semiconductor wafer. A heterostructure is grown on the release layer using epitaxial deposition techniques. The heterostructure has at least one layer of quantum dot material, and optionally, one or more layers of reflective Bragg reflectors. A mask is deposited over a top layer and reactive ion-beam etching applied to define a plurality of heterostructures. The release layer can be dissolved releasing the heterostructures from the wafer. Some exemplary applications of these methods include formation of fluorophore materials and high efficiency photon emitters, such as quantum dot VCSEL devices. Other applications include fabrication of other optoelectronic devices, such as photodetectors.

Owner:SPIRE

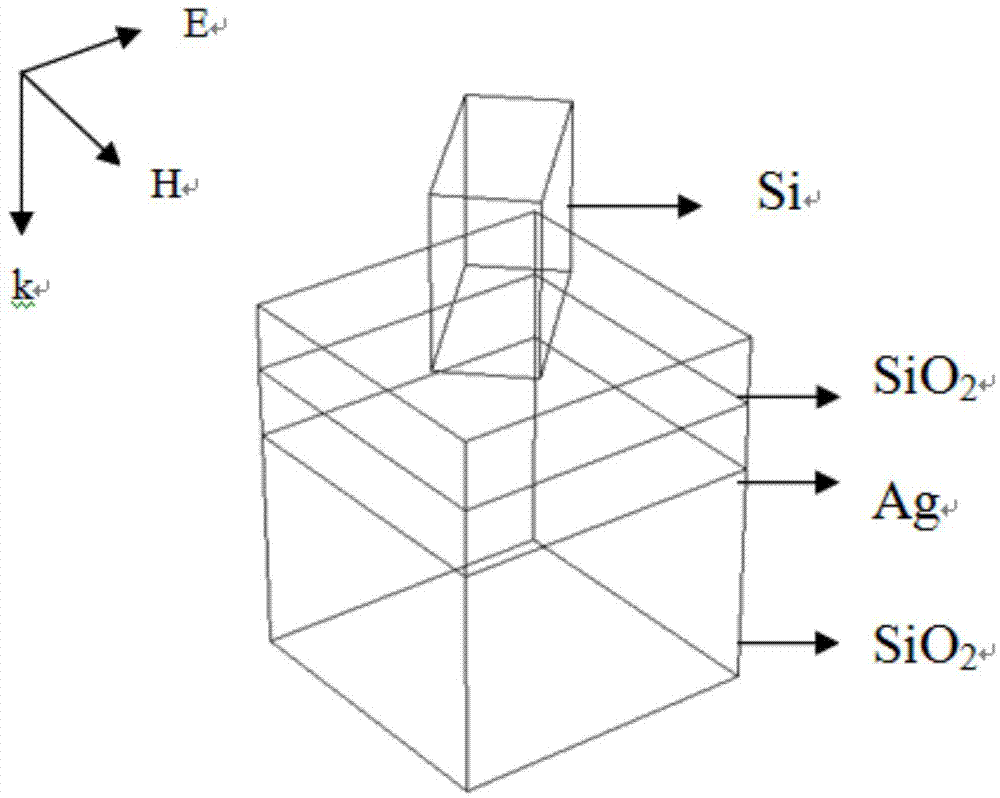

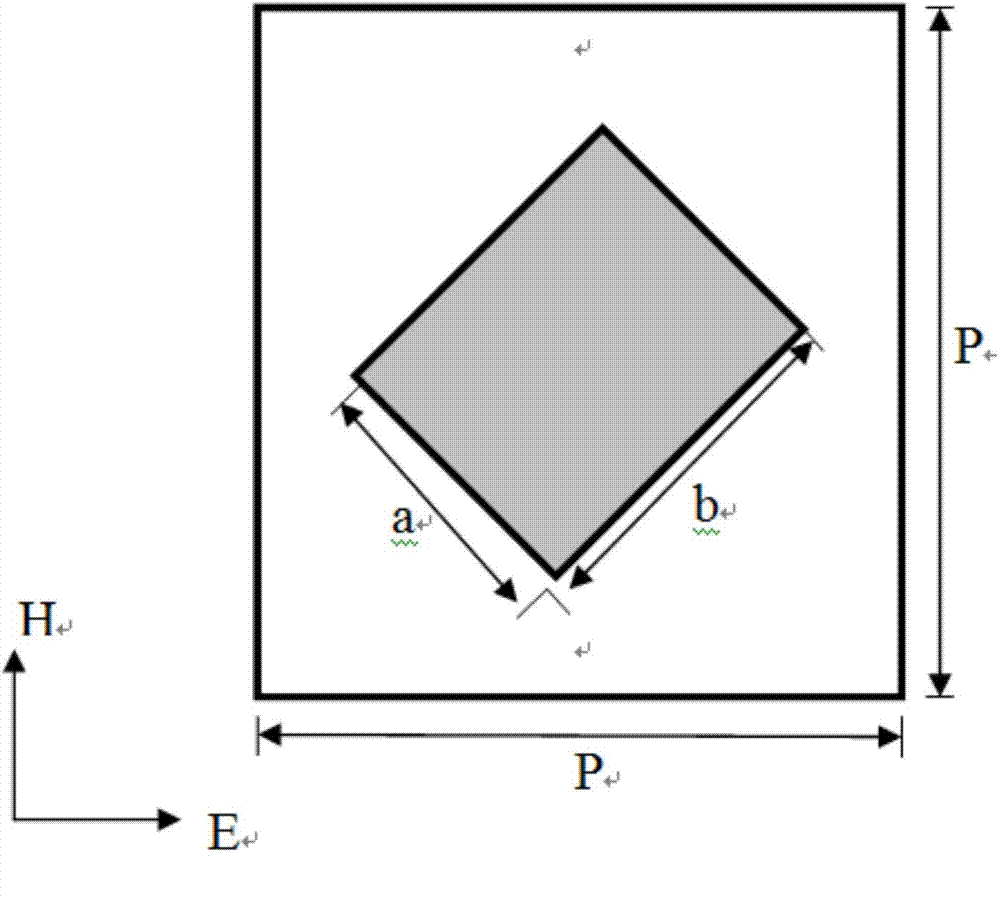

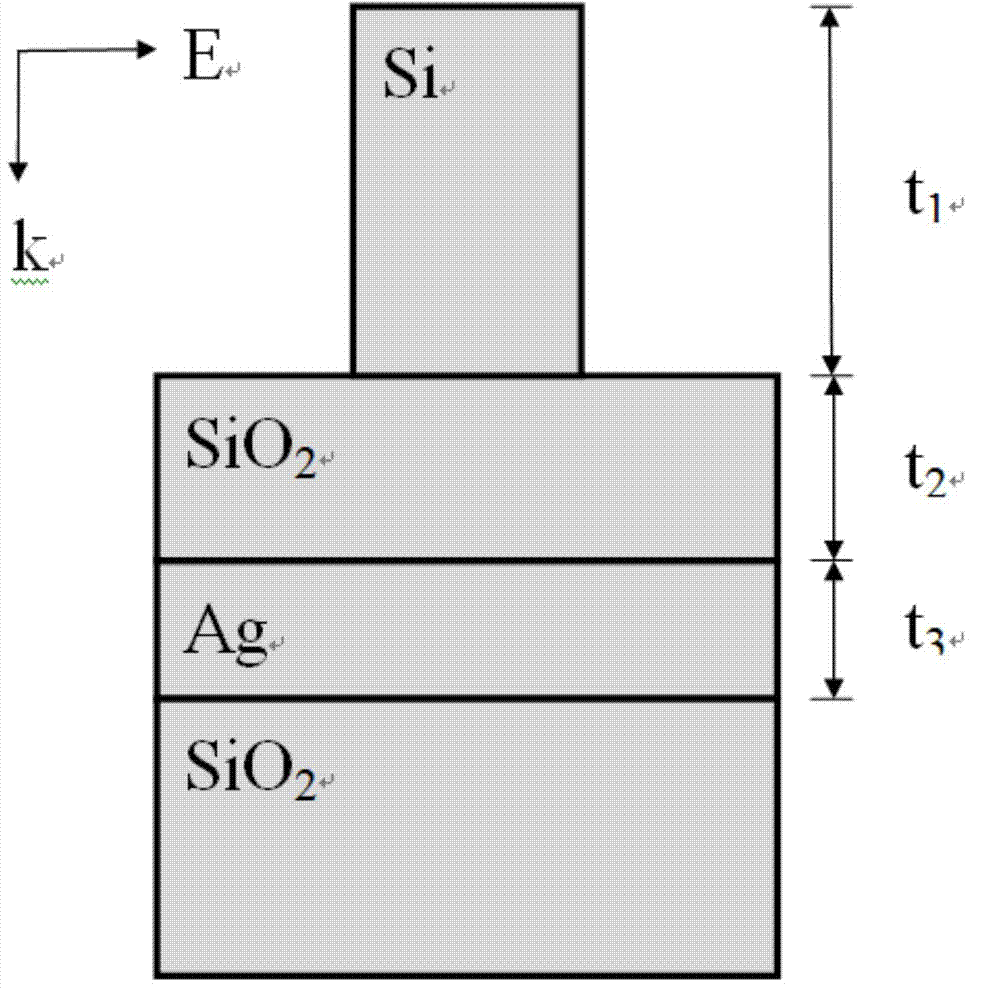

Planar lens unit based on dielectric material, planar lens and preparation method

The invention provides a planar lens unit based on dielectric material, a planar lens and a preparation method. The unit comprises an antenna made of dielectric material with high refractivity, a silica filling layer, a silver mirror and a silica substrate. The planar lens comprises the planar lens units distributed about the center, and the antennas of the planar lens units are distributed on the axis X regularly and are distributed symmetric about the axis y when y equals to zero. The method includes firstly, covering the silica substrate with a layer of silver film, and covering the surface of the silver film with the filling layer of silica and a silicon film through electron beam vapor deposition continuously; secondly, coating the silicon film with photoresist, and completing the etching and developing of the photoresist by the electron beam exposure technology; thirdly, etching the silicon film by the reactive ion beam etching technology; fourthly, performing peeling to obtain the finished nano silicon antenna. Thus, the focusing efficiency can be improved by one order of magnitude, and the high practical application value is provided.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

