Mesa type silicon-doped-arsenic blocked-impurity-band detector and preparation method thereof

A technology to block impurities and detectors, applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem of limited absorption layer thickness, shortened photo-generated carrier transmission path, and long photo-generated carrier transmission path and other problems, to achieve the effect of improving absorption efficiency and device responsivity, shortening the transport path, and increasing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

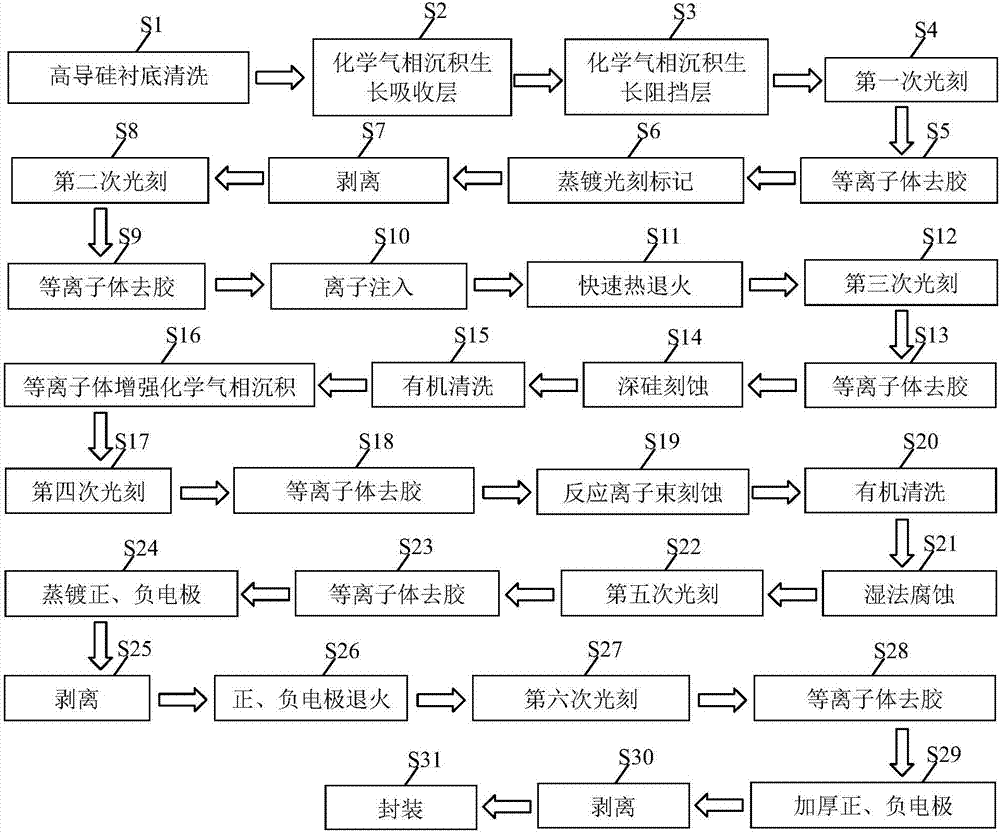

Method used

Image

Examples

Embodiment 1

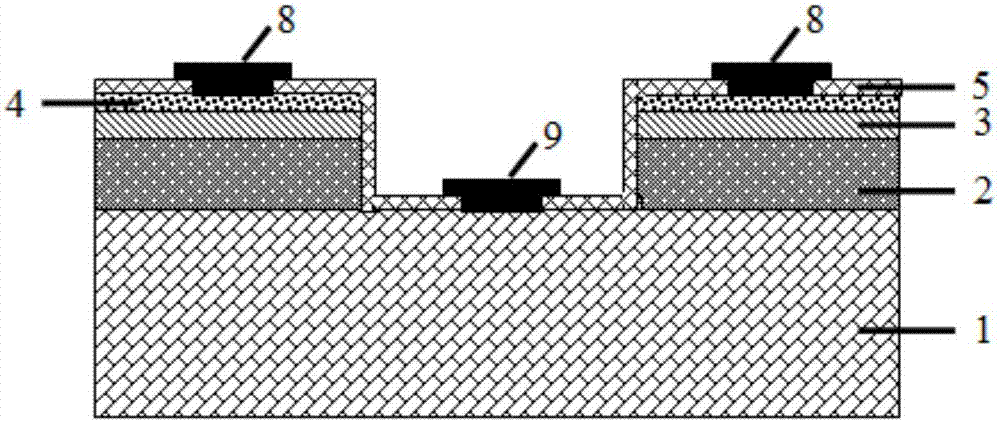

[0046] This embodiment relates to a mesa-type silicon-doped arsenic barrier impurity band detector, which includes a high-conductivity silicon substrate 1 and a first region and a second region arranged on the high-conductivity silicon substrate 1; the first region includes sequentially A silicon-doped arsenic absorber layer 2, a high-resistance silicon barrier layer 3, a positive electrode contact region 4, and a silicon nitride passivation layer 5 are arranged, wherein the silicon-doped arsenic absorber layer 2 is arranged on a high-conductivity silicon substrate 1, The silicon nitride passivation layer 5 covers the side surface formed by the silicon-doped arsenic absorbing layer 2, the high-resistance silicon barrier layer 3 and the positive electrode contact region 4 at the same time, and is arranged on the silicon nitride passivation layer 5 There is a positive electrode 8; the second region includes a silicon nitride passivation layer 5 arranged on a high-conductivity sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com