InGaP wet etching method

A wet etching and epitaxial layer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as the inability to guarantee the smooth progress of the HBT process, and achieve the effect of removing the influence and ensuring the smooth progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

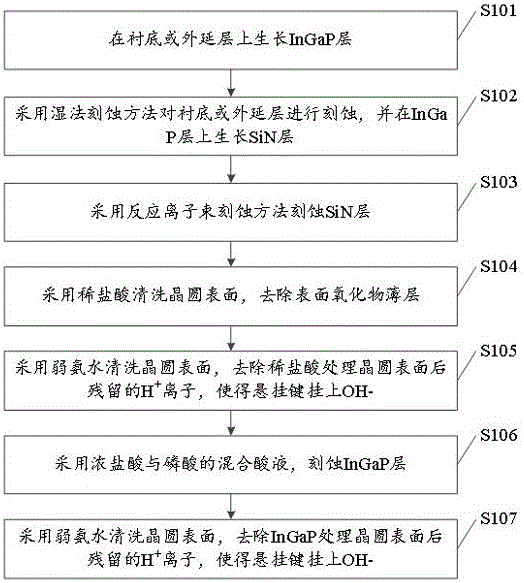

[0027] The embodiment of the present invention provides an InGaP wet etching method, which solves the problem that in the prior art, when etching the InGaP layer, the smooth progress of the HBT process cannot be guaranteed due to the influence of the previous process on the surface of the InGaP layer.

[0028] In order to solve the above-mentioned technical problems, the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0029] The invention provides a wet etching method of InGaP, such as figure 1 As shown, it includes: S101, growing an InGaP layer on a substrate or an epitaxial layer, the material of the substrate is any one of GaAs, InP, Si, and SiC, and the epitaxial layer is specifically a GaAs epitaxial layer, an InP epitaxial layer Any one, the thickness of the InGaP layer is 100 Å~1μm.

[0030] Next, in S102, the substrate or the epitaxial layer is etched by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com