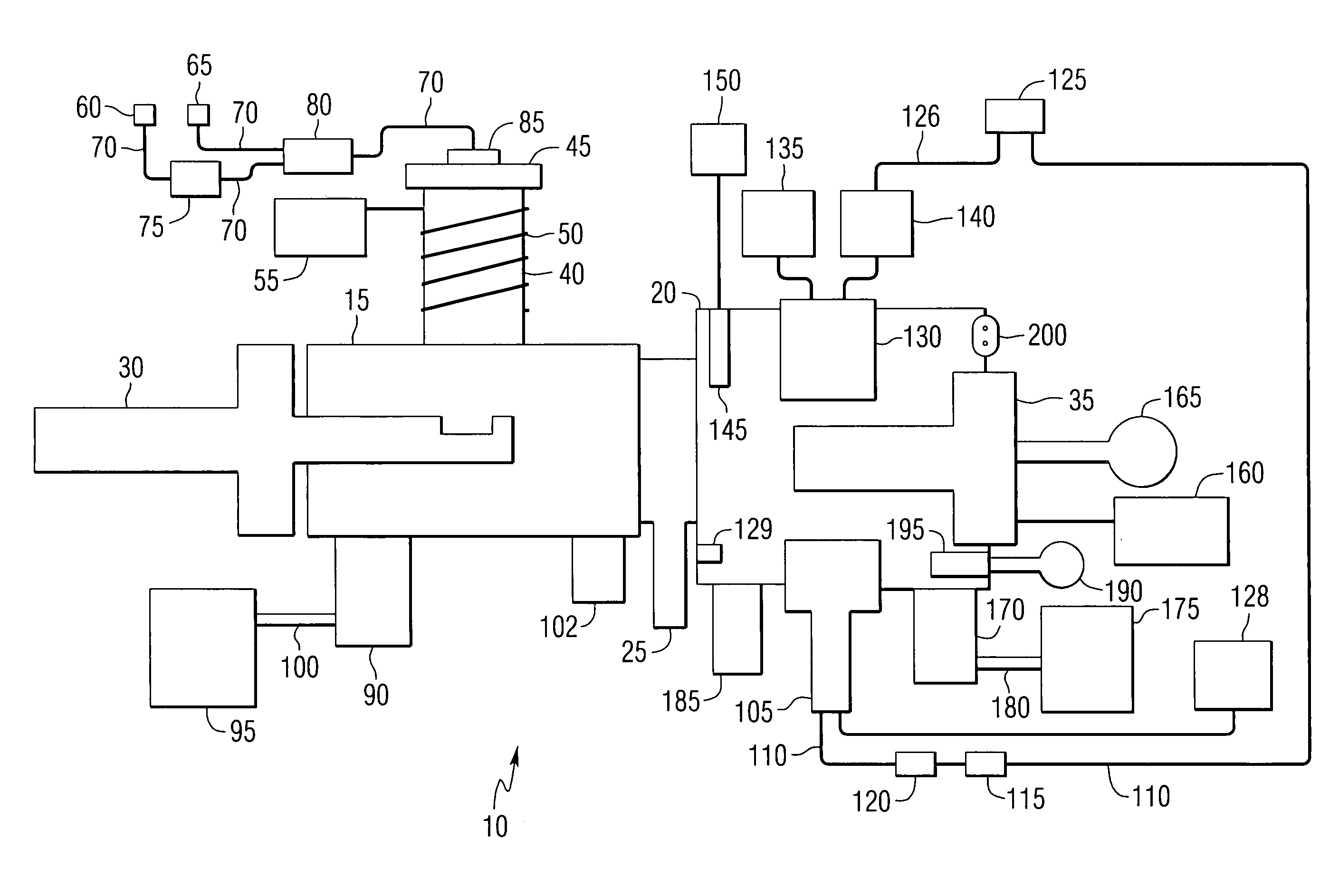

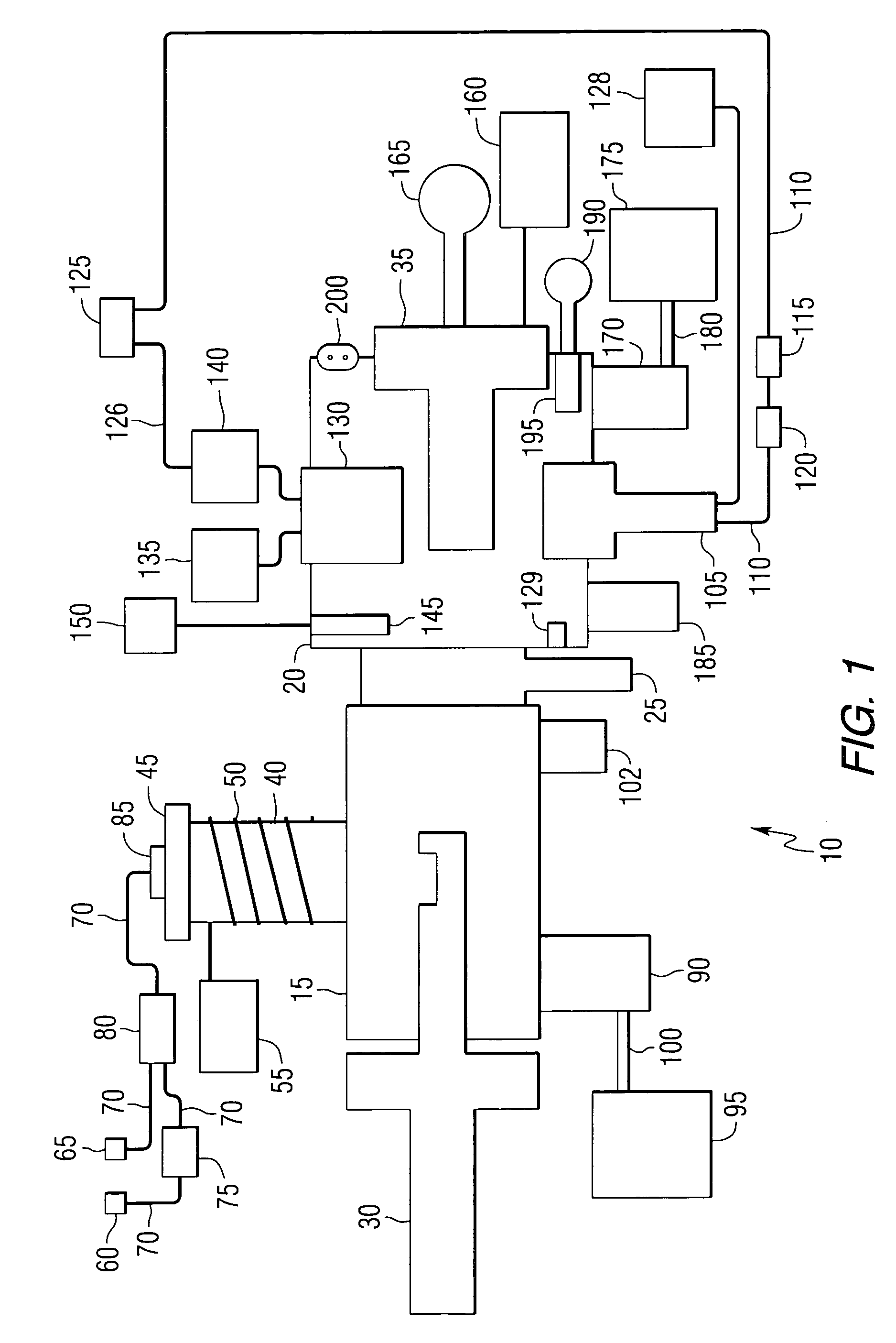

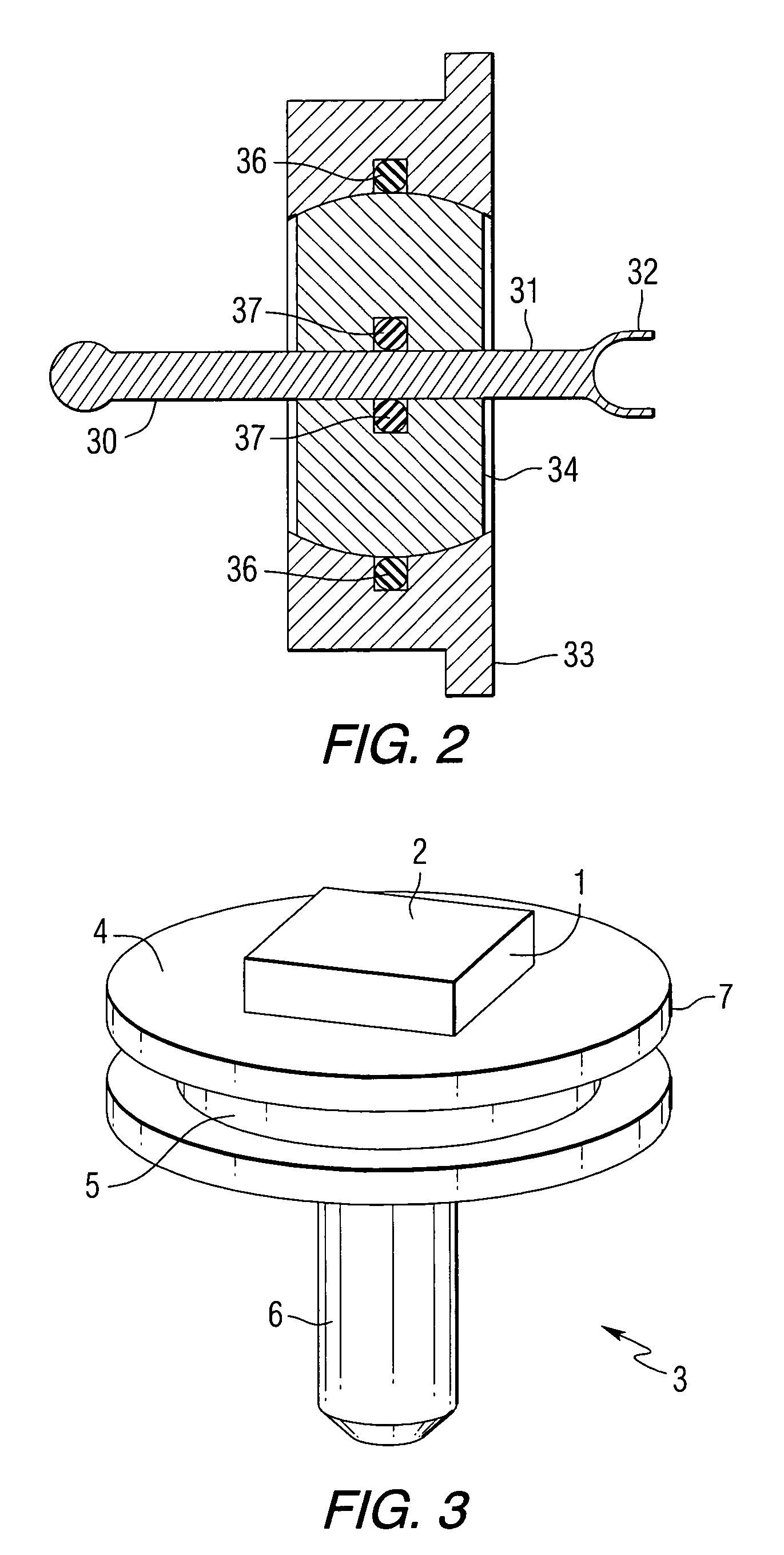

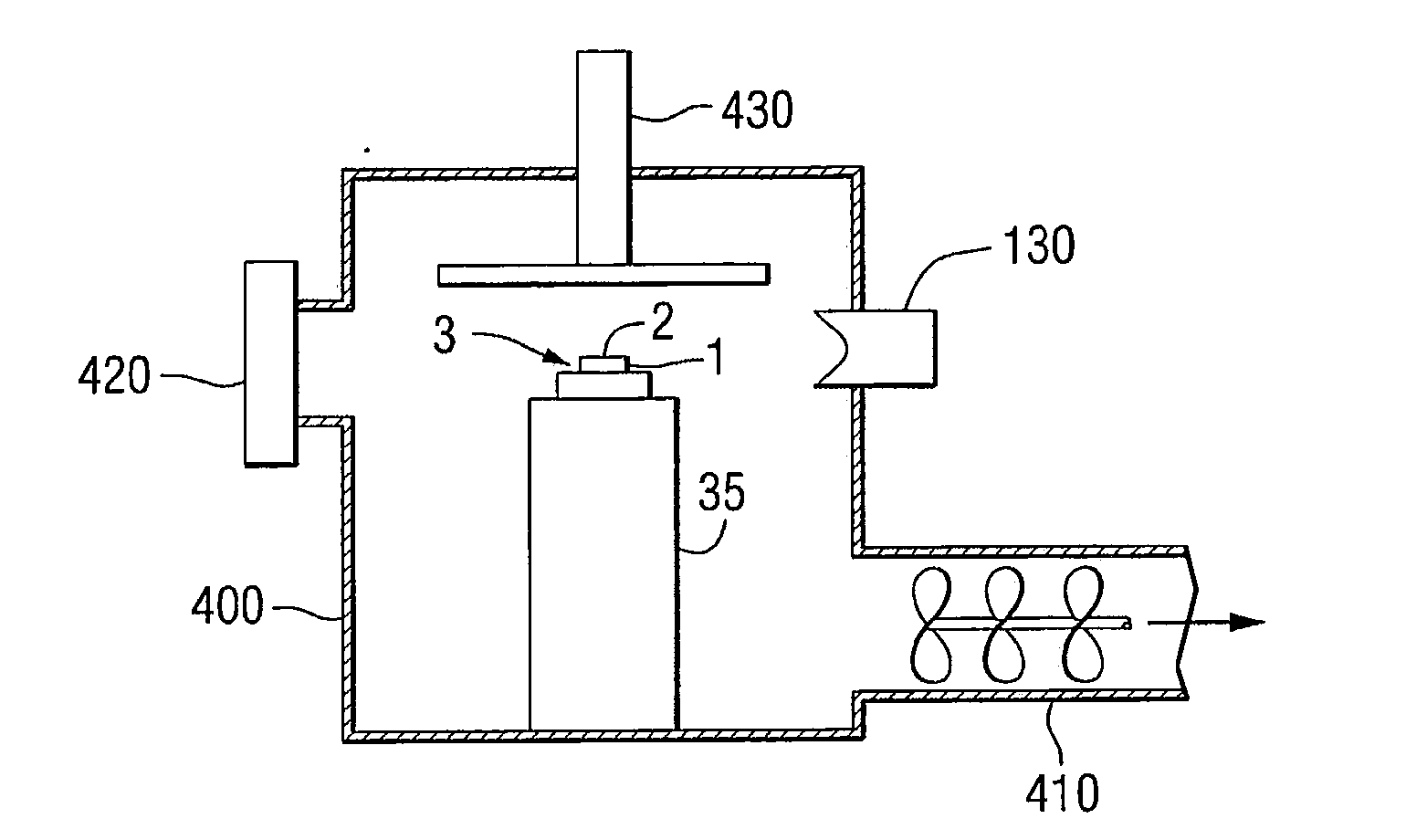

Method and apparatus for preparing specimens for microscopy

An apparatus for preparing specimens for microscopy including equipment for providing two or more of each of the following specimen processing activities under continuous vacuum conditions: plasma cleaning the specimen, ion beam or reactive ion beam etching the specimen, plasma etching the specimen and coating the specimen with a conductive material. Also, an apparatus and method for detecting a position of a surface of the specimen in a processing chamber, wherein the detected position is used to automatically move the specimen to appropriate locations for subsequent processing.

Owner:E A FISCHIONE INSTR

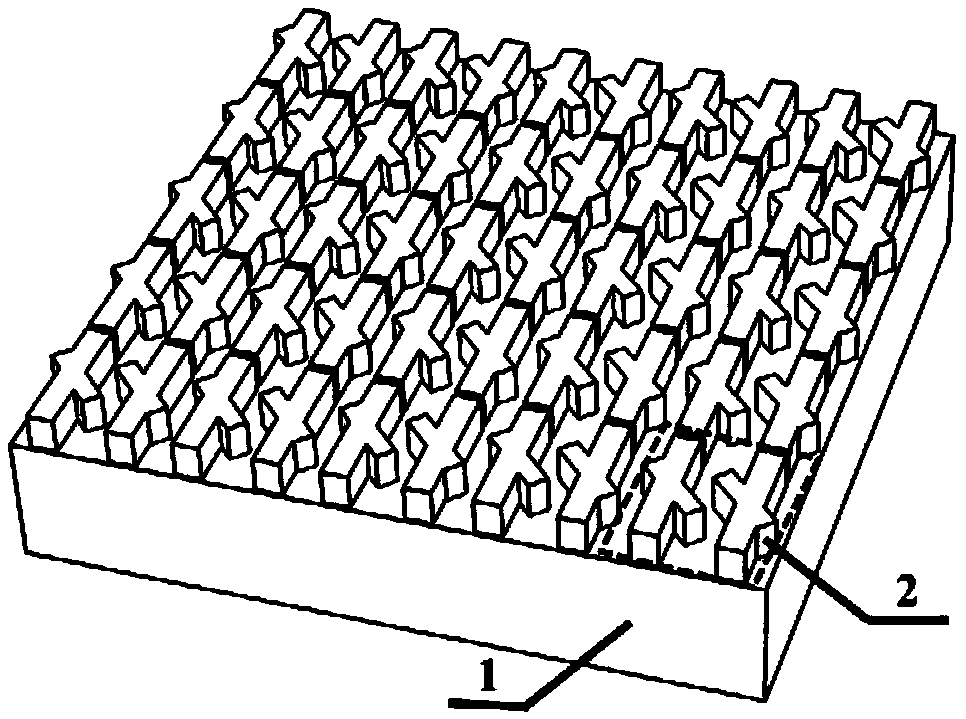

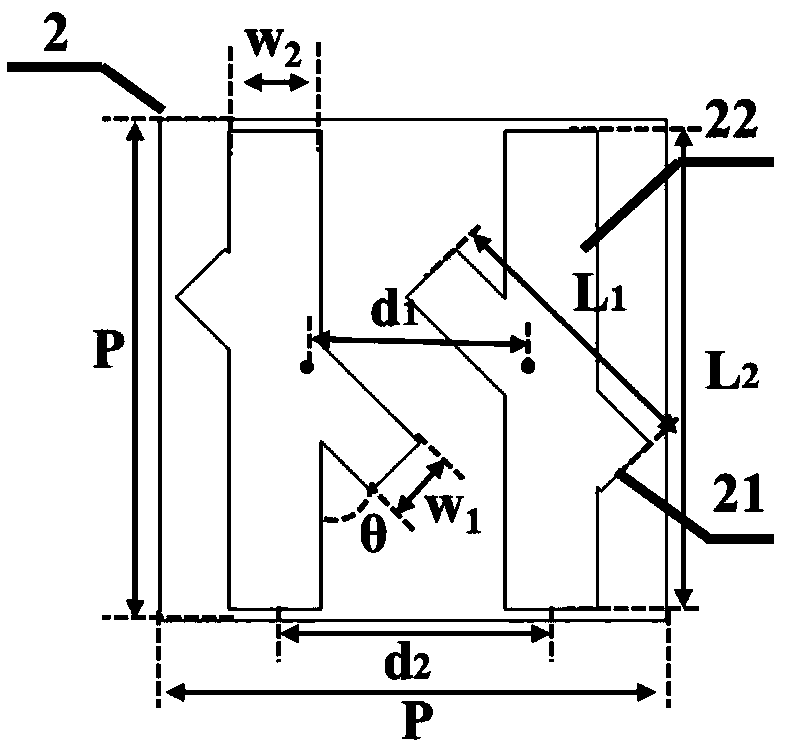

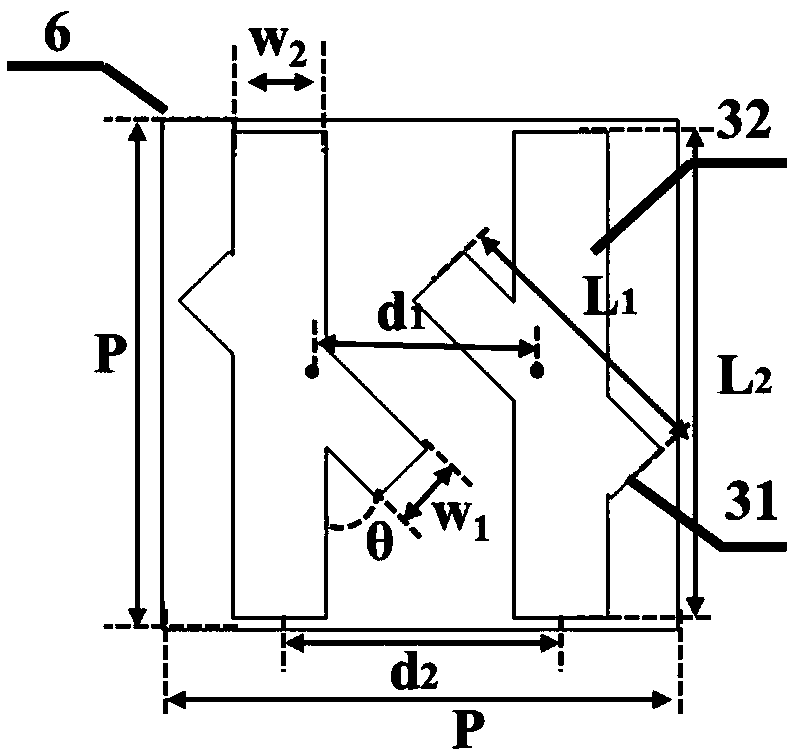

Metasurface circularly-polarized light detection component and production method thereof

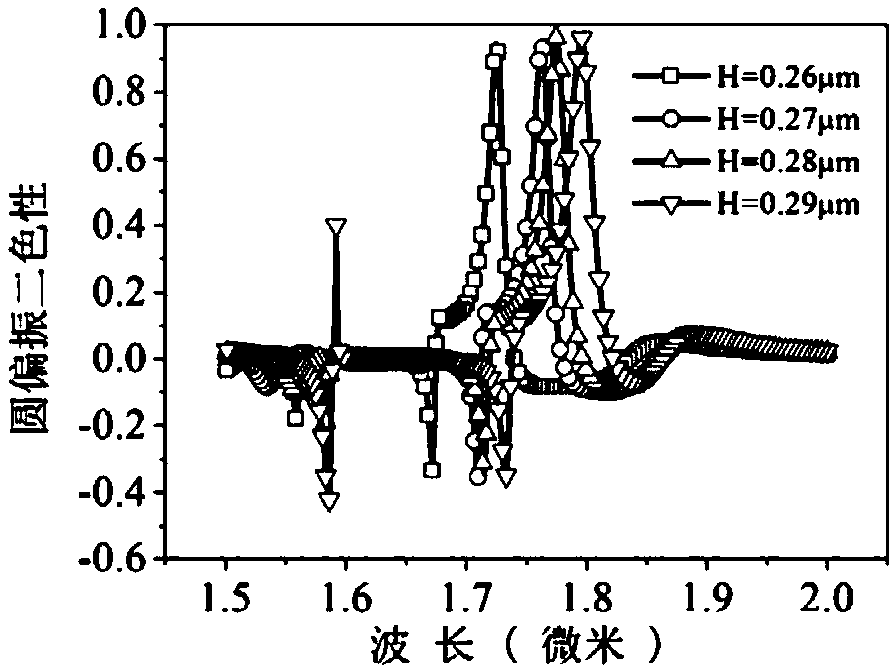

ActiveCN108801461AStrong circular dichroismStructural size parameters are adjustableRadiation pyrometryPolarisation spectroscopyDielectricPhotonics

A metasurface circularly-polarized light detection component comprises a light-permeable substrate and rotationally symmetric chiral medium structural units arrayed on the light-permeable substrate; each rotationally symmetric chiral dielectric structural unit is composed of two pairs of dielectric arms crossed; a gap is formed between every two rotationally symmetric chiral dielectric structuralunits. The metasurface circularly-polarized light detection component may be made by means of electron beam lithography and photolithography, reactive ion etching and other processes. The metasurfacecircularly-polarized light detection component has great circularly-polarized dichroism, and can distinguish circular polarization states; the circularly-polarized dichroism is up to 96.8% at 1.75 mum; the metasurface circularly-polarized light detection component has excellent properties and is highly worthy of application in optical sensing systems, advanced nan photonic devices and integratedoptical systems.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

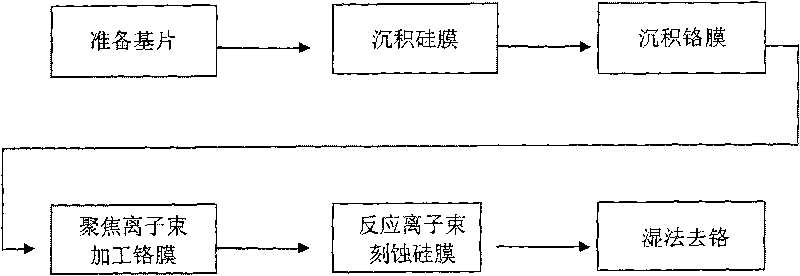

Silicon mask used for super-diffraction photoetching with line width of below 200 nanometers and manufacturing method thereof

InactiveCN101726990AReduce processing difficultyAdd depthOriginals for photomechanical treatmentNanolithographyLine width

The invention discloses a silicon mask used for super-diffraction photoetching with line width of below 200 nanometers and a manufacturing method thereof. The mask uses a silicon film on an ultraviolet transparent material substrate as a graph layer. The manufacturing method for the silicon mask comprises the following steps: firstly, processing the silicon film with a certain thickness on the substrate to have the ultraviolet transmittance within 5 percent; then, processing a layer of thin chromium film on the surface of the silicon film; preparing a graph with the line width of less than 200 nanometers on the chromium film by using focusing ion beams; etching the silicon film through reaction ion beams by using the silicon film layer as a shielding layer so as to transfer the graph on the chromium film to the silicon film; and finally, corroding the residual chromium film by using chromium solution to form the practical silicon mask with high resolution and great depth of the graph layer. The silicon mask and the processing method solve the technical problem that a chromium mask with great depth of the graph layer and line width of less than 200 nanometers is difficult to manufacture by the focusing ion beams, and have broad application prospect in the nano photoetching technology.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

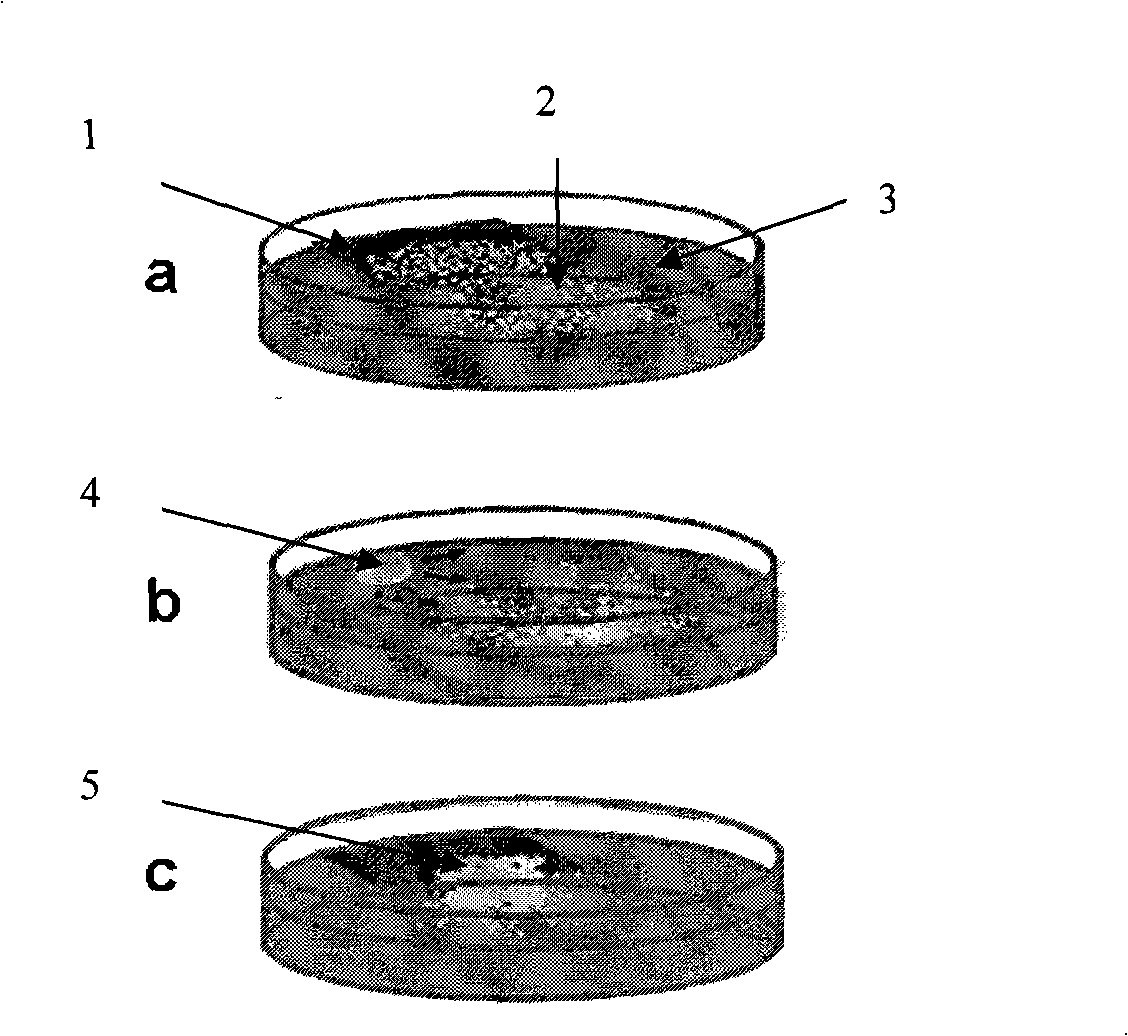

Preparation method of photonic crystal scintillator by using polymer template

InactiveCN105350077AAvoid radiation damageGuaranteed periodicityPolycrystalline material growthSingle crystal growth detailsNuclear radiationRefractive index contrast

