Method for reactive ion beam etching of blazed convex grating

A technology of ion beam etching and convex grating, which is applied in the direction of diffraction grating, photographic process of pattern surface, optics, etc., and can solve the problems of immature research on grating manufacturing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples, but the protection scope of the present invention should not be limited thereby.

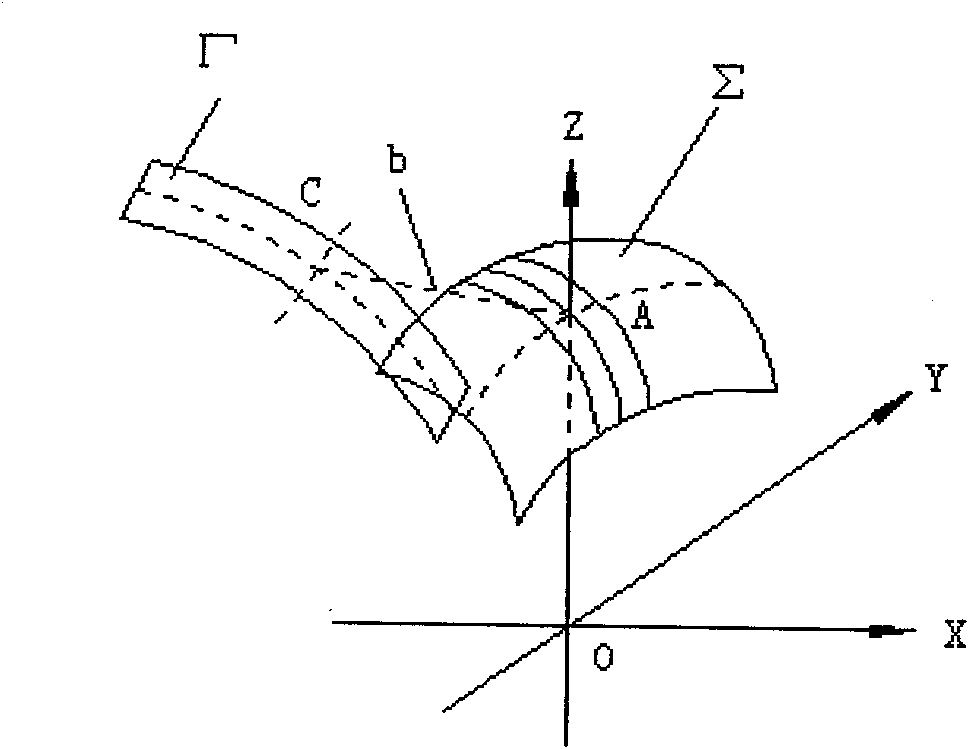

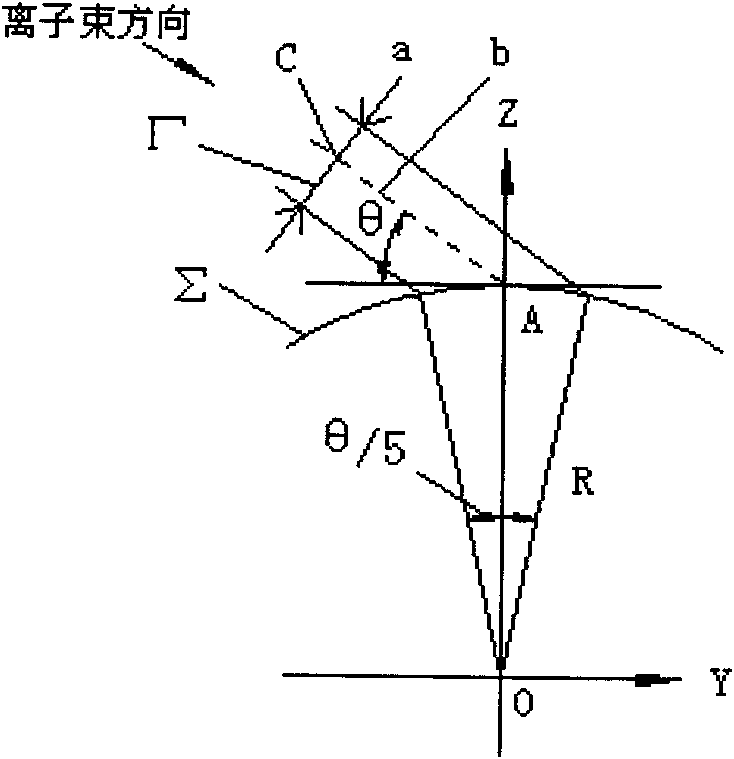

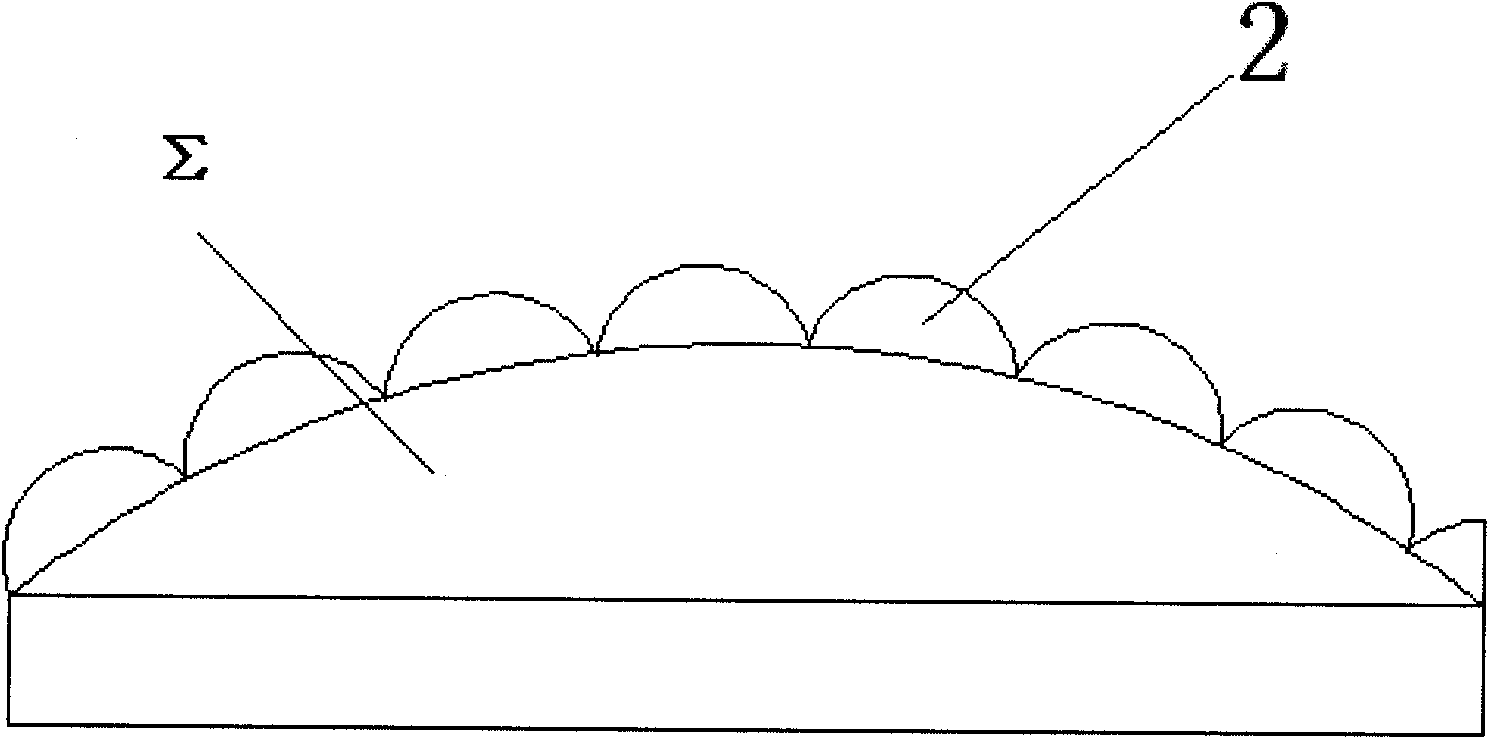

[0024] The design steps of the blazed convex grating reactive ion beam etching method are:

[0025] 1. Placement of convex grating mask quartz substrate. A convex grating mask quartz substrate with a sinusoidal groove shape is placed on a rotary table, and the center of the sphere is on the rotary axis of the rotary table. The plane where the reticle lines are located at the apex of the convex grating mask passes through the axis of rotation, and the planes where the other reticle lines are located are parallel to the axis of rotation.

[0026] 2. If the spherical radius of the quartz substrate of the convex grating mask is R, and the blaze angle of the blazed convex grating to be made is θ, then the direction of the ion beam an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com