Owner:TONGJI UNIV

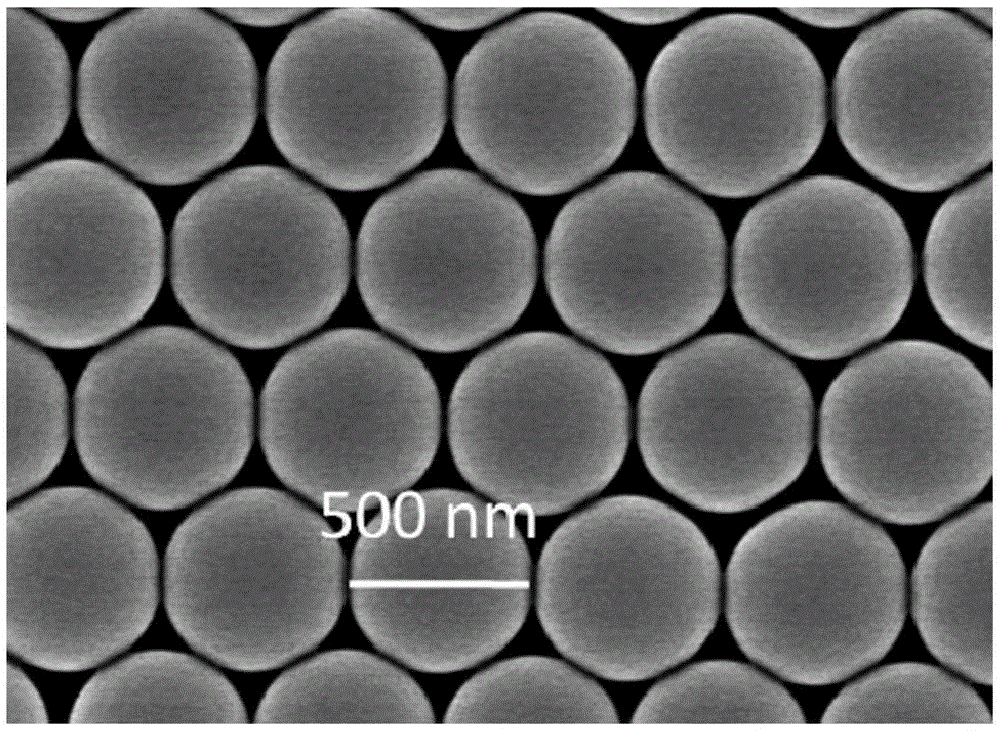

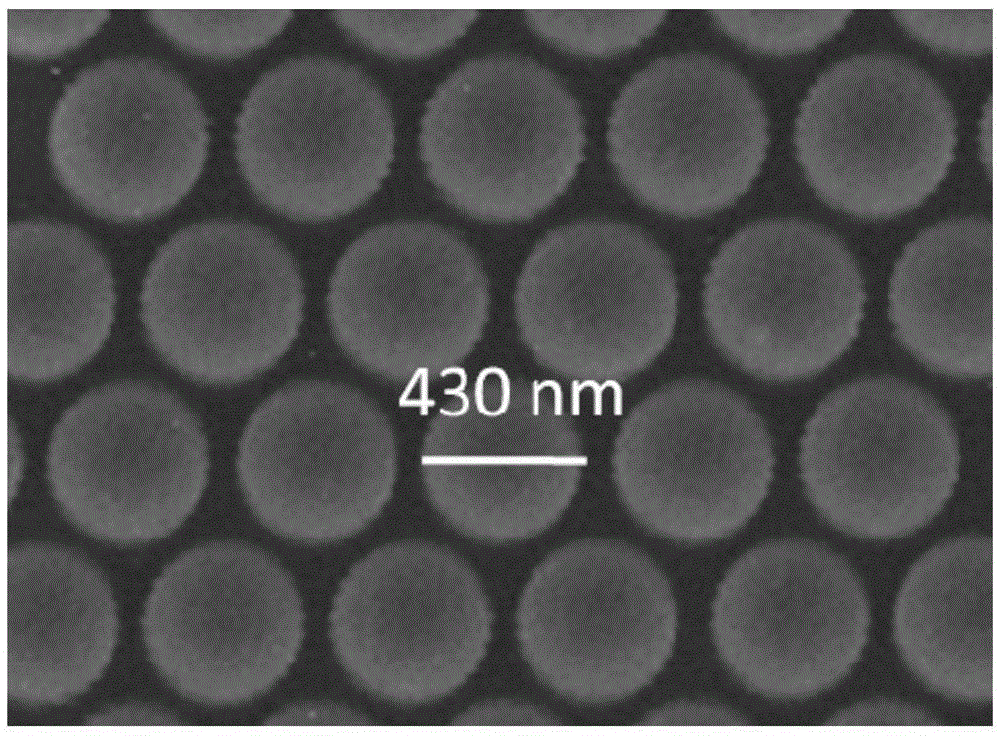

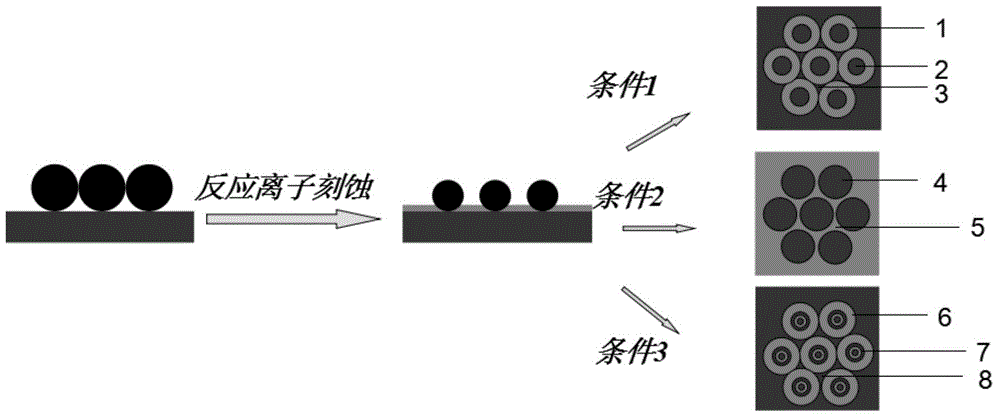

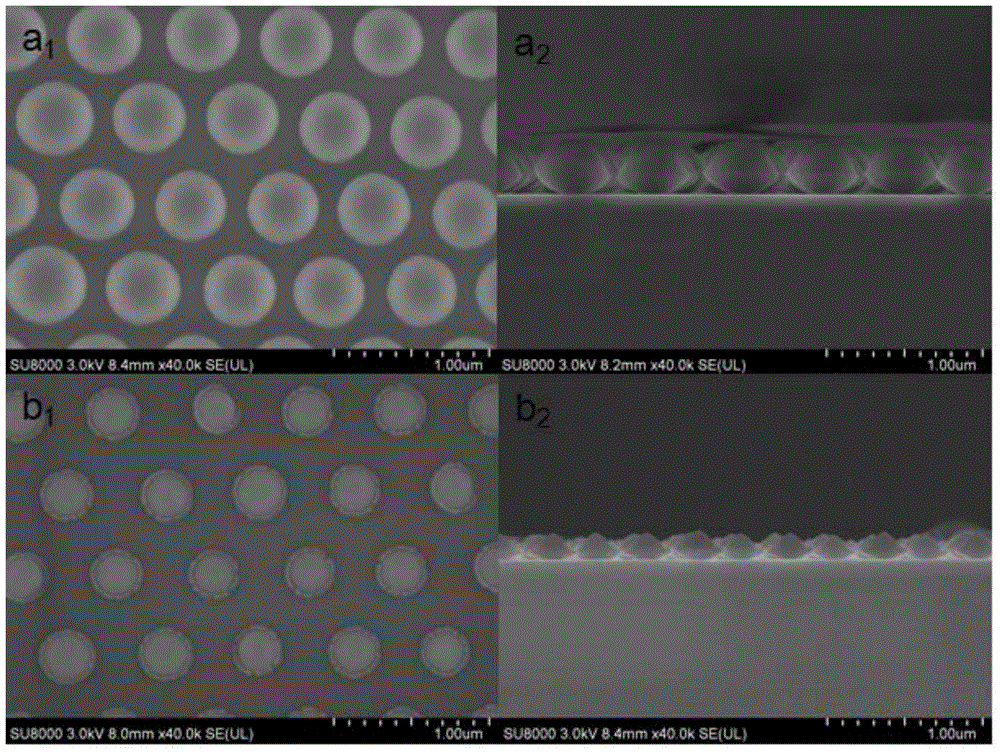

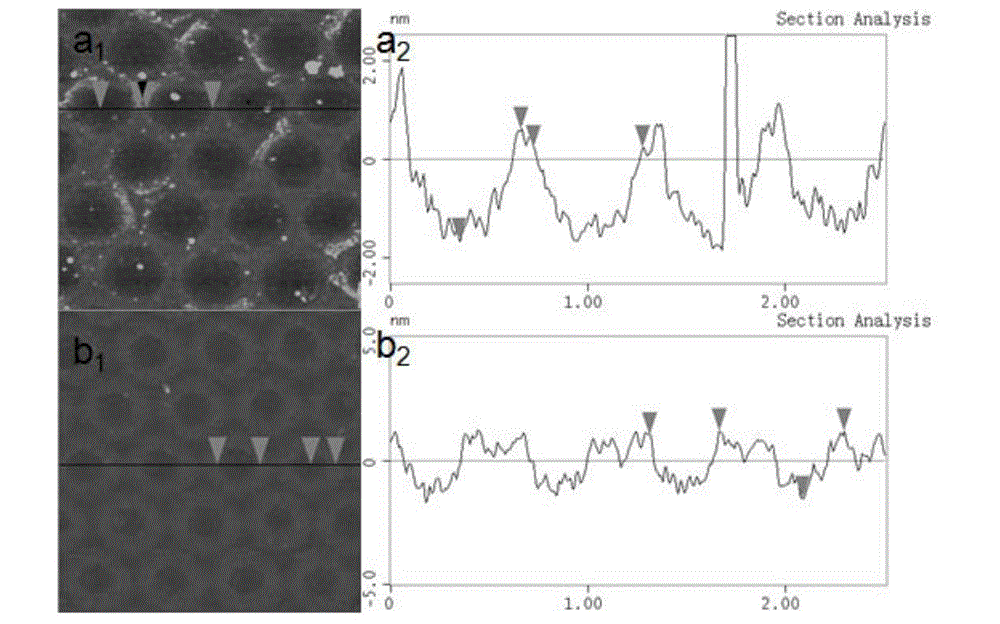

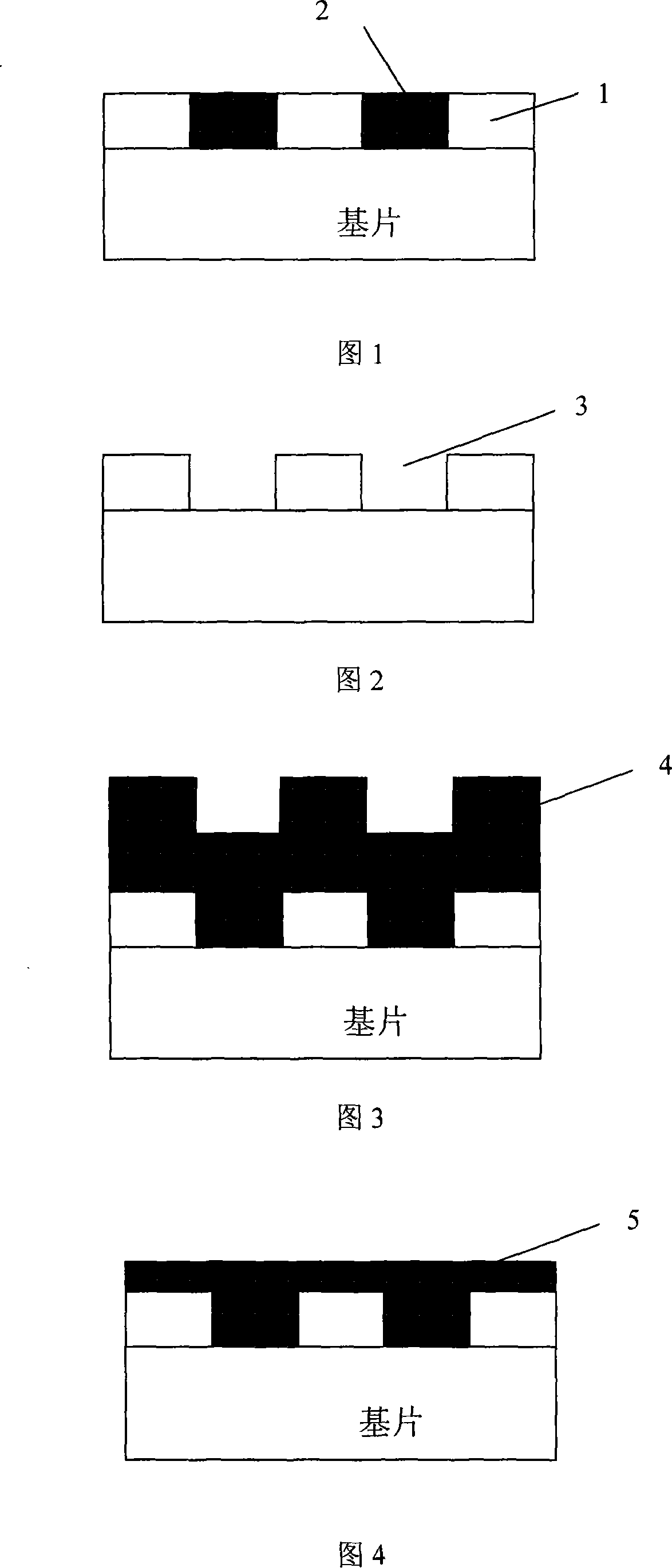

Method for preparing thin film ordered microstructure based on a reaction ion beam etching technology

InactiveCN104555910ANanostructure manufactureSemiconductor/solid-state device manufacturingMicrosphereElectroless deposition

The invention provides a method for preparing ordered thin film patterns based on a reaction ion etching polymer and belongs to the technical field of ordered microstructures. Specifically, reaction ion etching is conducted on a substrate and single-layer polymeric microspheres on the surface of the substrate, accordingly the ordered thin film patterns are formed on the surface of the substrate and can be regulated and controlled by changing reaction ion etching parameters. Furthermore, electroless deposition is conducted on the surface of the substrate, metal nano particles can be selectively absorbed in the area provided with no a thin film or a non-compact thin film, and further an ordered array of the metal nano particles is formed. The ordered array of the metal nano particles has certain application value on the aspects of Raman detection and plasma regulation and control. In addition, due to the fact that the surface of the generated thin film is provided with functional groups, the method can be applied to selective self assembly, preferential absorption of enzyme and protein and also has good application prospect on the aspects of biological monitoring and sensing.

Owner:JILIN UNIV

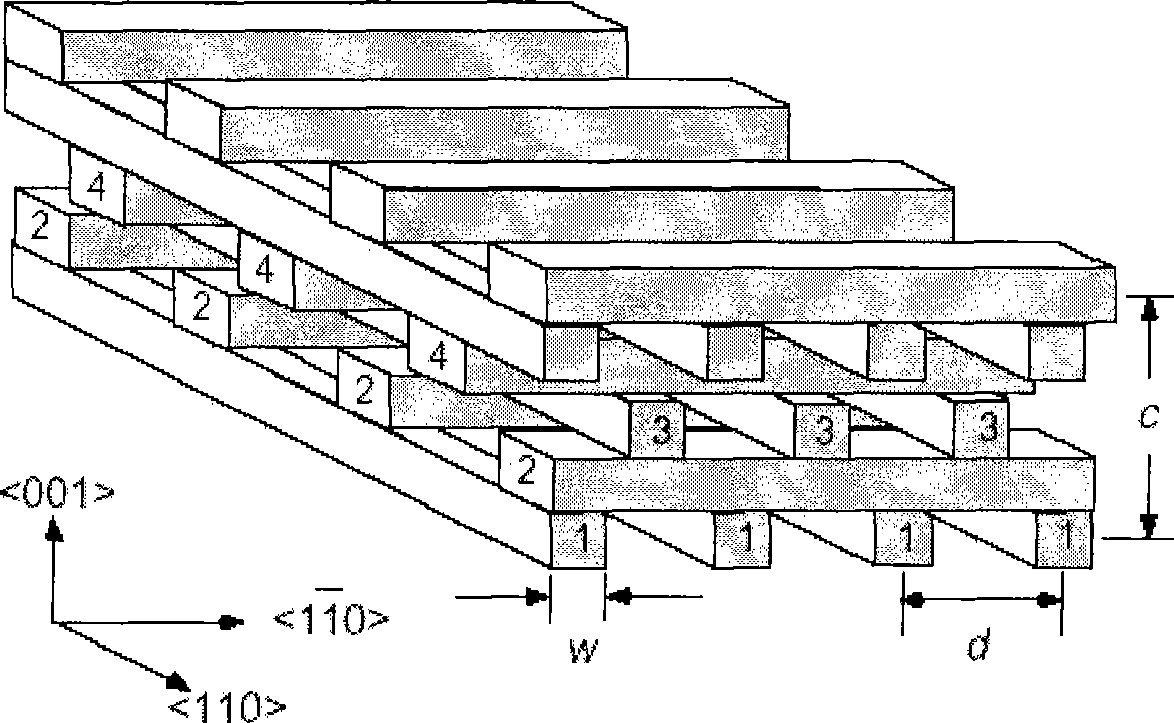

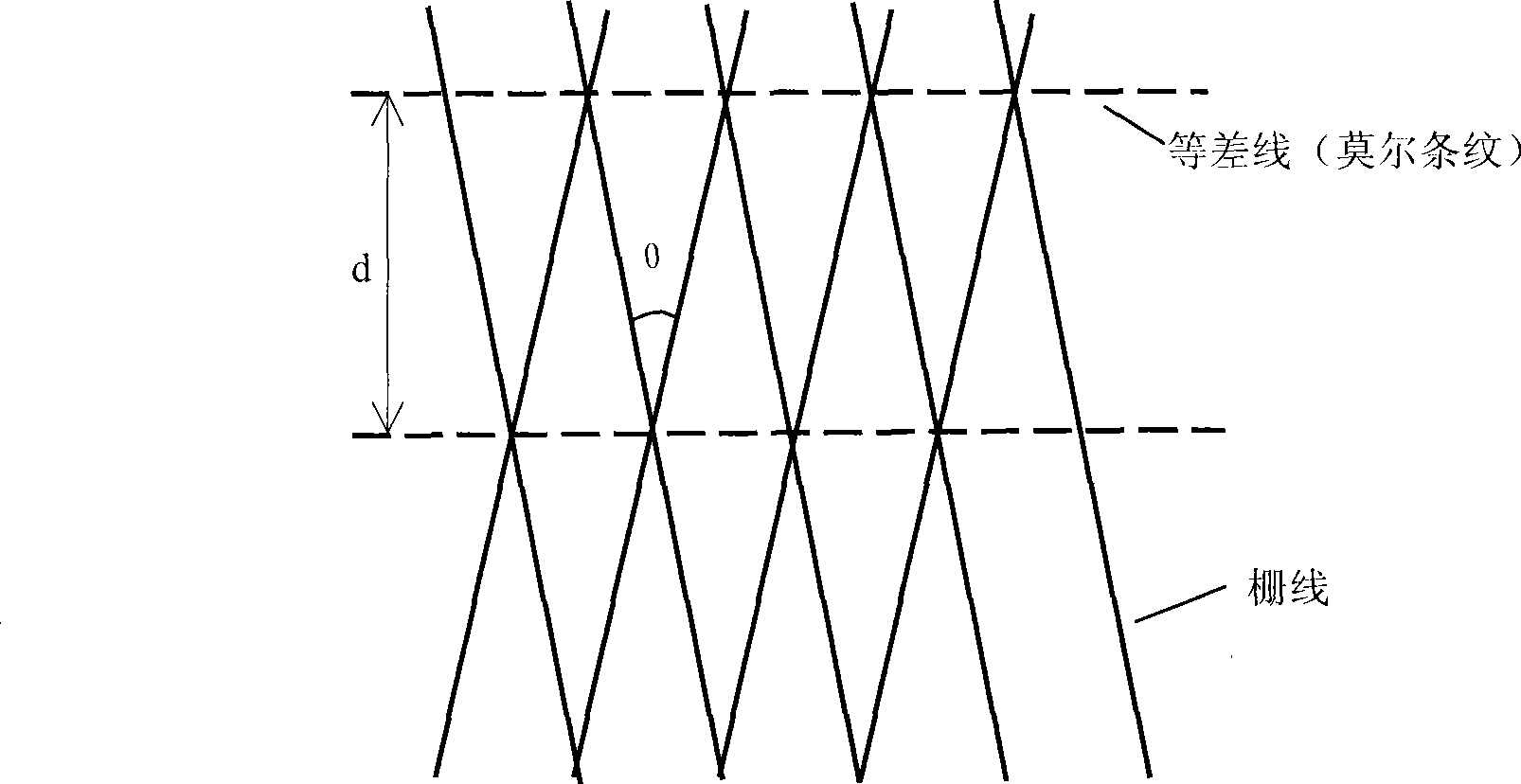

Method for making near infrared band three-dimensional photon crystal

ActiveCN101393303ALow costEasy to introduce areaPhotosensitive material processingOptical light guidesRefractive indexAcid washing

The invention discloses a method for manufacturing a near infrared waveband three-dimensional photonic crystal, wherein an one-dimensional crystal mask is formed by utilization of holographic interference, and is transferred onto a SiO2 layer on a silicon substrate material through ion beam etching or reactive ion beam etching; high refractive index materials are filled into an etched groove; the surface is polished by the ion beam etching method, and then SiO2 is deposited; a second layer is formed after coating of photoresist, holographic photoetching, ion beam etching and so on; the steps are repeated, and layers are aligned by the Moire fringe technique; and finally the SiO2 is removed by the acid washing method, and the three-dimensional photonic crystal required is obtained. The method fully utilizes the submicron resolution of holographic photoetching, can manufacture the large-area three-dimensional photonic crystal which can then be cut into small blocks as required, has the advantages of high efficiency and low cost, and simultaneously is convenient to overcome the defects of introduction of large area and periodicity by changing wave fronts of two beams of coherent light in an interference field.

Owner:SUZHOU UNIV

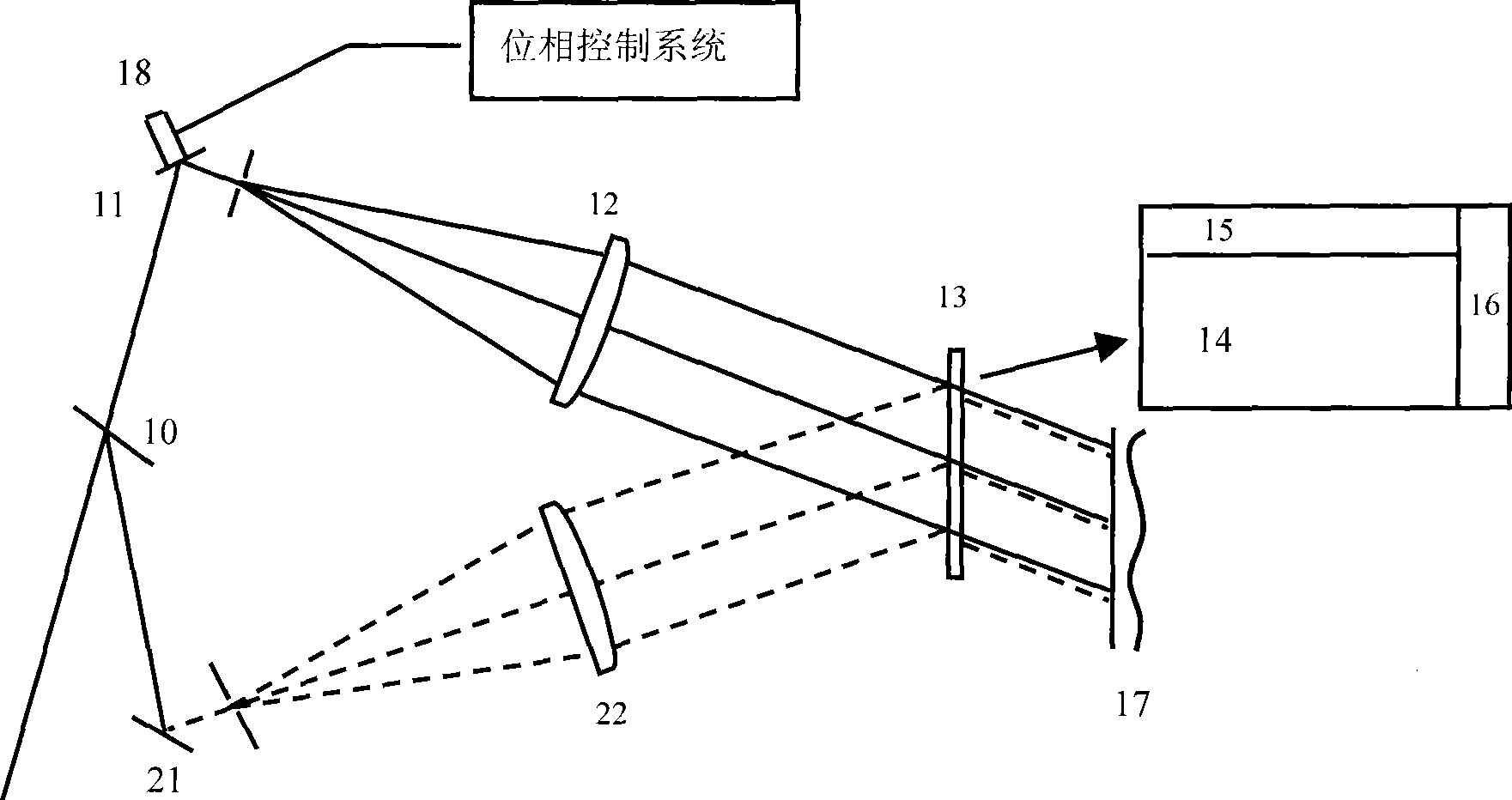

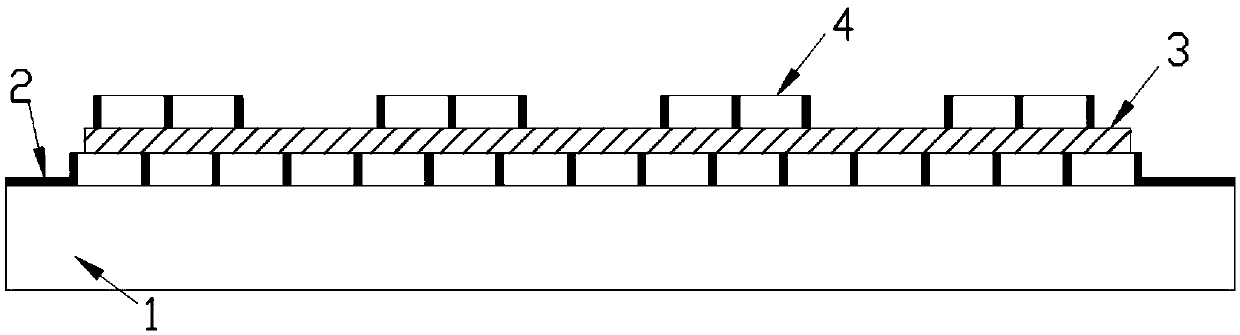

Production method of plane continuous diffraction condensing lens

ActiveCN101470224AProcess stabilityGood repeatabilityPhotomechanical apparatusDiffraction gratingsMicro structureOptoelectronics

The invention discloses a method for preparing a plane continuous diffractive focus lens, which comprises steps of manufacturing a mask of the plane continuous diffractive focus lens and utilizing a method of reactive ion beam etching to continuously transferring micro-structural patterns. The method utilizes the laser directing writing technique to carry out positional quantitative exposure to photoresist on the surface of a photoresist plate, after development, a continuous diffractive micro-structure is formed on the photoresist layer, then the mask is formed via heating and the like, and further the method utilizes the method of reactive ion beam etching to transfer the micro-structure on the surface of the mask to the surface of a substrate, thereby forming the plane continuous diffractive focus lens. The method has the advantages of high manufacturing precision, short manufacturing period, simple manufacturing process, low manufacturing cost and the like, and is suitable for manufacturing the lightweight and high-performance plane continuous diffractive focus lens. Compared with other manufacturing methods, the laser directing writing is the most advanced method, which can meet the manufacturing requirements of high-precision and high-performance continuous diffractive elements.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

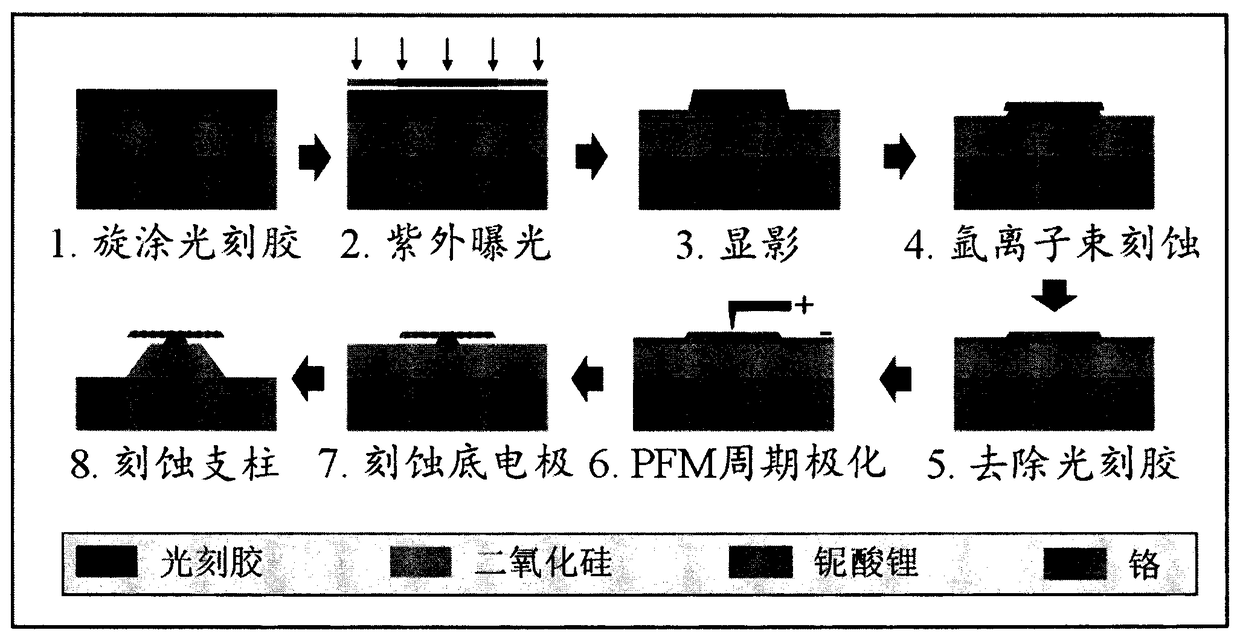

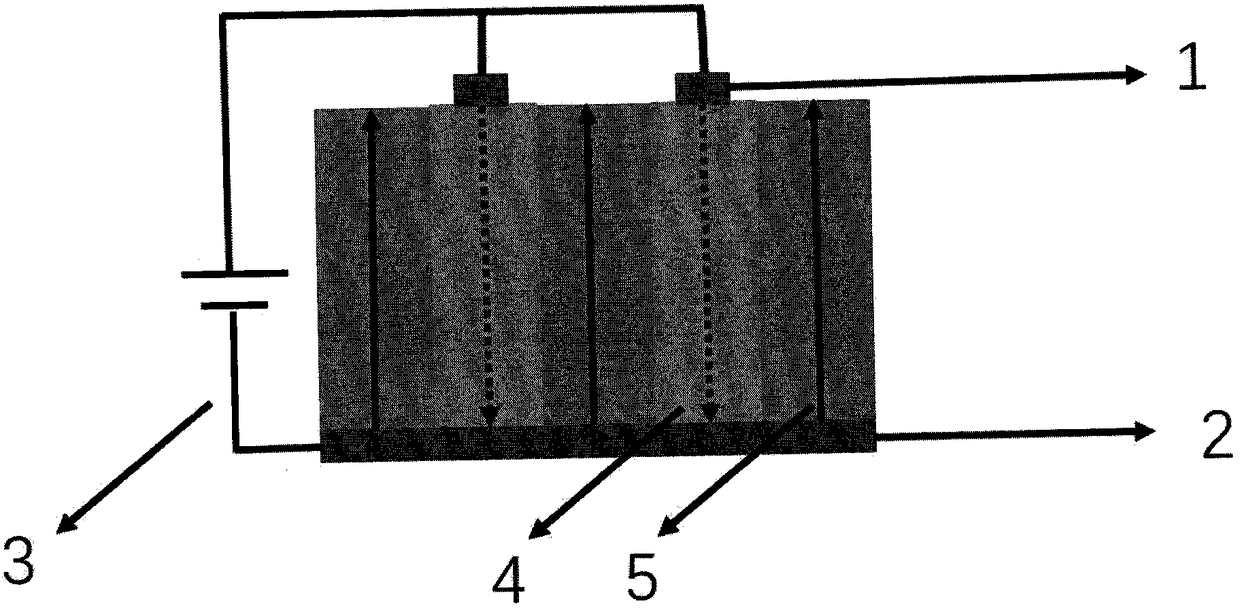

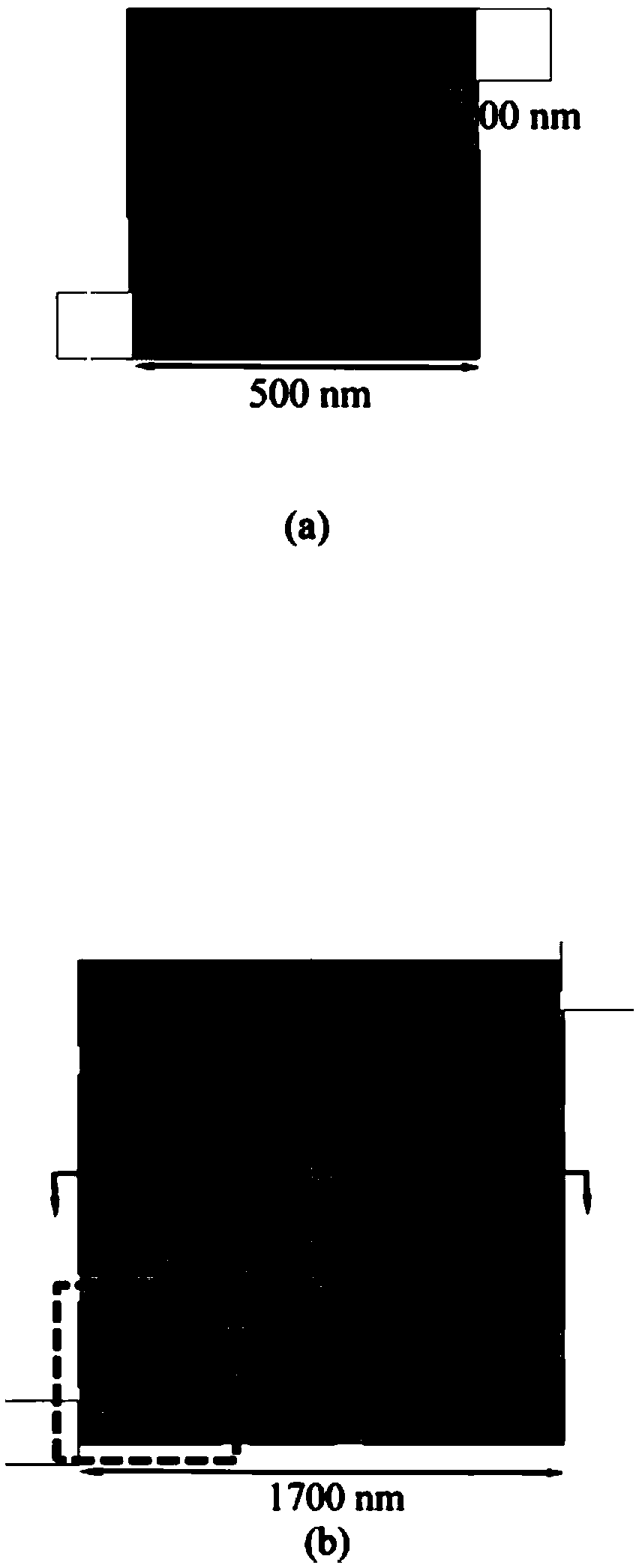

Method for preparing lithium niobate micro-disk cavity with any polarization pattern in submicron period

The invention provides a method for preparing a lithium niobate micro-disk cavity with any polarization pattern in a submicron period. The method comprises the following steps of step 1, generating alithium niobate thin film with a lower electrode; step 2, preparing a micro-disk cavity mask pattern on the lithium niobate thin film; 3, carrying out reactive ion beam etching on a sample to form a lithium niobate micro-disk; step 4, constructing a polarization structure of any pattern on the lithium niobate micro-disk; and step 5, performing etching on a metal layer and a silicon dioxide layer on the sample to form a periodically-polarized lithium niobate micro-disk cavity with suspended edges. The method is simple to operate and high in precision, and can be used for preparing ferroelectriccrystal microcavity with any polarization pattern with a small period.

Owner:NANKAI UNIV

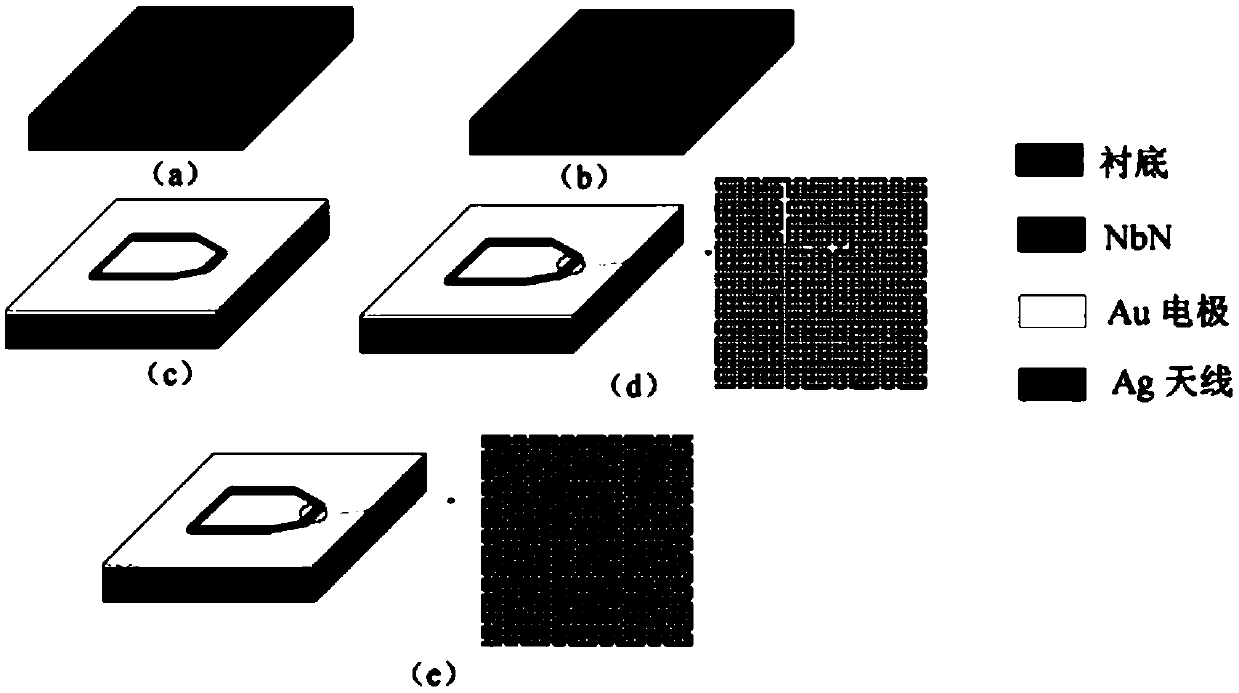

Superconducting fractal nanowire single-photon detector and preparation method thereof

InactiveCN105374928AReduce polarization sensitivityEffective absorptionSuperconductor detailsNanowireEvaporation

The invention discloses a superconducting fractal nanowire single-photon detector and a preparation method thereof. The single-photon detector comprises a substrate, nanowires, a nano antenna, a hydrogen silsequioxane layer and a silver reflecting layer, wherein the nanowires are arranged in a fractal manner and are used for achieving insensitive absorption and polarization of the nanowires on light in two polarization states; and an array nano antenna is added on the basis of the nanowires. The preparation method comprises the following steps: sputtering a layer of superconducting material on the substrate by a magnetron sputtering method; preparing an electrode in a manner of combining photoetching and electronic beam evaporation; the fractal nanowire is prepared in a manner of matching electron beam exposure with reactive ion beam etching; and the nano antenna is prepared in a manner of combining the electron beam exposure with the electronic beam evaporation. According to the superconducting fractal nanowire single-photon detector, the polarization sensitivity of the superconducting nanowire single-photon detector is lowered; the polarization sensitivity is less than 0.02; the absorption efficiencies of two orthogonal polarization states reach 80%; the wideband absorption efficiency is higher than 70%; and the superconducting fractal nanowire single-photon detector is applicable to various superconducting materials.

Owner:TIANJIN UNIV

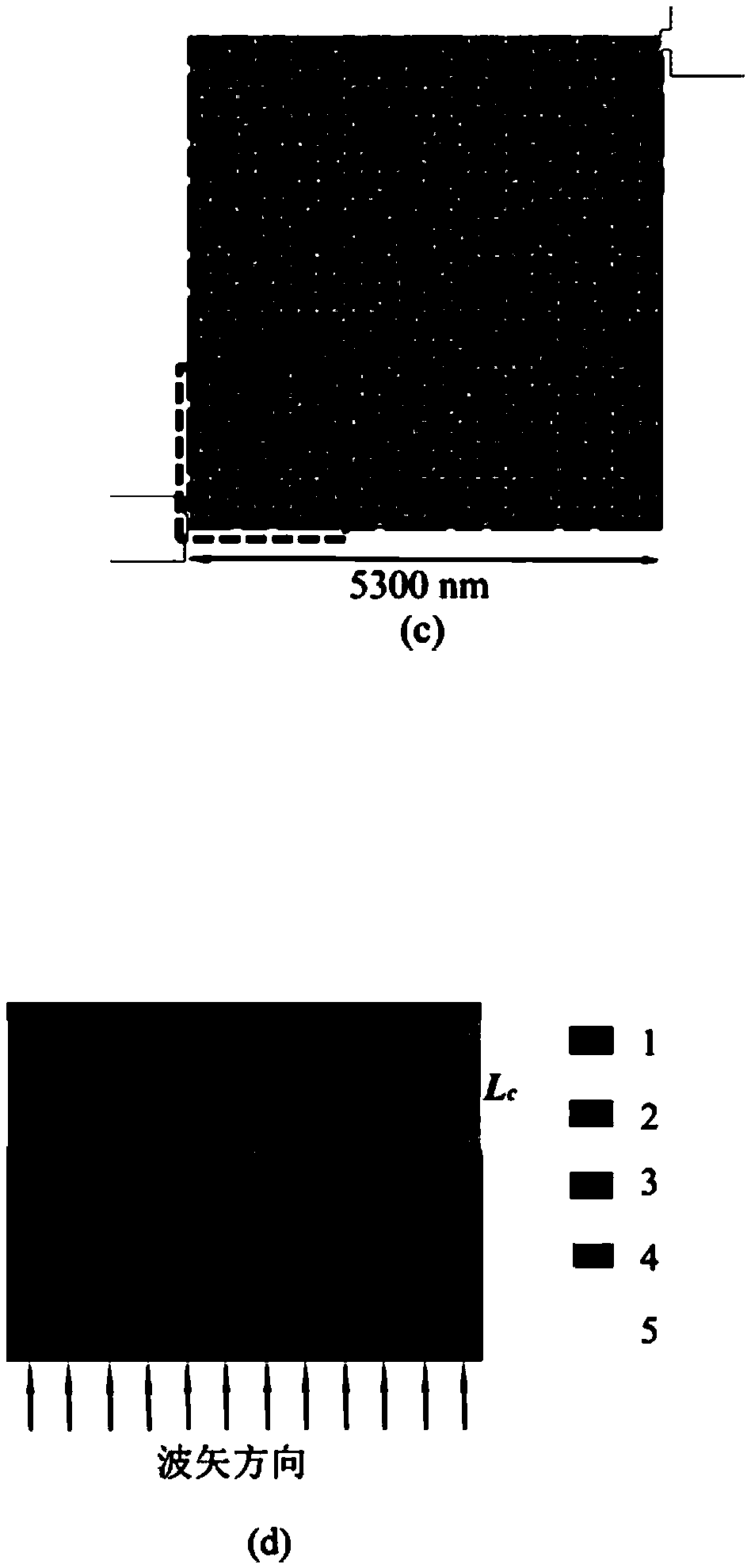

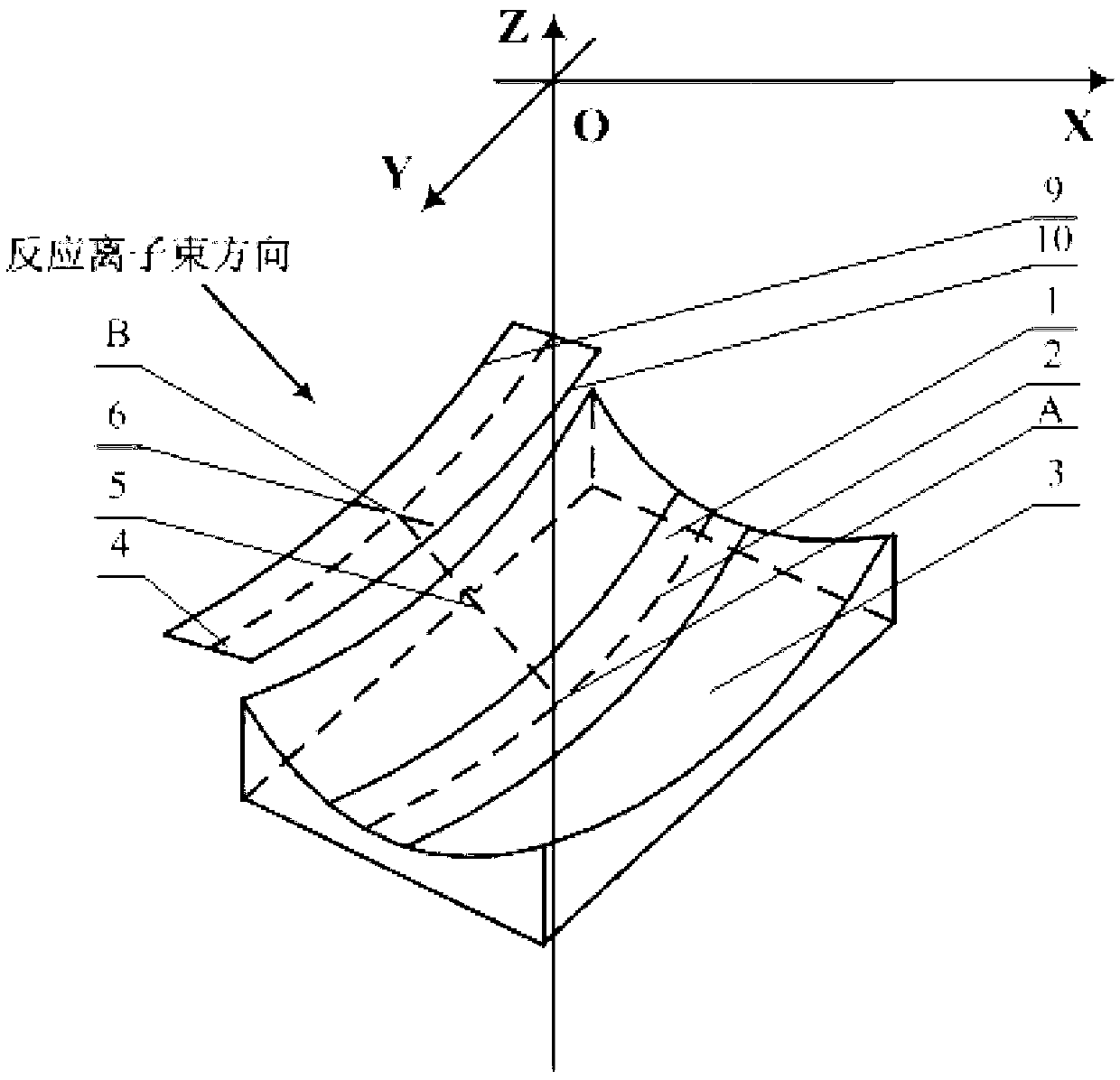

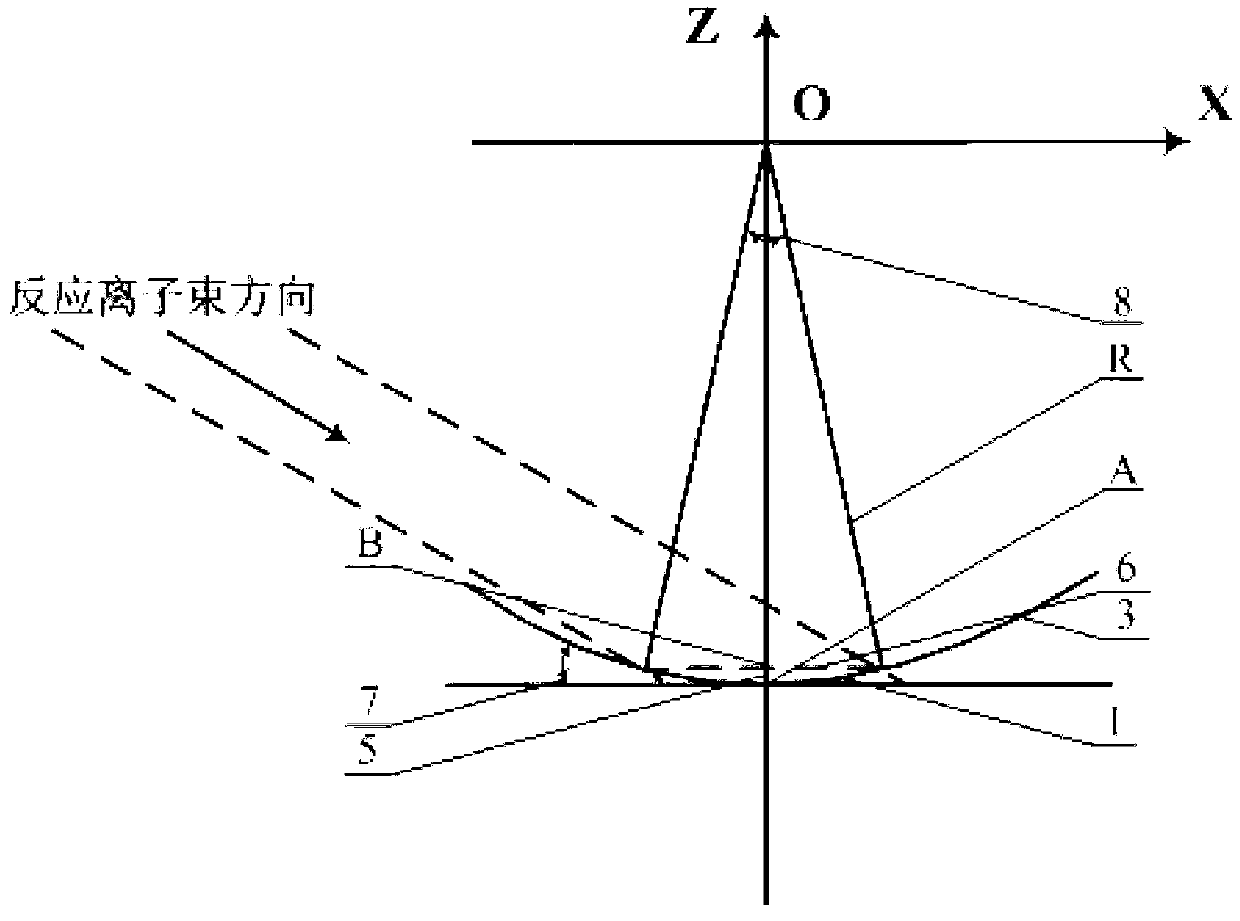

Etching method of blazing concave surface holographic grating subarea reaction ion beams

InactiveCN103105638AImprove consistencyHigh diffraction efficiencyPhotomechanical apparatusDiffraction gratingsReactive ion beam etchingIon beam etching

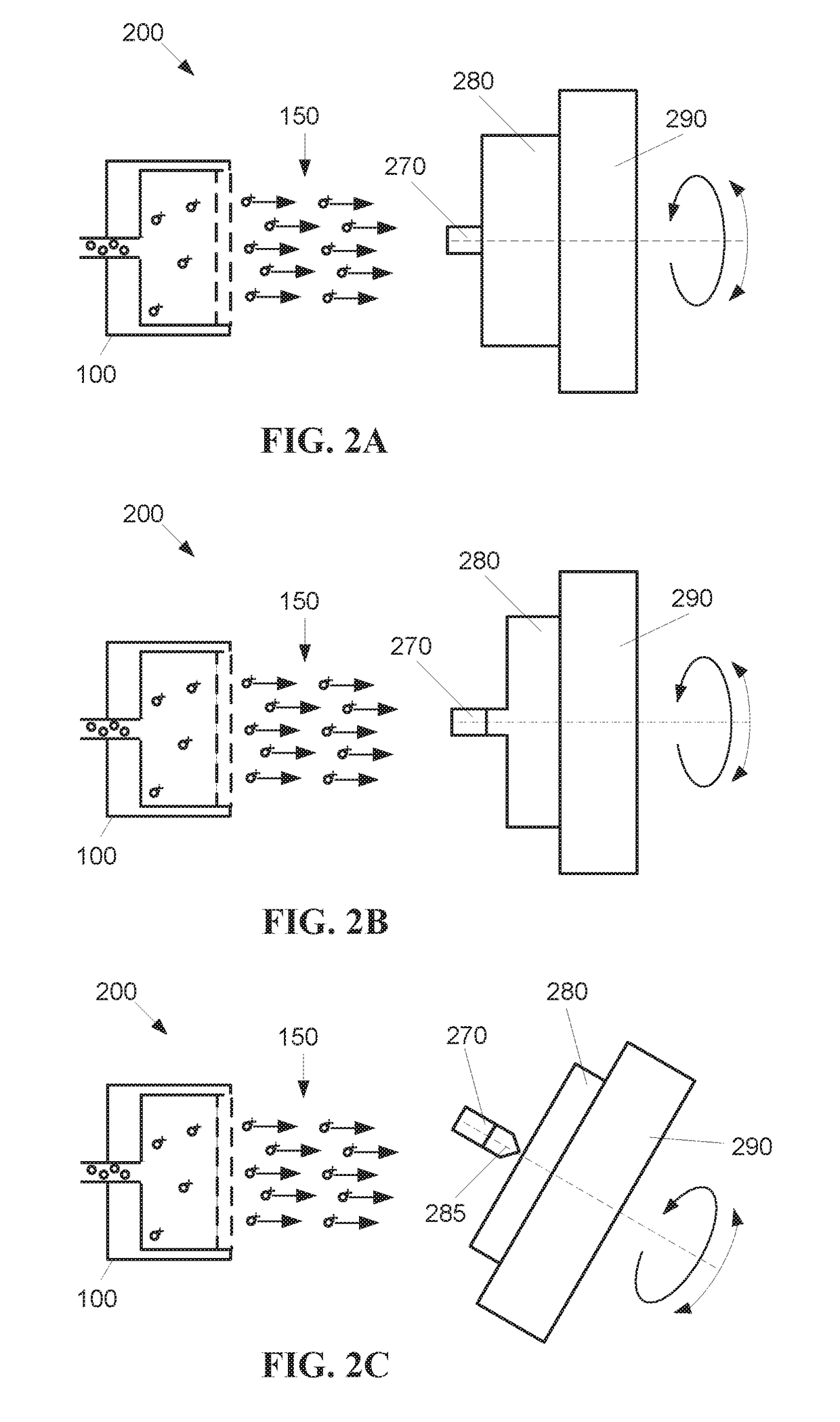

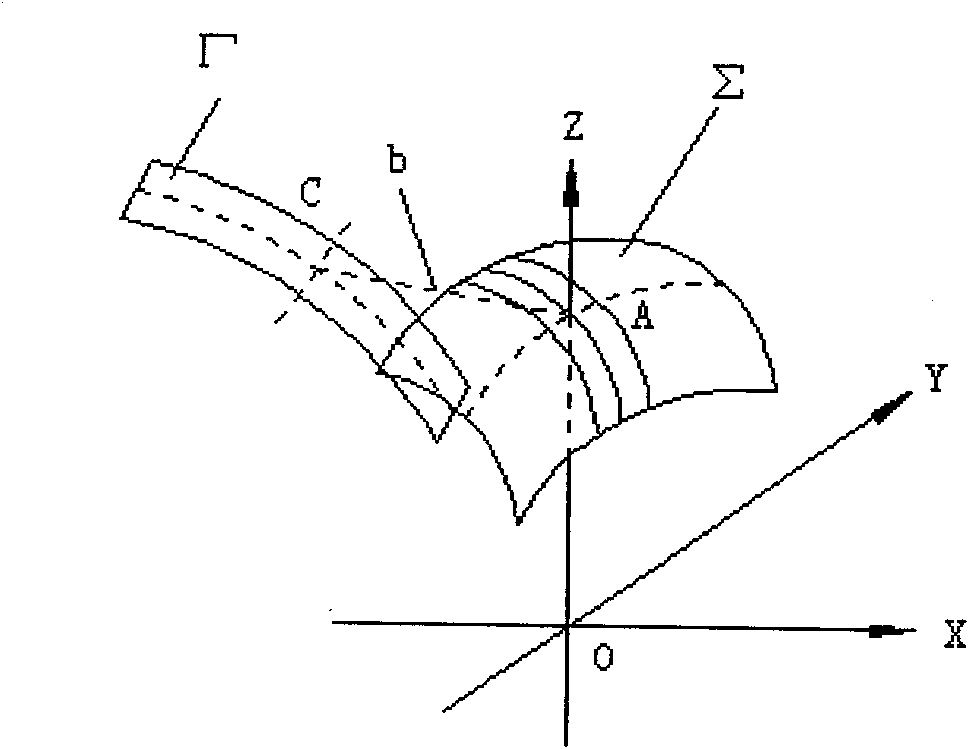

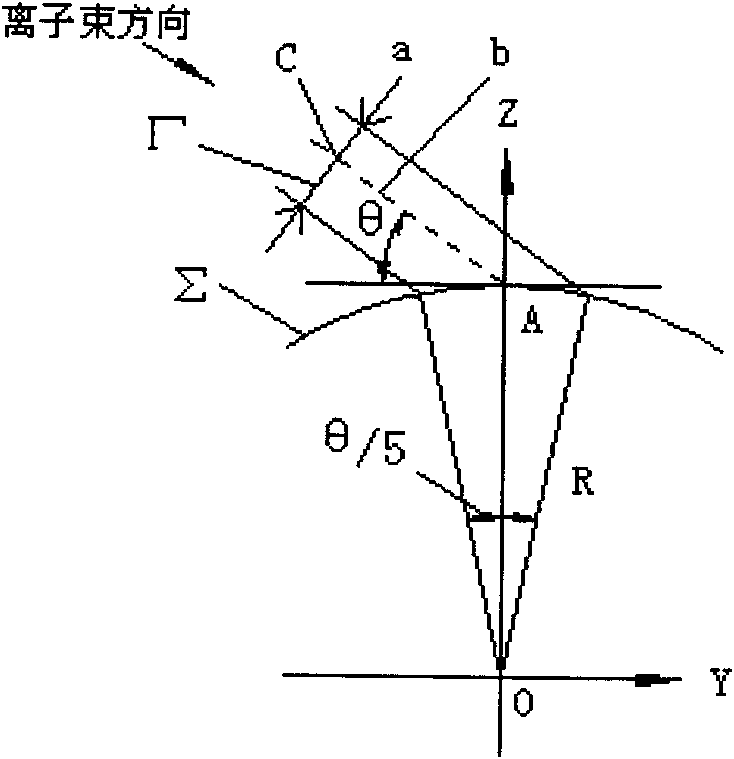

The invention discloses an etching method of blazing concave surface holographic grating subarea reaction ion beams, and relates to the spectrum technical field. The problems that blazing angles which are obtained by etching concave surface gratings by using an existing method are different, and meanwhile, the diffraction efficiency of the blazing concave surface gratings is affected by the difference of the blazing angles are solved. The etching method includes the steps of placing a concave surface grating mask substrate; selecting an ion beam incident angle; dividing a concave surface grating substrate; manufacturing etching narrow slits; placing the narrow slits; and etching the concave surface gratings. According to the etching method of the blazing concave surface holographic grating subarea reaction ion beams, subarea reaction ion beam etching is conducted on the concave surface grating mask substrate with the groove shape being of a sine shape or a rectangle-like shape, so that the consistency of the blazing angles of blazing concave surface holographic gratings after etching is high, and therefore the etching method of the blazing concave surface holographic grating subarea reaction ion beams has direct and great significance to manufacturing the blazing concave surface holographic gratings with the high diffraction efficiency.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

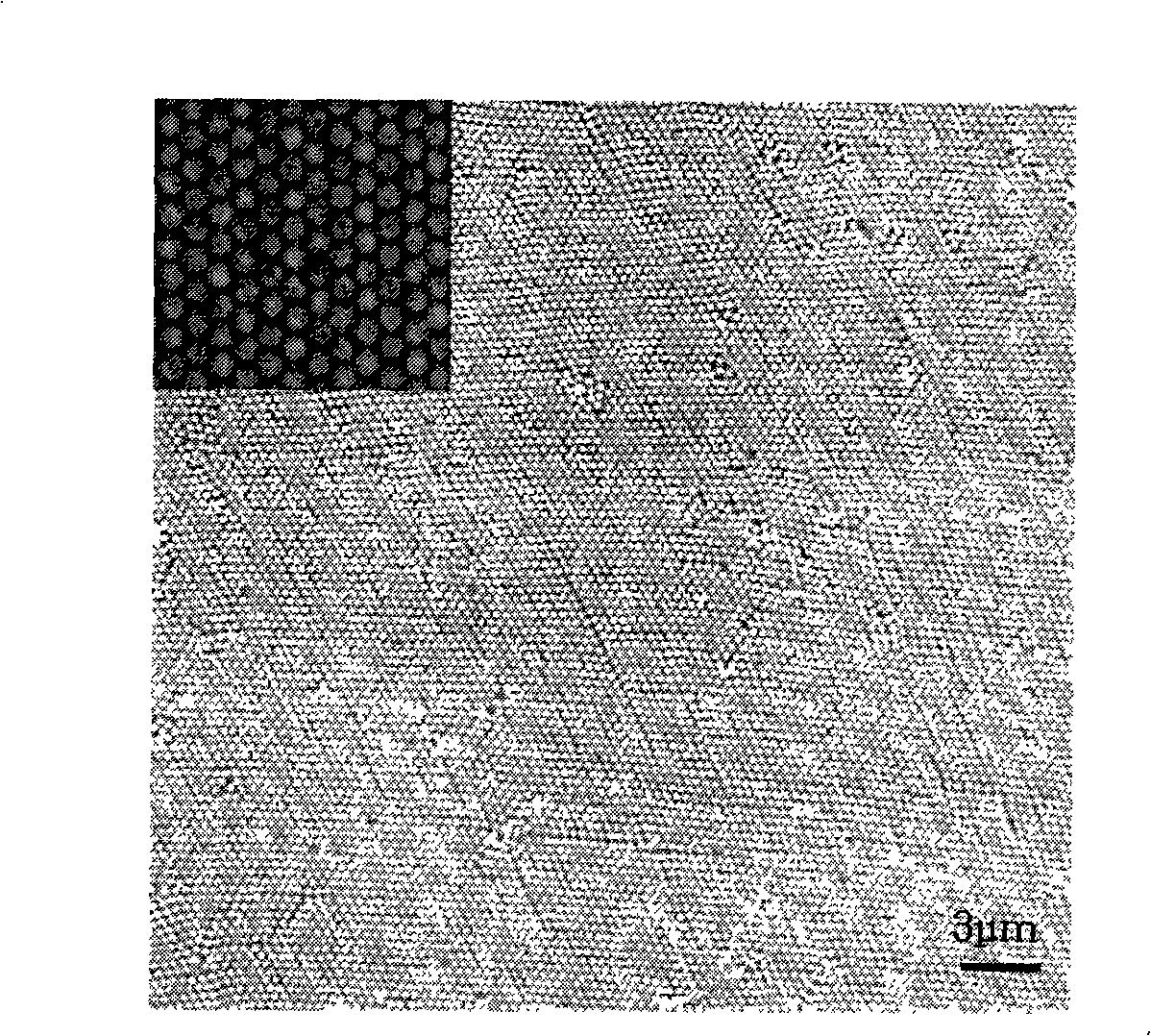

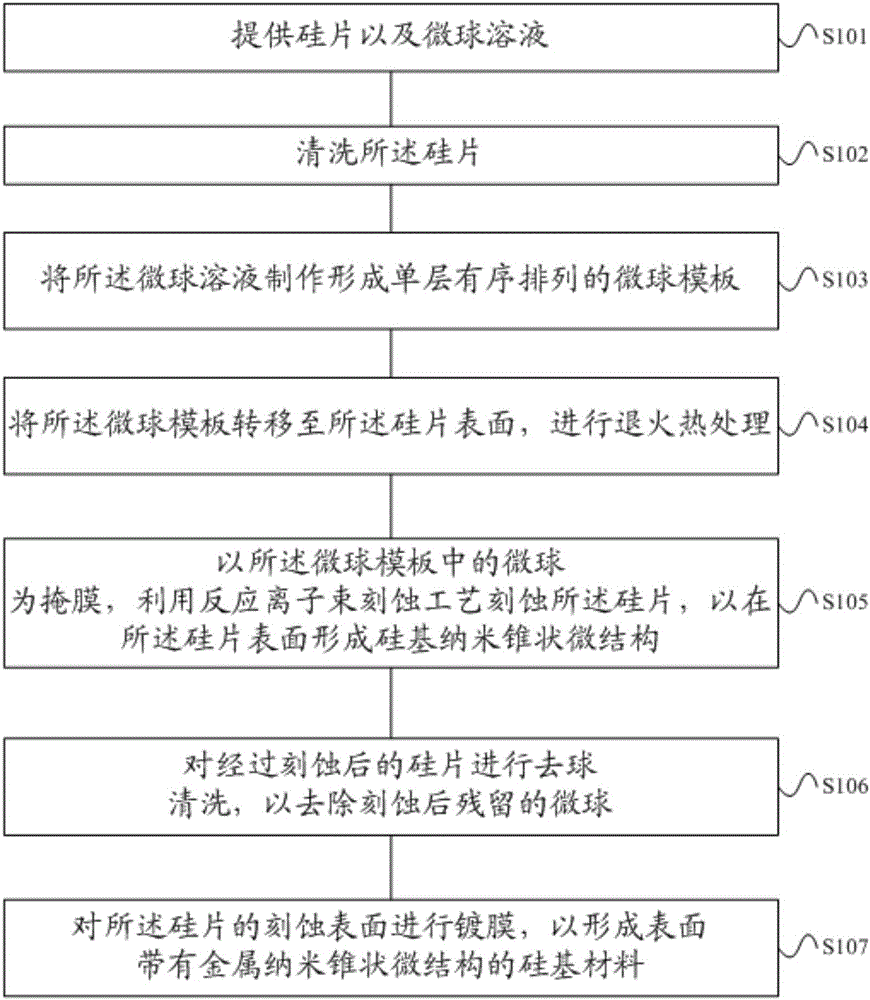

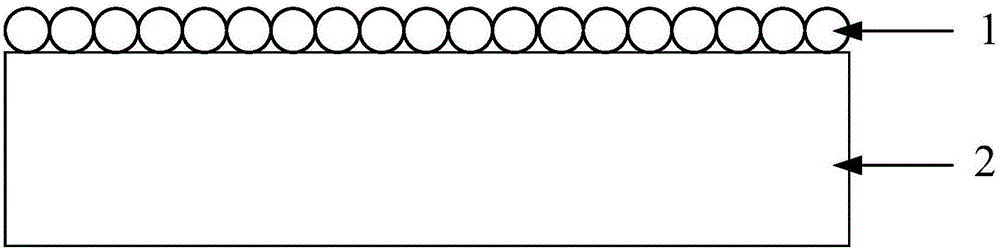

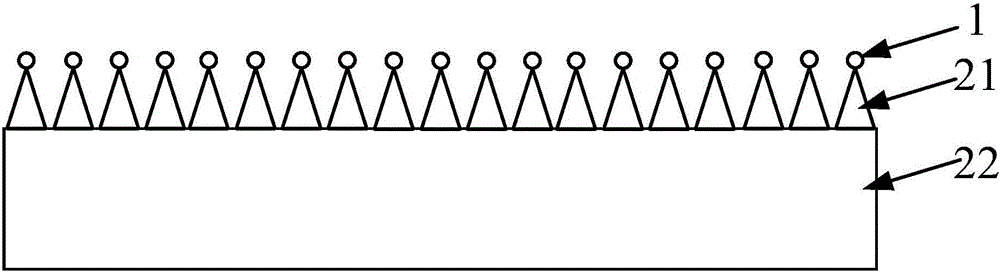

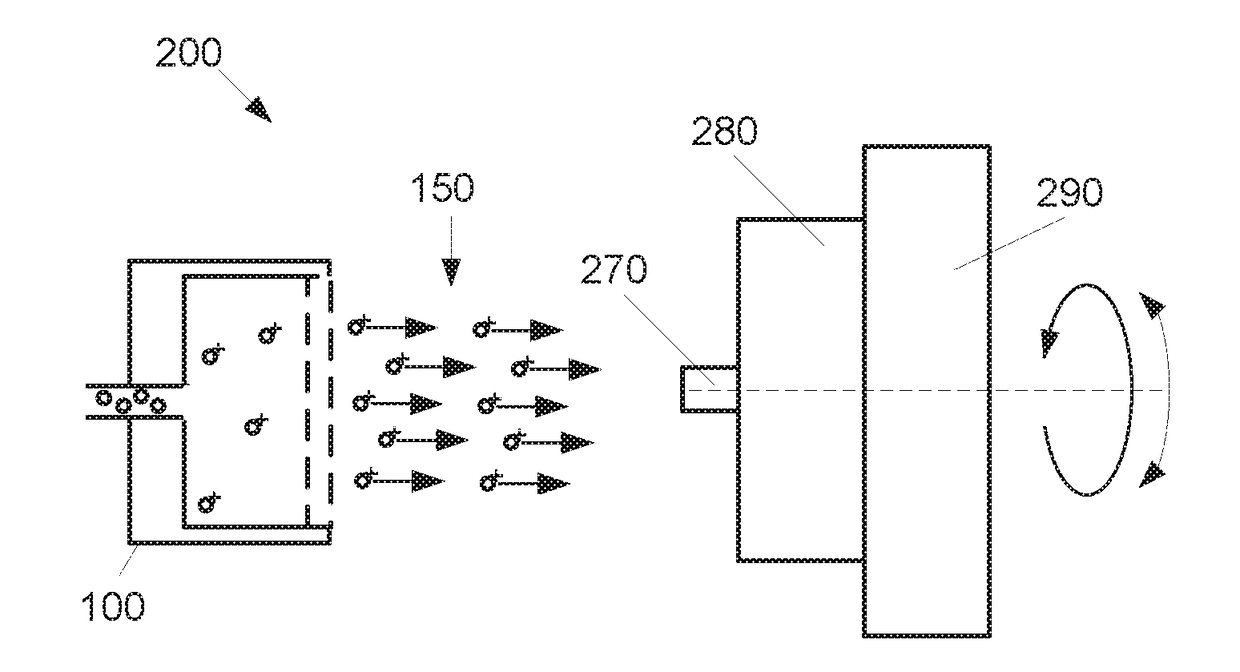

Microstructure silicon-based material, preparation method thereof and semiconductor device

InactiveCN106082112AEasy to prepareLow costDecorative surface effectsSolid-state devicesMicro nanoMicrosphere

The invention provides a microstructure silicon-based material, a preparation method thereof and a semiconductor device. The preparation method comprises the steps of providing a silicon wafer and microsphere solution; prepraring the microsphere solution into a microsphere template by employing a self-assembly mode; transferring the self-assembly template to the surface of the silicon wafer, and carrying out annealing heat treatment; and etching the silicon wafer by taking microspheres as masks and employing a reaction ion beam etching technology, washing the silicon wafer, and coating film, thereby forming a metal nanocone-shaped microstructure. According to the preparation method provided by the invention, firstly, the microsphere template obtained by employing the self-assembly mode is taken as the mask, and compared with the mask prepared by a special mask preparation technology in the prior art, the mask provided by the invention has the advantages of simple in preparation method and relatively low in cost; and secondly, according to the preparation method provided by the invention, the silicon wafer is etched by employing the relatively cheap reaction ion beam etching technology, and compared with the micro-nano machining methods such as a focusing ion beam etching technology, electron beam lithography and laser direct writing in the prior art, the preparation method has the advantages of simple technology and relatively low cost.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

System and Method for Wafer-Scale Fabrication of Free Standing Mechanical and Photonic Structures By Ion Beam Etching

ActiveUS20180138047A1Semiconductor/solid-state device manufacturingMicrostructural device manufactureResistPhotonics

A method for fabrication of free standing mechanical and photonic structures is presented. A resist mask is applied to a bulk substrate. The bulk substrate is attached to a movable platform. The bulk substrate is exposed to an ion stream produced by a reactive ion beam etching source. The platform is moved relative to the ion stream to facilitate undercutting a portion of the bulk substrate otherwise shielded by the mask.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Method for reactive ion beam etching of blazed convex grating

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Method of manufacturing a perpendicular magnetic recording write head with notched trailing shield

InactiveUS7748103B2Reduce saturationReduced-thickness gapManufacture head surfaceElectrical transducersFront edgeTrailing edge

A perpendicular magnetic recording write head has a write pole, a trapezoidal-shaped trailing shield notch, and a metal gap layer between the write pole and notch. The write pole has a trailing edge that has a width substantially defining the track width and that faces the front edge of the notch but is spaced from it by the gap layer. The write head is fabricated by reactive ion beam etching of a thin mask film above the write pole to remove the mask film and widen the opening at the edges of the write pole. The gap layer and notch are deposited into the widened opening above the write pole. The write pole has nonmagnetic filler material, such as alumina, surrounding it except at its trailing edge, where it is in contact with the gap layer, which is formed of a different material than the surrounding filler material.

Owner:WESTERN DIGITAL TECH INC

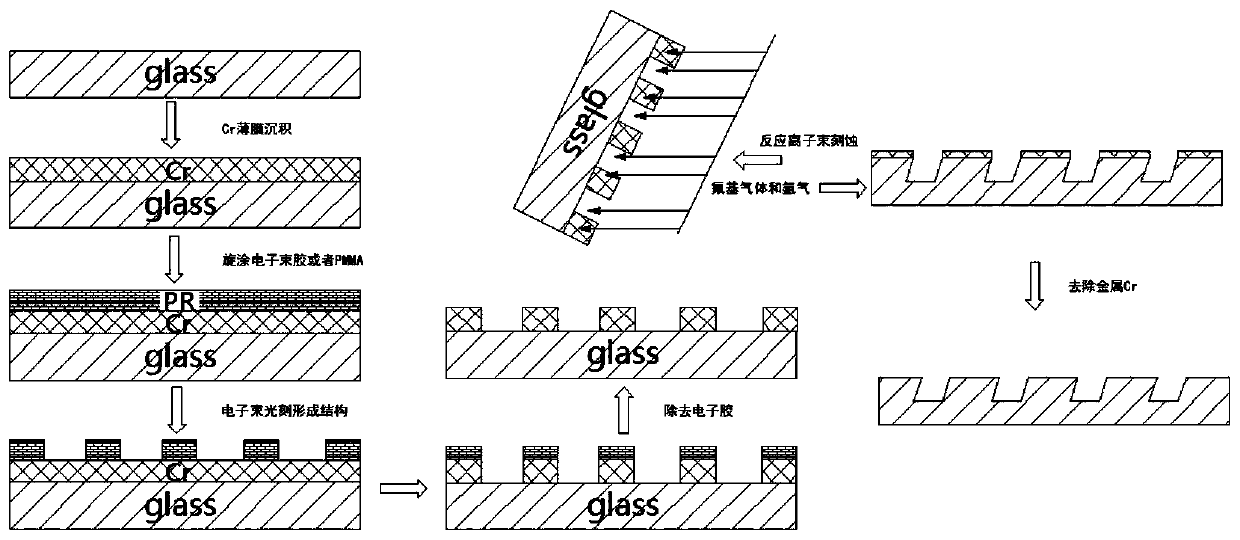

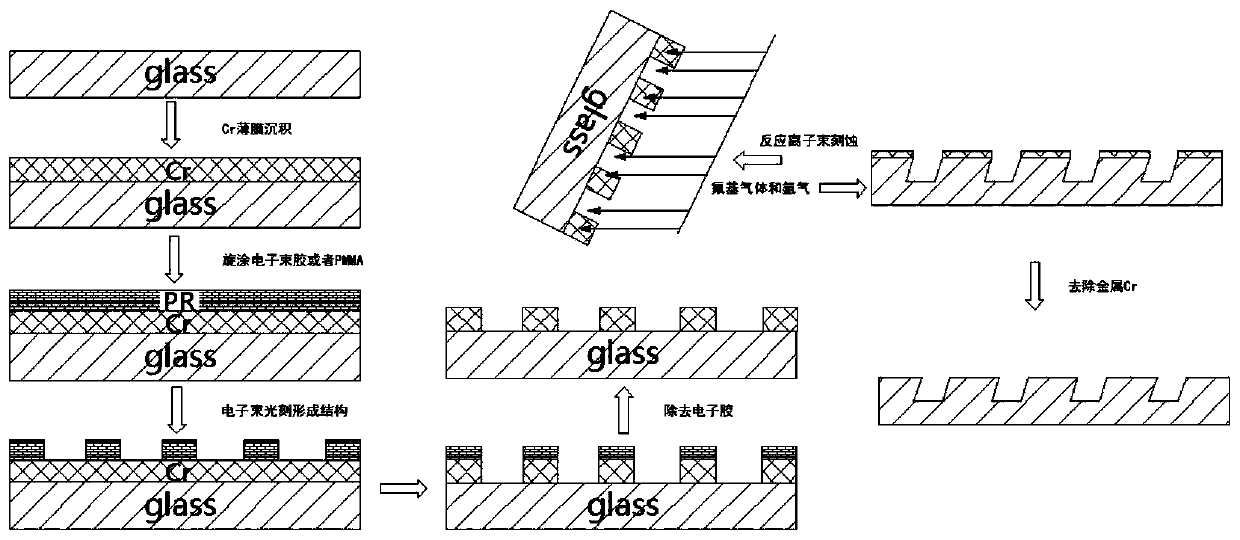

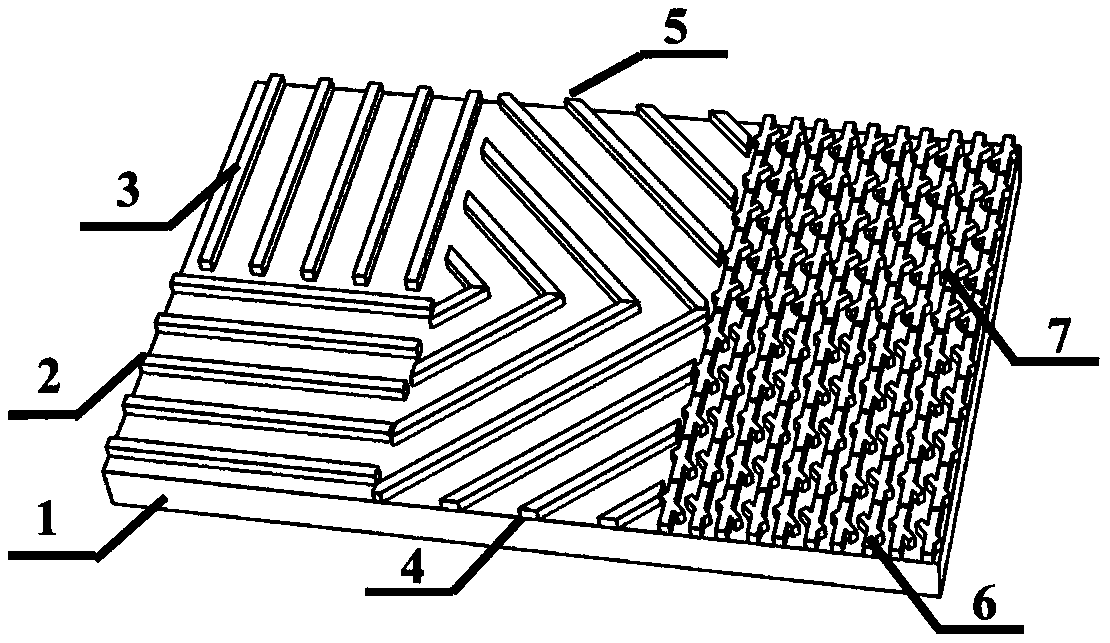

Method for manufacturing grating nano-imprinting template by using electron beam lithography technology

InactiveCN111158073AReduce productionSmall sizePhotomechanical coating apparatusDiffraction gratingsGratingElectron-beam lithography

The invention discloses a method for manufacturing a grating nano-imprinting template by using an electron beam lithography technology, and relates to a method for manufacturing a nano-imprinting template on silicon or glass by using electron beam lithography in combination with inductive coupling plasma etching and reactive ion beam etching technologies. The invention aims to improve the manufacturing process of a template to a nanoscale, improve the stability of the template and the uniformity of a nanostructure, and improve the imprinting quality and precision.

Owner:SHENZHEN LOCHN OPTICS TECH CO LTD

Full Stokes polarization imaging element and preparation method thereof

ActiveCN108878466AImprove technical effectSolid-state devicesRadiation controlled devicesPolarizerCircular dichroism

The invention provides a full Stokes polarization imaging element. The full Stokes polarization imaging element comprises a light transmissive substrate and a dielectric structure layer on the light transmissive substrate; the dielectric structure layer is composed of a super pixel unit array; the super pixel unit comprises four dielectric wire gating structures with different orientations and tworotationally symmetric chiral structures with different rotational directions. The full Stokes polarization imaging element can be fabricated through the processes such as electron beam exposure anddevelopment techniques, reactive ion beam etching and the like; the full Stokes polarization imaging element can realize real-time full polarization imaging; the transmittance of the linear polarizerin the full Stokes polarization imaging element is 99% or more at 1.7 to 1.8 [Mu]m, the extinction ratio is 20 dB or more, and the maximum of the extinction ratio is 55 dB; the highest circular polarization dichroism can reach 96.8% at 1.75 [Mu]m; meanwhile, the full Stokes polarization imaging element has simple structure and excellent performance, and has wide source of raw materials and simplepreparation, which has great application value in the field of polarization imaging.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

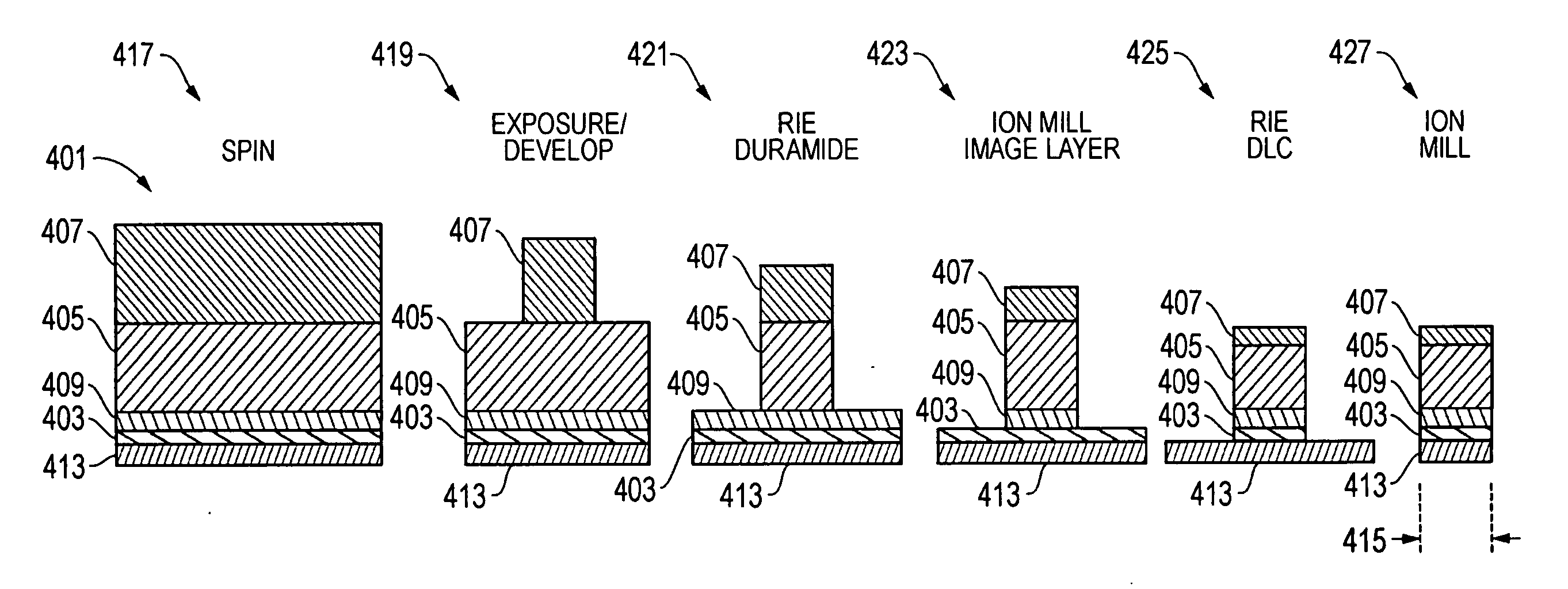

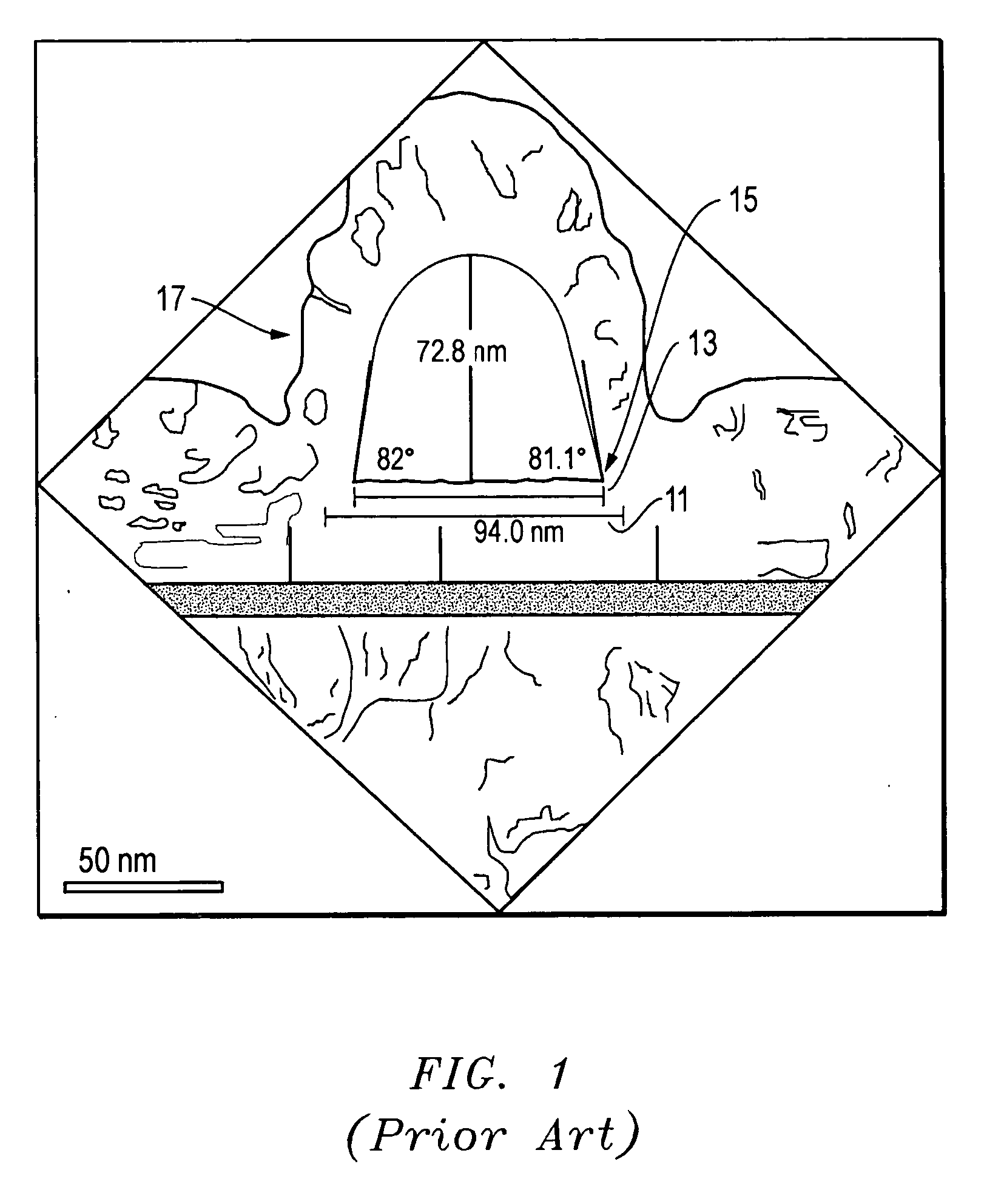

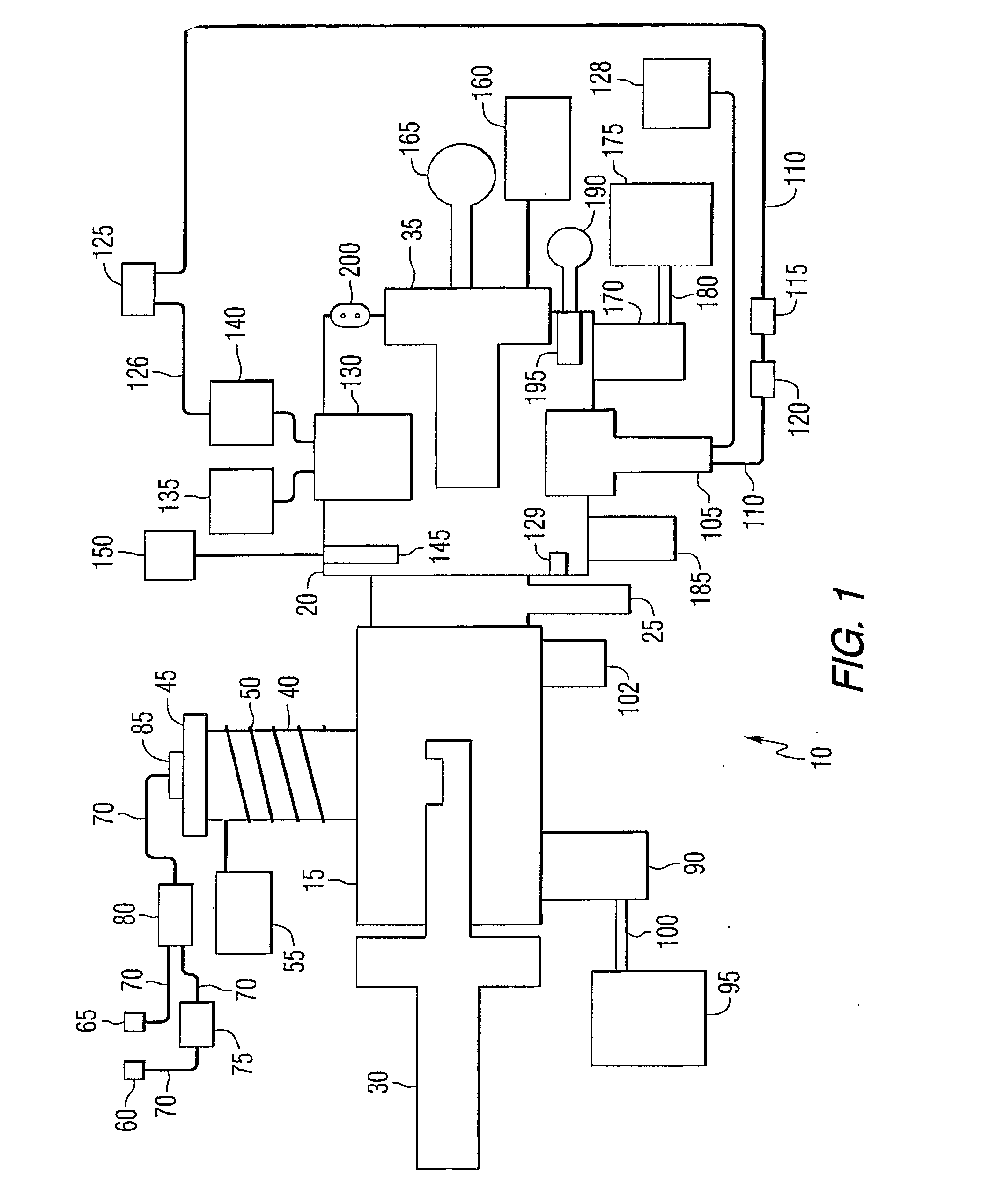

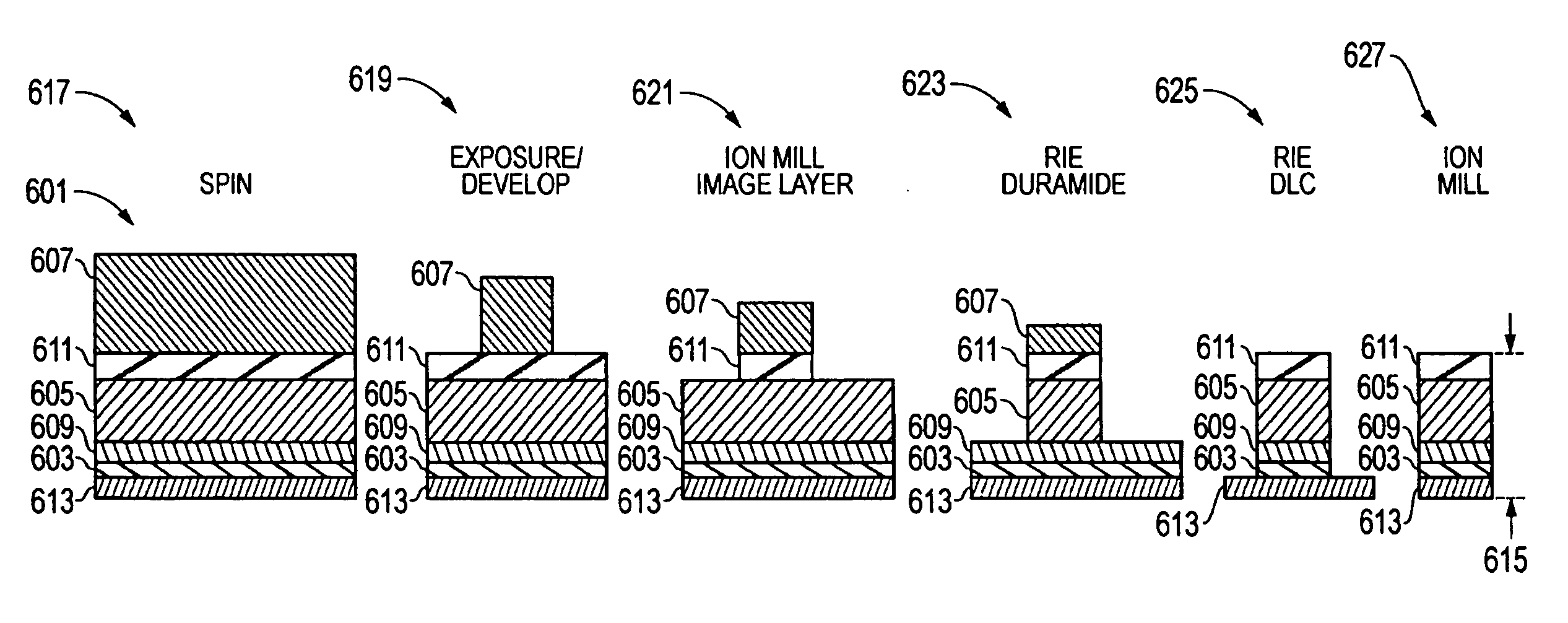

Method for sensor edge control and track width definition for narrow track width devices

InactiveUS20070010043A1Minimized line edge roughnessPrecise definitionSemiconductor/solid-state device detailsSolid-state devicesCompound (substance)Reactive ion beam etching

A process for defining and controlling the track width for sensor devices is disclosed. An RIE-resistant, image layer, such as Cu or NiFe, is deposited after the DLC layer. A combination of RIE and ion milling processes or reactive ion beam etching processes are used to form the mask structure. Having an RIE-resistant layer precisely defines the DLC edge and minimizes the line edge roughness that result from fast removal of duramide during RIE. This solution controls the formation of the edges of the sensors and provides good definition for DLC mask edges. The image layer may be chemical mechanical polished to eliminate ion milling before the final RIE step.

Owner:WESTERN DIGITAL TECH INC

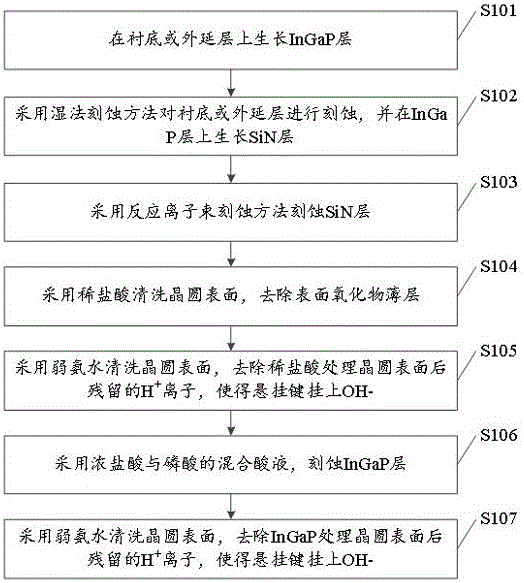

InGaP wet etching method

ActiveCN106486355AEliminate the effects ofHBT process goes wellSemiconductor/solid-state device manufacturingEtchingPhosphoric acid

The invention relates to the technical field of semiconductor manufacturing, and particularly relates to an InGaP wet etching method. The method comprises the following steps: an InGaP layer grows on a substrate or an epitaxial layer; a wet etching method is adopted to etch the substrate or the epitaxial layer, and an SiN layer grows on the InGaP layer; a reactive ion beam etching method is adopted to etch the SiN layer; dilute hydrochloric acid is adopted to clean the surface of a wafer, and a surface oxide thin layer is removed; weak ammonia is adopted to clean the surface of the wafer, residual H<+> ions after the dilute hydrochloric acid processes the surface of the wafer are removed, and OH- is dangled on a dangling bond; a mixed acid solution of concentrated hydrochloric acid and phosphoric acid is adopted to etch the InGaP layer; and the weak ammonia is adopted to clean the surface of the wafer, residual H<+> ions after the wafer surface is processed by InGaP, and OH- is dangled on a dangling bond. Influences on the surface of the InGaP layer by a preceding process can be removed, and smooth going of the HBT process is ensured.

Owner:CHENGDU HIWAFER SEMICON CO LTD

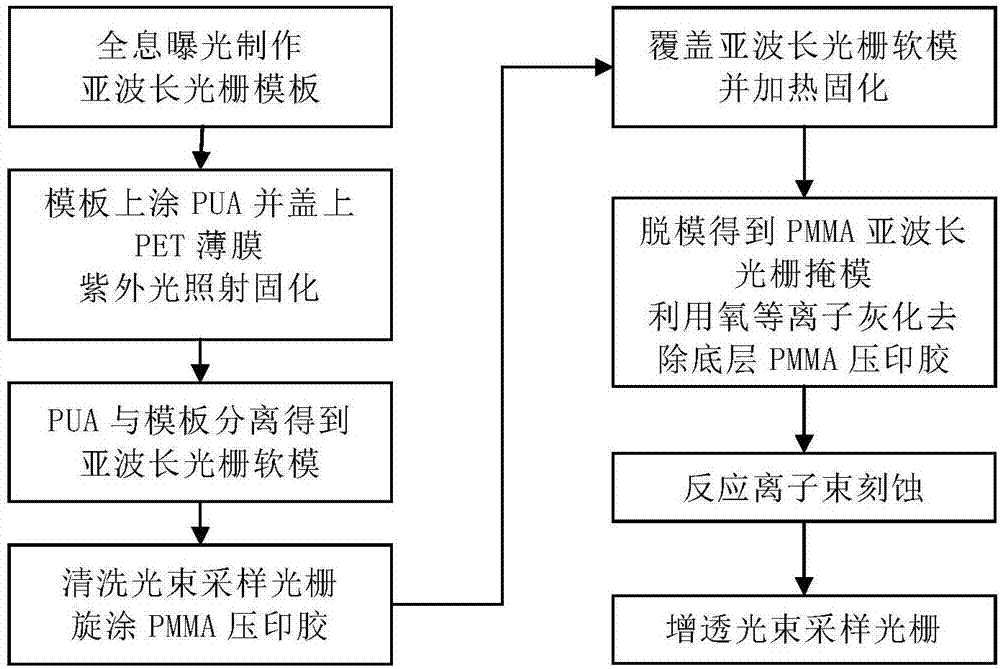

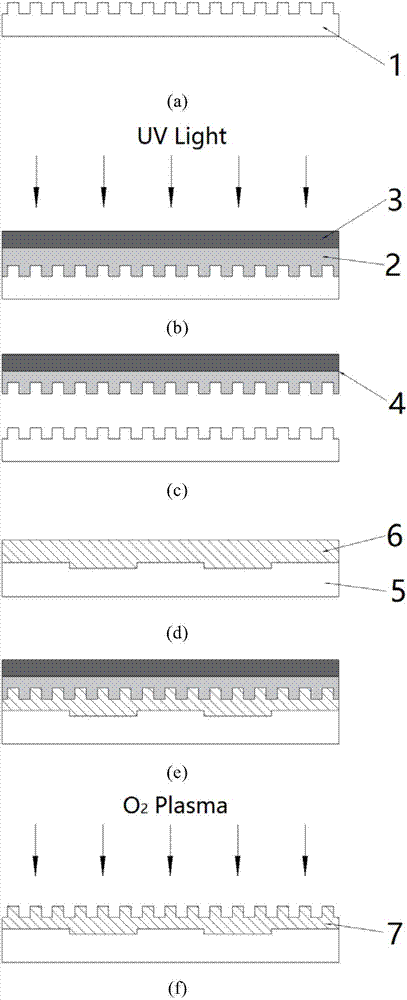

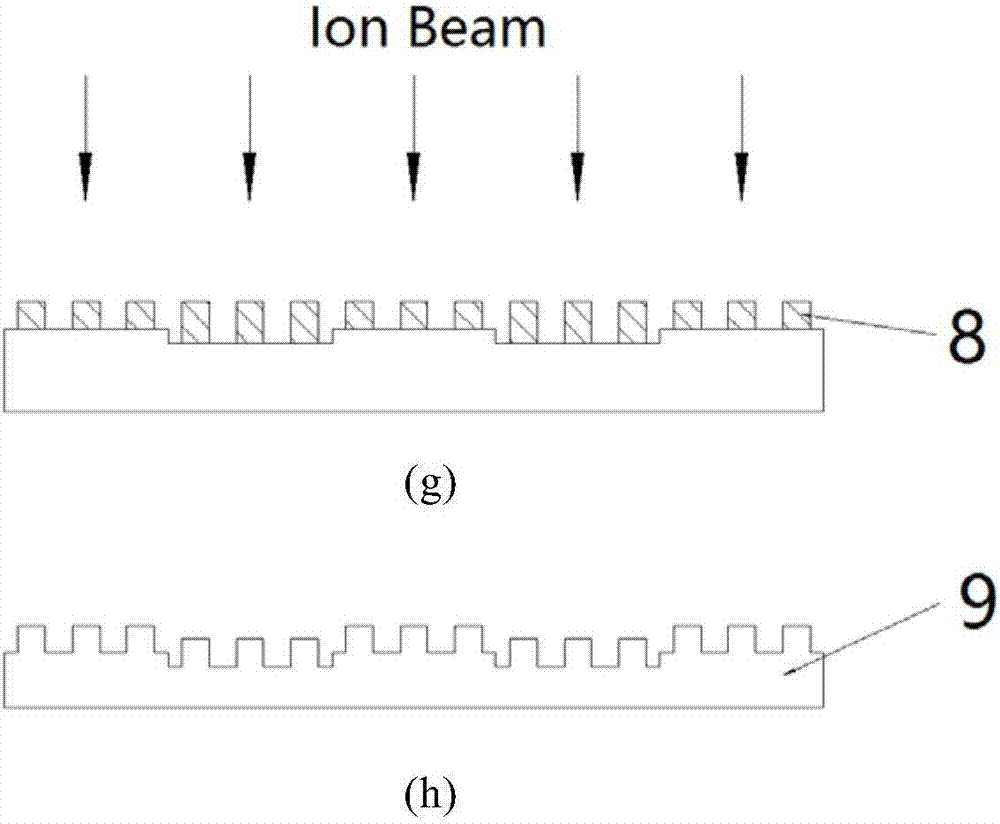

Anti-reflection method for beam sampling grating in intense laser system

The invention provides an anti-reflection method for a beam sampling grating in an intense laser system. The method comprises the following steps: to begin with, preparing a sub-wavelength grating template on a fused quartz substrate through a holographic ion beam etching method; dropping a little PUA UV imprinting photoresist on the sub-wavelength grating template, and then, covering a PET film on the PUA; curing the PUA through UV irradiation, and separating the cured PUA from the grating template to obtain a sub-wavelength grating soft template; clearing the surface of the beam sampling grating, and then, spin coating PMMA imprinting photoresist on the surface; covering the sub-wavelength grating soft template on the PMMA, wherein soft template grating fringe direction can be parallel, vertical or form angle with the fringe direction of the beam sampling grating; clamping the two through a clamping mechanism and placing the two into a baking oven for heating and curing; separating the sub-wavelength grating soft template from the substrate, and forming a sub-wavelength grating on the PMMA; then, removing bottom residual photoresist of the PMMA grating through oxygen plasma ashing; by utilizing a to-the-bottom PMMA subwavelength grating mask, carrying out CHF3 reaction ion beam etching; and finally, carrying out cleaning to remove residual photoresist to obtain the beam sampling grating having an anti-reflection effect.

Owner:UNIV OF SCI & TECH OF CHINA

Preparation method of filling type sub-wavelength guide mode resonance optical filter

InactiveCN101178454AReduce difficultyPadding achievedOptical filtersPhotomechanical apparatusGratingWavelength

The invention relates to a production method of a filling type subwavelength guided mode resonance light filtering piece. The initial air filling type subwavelength grating is produced by adopting methods of plate covering light charactering and reaction ion beam etching, then film plating and etching are proceeded by taking the air filling type subwavelength grating as the base piece. The invention is characterized in that: a) a film plating uses a method of physics vacuum sediment, the material of the film is the material being filled in a grating groove and the thickness of the film is 2 times of the depth of the subwavelength grating groove; b) the reaction ion beam is used for etching the light filtering piece being plated, the etching thickness is 2 times of the depth of the subwavelength grating groove. The invention fills the material, the thickness of which has the exactitude to the nanometer grade in the grating groove with nanometer yardstick and which no doubt is one of the production in the light filtering pieces with the most difficult. The invention combines the plating technique and the etching technique to provide a practical and feasible etching production method; the method used can conveniently produce filling type subwavelength guided mode resonance light filtering pieces.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

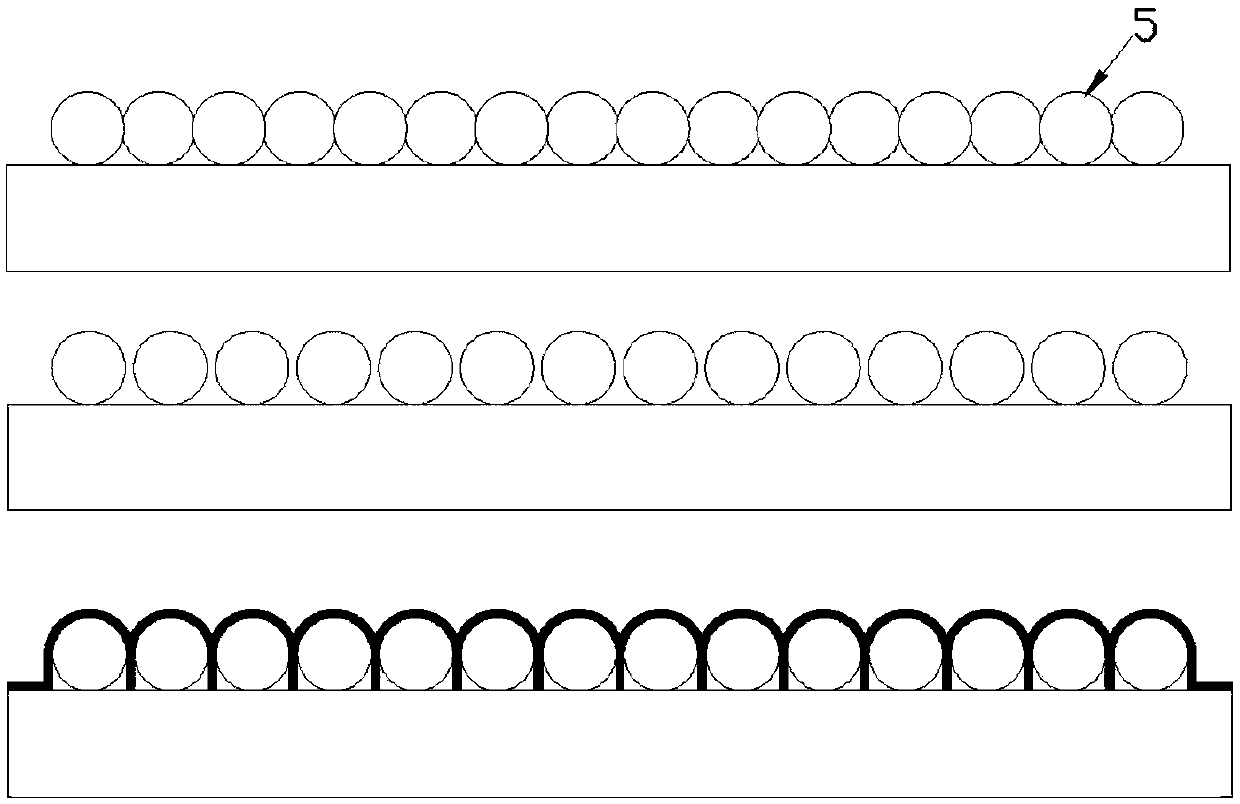

Method for manufacturing transparent flexible capacitor with high quality factor

InactiveCN109545553ALow priceRealize large area preparationFixed capacitor electrodesThin/thick film capacitorEtchingEvaporation

The invention provides a method for manufacturing a transparent flexible capacitor with a high quality factor. Specific steps include: (1) transferring a PS ball on a plastic flexible substrate; (2) performing retraction ball treatment on a PS ball template obtained in the step (1) by using a reactive ion beam etching technique; (3) depositing metal on the PS ball template in the step (2) by a thermal evaporation process; (4) removing the PS ball template in the step (3), leaving a metal nano-net as a bottom electrode of the transparent flexible capacitor; (5) growing a high-k dielectric material as a dielectric layer on the metal nano-mesh electrode prepared in the step (4); (6) repeating the above steps (1-4), and making the metal nano-net on the dielectric layer as a top electrode of the capacitor; (7) performing photolithography and wet etching on the top electrode, to obtain a transparent flexible capacitor device. The capacitor prepared by the method has good performance in flexibility and transparency, and can be used for transparent flexible electronic devices.

Owner:WUHAN UNIV

Method for Preparing Specimens for Microscopy

InactiveUS20140098380A1Electric discharge tubesPreparing sample for investigationConductive materialsReactive ion beam etching

Owner:FISCHIONE PAUL E +3

Method for sensor edge and mask height control for narrow track width devices

InactiveUS20070010044A1Minimized line edge roughnessClear processSemiconductor/solid-state device detailsSolid-state devicesCompound (substance)Engineering

A process for defining and controlling the mask height of sensor devices is disclosed. An RIE-resistant, image layer, such as Cu or NiFe, is deposited after the DLC layer. A combination of RIE and ion milling processes or reactive ion beam etching processes are used to form the mask structure. Having an RIE-resistant layer precisely defines the DLC edge and minimizes the line edge roughness that result from fast removal of duramide during RIE. This solution controls the formation of the edges of the sensors and provides good definition for DLC mask edges. The image layer may be chemical mechanical polished to eliminate ion milling before the final RIE step.

Owner:WESTERN DIGITAL TECH INC

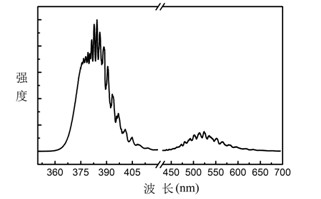

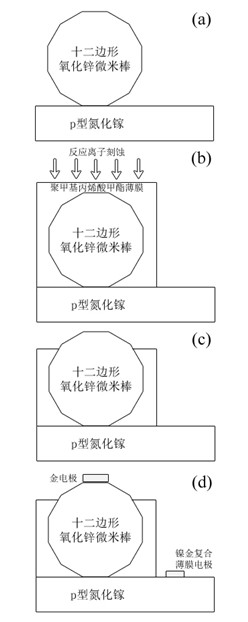

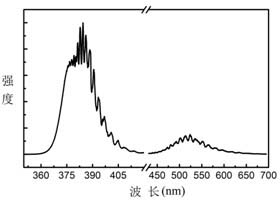

Preparation of dodecagon zinc oxide whispering-gallery mode ultraviolet faint laser heterojunction diode

InactiveCN102496852AHigh quality factorLower lasing thresholdLaser optical resonator constructionLaser active region structureWhispering galleryGas phase

The invention discloses a preparation method of a dodecagon zinc oxide whispering-gallery mode ultraviolet faint laser heterojunction diode combined with a p type gallium nitride substrate. The method comprises the following steps: preparing a zinc oxide microrod with a dodecagon cross section by utilizing a high temperature gas phase transmission method; distributing the zinc oxide microrod on the p type gallium nitride substrate to form a pn structure device, depositing a polymethyl methacrylate film on a surface of the pn structure device by utilizing a spin coating method, exposing an upper surface of the zinc oxide microrod from the polymethyl methacrylate film by utilizing reaction ion beam etching, and preparing an electrode on a surface of the p type gallium nitride and a surface of the zinc oxide microrod by employing magnetron sputtering technology so as to form the whispering-gallery mode ultraviolet faint laser heterojunction diode. According to the method, high quality whispering-gallery mode faint laser is formed by utilizing inner wall total reflection of light in the dodecagon zinc oxide microrod, and different requirements of ultraviolet laser output wavelengths can be realized through selecting zinc oxide microrods with different dimensions.

Owner:SOUTHEAST UNIV

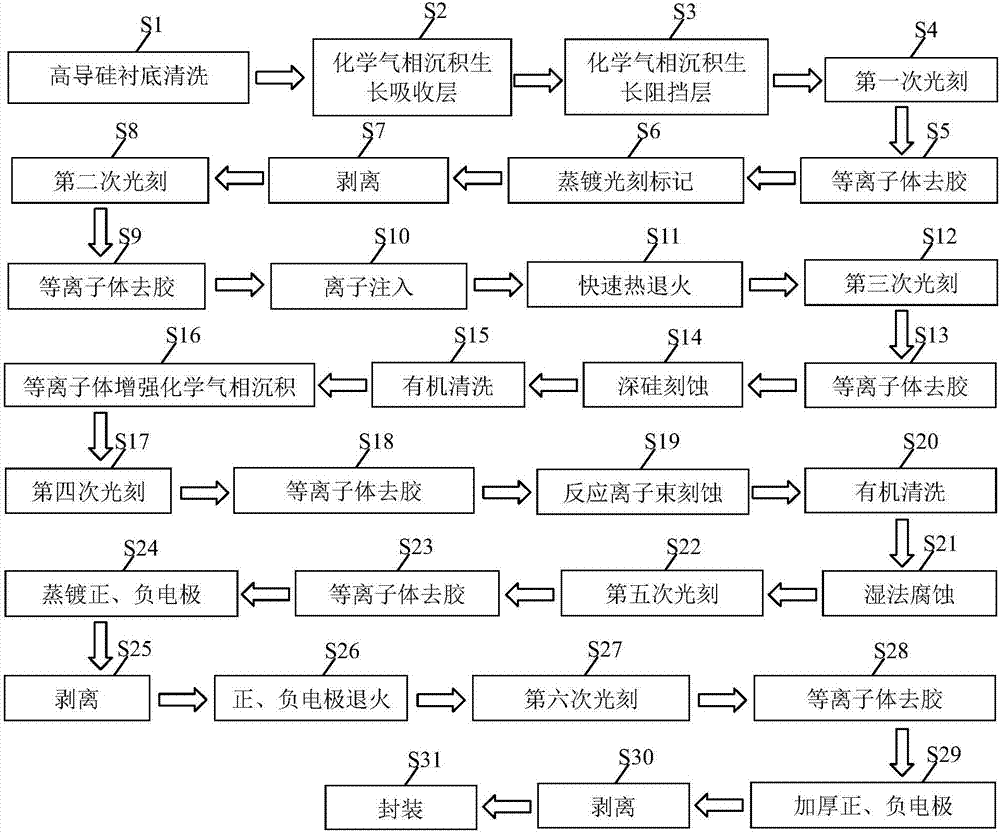

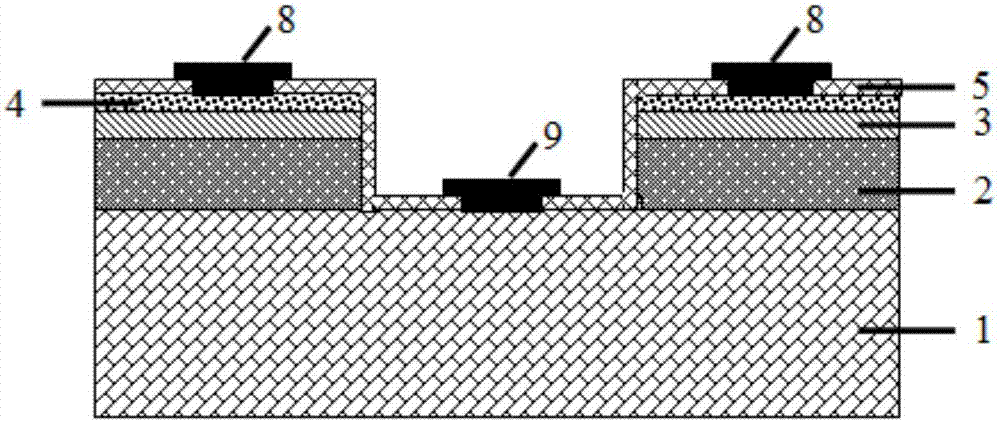

Mesa type silicon-doped-arsenic blocked-impurity-band detector and preparation method thereof

ActiveCN107507882AIncreasing the thicknessAdjust doping concentrationFinal product manufactureChemical vapor deposition coatingHigh resistanceEvaporation

The invention provides a mesa type silicon-doped-arsenic blocked-impurity-band detector and a preparation method thereof. The preparation method comprises: carrying out epitaxial growth of a silicon-doped-arsenic absorption layer on a high-conductivity silicon substrate and carrying out doping of arsenic ions; carrying out epitaxial growth of high-resistance silicon barrier layer on the absorption layer; and carrying out photoetching, ion implantation, rapid thermal annealing, deep silicon etching, plasma-enhanced chemical vapor deposition, reactive ion beam etching, wet etching, electron beam evaporation and other processes to manufacture positive and negative electrodes. The detector and the preparation method have the following advantages: epitaxial growth of the silicon-doped-arsenic absorption layer is carried out by using a chemical vapor deposition method, so that the thickness of the absorption layer is increased and the doping concentration is adjusted, the absorption efficiency of the absorption layer and the device response ratio are improved, the damages caused by ion implantation are avoided, and the dark currents are reduced; and because the negative electrode is arranged on the high-conductivity silicon substrate, the transport path of the photo-generated carrier is shortened, the probability of photo-generated carrier capturing by impurities and defects in the high-conductivity silicon substrate is reduced, and thus the dark current of the device is reduced and the response rate is improved.

Owner:NO 50 RES INST OF CHINA ELECTRONICS TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com